Washing device of labor protection safety net

A cleaning device and safety net technology, applied in the field of cleaning machines, can solve the problems of poor cleaning effect, high labor intensity, and large water consumption, so as to achieve great social and economic benefits, reduce labor intensity, and reduce water consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

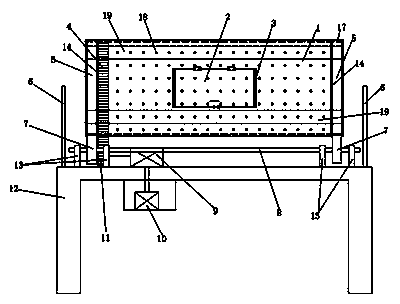

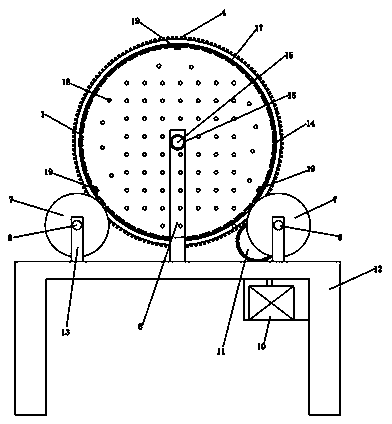

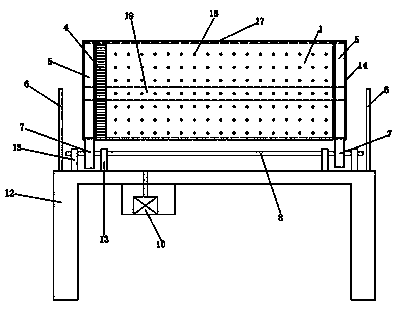

[0012] Such as figure 1 , figure 2 and image 3 Shown, the cleaning device of a kind of labor insurance safety net comprises frame 12, speed reducer 9 and motor 10, on frame 12 is fixedly provided with fixed frame 13, cross bar 8 passes fixed frame 13 and is fixedly arranged on On it, pulleys 7 are movable at both ends of the cross bar 8, and the pulleys 7 are placed between two fixed frames 13; pulley tracks 5 are ring-shaped at both ends of the drum 1, and pulley tracks 5 are ring-shaped on both sides of the pulley track 5, respectively. Higher than the rib 14 of the pulley track 5, the pulley 7 is matched with the pulley track 5; a large gear ring 4 is annularly arranged on the inner side of the pulley track 5, and the small gear ring 11 is connected to the speed reducer 9 and is fixedly arranged on the machine. On the frame 12, the reducer 9 is connected to the motor 10, and the motor 10 is suspended and fixed on the lower part of the frame 12, and the pinion ring 11 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com