Wireless remote control electro-hydraulic drive tire type gantry crane

A gantry crane, wireless remote control technology, applied to cranes, trolley cranes, load hanging components, etc., can solve the problems of high price, poor flexibility and applicability, and high cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

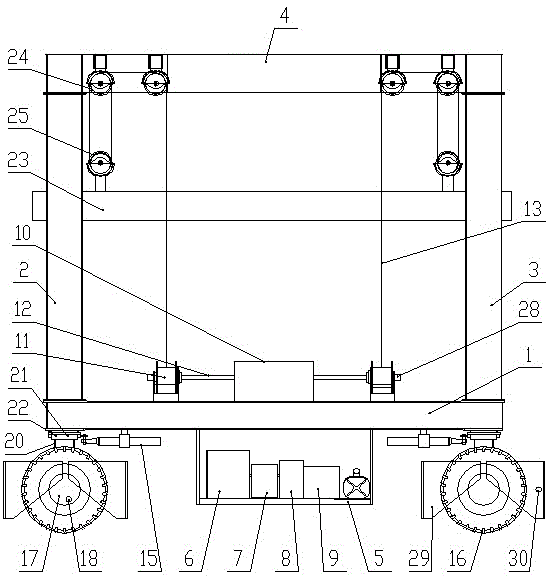

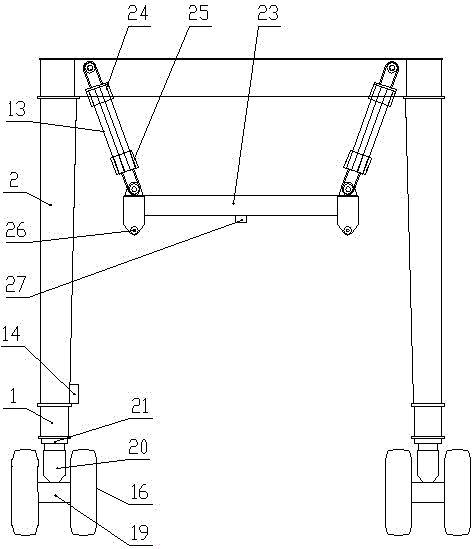

[0013] Such as figure 1 with figure 2 As shown, the radio-controlled electro-hydraulic drive rubber-tyred gantry crane of the present invention includes two lower longitudinal beams 1 arranged horizontally, a front gantry frame 2 is arranged between the front end upper surfaces of the two lower longitudinal beams 1, and two lower longitudinal beams 1 A rear gantry 3 is arranged between the upper surface of the rear end of the beam 1, an upper longitudinal beam 4 is respectively arranged on the left and right sides of the front gantry 2 and the rear gantry 3, and the lower surface of the front end and the rear end of each lower longitudinal beam 1 All are equipped with a walking steering system, one of the lower longitudinal beams 1 is provided with a bracket 5, and the bracket 5 is equipped with an engine 6, a transfer case 7, a hydraulic station 8 and a generator set 9, and each lower longitudinal beam 1 There are motors 10 and winches 11 located at the front and rear sides...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com