Automatic ridged-bar feeding and discharging system applicable to numerically controlled lathe and application thereof

A technology of automatic loading and unloading, CNC lathe, applied in metal processing and other directions, to achieve the effect of reducing product cost, simple and practical structure, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

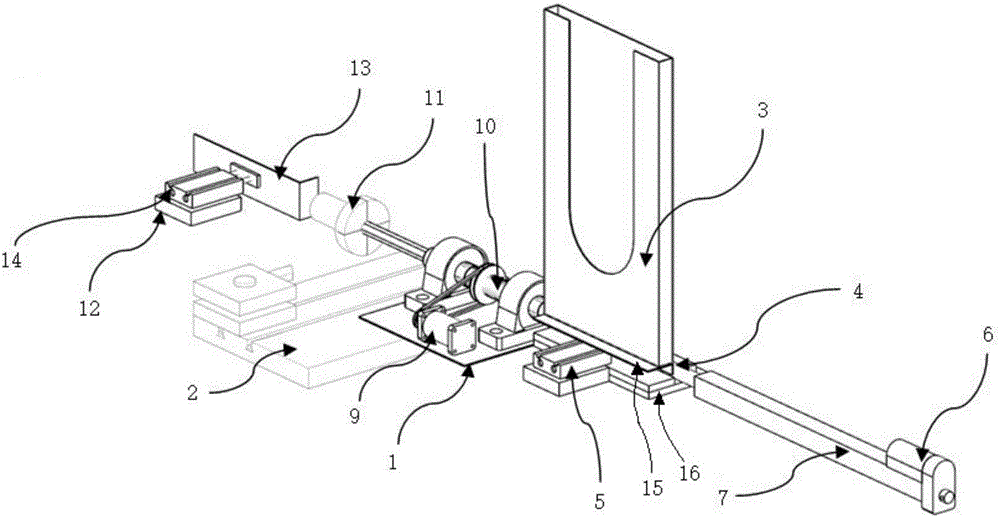

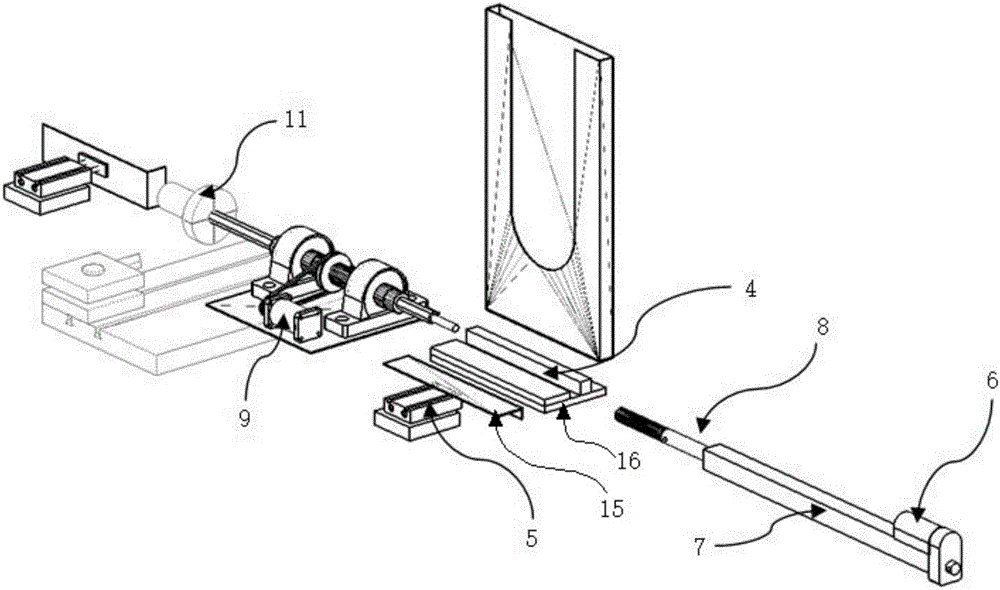

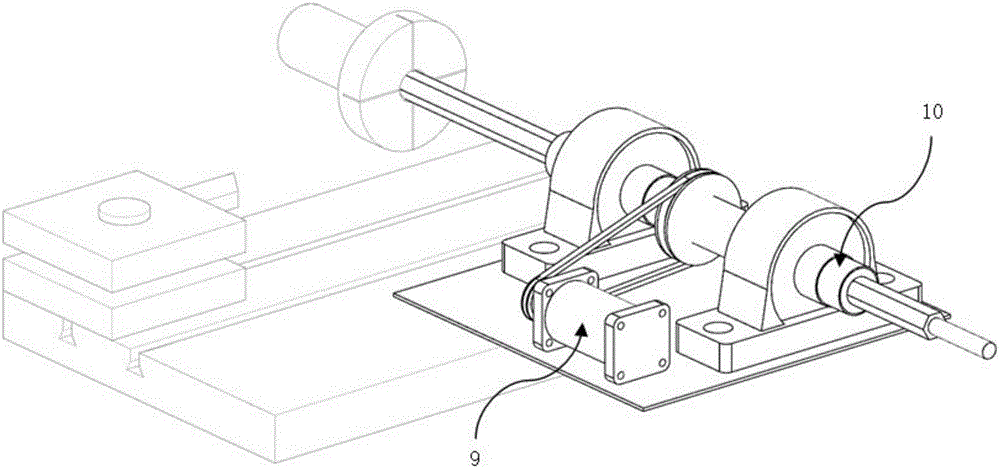

[0041] like Figure 1 to Figure 6 As shown, this embodiment provides an automatic loading and unloading system for corrugated bar materials suitable for CNC lathes. : Among them, the storage mechanism is used to store corrugated bar workpieces; the feeding mechanism is located under the storage mechanism to receive the workpieces in the storage mechanism; the introduction mechanism pushes the workpieces in the feeding mechanism to the CNC lathe for completion The loading of the workpiece; the unloading mechanism pushes the processed workpiece from the CNC lathe to complete the unloading process; the controller is electrically connected with the storage mechanism, the feeding mechanism, the introduction mechanism, and the unloading mechanism to realize the entire loading and unloading Automated operation of the material system.

[0042] Specifically, the storage mechanism includes a silo 3, which is a cuboid with a cavity, and a U-shaped opening is provided on the side wall of...

Embodiment 2

[0051] An automatic loading and unloading system for corrugated bar materials suitable for CNC lathes, the structure is as described in Embodiment 1, the difference is that the vertical distance between the lower surface of the material bin 3 and the upper surface of the material receiving platform 16 is 1 / 2 of the cross-sectional diameter of the workpiece 1.5 times. The horizontal long side of the L-shaped pusher plate 15 is slightly lower than the height of the workpiece cross-sectional diameter, then the vertical short side of the L-shaped pusher plate 15 can effectively stop the workpiece from falling in the feed bin when the workpiece is advanced, and can Ensure that the L-shaped pusher only pushes one workpiece into the receiving chute at a time.

[0052] In addition, baffles can be set on both sides of the material receiving platform 16 to prevent the workpiece from accidentally falling off the material receiving platform 16 when the L-shaped pushing plate 15 pushes the...

Embodiment 3

[0054] An automatic loading and unloading system for corrugated bars suitable for CNC lathes, the structure is as described in Embodiment 1, the difference is that when processing cylindrical or cylindrical bars, the second stepper motor 9 and The guide sleeve 10 is removed, and the control program is modified accordingly to simplify the loading and unloading process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com