Efficient whole-rod type sugarcane combine-harvester

A combine harvester, whole-rod technology, applied in the fields of harvesters, agricultural machinery and implements, applications, etc., can solve the problems of high breakage rate, high impurity content, low efficiency, etc., to improve yield, rational fertilization, reduce The effect of head break rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

[0056] Aiming at the technical problems of high head breaking rate, low efficiency and high impurity content of sugarcane harvesters in the prior art, the invention provides a high-efficiency whole-rod sugarcane combine harvester.

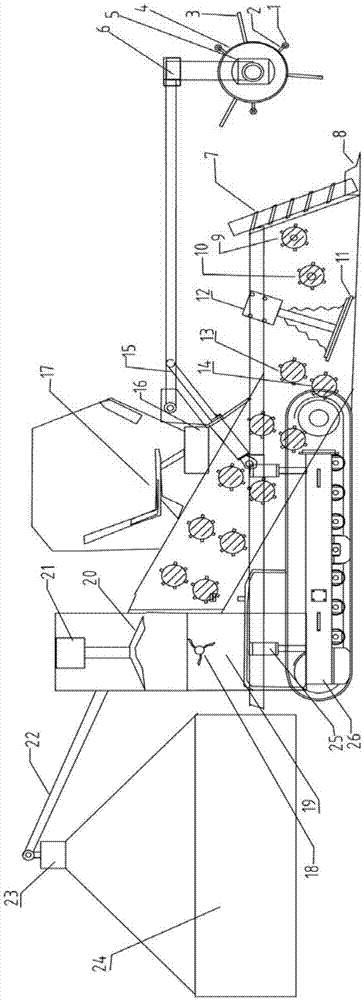

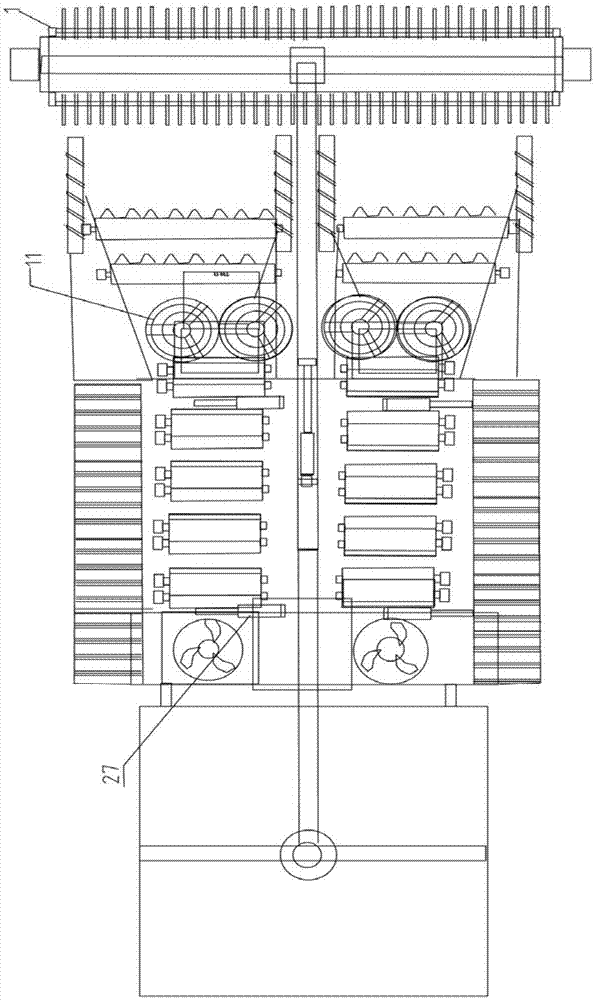

[0057] Such as figure 1 and figure 2 As shown, the embodiment of the present invention provides a high-efficiency whole-rod sugarcane combine harvester, including a tail removal device arranged on the vehicle frame, two or more sets of centering devices with adjustable spacing between outer rollers, and two or more sets of spacing Adjustable root cutting device, conveying device, loading and unloading device, and walking mechanism with adjustable left and right wheelbase;

[0058] The tail removal device includes a beating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com