Plate spring double-headed synchronous eye coiling production line and head cutting, eye coiling and shaping units thereof

A technology of shaping unit and production line, applied in feeding device, positioning device, storage device, etc., can solve the problems of poor product quality, decreased parallelism of two ears, low production efficiency and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

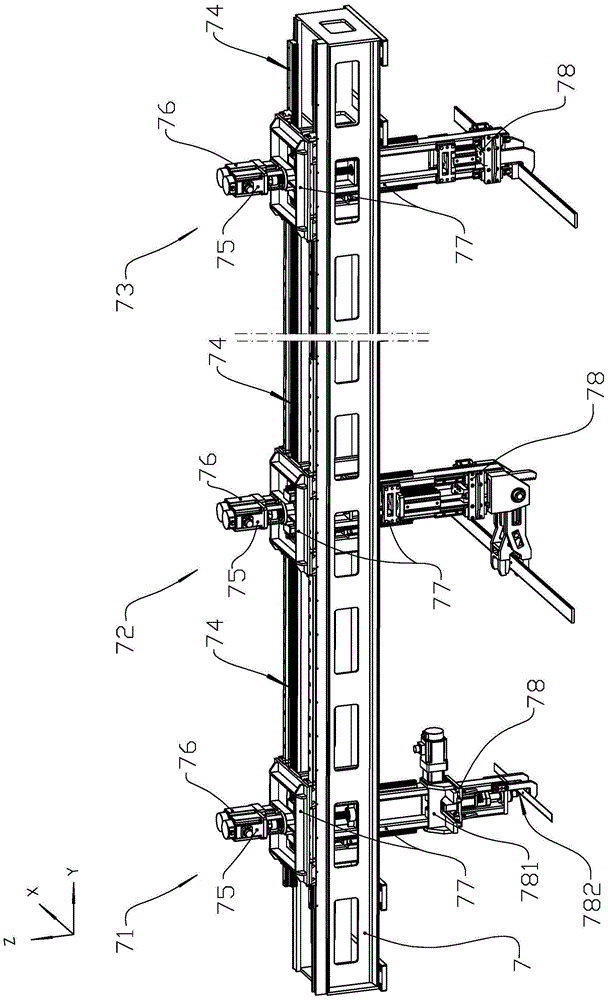

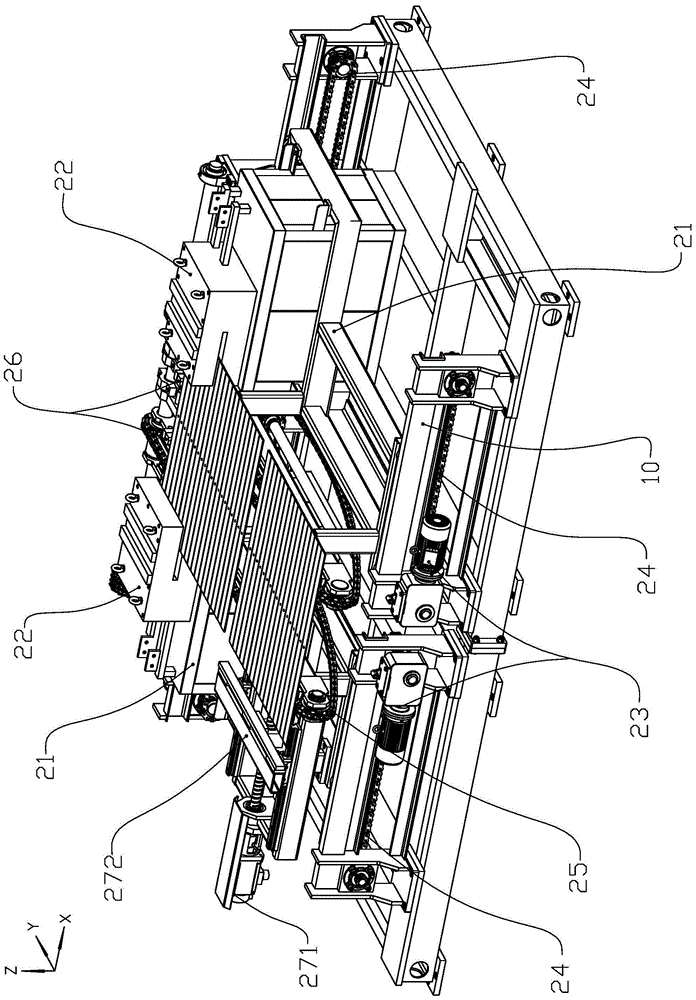

[0067] In order to facilitate the understanding of the technical content of the present invention, the technical solutions thereof will be further described below in conjunction with the accompanying drawings. For ease of description, it is specifically defined here that the positive direction of the X-axis in the drawings is right, the positive direction of the Y-axis is backward, and the positive direction of the Z-axis is upward.

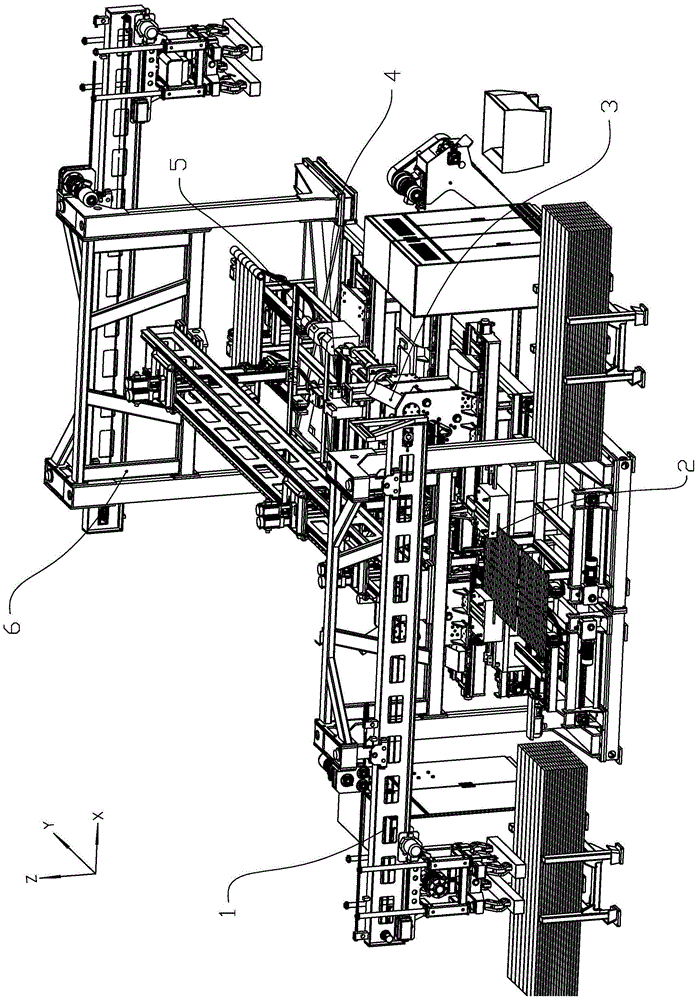

[0068] Such as Figure 1 to Figure 7 The leaf spring double-head synchronous ear rolling production line shown:

[0069] It includes a feeding unit 1, a heating unit 2, a head cutting unit 3, an ear rolling unit 4, a shaping unit 5, a product assembly unit 6 and a control system arranged in sequence from front to back. Various motors, oil cylinders (or belt encoders), cylinders, and circuit control elements involved in the feeding unit 1, heating unit 2, head cutting unit 3, ear rolling unit 4, shaping unit 5, and product assembly unit 6 , hydr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com