Bobbin burying machine

A technology for managing machines and storage pipes, which is used in thin material handling, conveying filamentous materials, transportation and packaging. Accuracy, ensuring work efficiency, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

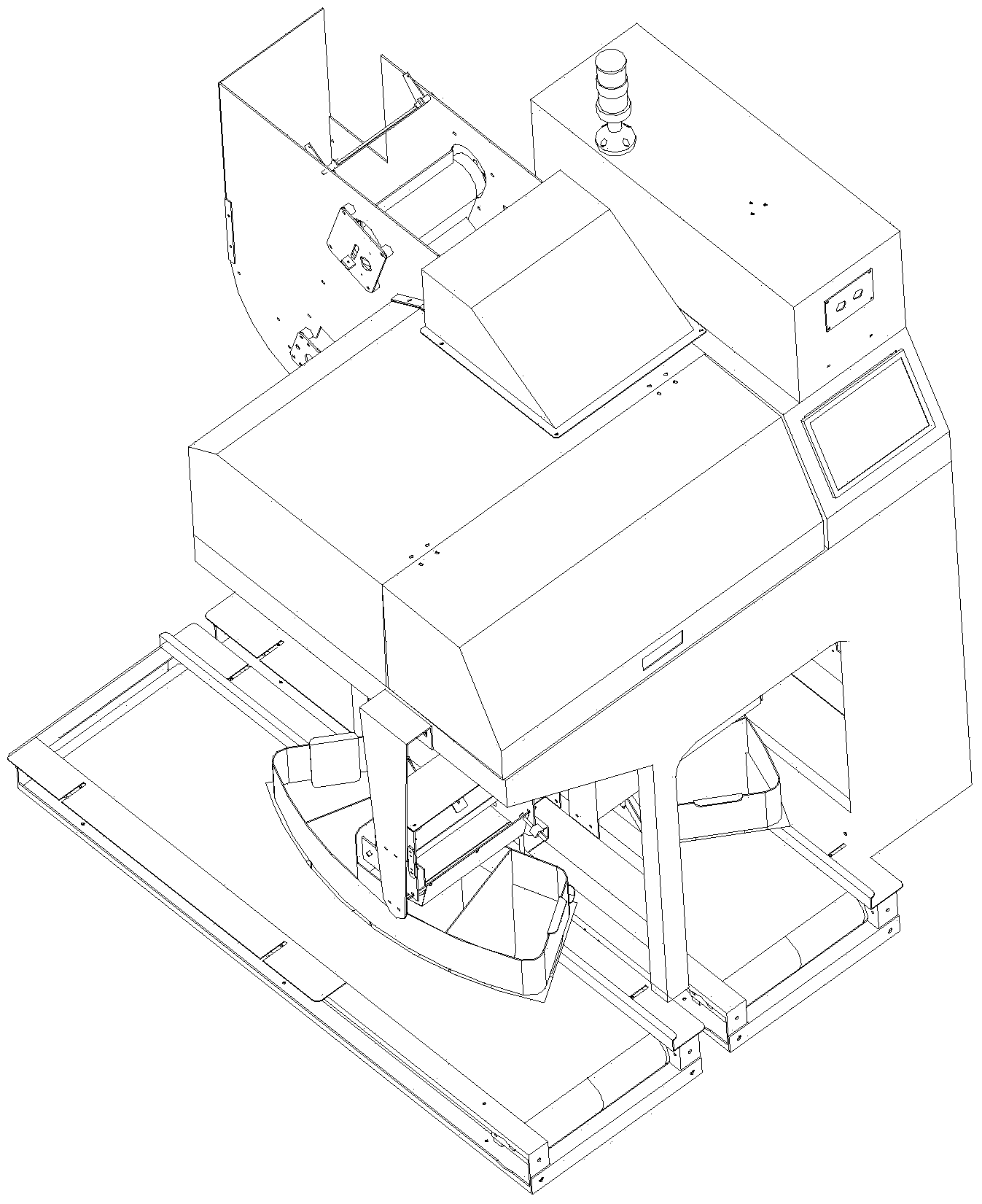

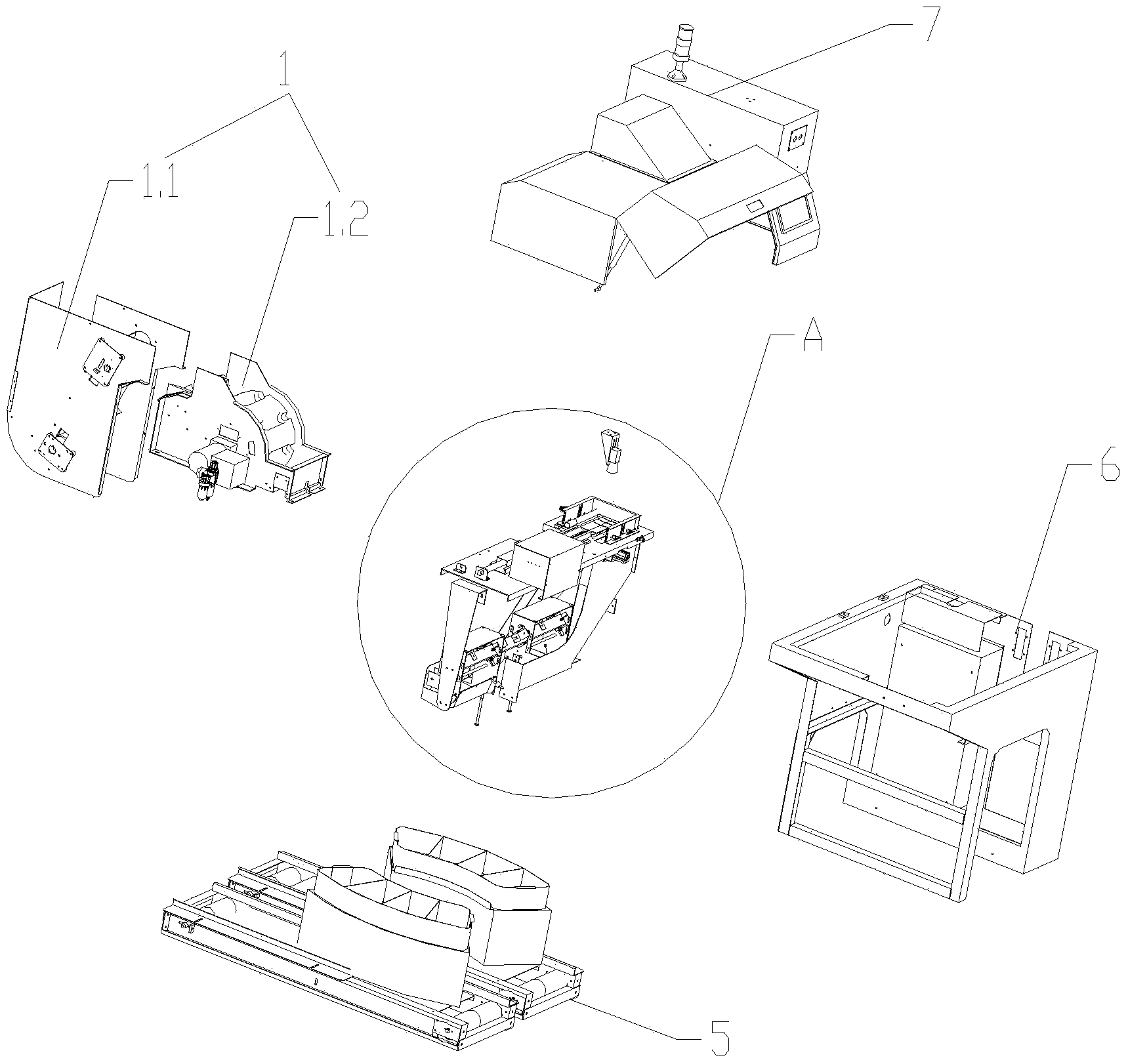

[0069] see Figure 1-Figure 27 , a kind of management machine that the present invention relates to, it comprises storage management mechanism 1, management mechanism 2, drop management mechanism 3, takeover buffer mechanism 4, takeover mechanism 5, frame 6 and shell 7, described storage management mechanism 1, The management mechanism 2 , the drop mechanism 3 and the buffer mechanism 4 are arranged on the frame 6 .

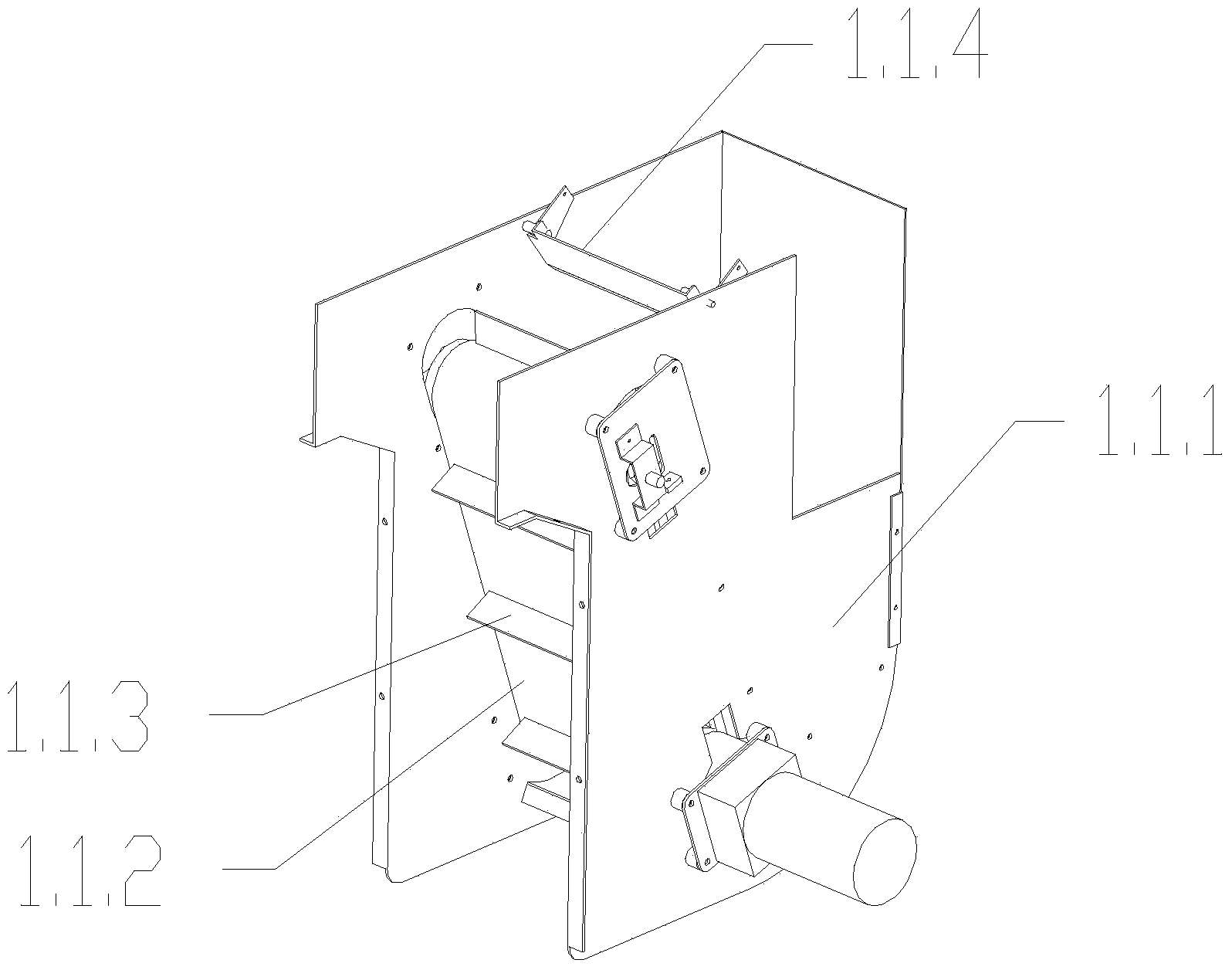

[0070] The tube storage mechanism 1 includes a tube storage rough finishing device 1.1 and a tube storage fine finishing device 1.2. The tube storage rough finishing device 1.1 includes a takeover box 1.1.1, and the bobbins dropped by the winder fall to the takeover box 1.1.1 At the inlet of the pipe, the takeover box 1.1.1 is provided with an inclined rough finishing conveyor belt 1.1.2. The rough finishing conveyor belt 1.1.2 is driven by two conveying rollers, and the conveying roller is driven by a reducer. The outer surface of the rough finishing conveyor b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com