Automatic assembling machine for folding spoon or fork and box cover in can/barrel food

An assembly machine and food technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of low assembly efficiency and high labor intensity of workers, and achieve the effect of improving assembly efficiency, avoiding high labor intensity and reducing pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

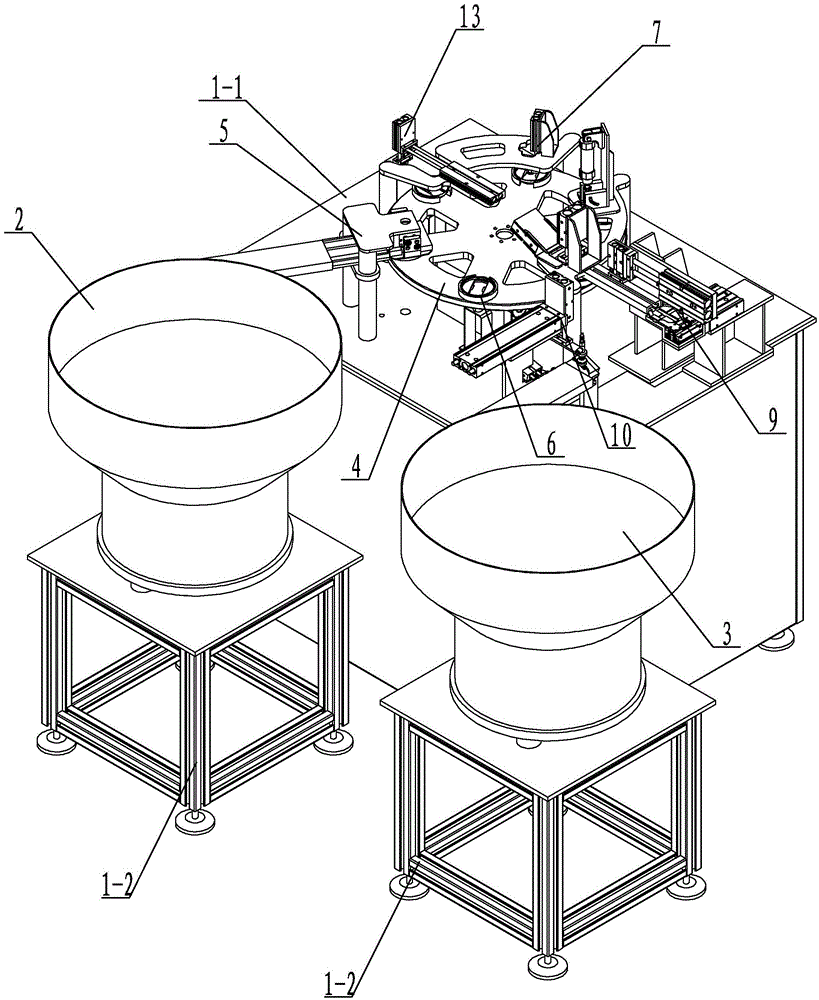

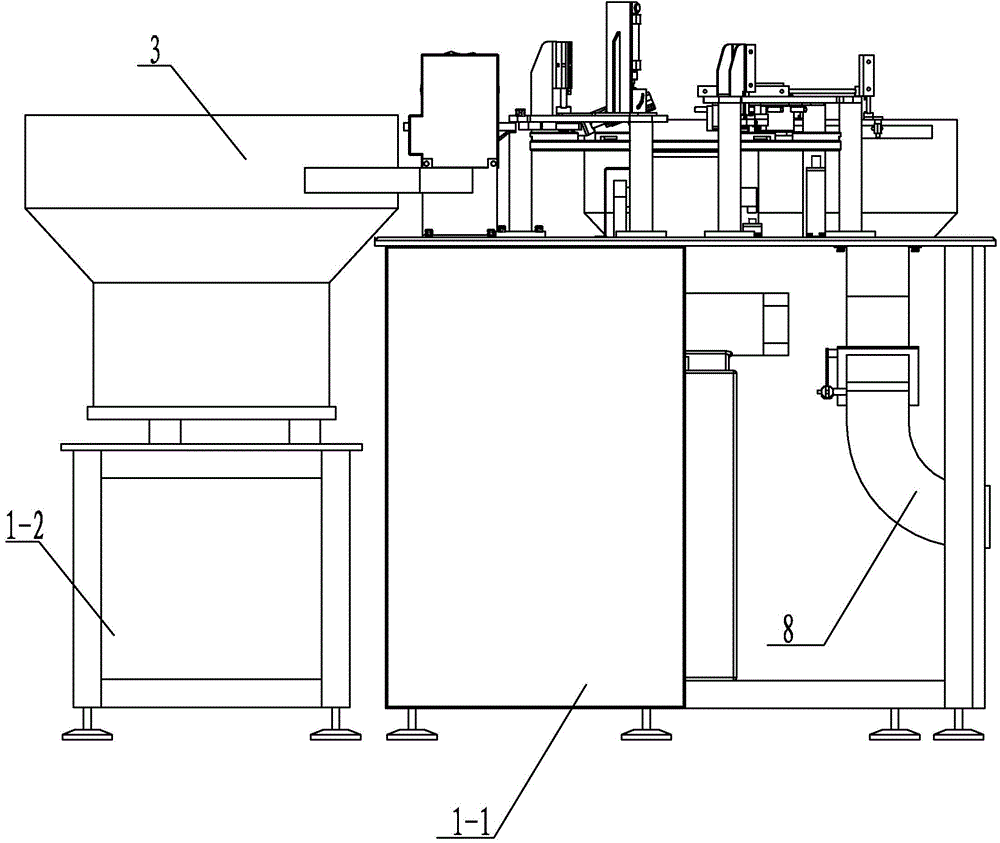

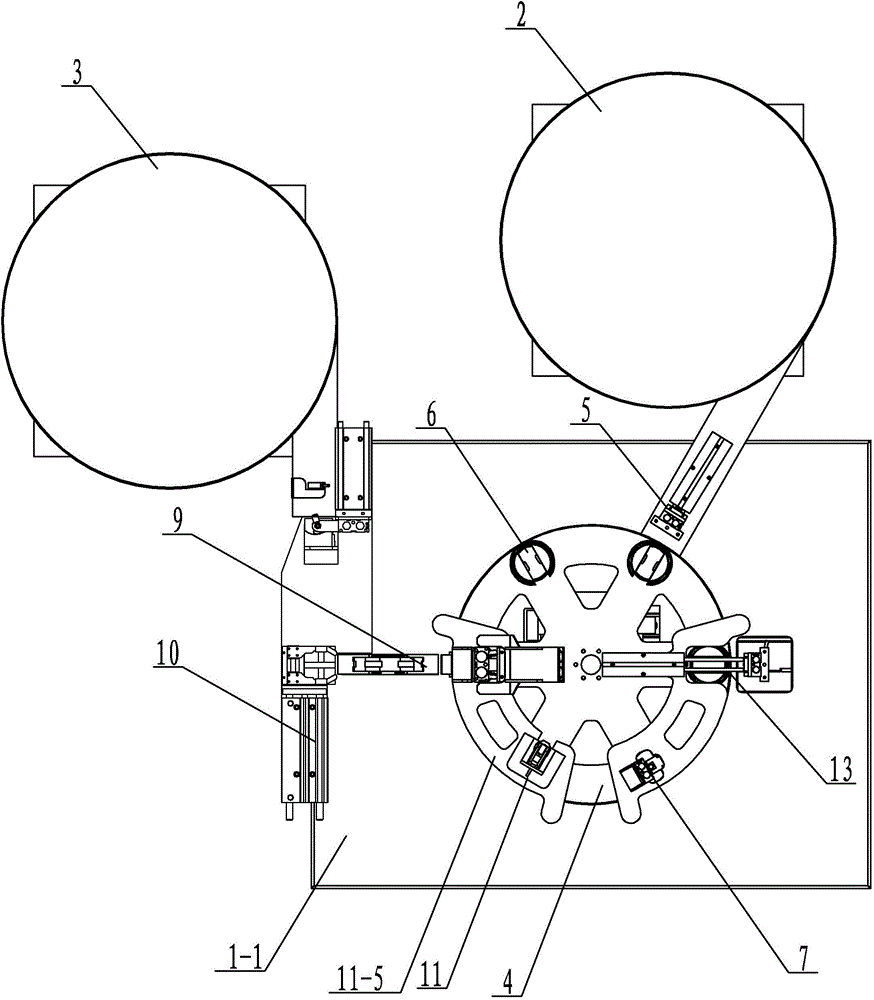

[0020] Specific implementation mode one: combine Figure 1 to Figure 27 Describe this embodiment, the automatic assembly machine of a kind of folding spoon, fork and box lid for canned / canned food of this embodiment comprises main frame body 1-1, auxiliary frame body 1-2, feeding tray 2, feeding Spoon tray 3, rotary indexing mechanism 4, cover loading station assembly 5, cover presence detection station assembly 6, spoon presence detection station assembly 7, sorting and unloading assembly 8, and unloading station assembly 13 ,

[0021] The auxiliary frame body 1-2 is installed on one side of the main frame body 1-1, the cover feeding tray 2 and the scoop feeding tray 3 are installed on the auxiliary frame body 1-2, and the rotary indexing mechanism 4 is installed on the main frame body 1 On -1, the cap feeding tray 2 and the rotary indexing mechanism 4 are connected through the cap feeding station assembly 5 and the cap is fed, and the cap presence detection station assembly...

specific Embodiment approach 2

[0034] Specific implementation mode two: combination figure 1 , figure 2 , image 3 , Figure 19 with Figure 20 To illustrate this embodiment, the spoon delivery mechanism 10 of this embodiment includes a spoon delivery cylinder 10-1, a suction cup cylinder 10-2, a suction cup 10-3, a spoon receiving platform 10-4, a spoon clamping claw 10-5 and a spoon receiving cylinder 10-6, the spoon delivery cylinder 10-1 is vertically arranged, the suction cup cylinder 10-2 is fixedly installed on the upper side end surface of the spoon delivery cylinder 10-1, the suction cup 10-3 is installed on the lower end of the suction cup cylinder 10-2, and receives the spoon The platform 10-4 is installed directly below the suction cup 10-3, the ladle receiving cylinder 10-6 is installed on one side of the ladle feeding cylinder 10-1, and the scoop clamping claw 10-5 is installed on the side end surface of the ladle receiving cylinder 10-6 upper part. With such an arrangement, the scoops s...

specific Embodiment approach 3

[0037] Specific implementation mode three: combination figure 1 , figure 2 , image 3 , Figure 4 with Figure 5 Describe this embodiment, the rotary indexing mechanism 4 of this embodiment comprises index plate 4-1, a plurality of index plate cover supports 4-2, cam divider 4-3, conveyor belt 4-4, motor 4-5 and Cover the material cover support 5-5, cover the material cover support 5-5 and a plurality of index plate cover supports 4-2 in the form of an annular array and be installed on the index plate 4-1, the index plate 4-1 can be Rotation is installed on the cam divider 4-3, and the cam divider 4-3 is installed on the main frame body 1-1, and the motor 4-5 is installed on the lower end of the main frame body 1-1, and the cam divider 4-3 and the motor 4-5 are connected by conveyor belt 4-4. With this setting, according to the needs of different processes, the tasks of each process can be completed by adjusting different speeds. Other compositions and connections are t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com