Special dismantling device for liner bolts and flanges of large mills

A technology for dismantling devices and mills, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve problems such as increasing the difficulty of construction, reducing construction safety, and difficulty in getting out of the feeding port, and achieves the speed and height of realization. , Improve the effect of disassembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

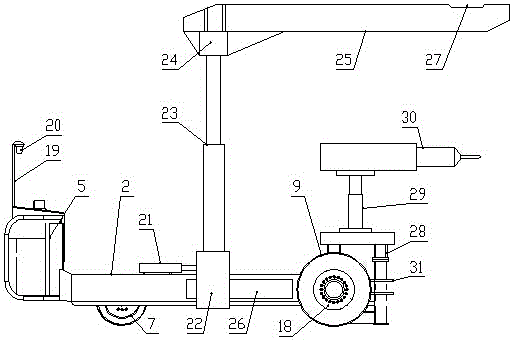

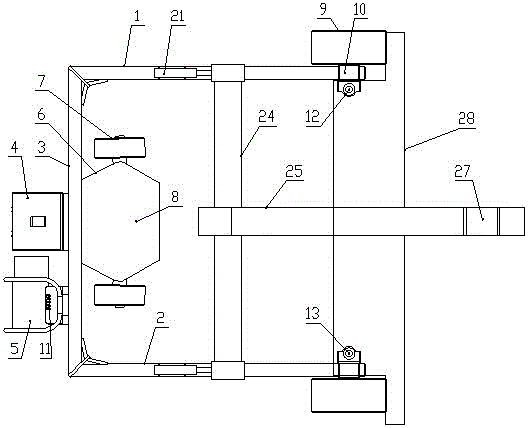

[0028] like figure 1 and figure 2 As shown, the large-scale mill liner bolt and flange special dismounting device of the present invention includes a left longitudinal beam 1 and a right longitudinal beam 2 arranged in parallel along the front and rear directions, between the rear ends of the left longitudinal beam 1 and the right longitudinal beam 2 Connected by a beam 3, the rear side of the beam 3 is provided with a hydraulic power station 4 and the driving console 5, the front side of the beam 3 is provided with a bracket 6, the left and right sides of the bracket 6 are respectively provided with a steering wheel 7, and the bracket 6 is provided with A hydraulic steering system 8 that controls the simultaneous steering of two steering wheels 7, a driving wheel 9 is respectively provided at the front ends of the left longitudinal beam 1 and the right longitudinal beam 2, and a hydraulic travel motor 10 is connected to the center of each driving wheel 9, respectively. A le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com