Goods sorting and split charging equipment and method thereof

A technology of goods and equipment, which is applied in the field of goods sorting and packaging equipment, can solve the problems of high operating cost, large floor area, and large number of workers, and achieve the effect of low operating cost, small floor area, and low construction investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach specific

[0102] The first implementation method specifically includes the following steps A to H:

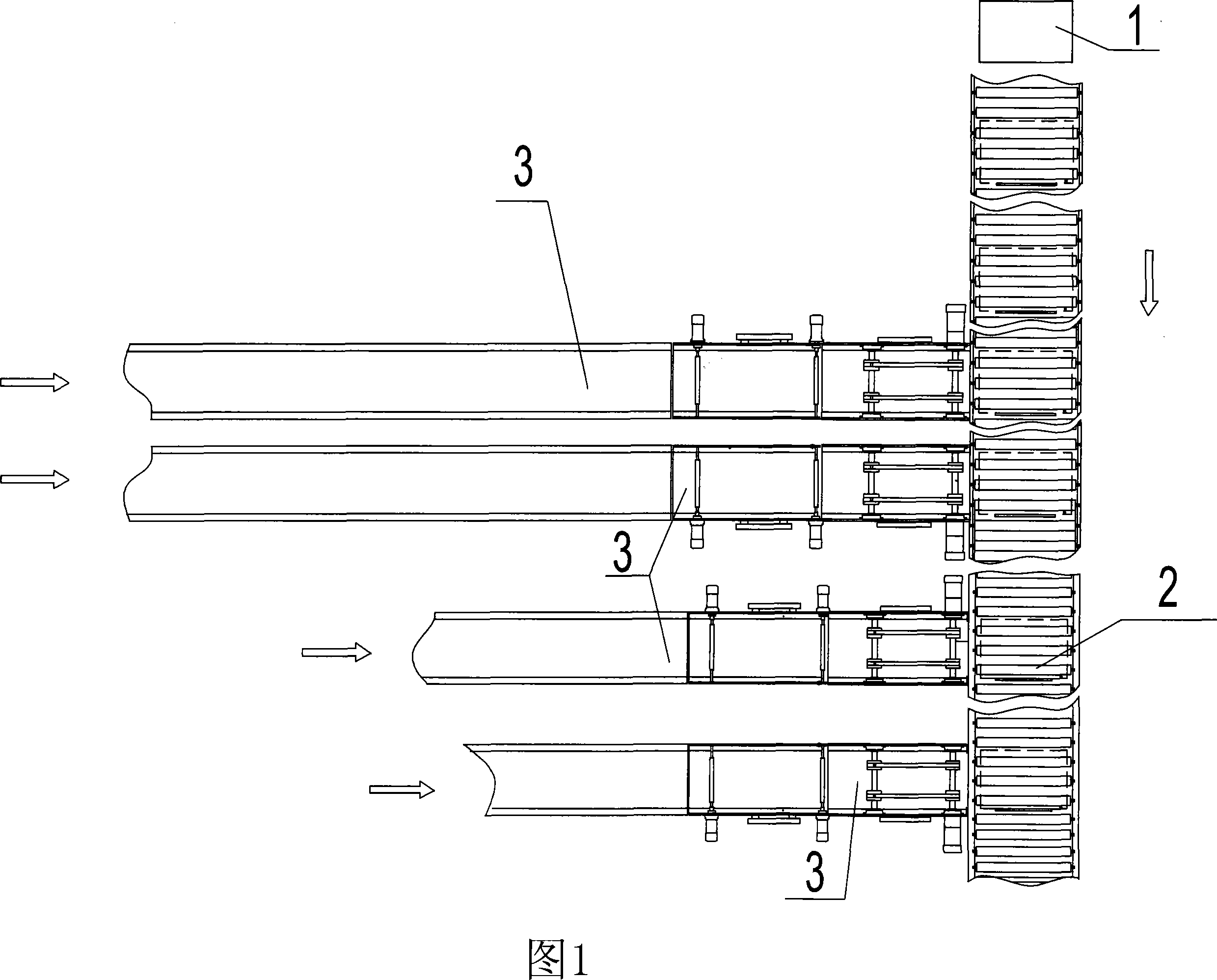

[0103] A. Configure the whole line equipment and determine the brand specifications of the delivered goods

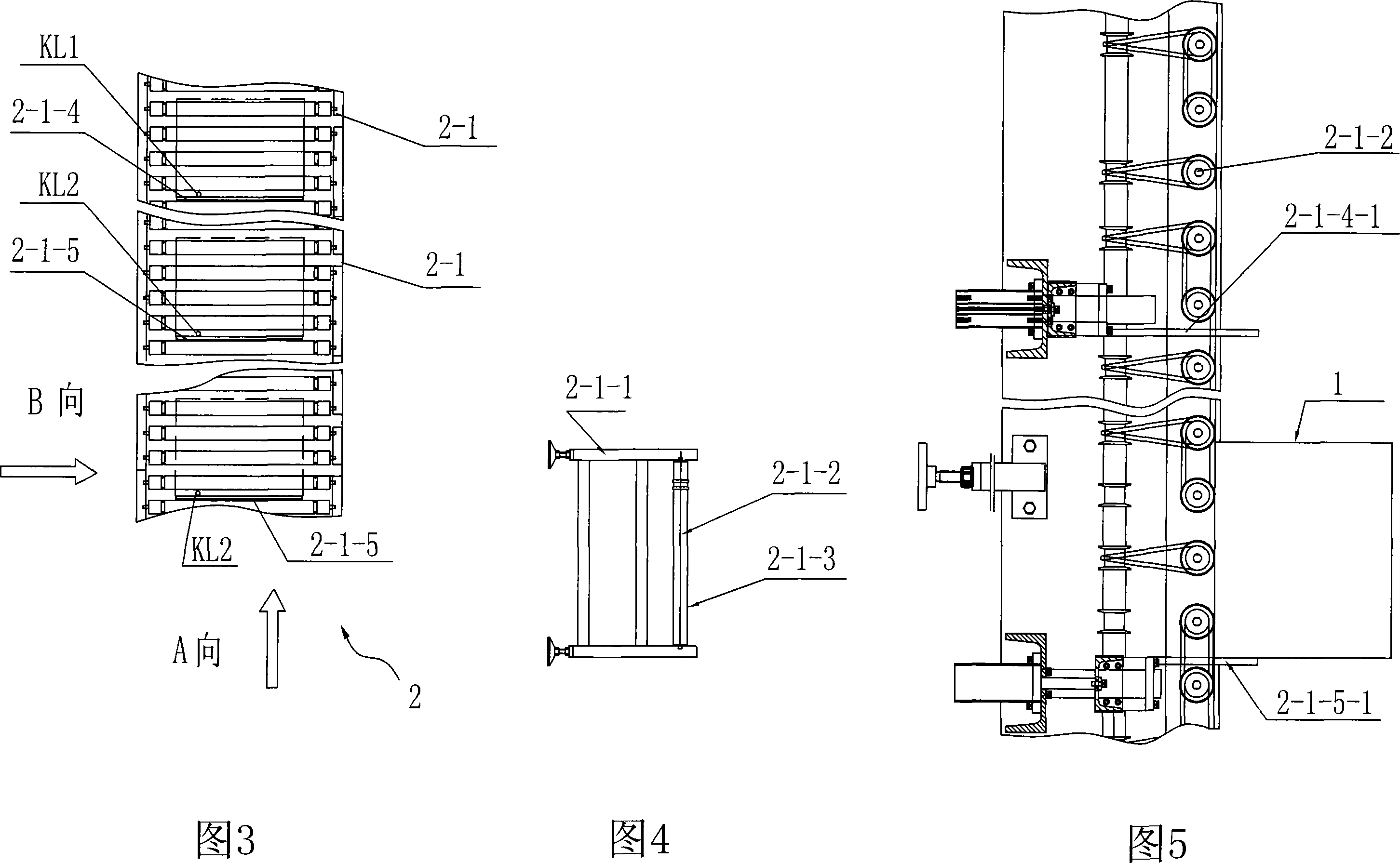

[0104] A1. According to the total annual distribution of goods in the distribution center, the number of brand specifications and the site conditions, determine the composition type of the box-basket conveying device 2 and the input form of the empty box-basket 1, so that the entire line can be completed on time. Daily or every batch The sorting and packing task of the purchase order.

[0105] A2. According to the size of the total annual distribution of goods in the distribution center, the number of brand specifications of the annual distribution goods, the size of the annual distribution of goods of each brand specification, and the determined composition type of the box and basket conveying device 2 and the input form of the empty box and basket 1 , according to the following...

no. 2 approach specific

[0170] The second implementation method specifically includes the following steps A to H:

[0171] A. Configure the whole line equipment and determine the brand specifications of the delivered goods

[0172] A1. According to the total annual distribution of goods in the distribution center, the number of brand specifications and the site conditions, determine the composition type of the box-basket conveying device 2 and the input form of empty box-baskets, so that the entire line can complete daily or every batch of orders on time Single sorting and packaging tasks;

[0173] A2. According to the size of the total annual distribution of goods in the distribution center, the number of brand specifications of the annual distribution goods, the size of the annual distribution of goods of each brand specification, and the determined composition type of the box and basket conveying device 2 and the input form of the empty box and basket, According to the following principles 1) to ...

no. 2 approach

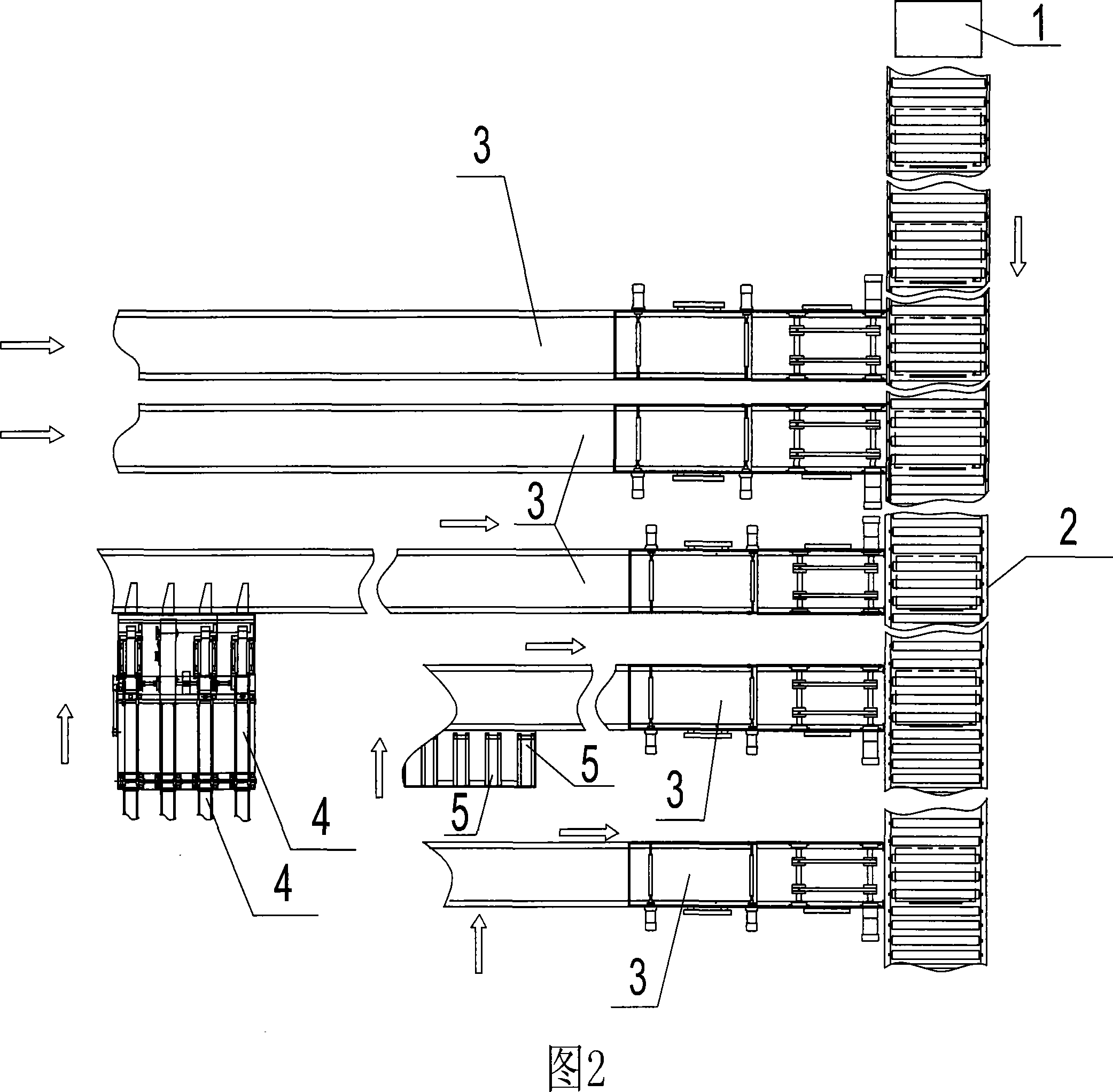

[0246] For the second implementation method, the device completes the step E of delivering the distribution and also includes:

[0247] Several brand-specific goods with smaller and / or smaller annual distribution volumes and other brand-specific goods that need to be transported are transported to the first low-speed conveyor 3-1 of the corresponding goods distribution device 3 through each group of goods sorting devices , including the steps:

[0248] E4-1) When the tenth sensitive element KL10 on the first low-speed conveyor 3-1 determines that there is no goods on its corresponding position, the group of goods sorting devices corresponding to the first low-speed conveyor 3-1 starts to select goods . The sequence of picking up the goods is: according to the system settings, the order of the boxes and baskets distributed on the station in front of the goods distribution device 3 corresponding to the group of goods sorting devices, the number of layers loaded into each box, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com