Tube managing machine

A tube management machine and tube turning technology, which is applied in the direction of thin material processing, delivery of filamentous materials, transportation and packaging, etc., can solve the problems of messy tubes, vibration, and aggravated wear between parts, so as to save the number of workers, The effect of releasing the intensity of operation and relieving labor pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

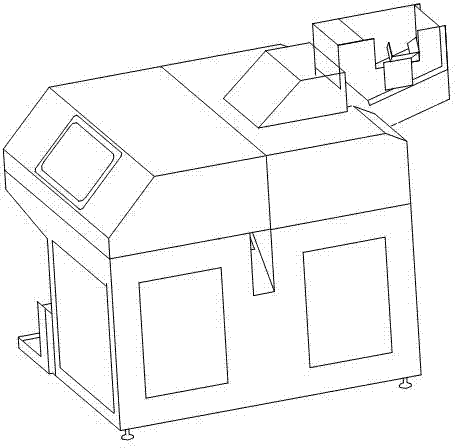

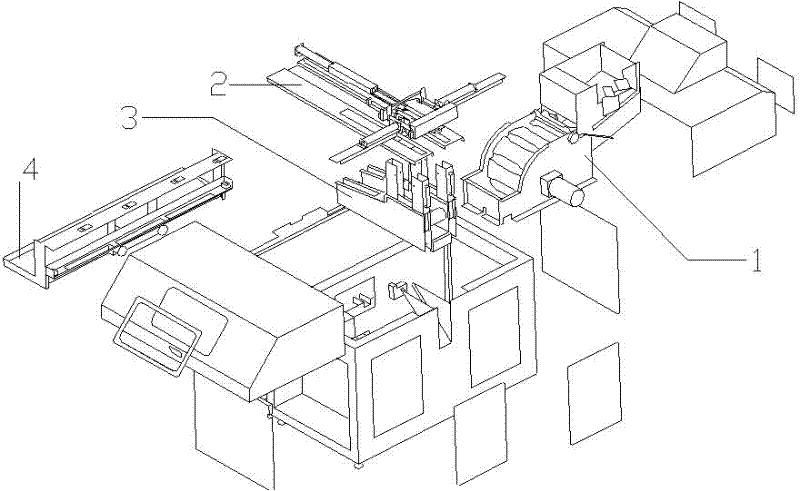

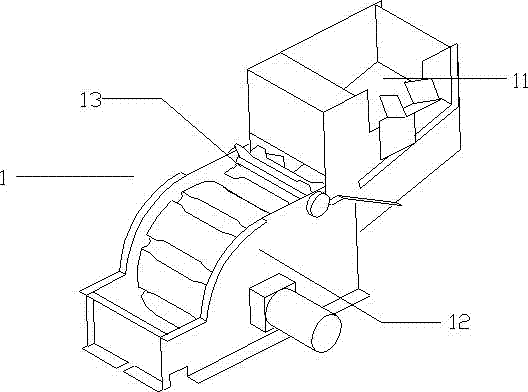

[0043] see figure 1 - Fig. 6, a kind of management machine that the present invention relates to, comprises chassis, and described chassis is provided with storage tube mechanism 1, branch management mechanism 2 and tube turning mechanism 3, and described tube storage mechanism 1 includes takeover box 11 and transportation tube Roller 12, described connection box 11 is positioned at the top of cabinet, and the pipe inlet of described connection box 11 is provided with a movable baffle plate, and the inside of described connection box 11 is provided with a slope toward the left bottom, and described transportation roller 12 is located at the pipe outlet at the lower left side of the connection box 11. The pipe conveying roller 12 is a cylinder with a diameter of 320mm, and the outer edge of the cylinder is provided with eight circular arc concave surfaces. Drive, between described transporting pipe roller 12 and the pipe outlet of takeover box 11, be provided with a pipe-drawin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com