Sugarcane root cutting and laying mechanism and small sugarcane cutting and laying machine

A technology for cutting paver and sugarcane, applied in agricultural machinery and implements, harvesters, agriculture, etc., can solve the problems of cumbersome operation, complex structure, high breakage rate, and achieve the effects of low energy consumption, small size, and reduced labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0070] The present invention will be further described in detail below with reference to the accompanying drawings. The detailed description, which is made in connection with exemplary embodiments of the present invention, includes various details of the embodiments of the present invention to facilitate understanding and should be considered as exemplary only. Accordingly, those of ordinary skill in the art will recognize that various changes and modifications of the embodiments described herein can be made without departing from the scope and spirit of the invention. Also, descriptions of well-known functions and constructions are omitted from the following description for clarity and conciseness.

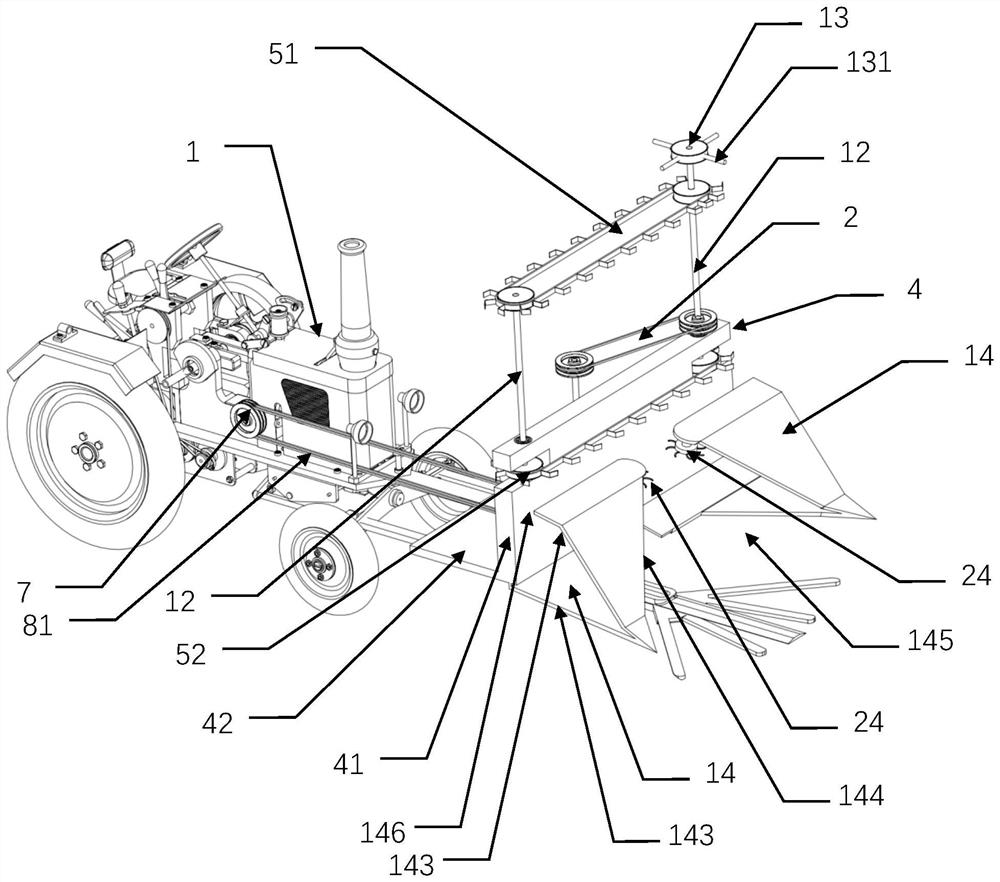

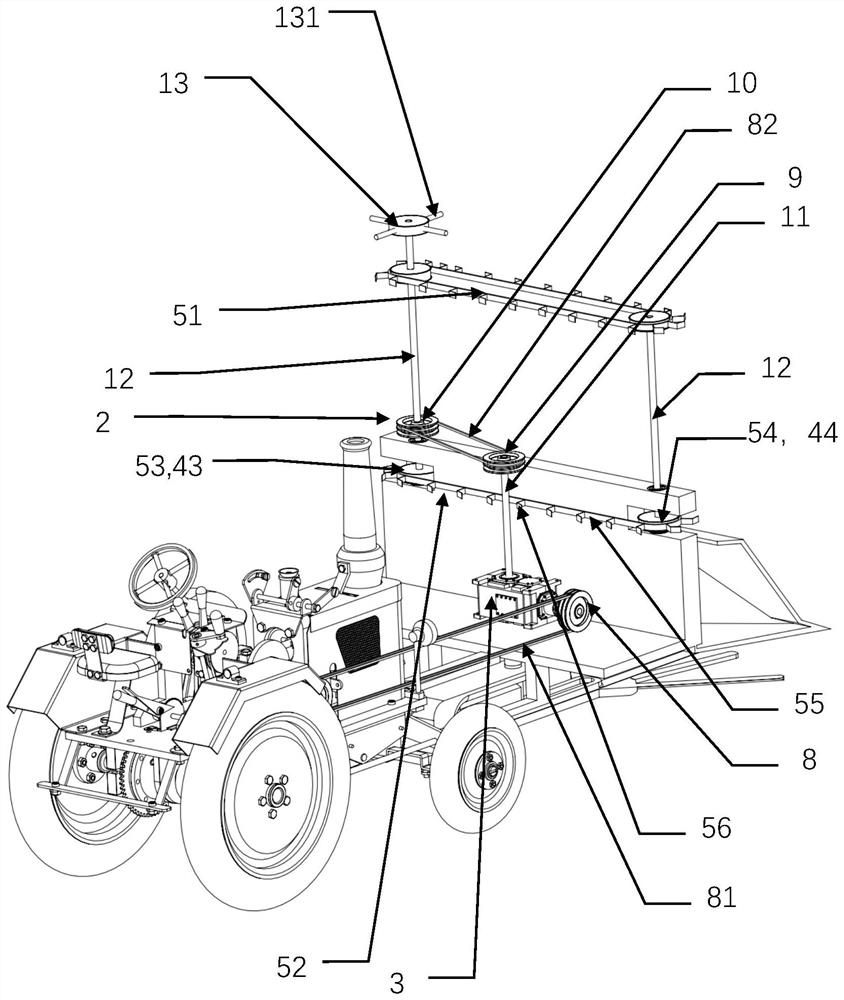

[0071] like Figure 1-Figure 4 As shown, the present invention provides a sugarcane root cutting and laying mechanism, comprising:

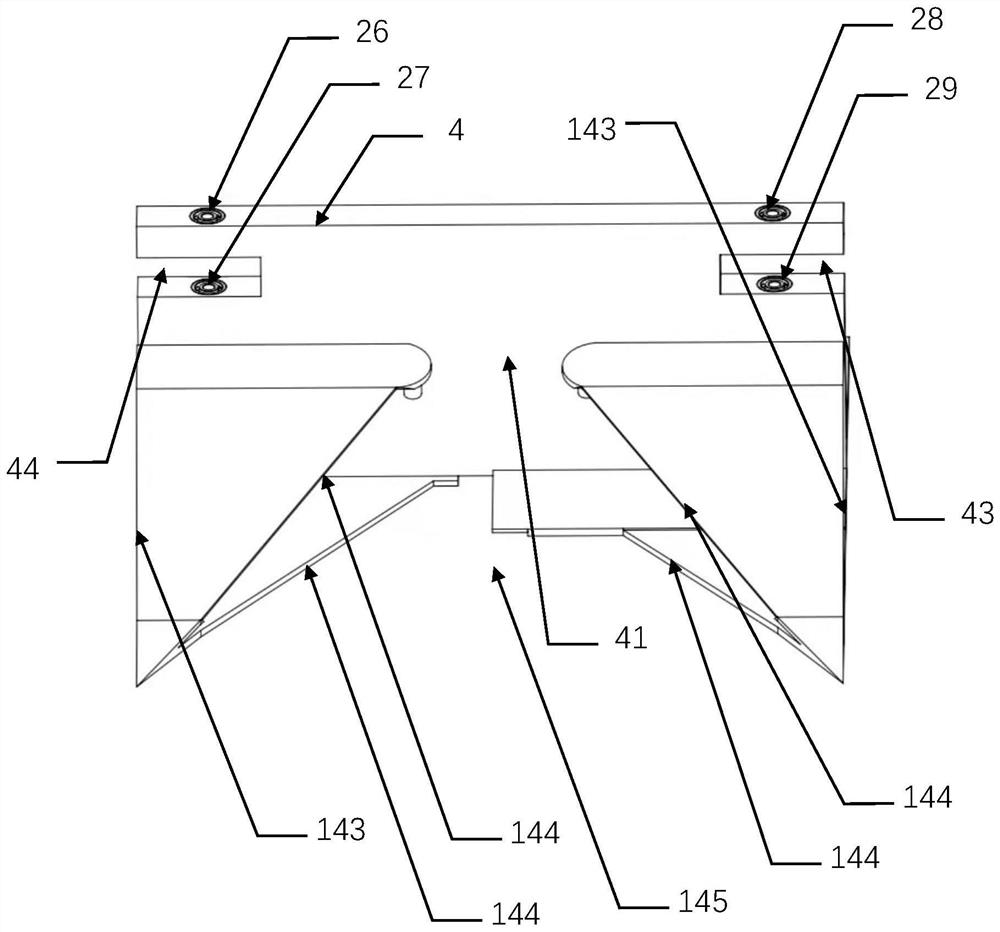

[0072] The stand device 4 has an L-shaped cross section of its main body, including a vertical plate body 41 and a transverse plate body 42 exten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com