Material rack provided with automatic overturning structure

A technology of automatic overturning and linkage mechanism, applied in the direction of manufacturing tools, tool storage devices, etc., can solve the problems of high labor intensity, affecting the service life of the material rack, and easily damaged parts of the positioning block of the material rack, so as to reduce labor intensity, The effect of prolonging the service life and reducing the number of workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

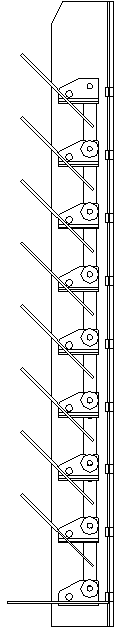

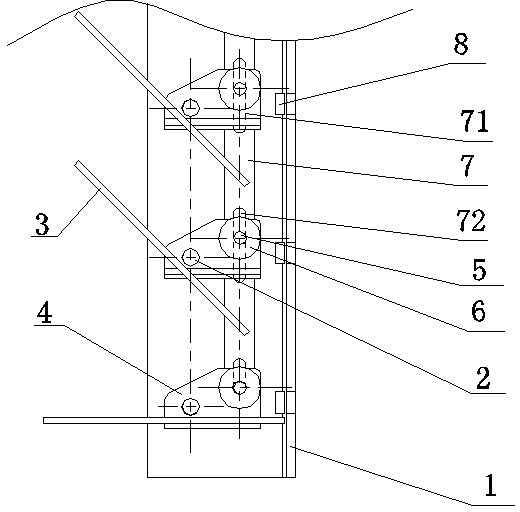

[0010] Such as figure 1 , 2 As shown, the present invention includes four frame columns 1, and a set of material rack interlocking mechanisms are respectively arranged inside each frame body upright column 1, and the material rack interlocking mechanisms are arranged symmetrically and in pairs.

[0011] The interlocking mechanism of each group material rack includes a number of small rotating rods 2 vertically arranged along the height direction of the frame body column 1, and the distance between each adjacent small rotating rods 2 is equal.

[0012] The two ends of each small rotating rod 2 are rotatably supported on the frame column 1 respectively, and a rotating plate 3 and a bending piece 4 are respectively fixedly connected to each small rotating rod 2 .

[0013] A large rotating rod 5 is rotatably placed on each bending piece 4 respectively, and a large roller 6 is connected coaxially outside each large rotating rod 5 .

[0014] A connecting plate 7 is set between the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com