Cutting device for sugarcane end breakage prevention

A cutting device and anti-breaking technology, applied in the field of sugarcane cutting, can solve the problems of sugarcane splitting and head breaking, sugarcane germination rate and yield impact, and easy contact with the cutter again, so as to reduce the breaking head rate and reduce the The phenomenon of broken head and the effect of improving the flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

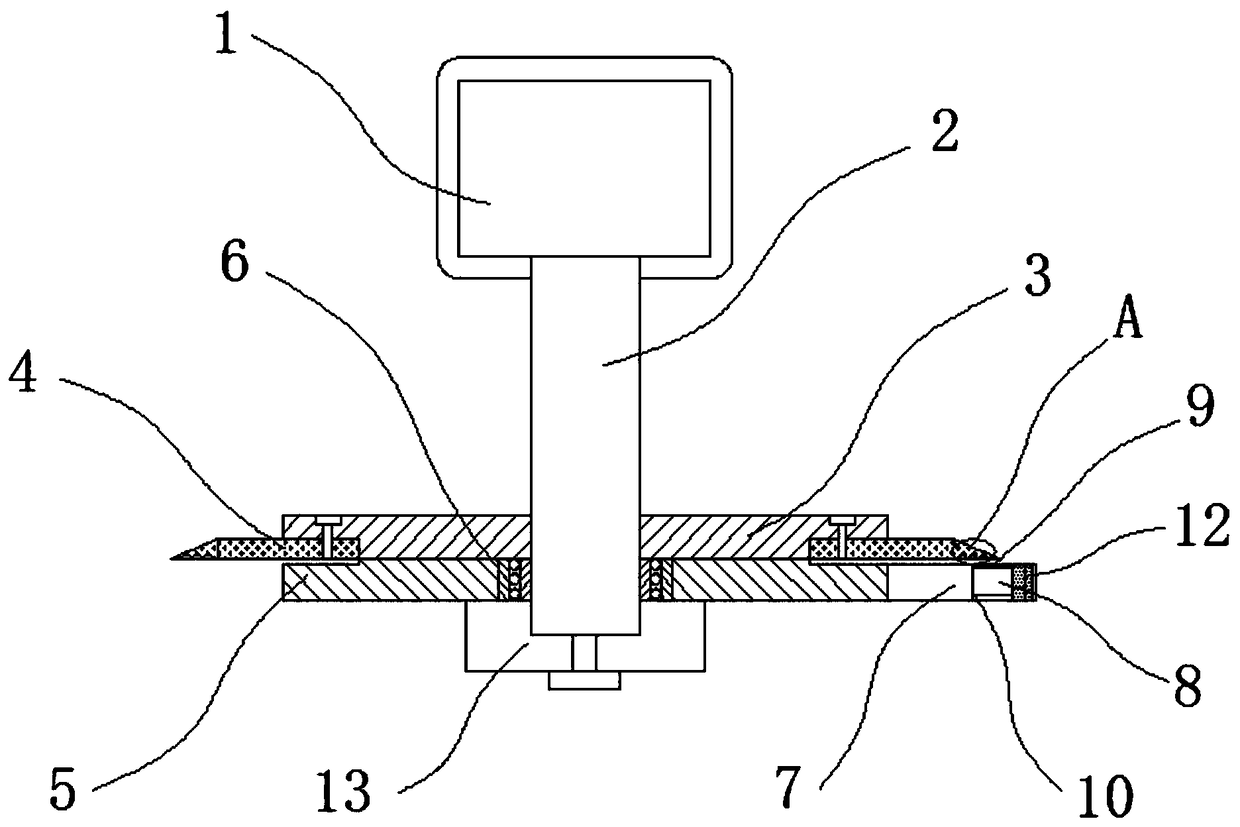

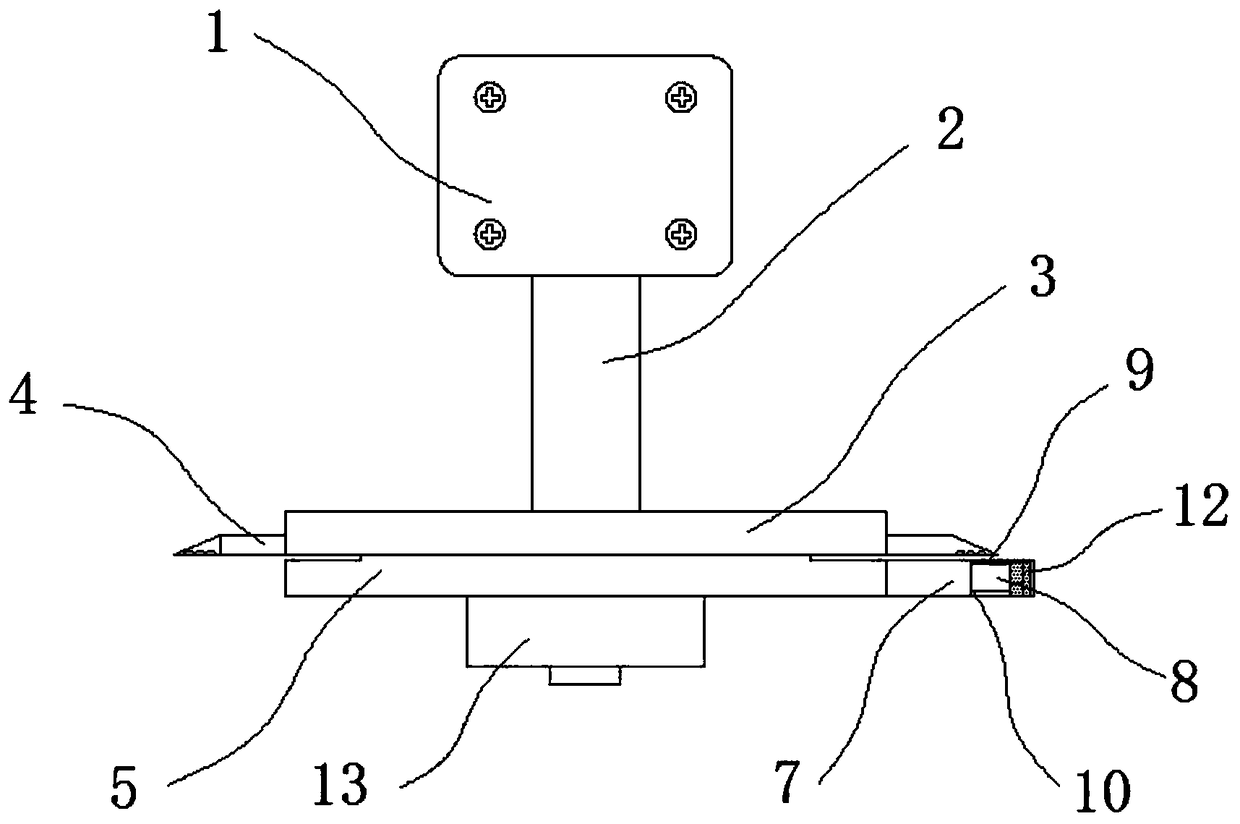

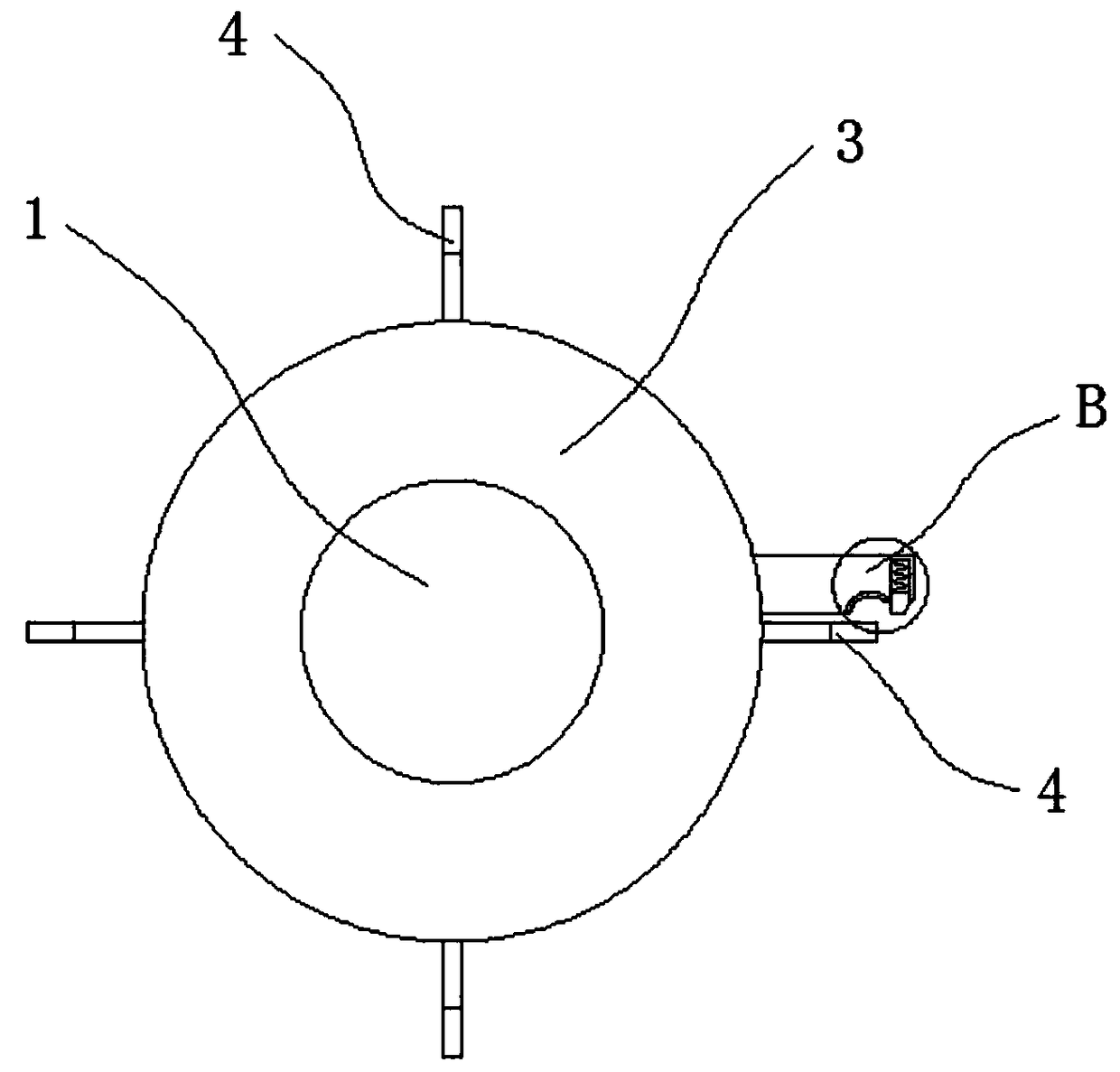

[0029] as attached figure 1 to attach Figure 7 Shown:

[0030] A cutting device for sugarcane head breakage prevention, comprising: a motor 1, a main shaft 2, a cutter head 3, a cutter 4, an inner groove 401, a toothed block 402, a fixed plate 5, a bearing 6, a baffle plate 7, and a spring groove 701, semi-circular groove 8, cutting block 9, fixed block 10, spring 11, movable block 12 and stop plate 13; A cutter 4 is fixedly connected around the bottom, an inner groove 401 is provided on the bottom side of the cutter 4 away from the main shaft 2, a toothed block 402 is fixedly connected to the inner side of the inner groove 401, and a bearing 6 is fixedly connected to the bottom of the main shaft 2 , the side of the bearing 6 facing away from the main shaft 2 is fixedly connected with a fixed disk 5, both the bearing 6 and the fixed disk 5 are located below the cutter head 3, and the side of the fixed disk 5 is fixedly connected with a baffle 7, and the baffle 7 faces away ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com