Whole rod type sugarcane combine harvester suitable for hilly areas

A combined harvester and regional technology, applied in the direction of harvesters, cutters, agricultural machinery and implements, etc., can solve the problems of high root breaking rate, stuck sugarcane leaf separation, incompleteness, etc., to reduce the rate of breaking heads , Improve dynamic stiffness and reduce height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

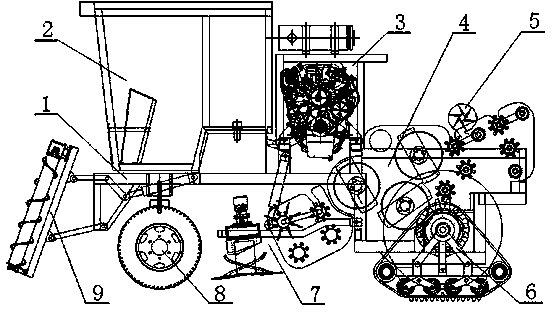

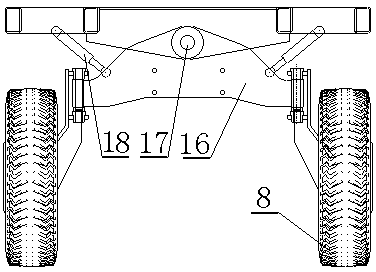

[0032]As shown in the attached figure, the whole pole sugarcane combine harvester suitable for hilly areas includes a vehicle frame (1), a cane splitting device (9) with the vehicle frame (1) as the installation carrier, and a cutting and feeding system assembly. assembly (7), stripping leaf and tail assembly (4), power assembly (3), cab (2), front wheel (8) and rear wheel (6), the logistics layout of the sugarcane harvester is The abdomen is horizontal, and the bottom of the entire logistics channel is hollow; the power assembly (3) is arranged above the logistics channel and behind the cab (2); the cutting and feeding system assembly (7) is arranged on the front and rear wheels between, the rear end of the cutting feeding system assembly (7) is connected to the frame (1) through a hinge, and the front end is connected to the middle of the frame (1) through a lifting cylinder (20); the leaf stripping and tail breaking assembly (4) It is closely connected with the cutting and ...

Embodiment 2

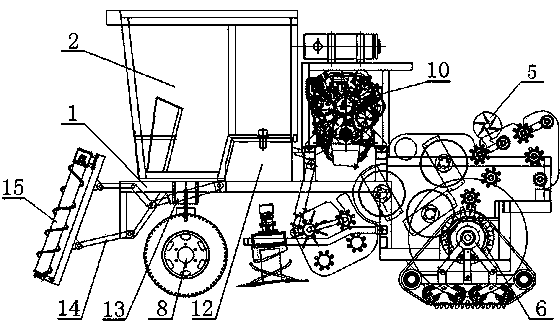

[0040] A whole-bar sugarcane combine harvester suitable for hilly areas, including a vehicle frame (1), a cane splitting device (9) with the vehicle frame (1) as the installation carrier, a cutting and feeding system assembly (7), stripping The leaf docking assembly (4), the power assembly (3), the cab (2), the front wheel (8) and the rear wheel (6). The bottom of the channel is hollow; the power assembly (3) is arranged above the logistics channel and behind the cab (2); the cutting and feeding system assembly (7) is arranged between the front and rear wheels, and the cutting and feeding The rear end of the system assembly (7) is connected to the vehicle frame (1) through a hinge, and the front end is connected to the middle part of the vehicle frame (1) through a lifting cylinder (20); The benchmark is closely connected with the cutting and feeding system assembly (7); the cutting and feeding system assembly (7) includes a cutting device and a feeding device, and the cutting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com