Movable special vehicle for removing bolts from lining plate of large-sized mill

A mobile, special-purpose vehicle technology, applied in vehicle components, fluid steering mechanisms, transportation and packaging, etc., can solve the problems of reducing construction safety, high labor intensity, and prolonging the maintenance time of large-scale mills, so as to reduce worker labor. Strength, the effect of improving disassembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

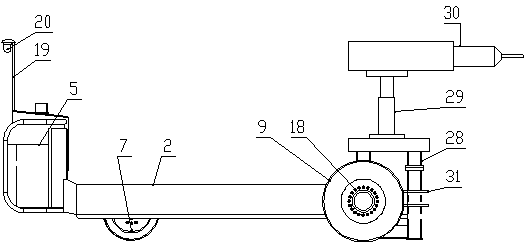

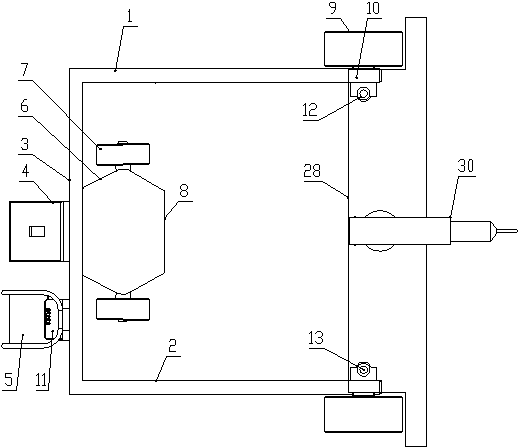

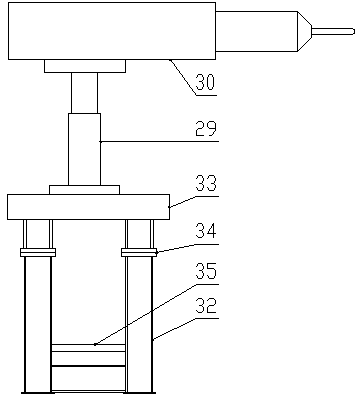

[0023] Such as figure 1 , figure 2 and image 3 As shown, the large-scale mill liner bolt removal movable special vehicle of the present invention includes a left longitudinal beam 1 and a right longitudinal beam 2 arranged in parallel along the front and rear directions, and a rear end of the left longitudinal beam 1 and the right longitudinal beam 2 passes through a The root beam 3 is connected, the rear side of the beam 3 is provided with a hydraulic power station 4 and the driving console 5, the front side of the beam 3 is provided with a bracket 6, the left and right sides of the bracket 6 are respectively provided with a steering wheel 7, and the bracket 6 is equipped with A hydraulic steering system 8 in which two steering wheels 7 are turned at the same time. The front ends of the left longitudinal beam 1 and the right longitudinal beam 2 are respectively provided with a driving wheel 9, and the center of each driving wheel 9 is connected with a hydraulic travel moto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com