Spindle automatic package system and spindle separation counter weight method

An automatic packaging and spinning spindle technology, applied in the field of chemical fiber production, can solve the problems that the production mode is difficult to maintain, the impact of personnel flow on the management of enterprise personnel, and the increase in labor costs, etc., achieve a wide range of applications, reduce the number of employees, The effect of saving labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to understand the purpose, technical solutions and beneficial effects of the present invention more clearly, the present invention will be further described below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following examples.

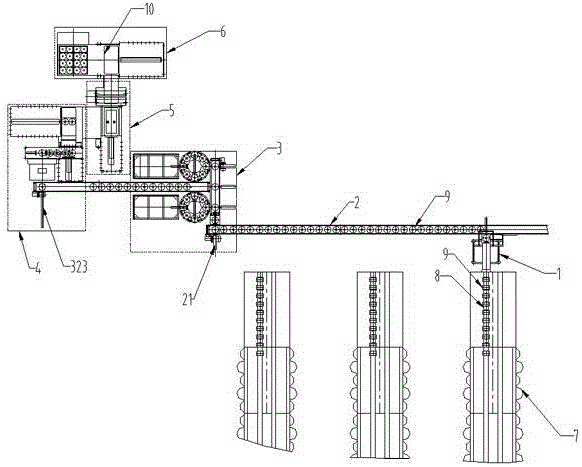

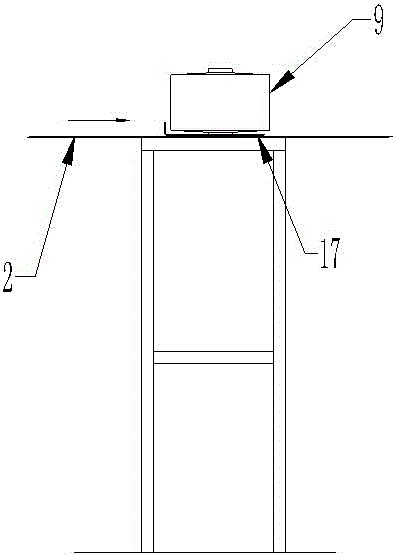

[0043] see figure 1 , a kind of automatic packaging system for spindles provided by the present invention, comprising sequentially connected doffing trolley 1, spindle conveyor belt 2, fixed weight sorting mechanism 3, automatic bagging and bagging mechanism 4, automatic packing belt mechanism 5 and automatic code bag Mechanism 6; the doffing trolley 1 is arranged between the spinning machine 7 and the spindle conveyor belt 2, and the discharge end of the spindle conveyor belt 2 is provided with a feeding cylinder 21.

[0044] see Figure 2 to Figure 4 , the doffing dolly 1 includes a vehicle frame 11, a horizontal cylinder 12, a vertical cylinder 13 and an over...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com