Plastic flexible pipe winder

A winding machine and hose technology, which is applied in the direction of conveying filamentous materials, thin material processing, transportation and packaging, etc., can solve the problems of increasing the economic benefits of plastic hose enterprises, achieve neat and uniform arrangement, and improve work efficiency , the effect of reducing the damage rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below in conjunction with accompanying drawing and embodiment, further elaborate the present invention.

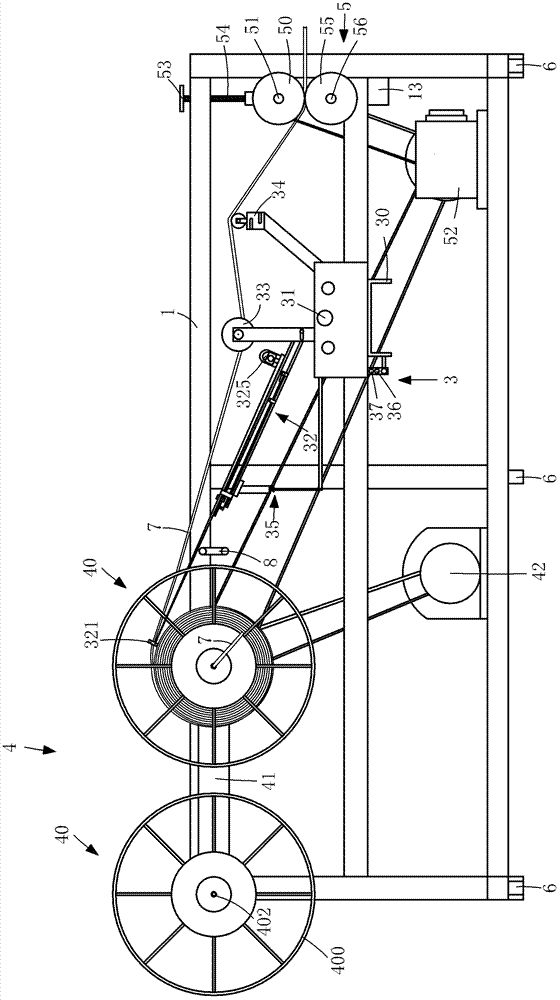

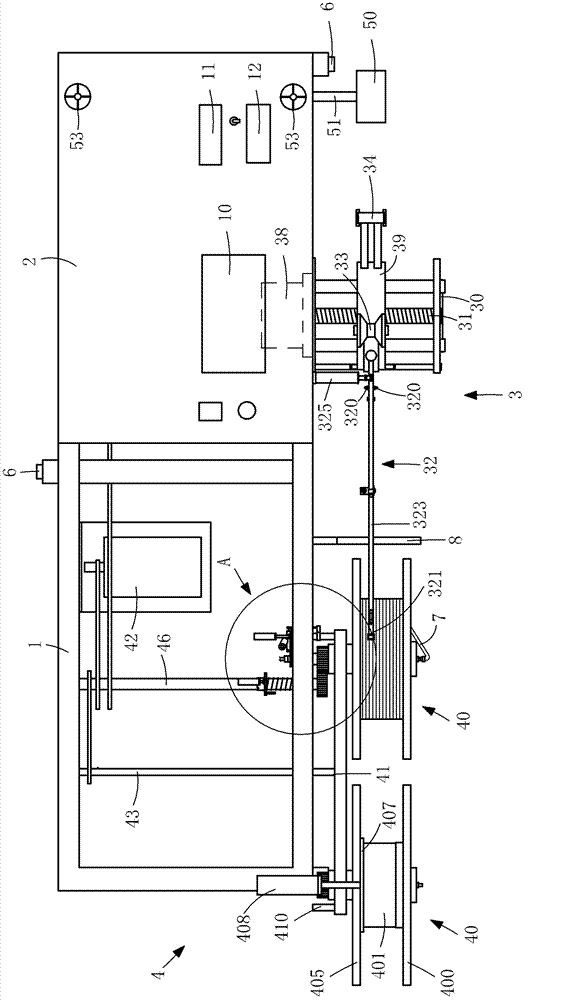

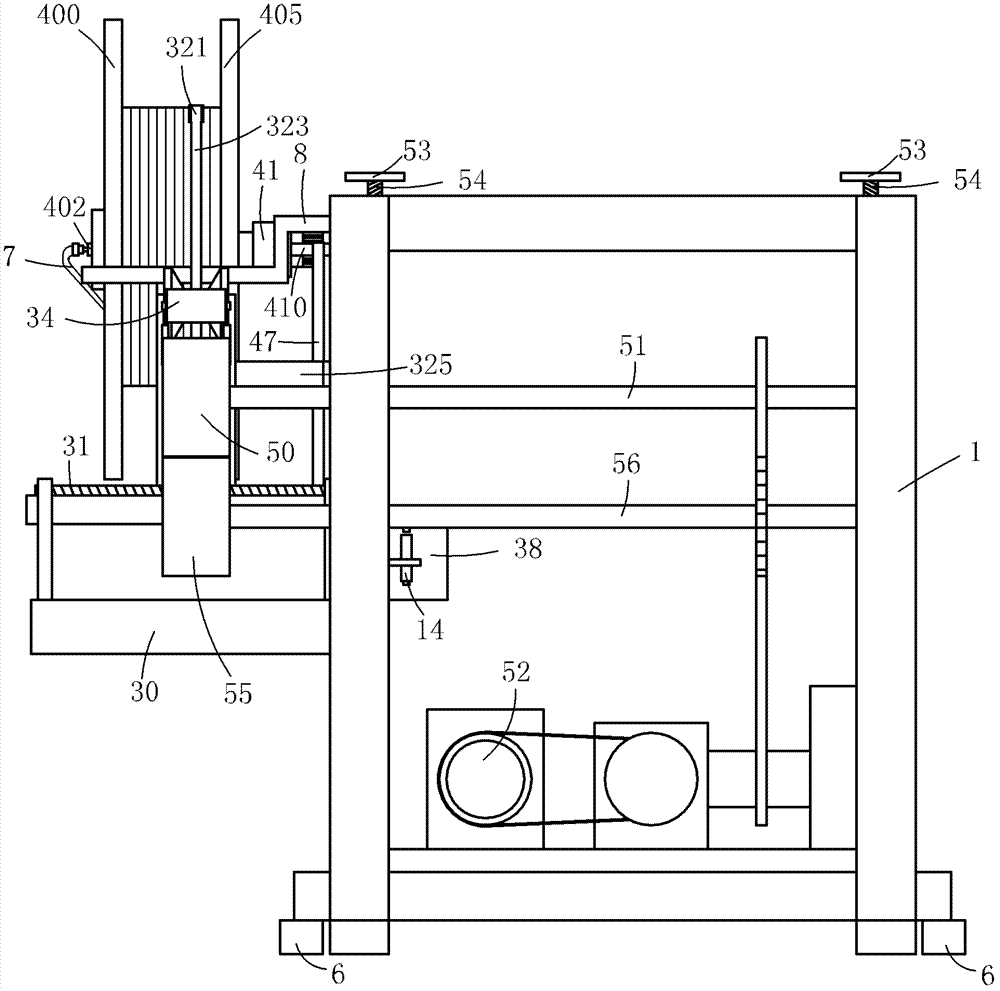

[0031] like figure 1 , figure 2 and image 3 Commonly shown, a plastic hose rewinding machine, which sequentially includes a feeding device 5, a cable arrangement 3, and a rewinding device 4, and the feeding device 5, the cable arrangement 3, and the rewinding device 4 are all connected to an electrical control device, and also includes The inflation device for inflating the plastic hose 7, the inflation device includes an air intake pipe 403 connected to the mouth of the plastic hose 7, the air intake pipe 403 corresponds to the position of the winding device 4, and the upstream of the air intake pipe 403 is provided with a plastic soft The gas in the pipe 7 is returned to the gas stop device in the production process section. Air can be inflated into the plastic hose 7 at the same time during the winding operation, which can effectively prevent the deformation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com