Application method of edible fungus factory planting device

A planting device and edible fungus technology, applied in the directions of botanical equipment and methods, application, gardening, etc., can solve the problems of consuming large wood chips, unable to meet large-scale production, poor labor environment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

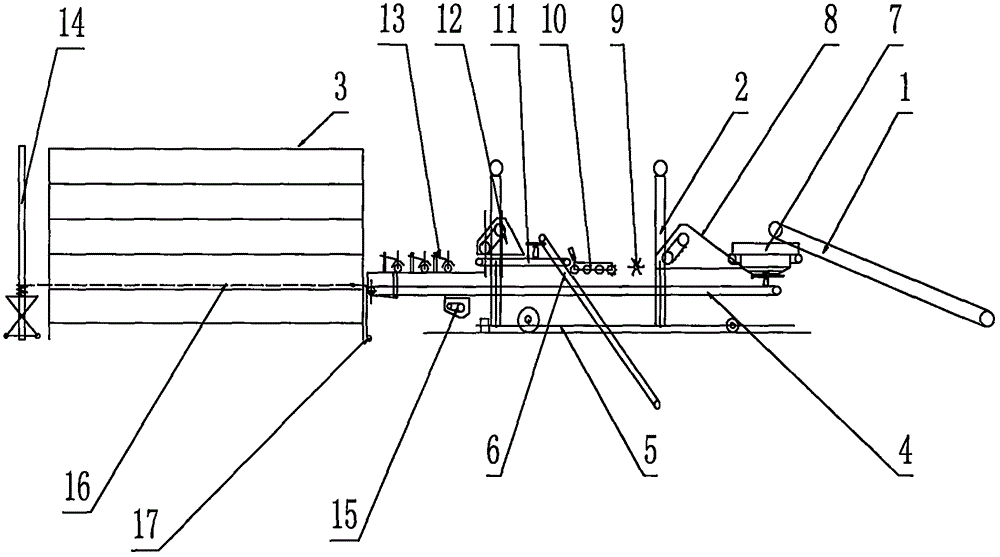

[0021] There are two sets of gantry elevators 2 at the front and rear of the loading platform, and a running mechanism 5 is arranged under the two sets of gantry elevators 2. A feeding conveyor belt 4 is arranged between the two sets of gantry elevators 2, and the front end of the feeding conveyor 4 is set on the upper side. Material conveyor belt 1, edible fungus bed 3 is arranged at the rear end of feeding conveyor belt 4, and lifting tractor 14 is arranged on one side of edible fungus bed 3, and cloth fertilizer conveyor belt 6 is arranged on one side of feeding conveyor belt 4 middle section;

[0022] The feeding conveyor belt 4 is set as the front section, the middle section, and the rear section respectively, and a distributor 7 is arranged above the feeding conveyor belt 4 of the front section, and a compost hopper 8 is arranged between the distributor 7 and the front door type lifting frame 2, and the upper opening of the distributor 7 corresponds to the feeding conveyor...

Embodiment 2

[0027] Start the edible fungus factory planting device, the feeding conveyor belt 1 of the edible fungus industrial planting device, the edible fungus base material is continuously loaded on the top of the feeding conveyor belt 1, and the feeding conveyor belt 1 is driven to transport the edible fungus base material to the upper After the end falls into the distributor 7, the distributor 7 evenly spreads the edible fungus base material to the top of the compost hopper 8 by swinging, and the compost hopper 8 rotates the edible fungus base material according to the preset height evenly. Pour into the top of the feeding conveyor belt 4;

Embodiment 3

[0029] The feed conveyer belt 4 transports the above edible fungus base material to the middle section by rotating, at the same time, the material mixing device 9 smooths the top of the edible fungus base material by rotating the plow rake, and then the edible fungus base material is smoothed by the plow rake leveling device 10 through rotation. The surface of the material is refined, leveled and compacted;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com