Chamfering machine

A technology of chamfering machine and chamfering mechanism, which is applied in the field of chamfering machine, can solve the problems of inconvenient processing operation and cleaning, complex structure of chamfering machine, dirty machine, etc., and achieve low cost, high production efficiency and convenient operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

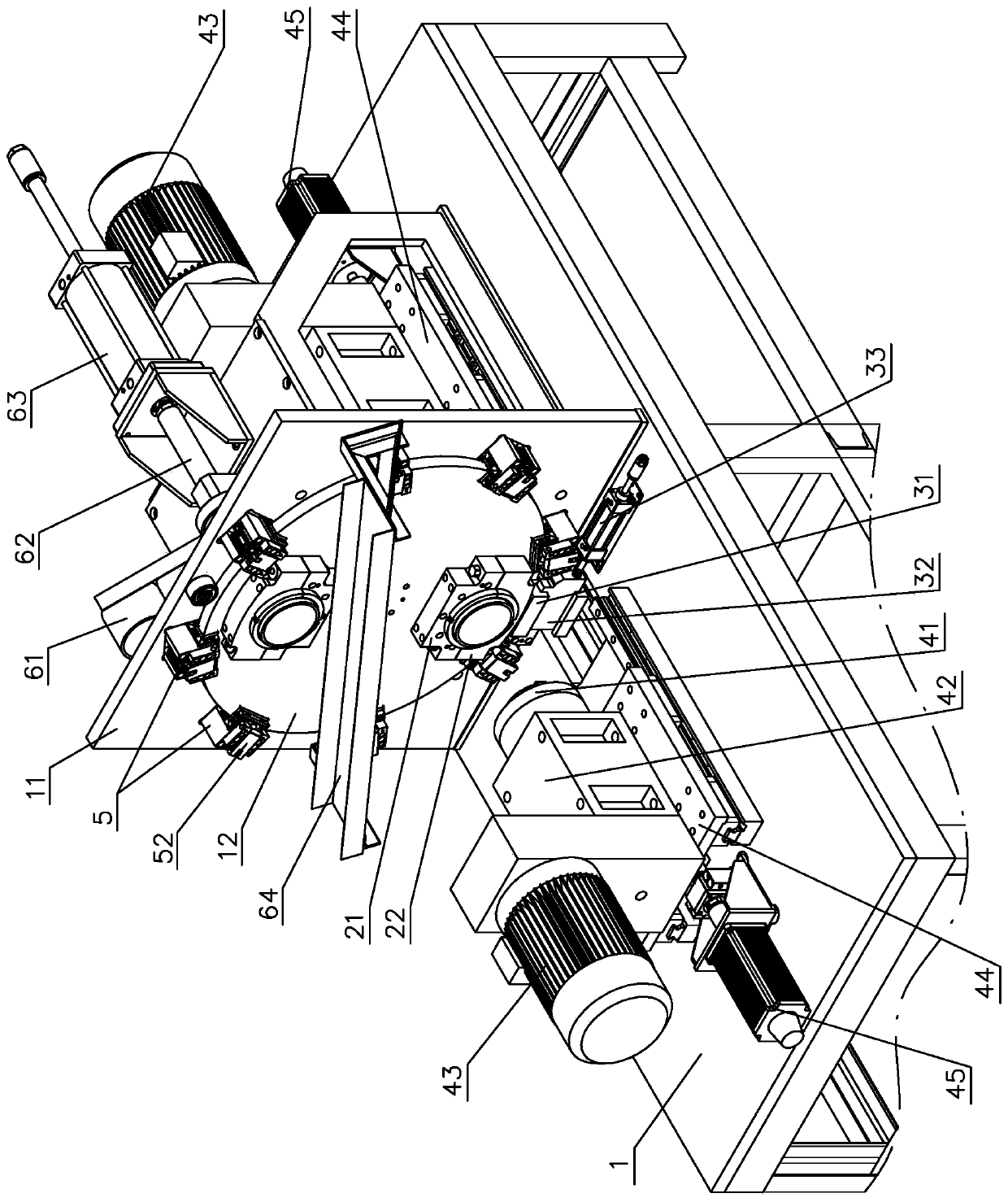

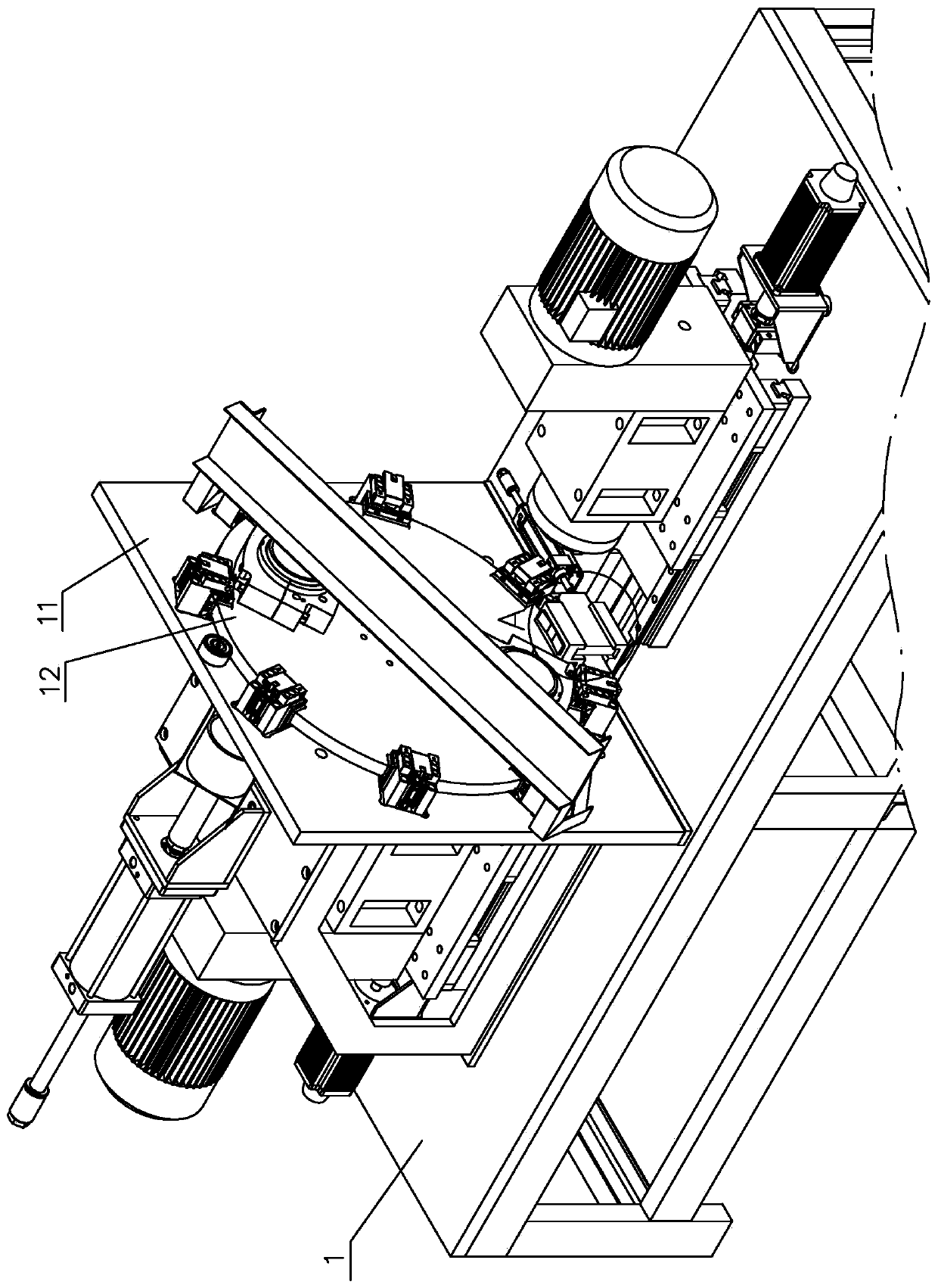

[0017] see figure 1 and figure 2 , The chamfering machine includes a machine table 1, a fixture, a propulsion mechanism and a chamfering mechanism. The machine table 1 includes a vertical vertical plate 11 and a turntable 12 arranged parallel to the vertical plate 11. The turntable 12 can rotate on the vertical plate 11, and the rotation axis is in the horizontal direction.

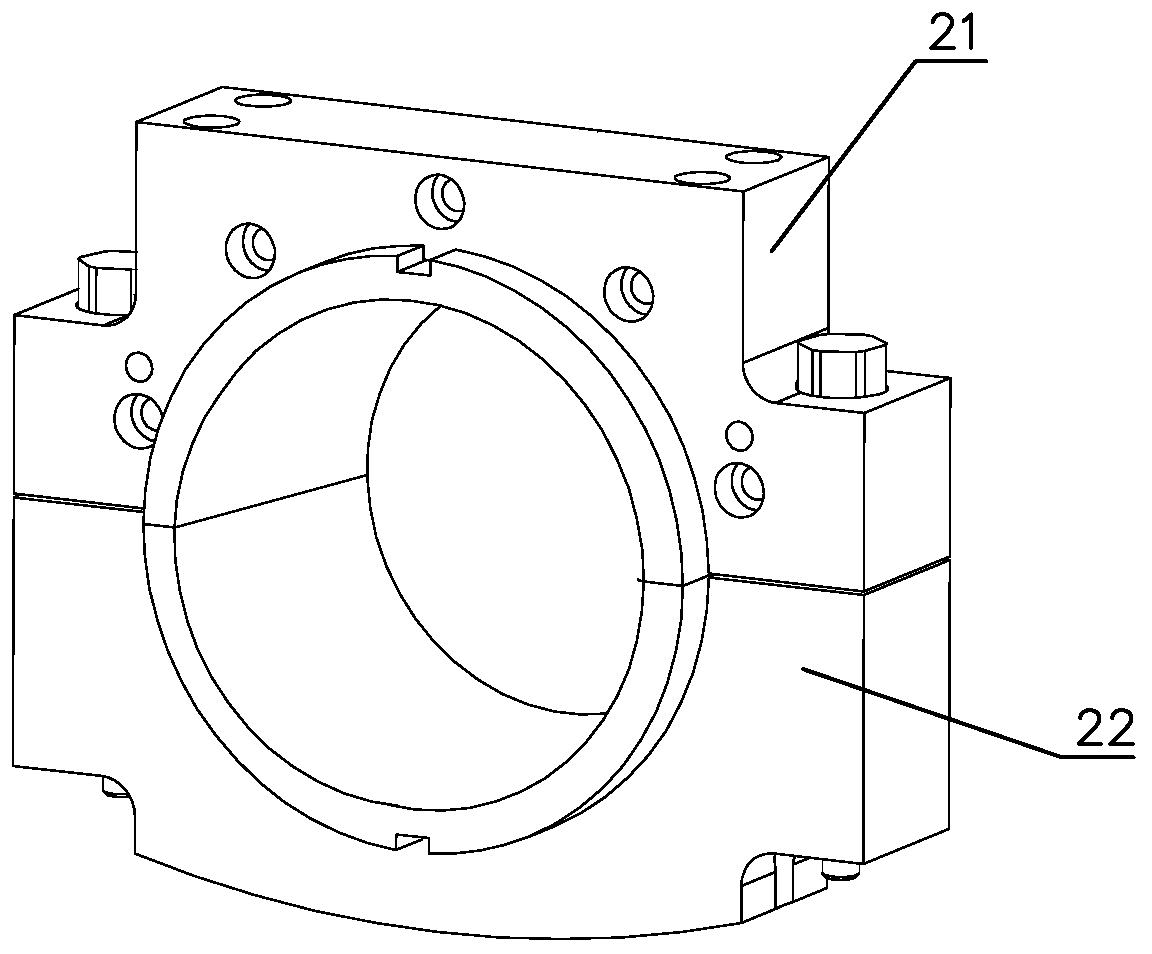

[0018] The fixture is arranged on the turntable 12, and is used for clamping the cylindrical workpiece (such as a bearing sleeve, etc.). see image 3 and Figure 4 , the fixture includes an upper fixture 21, a lower fixture 22 and a return spring 23. The upper fixture 21 is fixed on the turntable 12 with screws, and the lower fixture 22 is movably arranged on the upper fixture 21. Under the action of an external force, it can move up and down relative to the upper fixture 21. move. The upper clamp 21 has an arc-shaped upper clamping surface 210 on a surface opposite to the lower clamp 22 , and the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com