Patents

Literature

52results about How to "Enough width" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Manufacture of non-volatile memory

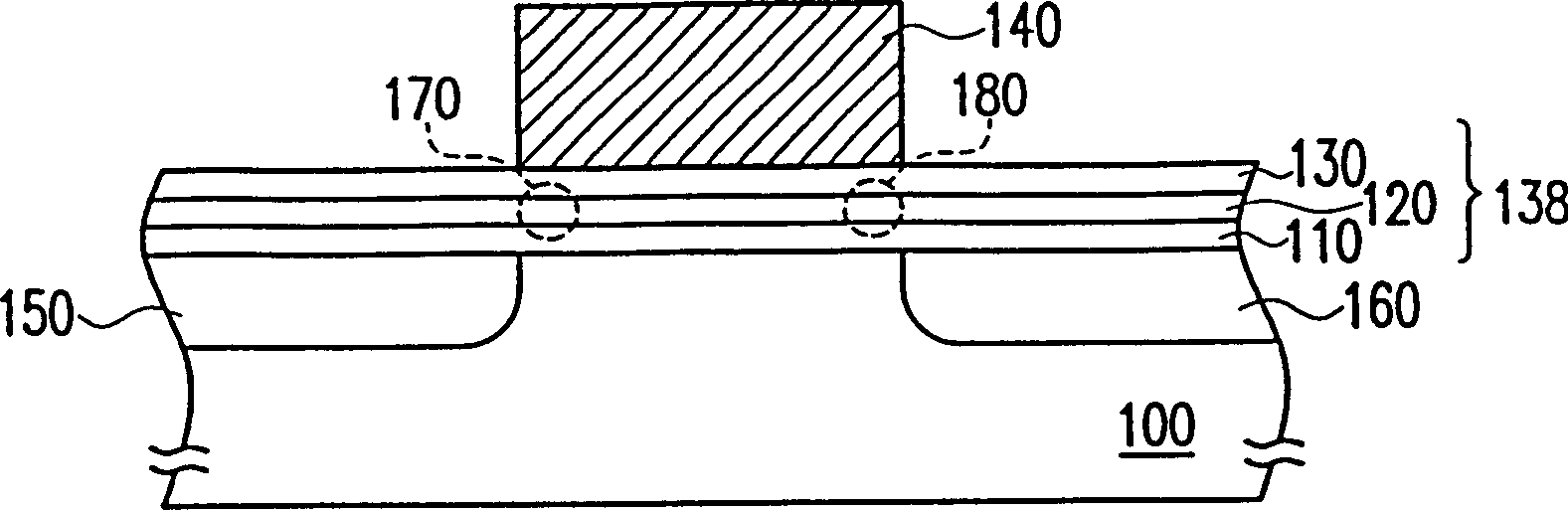

InactiveCN1421917AHigh dielectric constantIncrease widthSemiconductor/solid-state device manufacturingBit lineDielectric

The manufacture of non-volatile memory includes forming charge trap layer of insulating material and conducting strips as precursor of grid on the substrate; forming embedded bit lines between conducting strips with some interval being maintained between the embedded bit line and the adjacent conducting strips; forming high-dielectric constant interval walls on the side walls of the conducting strips; defining the conducting strips to form grids and finally forming electrically connecting word lines over the substrate. The high-dielectric constant interval walls is of material with sufficienthigh dielectric constant and has enough width, so that the channel formed by the non-volatile memory can extend to below the high-dielectric constant interval walls and form electric connection with the embedded bit lines.

Owner:MACRONIX INT CO LTD

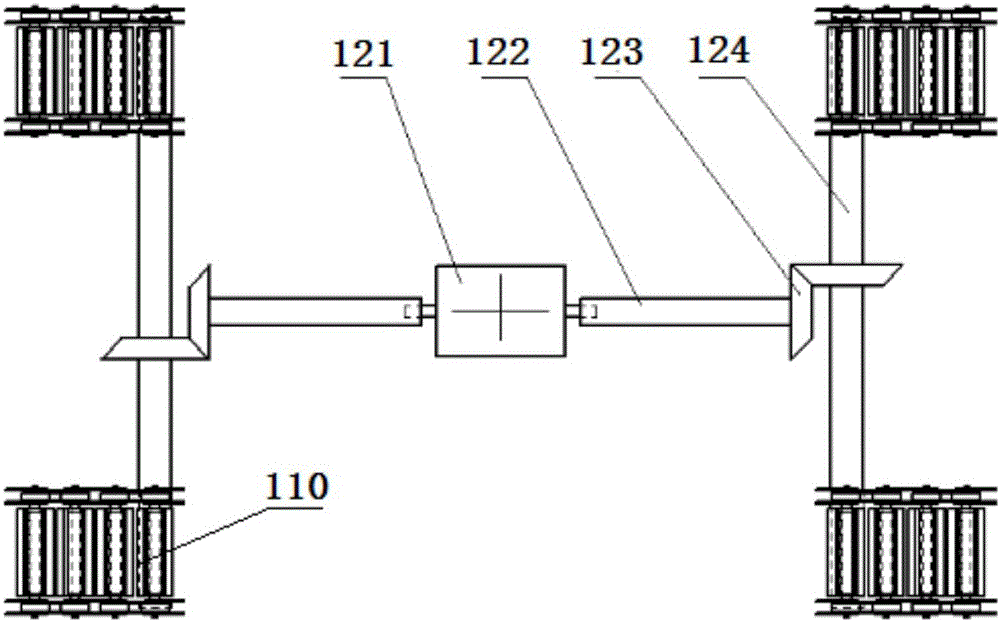

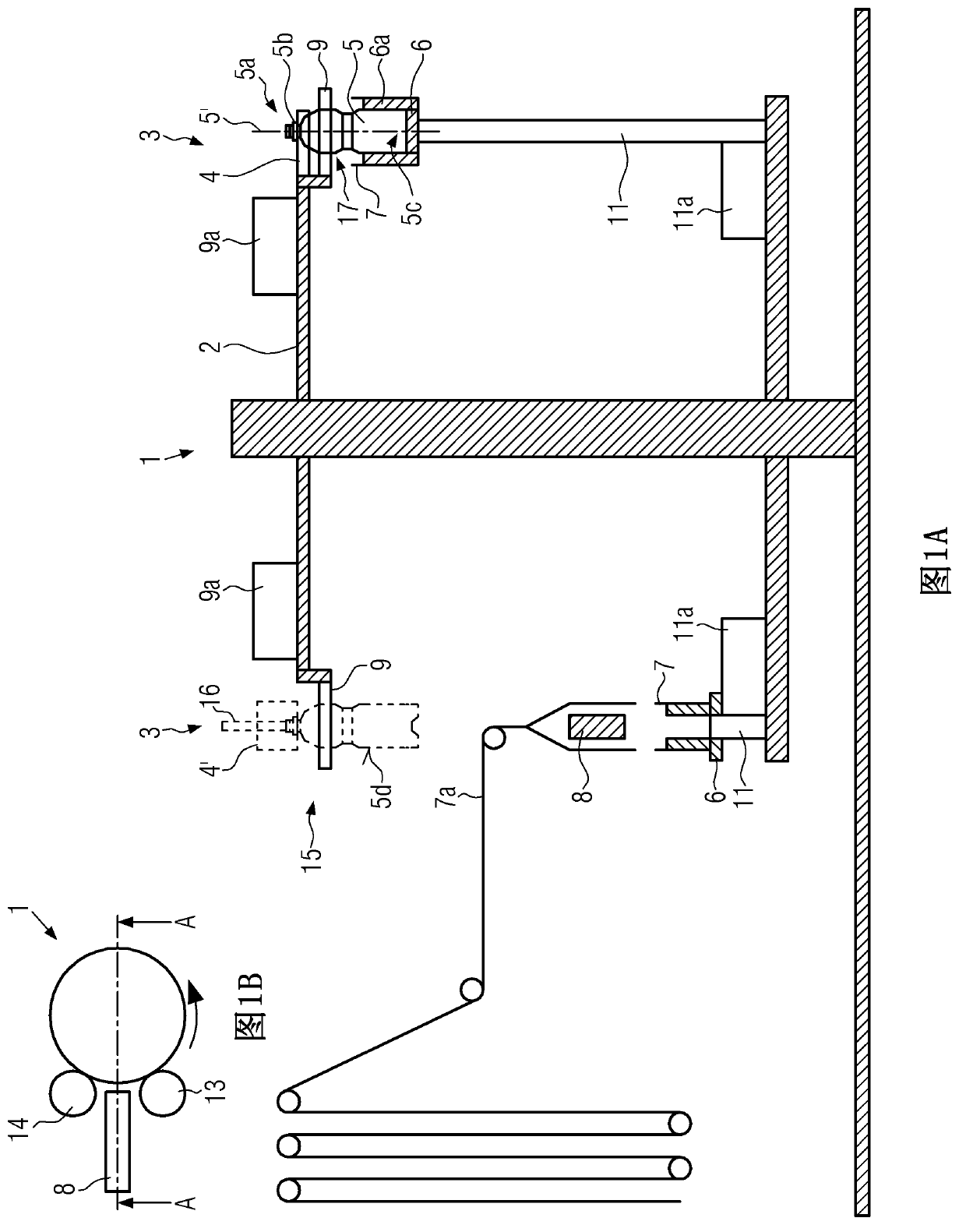

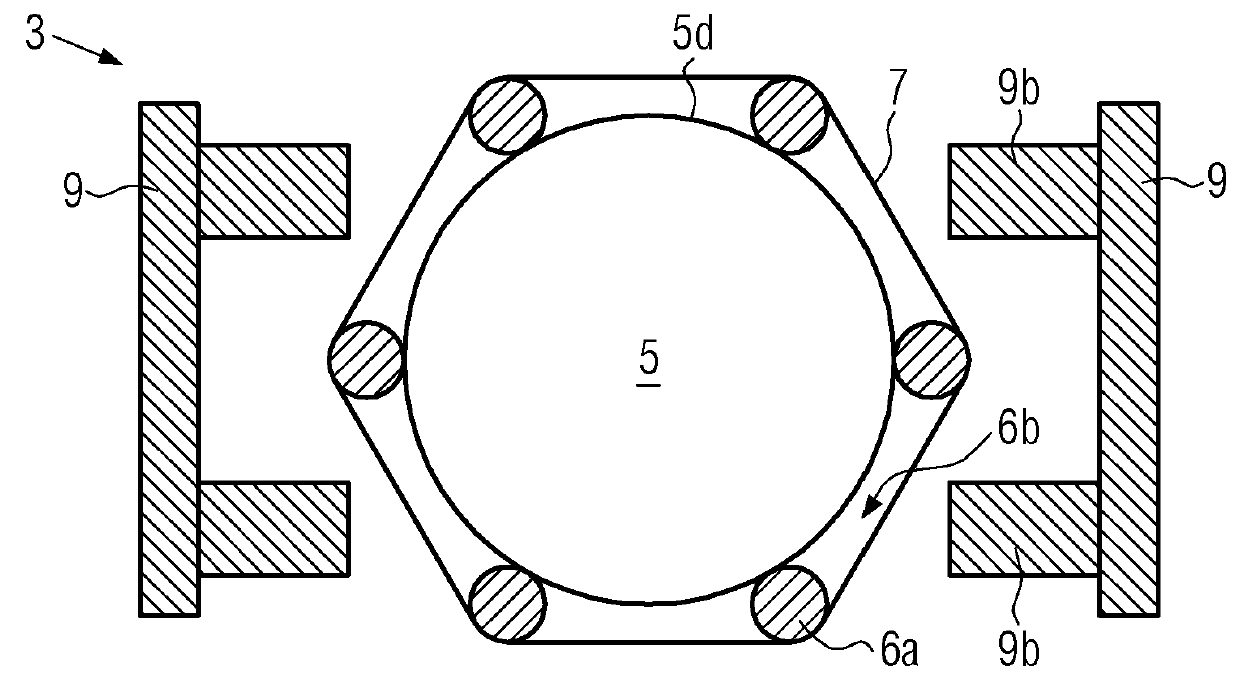

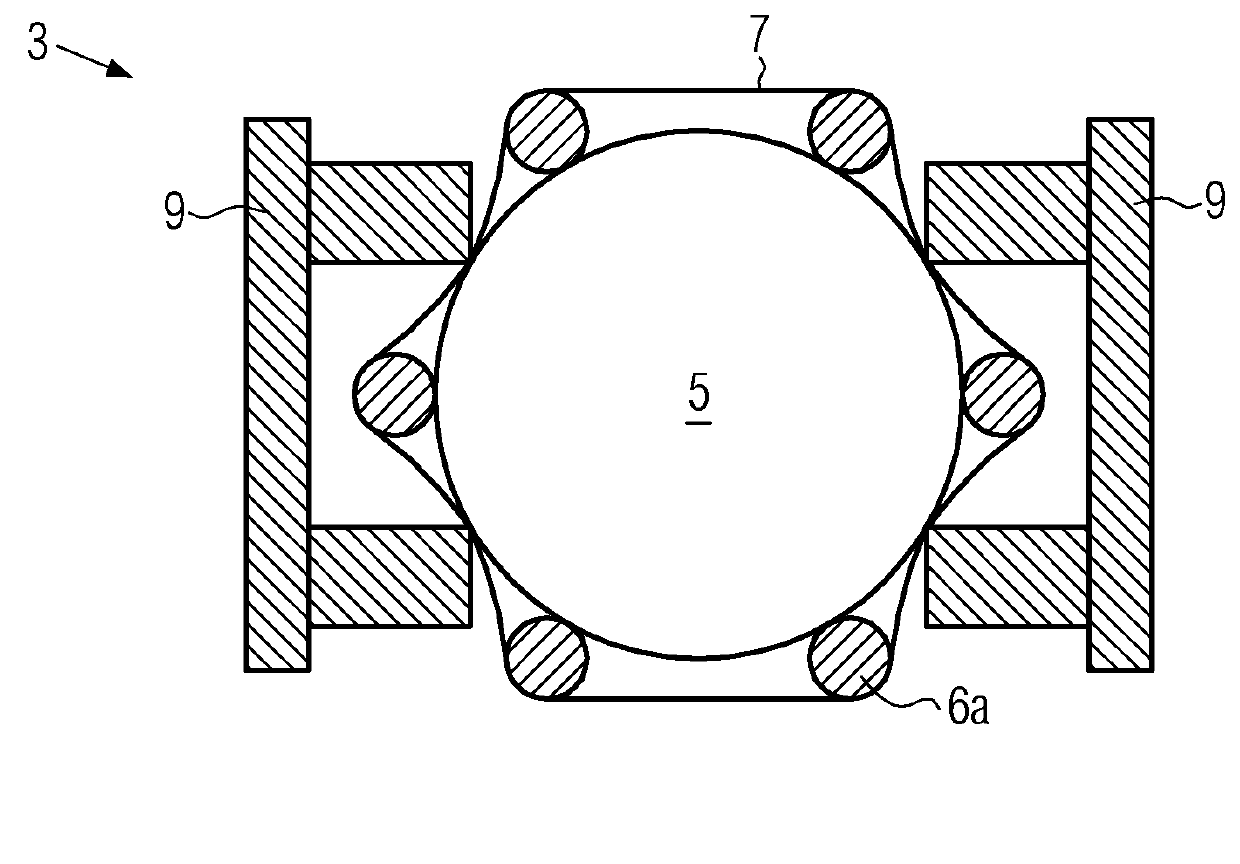

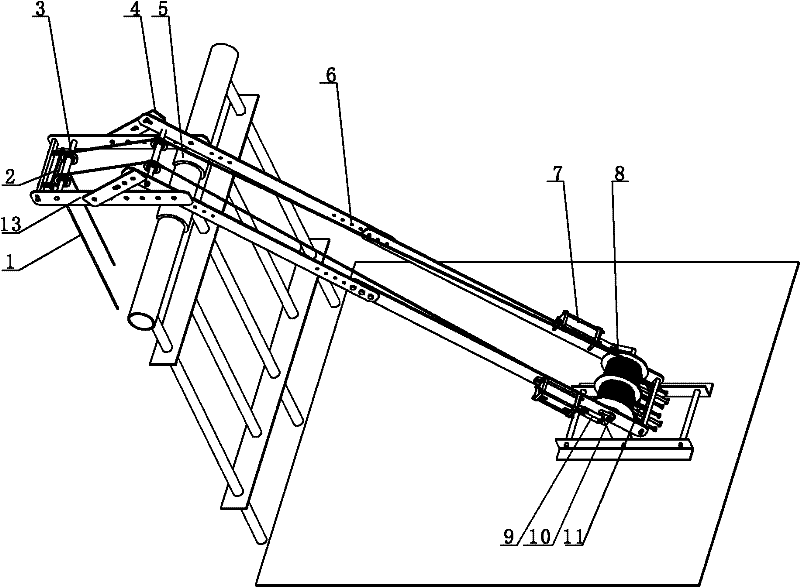

Flat board type changeable simulation road face testing device

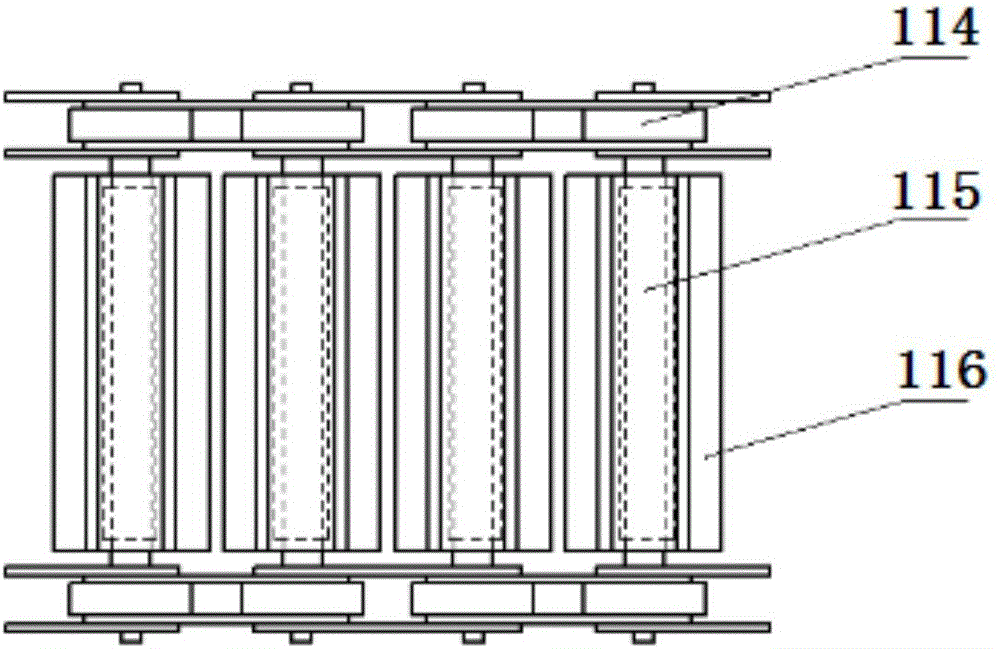

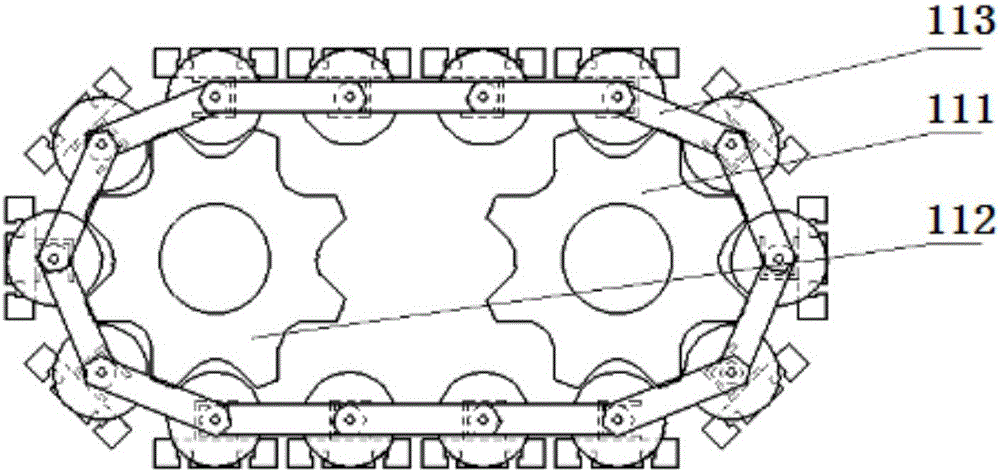

InactiveCN105699097AOvercome precisionOvercome the defect that it is difficult to simulate a straight roadVehicle testingEngineeringSprocket

The invention discloses a flat board type changeable simulation road face testing device including four road face simulation mechanism in contact with four wheels. The road face simulation mechanism includes a drive chain wheel and a driven chain wheel; chain links connected in a head-to-tail manner so as to form a loop chain engaged with the drive chain wheel and the driven chain wheel; a T-shaped channel steel board connected with the chain links fixedly and provided with a through T-shaped groove; a T-shaped block fitting with the T-shaped groove so as to enable the T-shaped block to embed into the T-shaped groove in a dismountable manner; and bosses arranged at the top end of the T-shaped block and in contact with wheels so as to realize road face excitation to an automobile, wherein the chain links between the drive chain wheel and the driven chain wheel are kept horizontal. The device provided by the invention is simple in structure and reasonable in design. Different road faces can be simulated through changing the shapes and distribution of the bosses.

Owner:LIAONING UNIVERSITY OF TECHNOLOGY

Inner annular backoff demoulding mechanism for injection mould cavity piece

Owner:ZHEJIANG KAIHUA MOLDS

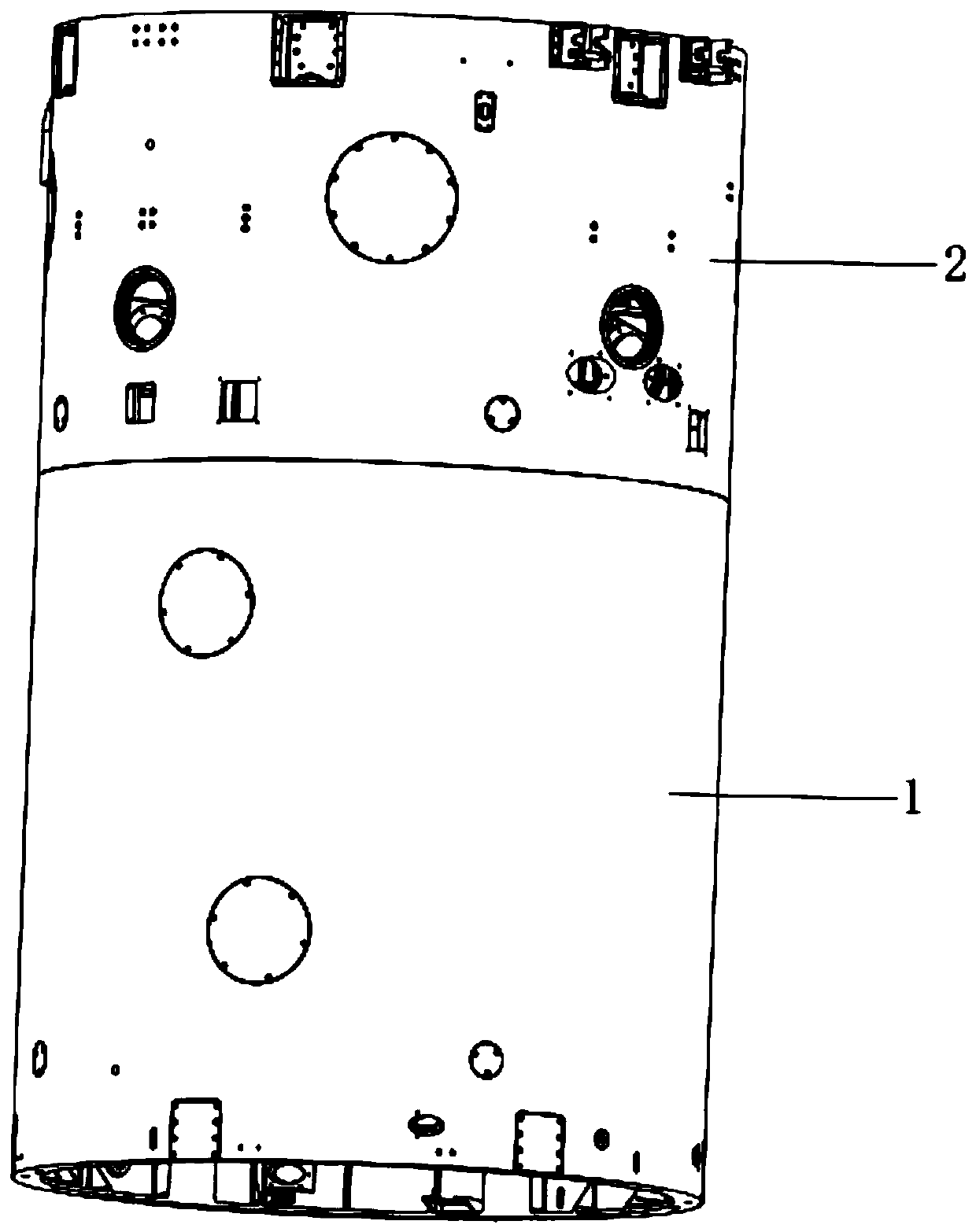

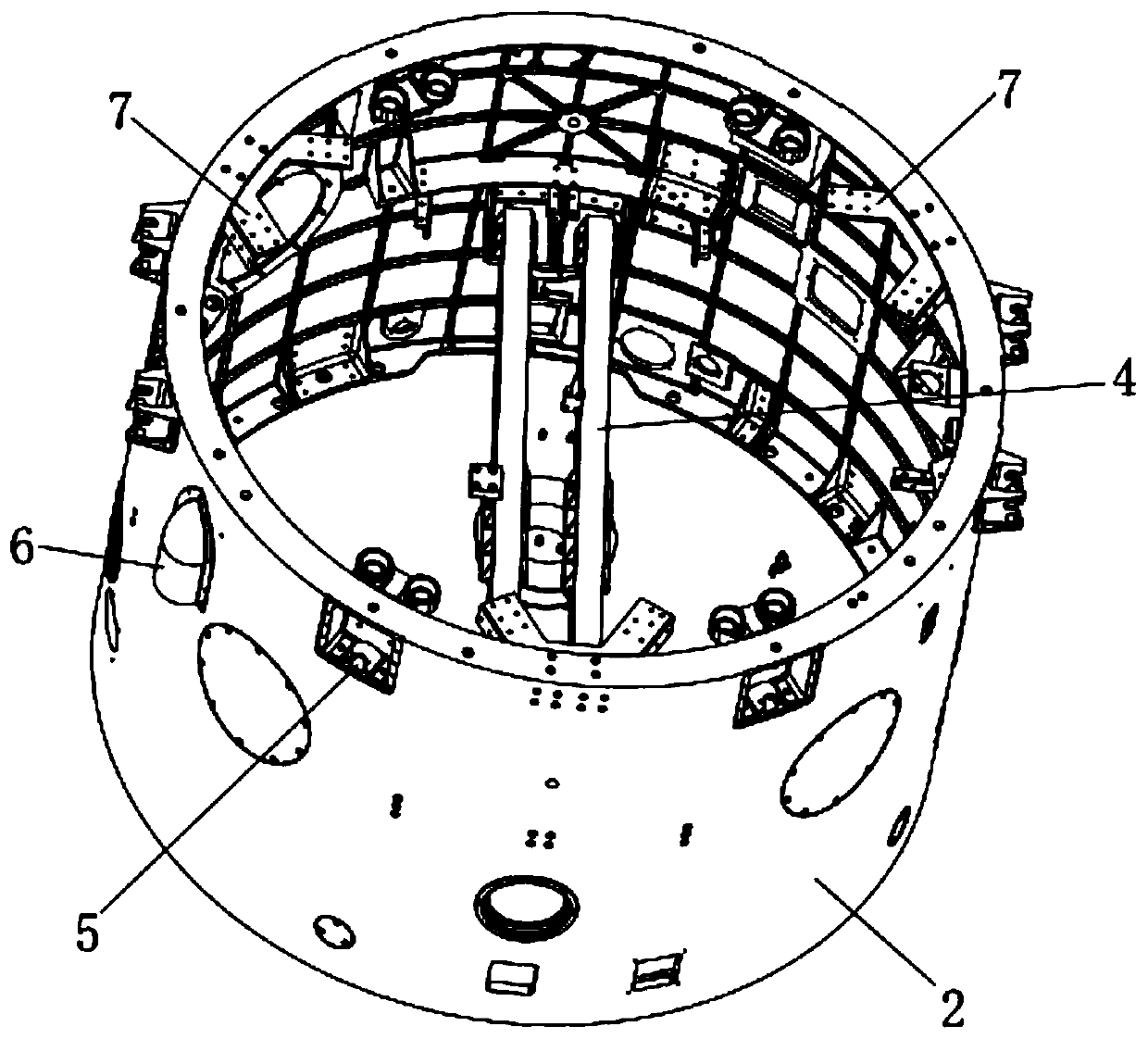

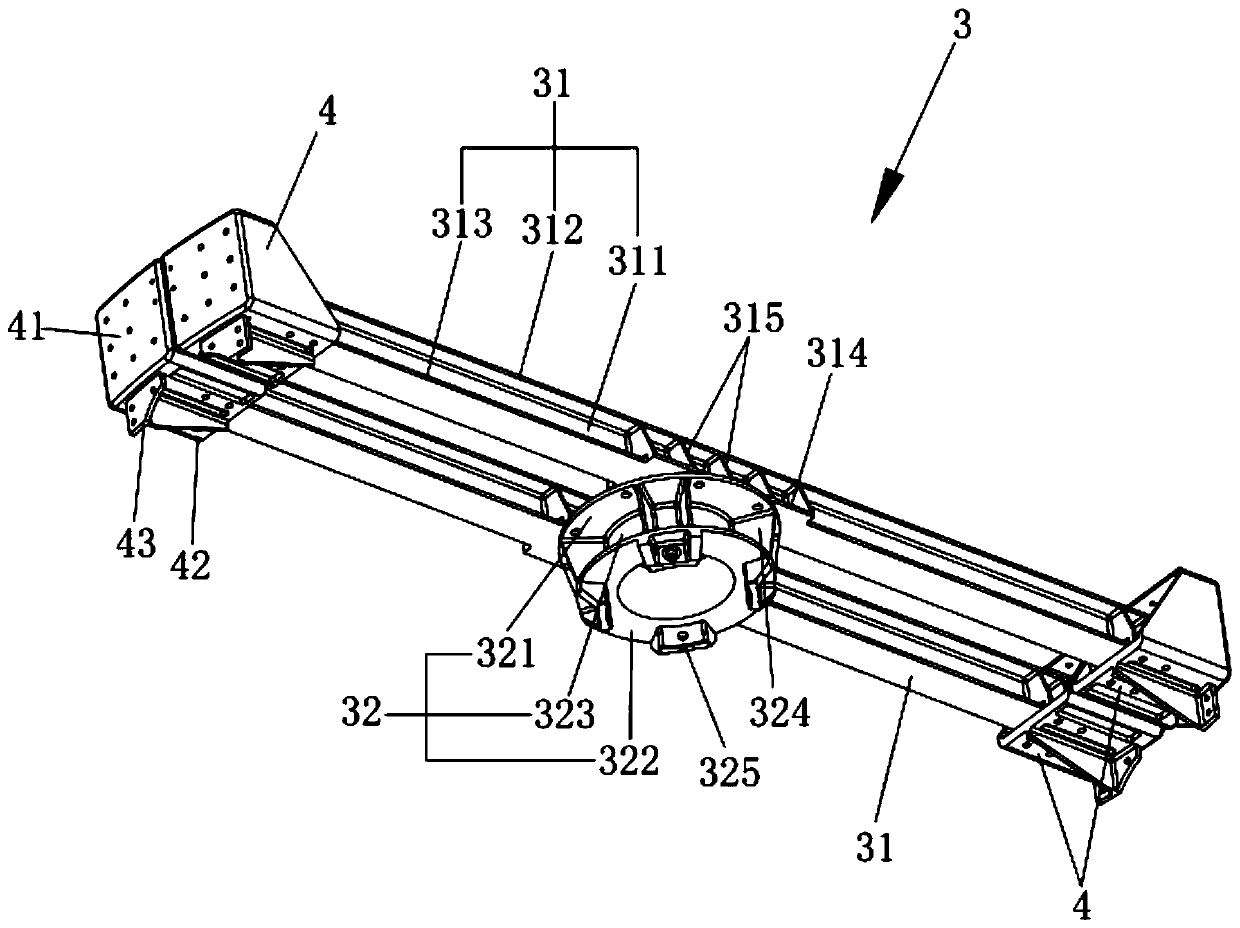

Carrier rocket tail sub-stage structure

PendingCN111023913AImprove delivery efficiencySimple structureSelf-propelled projectilesRocketMechanical engineering

The invention discloses a carrier rocket tail sub-stage structure, which comprises a power cabin, an instrument cabin and a stiffening beam structure, wherein the power cabin provides mounting space for a tail sub-stage power system; the instrument cabin is connected to the upper end of the power cabin, and a plurality of mounting interfaces for mounting instruments are formed in the inner wall ofthe instrument cabin; the stiffening beam structure comprises at least two stiffening beams which are arranged in parallel, and two ends of each stiffening beam are respectively connected with the inner wall of the instrument cabin; and the middle parts of the at least two stiffening beams are connected with a connecting disc for providing a connecting interface for the tail sub-stage power system. The stiffening beam structure of a double-beam parallel structure is adopted in the instrument cabin, the self weight of the stiffening beam structure can be reduced on the premise that the stability of a connecting disc installation structure is guaranteed, the power cabin and the instrument cabin are respectively made of an integrated structure, and the effect of reducing the self-weight of the whole carrier rocket tail sub-stage structure can also be achieved. Meanwhile, the inner wall of the instrument cabin can provide mounting interfaces for a large quantity of equipment, and the carrying efficiency of the rocket is improved while the starting resistance during rocket launching is reduced.

Owner:BEIJING XINGJI RONGYAO SPACE TECH CO LTD +1

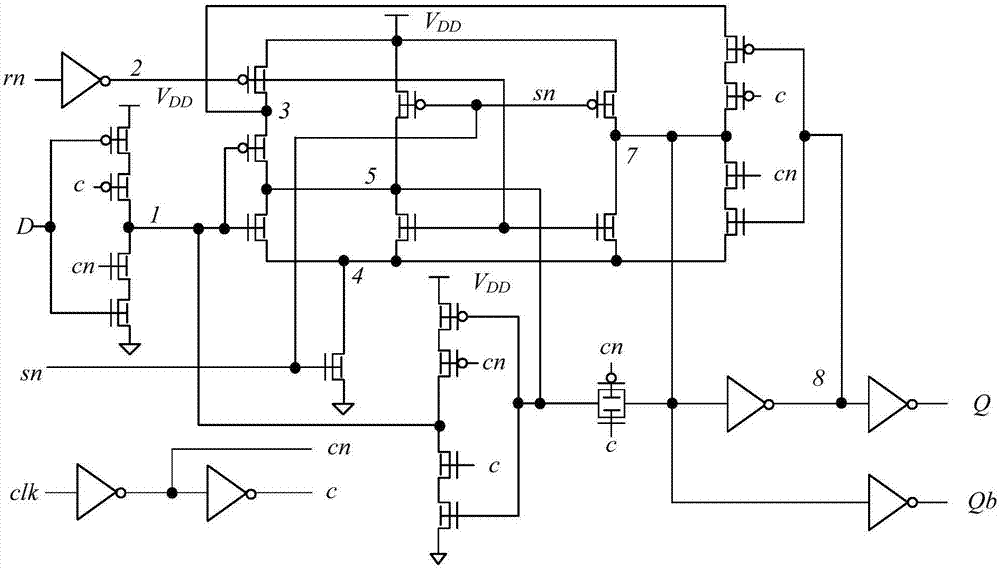

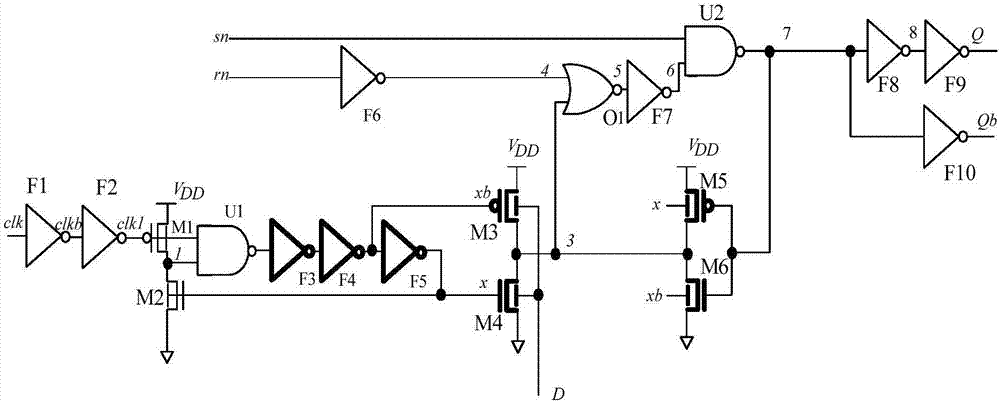

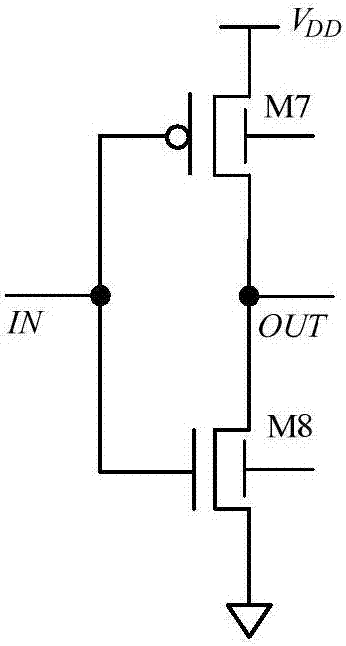

Short-pulse type D trigger based on FinFET device

The invention discloses a short-pulse type D trigger based on FinFET device. The short-pulse type D trigger comprises a first FinFET tube, a second FinFET tube, a third FinFET tube, a fourth FinFET tube, a fifth FinFET tube, a sixth FinFET tube, a first phase inverter, a second phase inverter, a third phase inverter, a fourth phase inverter, a fifth phase inverter, a sixth phase inverter, a seventh phase inverter, a seventh phase inverter, an eighth phase inverter, a ninth phase inverter, a tenth phase inverter, a first two-input NOR gate, a first two-input XOR gate and a second two-input XOR gate, wherein each of the first two-input NOR gate, the first two-input XOR gate and the second two-input XOR gate is provided with a first input, a second input and an output end; the short-pulse type D trigger has the advantages that the number of the FinFET tube is reduced, the circuit delay and the circuit area are further optimized since the series connection of the transistor is reduced; therefore, the circuit area, the time delay, the power consumption and the power delay product are small under the condition of not influencing the circuit performance.

Owner:NINGBO UNIV

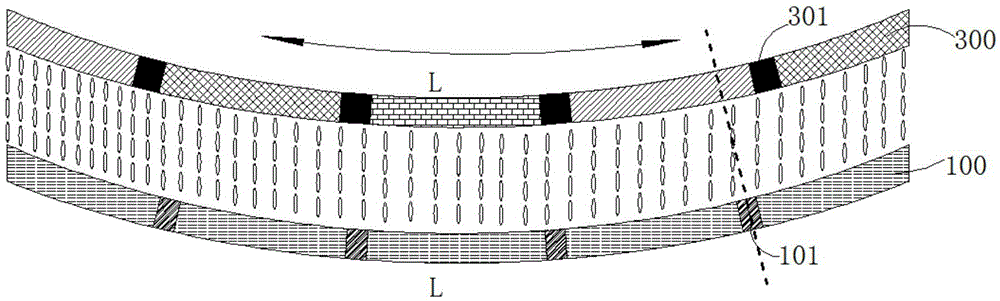

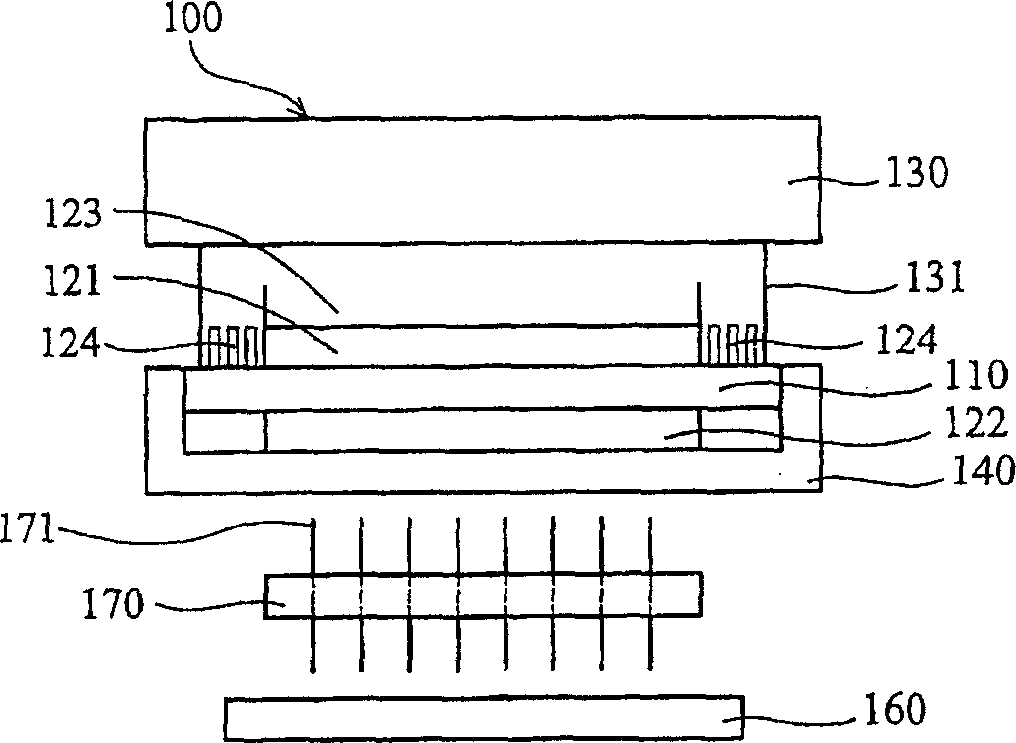

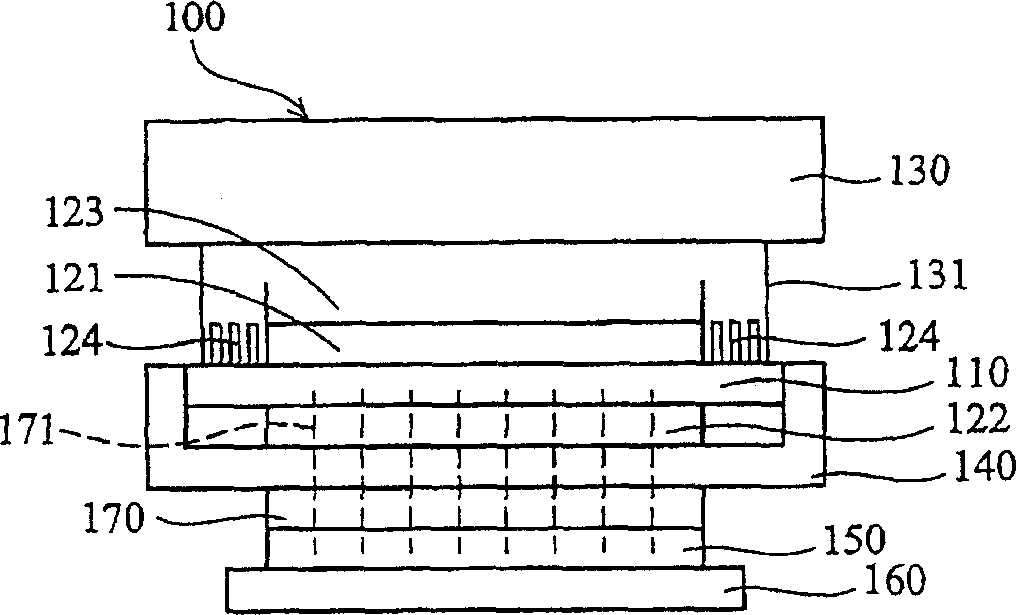

Curved-face liquid crystal panel

The invention discloses a curved-face liquid crystal panel which comprises a TFT substrate, a CF substrate corresponding to the TFT substrate and a liquid crystal layer arranged between the TFT substrate and the CF substrate. The CF substrate comprises a filter area and a black matrix. The TFT substrate comprises a plurality of data lines, common electrodes and pixel electrodes. The common electrodes comprise the first common electrode, the second common electrode and a common electrode connecting line for connecting the first common electrode with the second common electrode, the first common electrode, the second common electrode and the common electrode connecting line are of an H-shaped structure, and the first common electrode and the second common electrode are partially overlapped with the data line. The first common electrode and the second common electrode are overlapped with the pixel electrodes adjacent to the first and second common electrodes respectively. According to the technical scheme, when the panel is in a curved face state, light leakage caused by black matrix dislocation is avoided, the brightness will not be lowered, the aperture opening ratio is improved, and energy consumption is reduced.

Owner:NANJING CEC PANDA LCD TECH

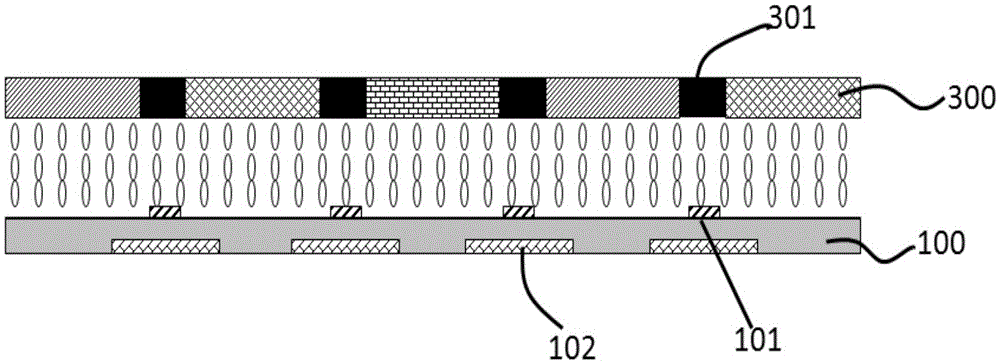

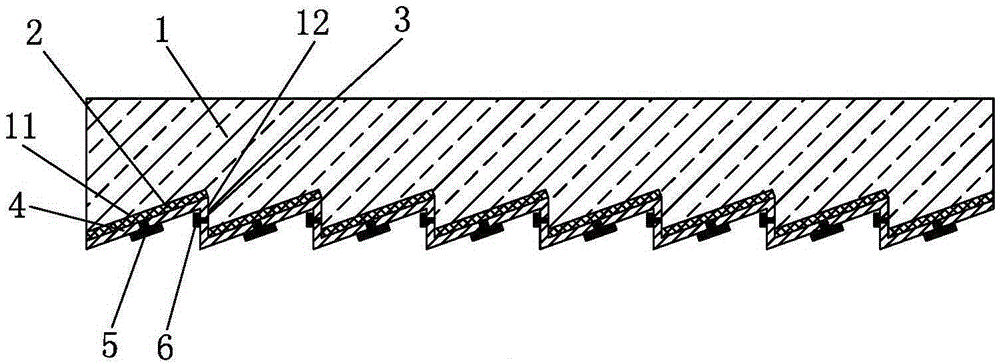

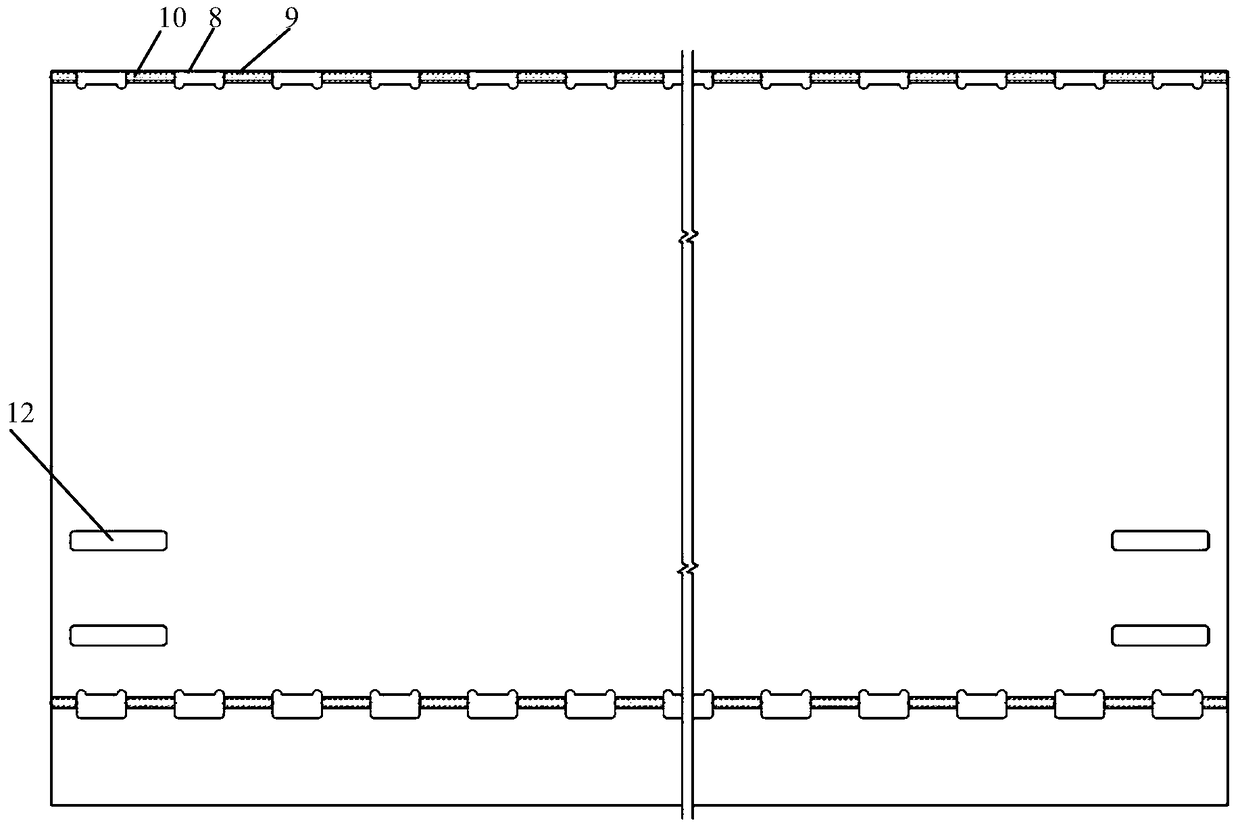

Efficient all back electrode type solar cell

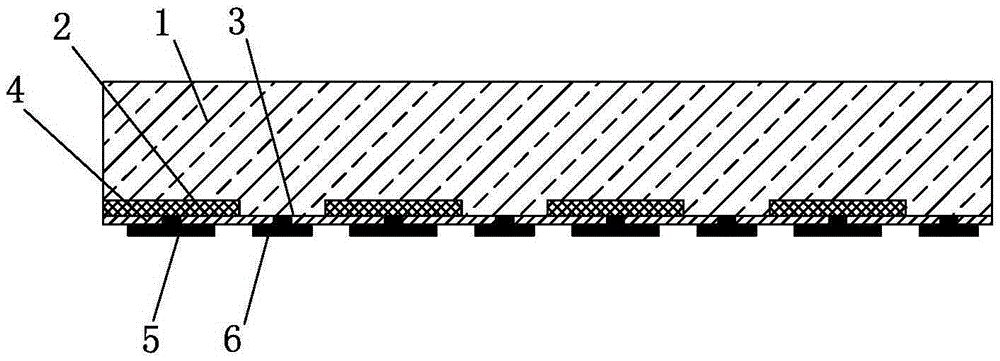

InactiveCN103762258AIncrease power generationImprove conversion efficiencyPhotovoltaic energy generationSemiconductor devicesSolar cellGenerating capacity

The invention relates to the technical field of solar cells, in particular to an efficient all back electrode type solar cell. The solar cell comprises a solar panel arranged on the outer layer, wherein a zigzag stepped surface with long edges and short edges arranged alternately is arranged on the bottom of the solar panel, each long edge is provided with a PN junction diffusion layer and a diffusion layer electrode, and each short edge is provided with a substrate electrode. Due to the fact that the PN junction diffusion layers are arranged on the zigzag long edges, the contact area between a P region and an N region, namely the area of a PN junction region is increased as much as possible. Besides, due to the fact that the substrate electrode layers are arranged on the short edges of the stepped surface, the short edges are arranged to be perpendicular to the surface of the solar panel as far as possible, so that solar rays shining on the solar panel can almost completely shine on the PN junction diffusion layers. In this way, the area of the PN junction diffusion layers can be increased, solar rays can be fully absorbed, sufficient width is guaranteed for the substrate electrode layers, and then the electric generating capacity and conversion efficiency of the solar cell are improved to the greatest extent.

Owner:DONGGUAN POLYTECHNIC

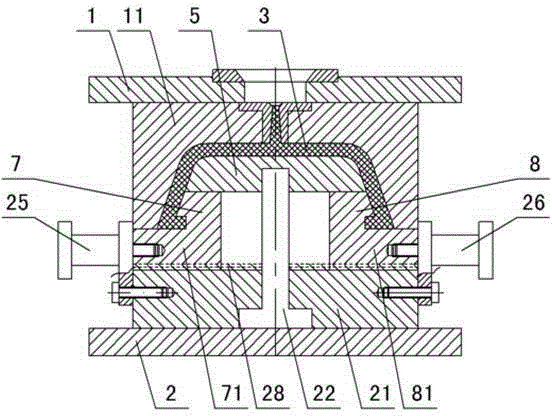

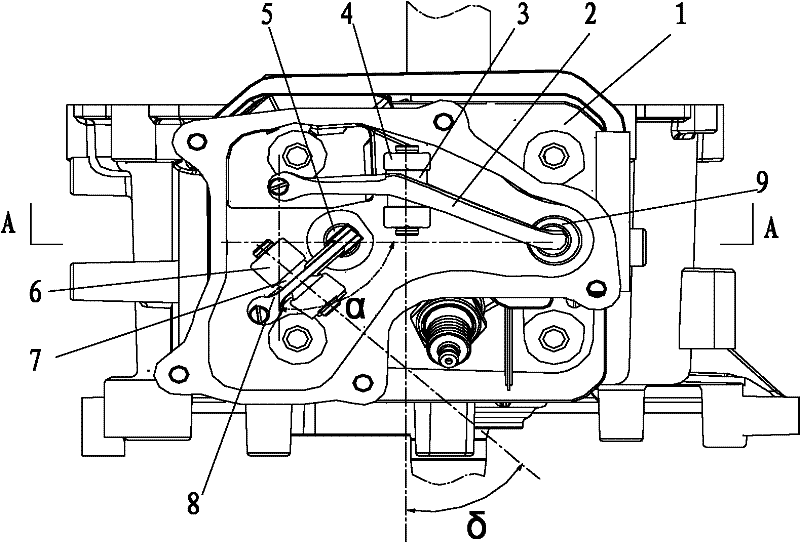

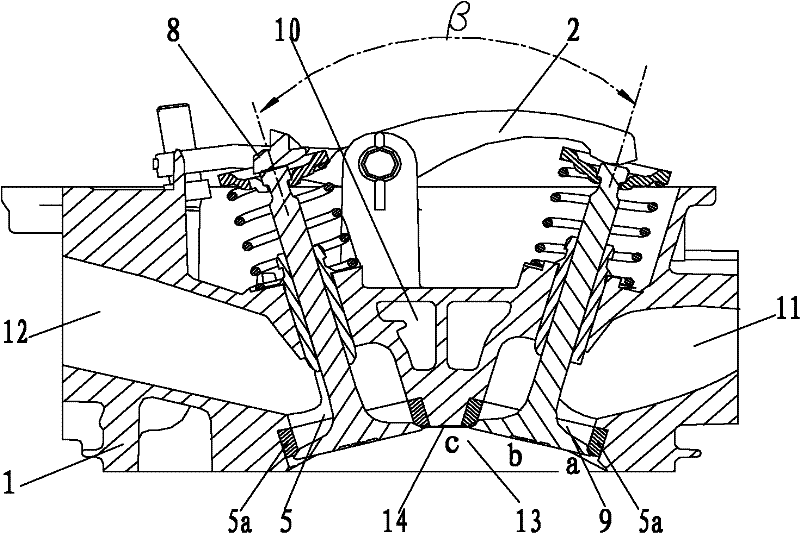

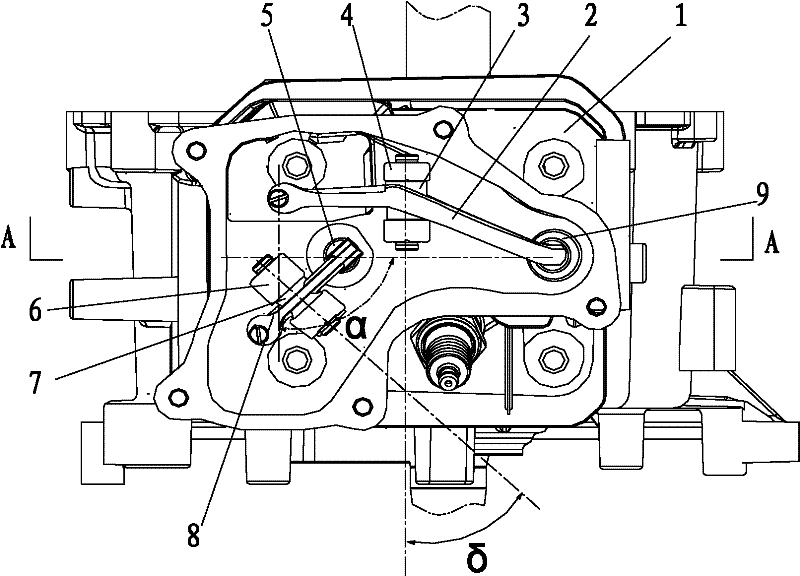

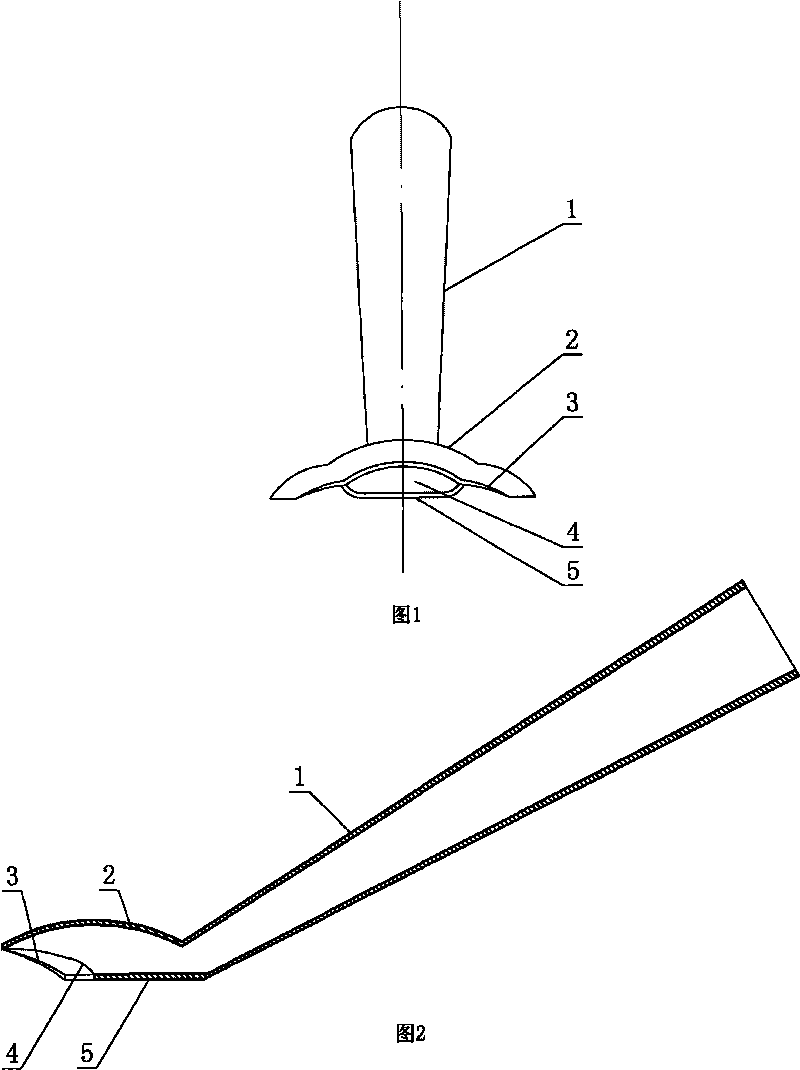

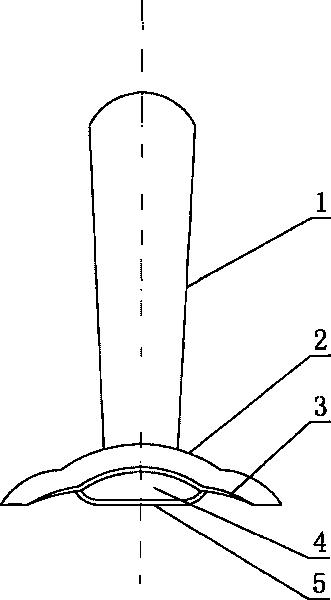

Cylinder head for arched combustion chamber and gasoline engine employing same

InactiveCN102305143AReduce consumption rateIncrease motivationInternal combustion piston enginesCylinder headsCombustion chamberCylinder head

The invention discloses a cylinder head for an arched combustion chamber and a gasoline engine employing the cylinder head. The cylinder head comprises a cylinder head body, wherein a combustion chamber face is formed on the inner side of the cylinder head body; the combustion chamber face has an arched face structure consisting of smooth curved surfaces; the surface to volume ratio of the combustion chamber can be reduced further, the working efficiency of the gasoline engine is improved, and gas flow which enters the combustion chamber is subjected to resistance in different directions, so that fuel oil mixed gas can be well formed into turbulent flow and combusted fully; therefore, the fuel oil consumption rate is reduced effectively, combustion is facilitated, and CH+NO(x) emission can be reduced, and gasoline power is increased; and the emission reaches or even exceeds the environmental protection agency (EPA) standard in America. The power of a gasoline engine with the maximum power of 3.0 kW (the rotating speed is 3,600 rpm) can be increased to 3.5 kW and the emission is reduced from 9.0 g / kW.h to 8.0 g / kW.h; the power of a gasoline engine with the maximum power of 3.5 kW can be increased to 4.0 kW and the emission is reduced from 9.0 g / kW.h to 8.0 g / kW.h; and the emission of the two gasoline engines meets the standard of 10 g / kW.h in the EPA3 stage; therefore, the power increment and the emission reduction of the gasoline engine are obvious, and environmental protection is facilitated.

Owner:LONCIN MOTOR

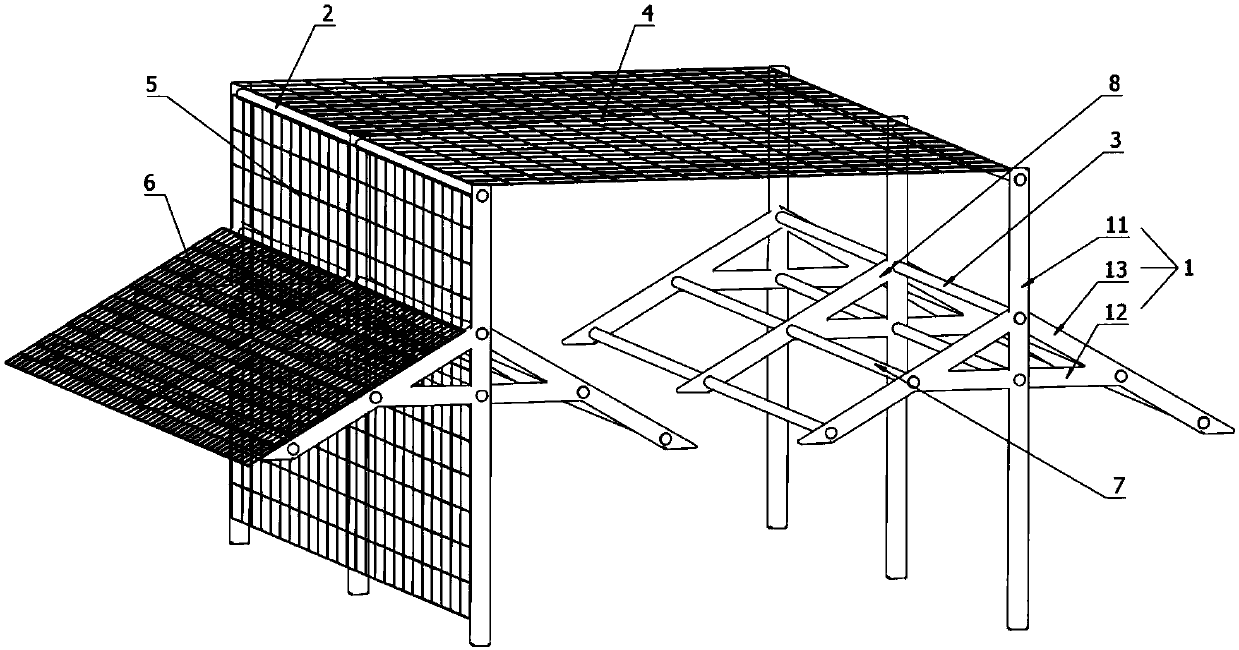

Method for interplanting passion fruits and kadsura coccinea

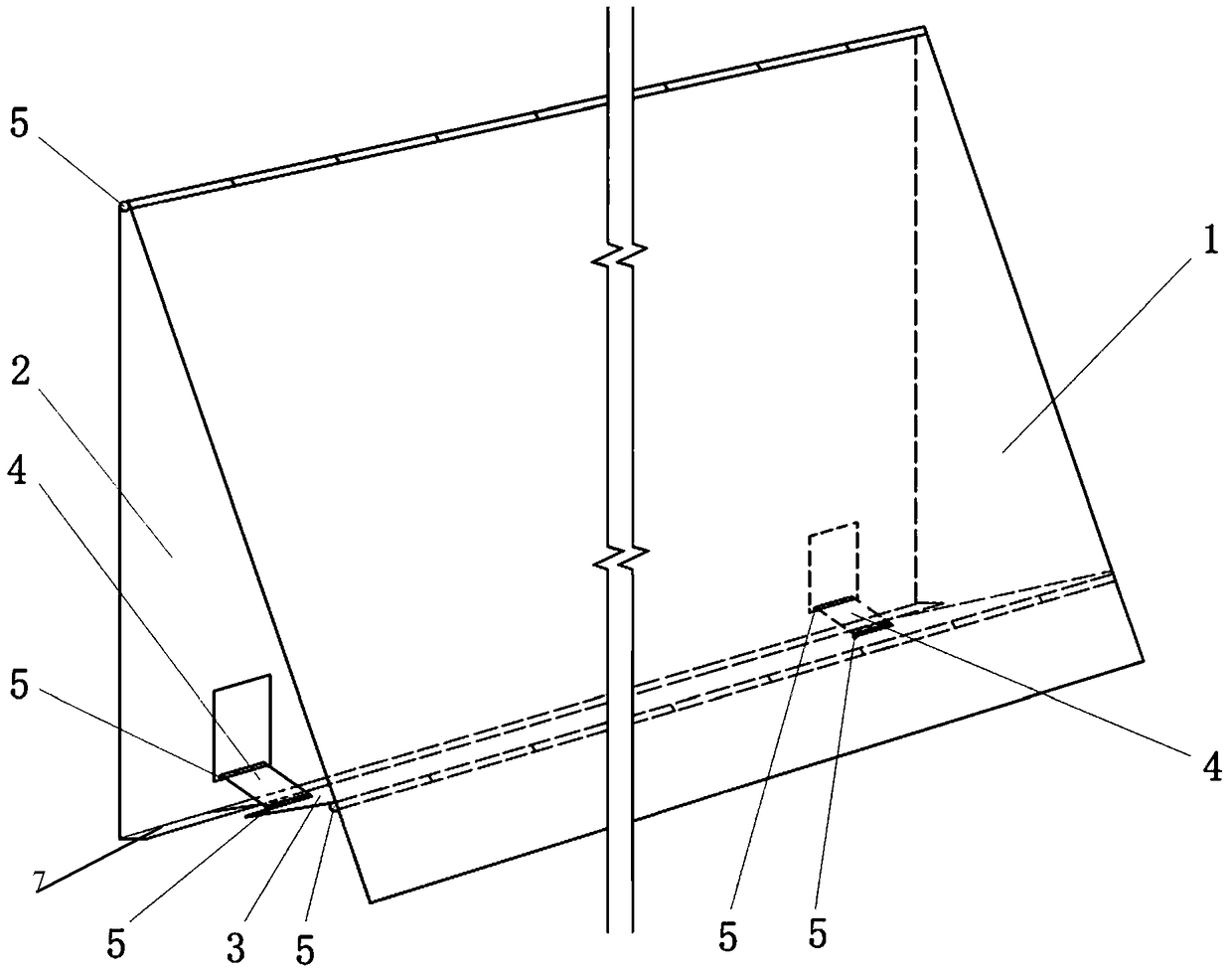

ActiveCN107750839AEasy to watchEasy to pickAnimal corpse fertilisersExcrement fertilisersEconomic benefitsHabit

The invention provides a method for interplanting passion fruits and kadsura coccinea. The method comprises the following steps: (1) selecting a planting land; (2) erecting planting frames; (3) planting young seedlings; (4) controlling vines; and (5) managing fertilizer and water. Each special planting frame adopted in the method provided by the invention is divided into an upper layer and a lowerlayer, and has a stable structure, and enough width is reserved between support frames, so that the ornamental and picking of the orchard fruits are facilitated. According to the method disclosed bythe invention, photophilous habit of the passion fruits and half-sciophilous habit of the kadsura coccinea are fully utilized for performing interplanting between the two plants, so that a natural favorable environment can be provided for the planting of the kadsura coccinea, the problem of land waste due to the fact that no income is generated in early years of the kadsura coccinea planting can be solved, the planting economic benefit of per unit area of the land is increased, and meanwhile, the cost needed for improvement for the growth of the kadsura coccinea if the kadsura coccinea is planted alone is saved.

Owner:莒县东辉建筑工程有限公司

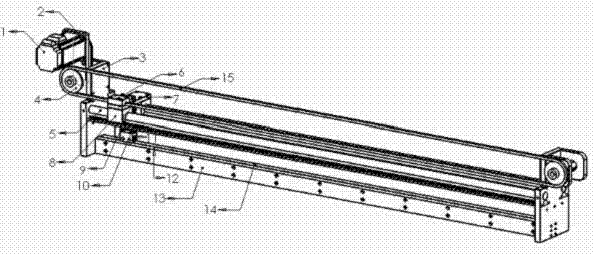

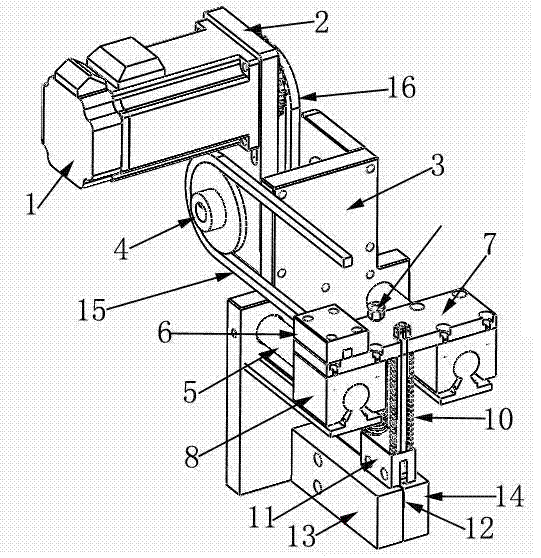

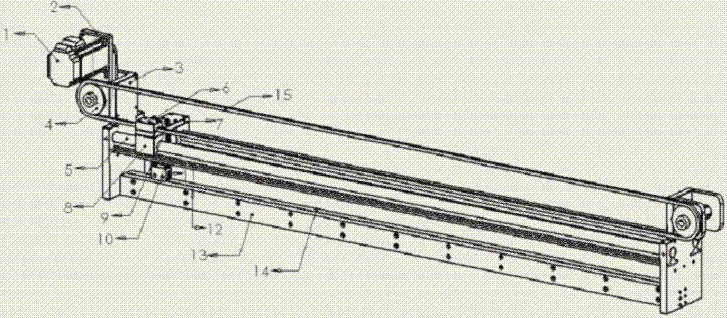

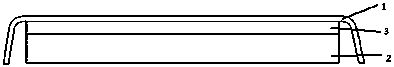

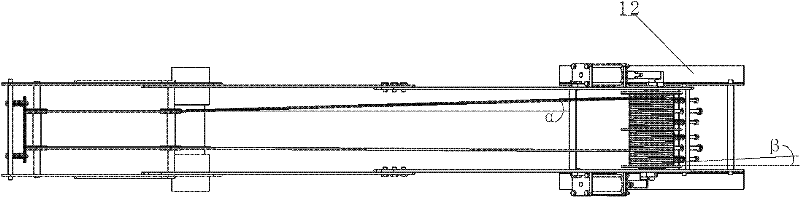

Ultra-wide cutter device for soft films

The invention discloses an ultra-wide cutter device for soft films, which comprises two sliding rail fixing plate. One sliding rail fixing plate is connected with a driving device, two linear guide rods, a front cutter clamp, a rear cutter clamp and a tungsten steel blade are connected between the two sliding rail fixing plates, the tungsten steel blade is clamped between the front cutter clamp and the rear cutter clamp, each of the sliding rail fixing plates is provided with a transmission sprocket, a transmission chain is connected onto the transmission sprockets, two linear sliders are respectively connected with the linear guide rods, a slider pressure plate is connected onto the two linear sliders, a chain pressing block is connected onto the slider pressure plate, the transmission chain penetrates through the chain pressing block and is fixed onto the chain pressing block, two cutter pressing guide rods are further connected to the lower side of the slider pressure block and connected with a cutter pressing box, the cutter pressing box is placed on the tungsten steel blade, and two cutter pressing springs are respectively sleeved on the cutter pressing guide rods. The cutter device is quick in cutting speed, and cuts the soft films neatly, lateral cut edges are smooth after cutting, accordingly, industrial injury accidents are reduced, and the requirement of sufficient cutting width can be met.

Owner:SUZHOU HUARI JINLING MACHINERY

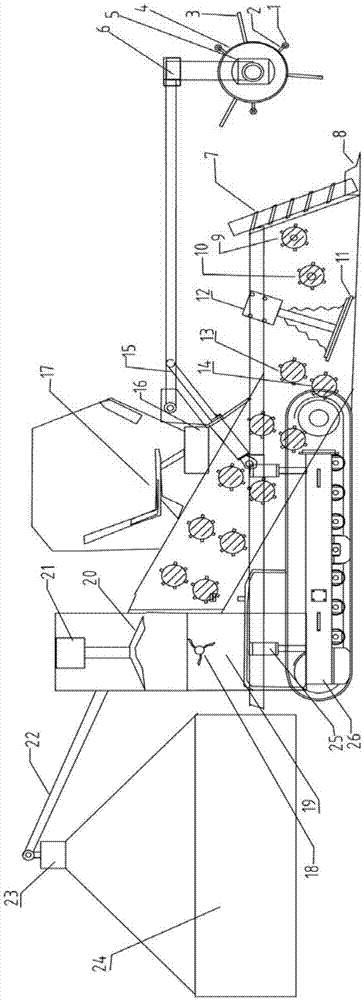

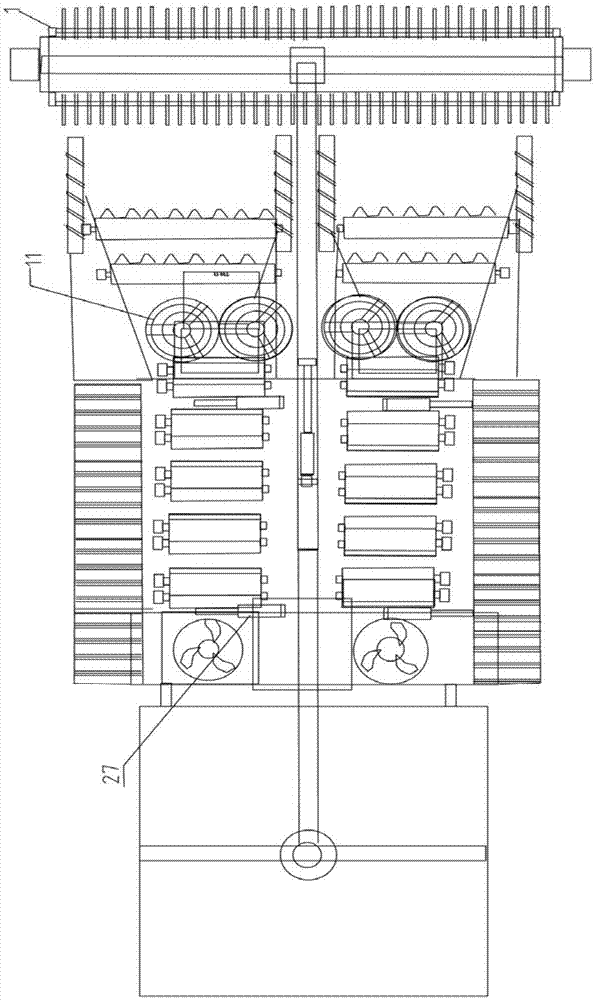

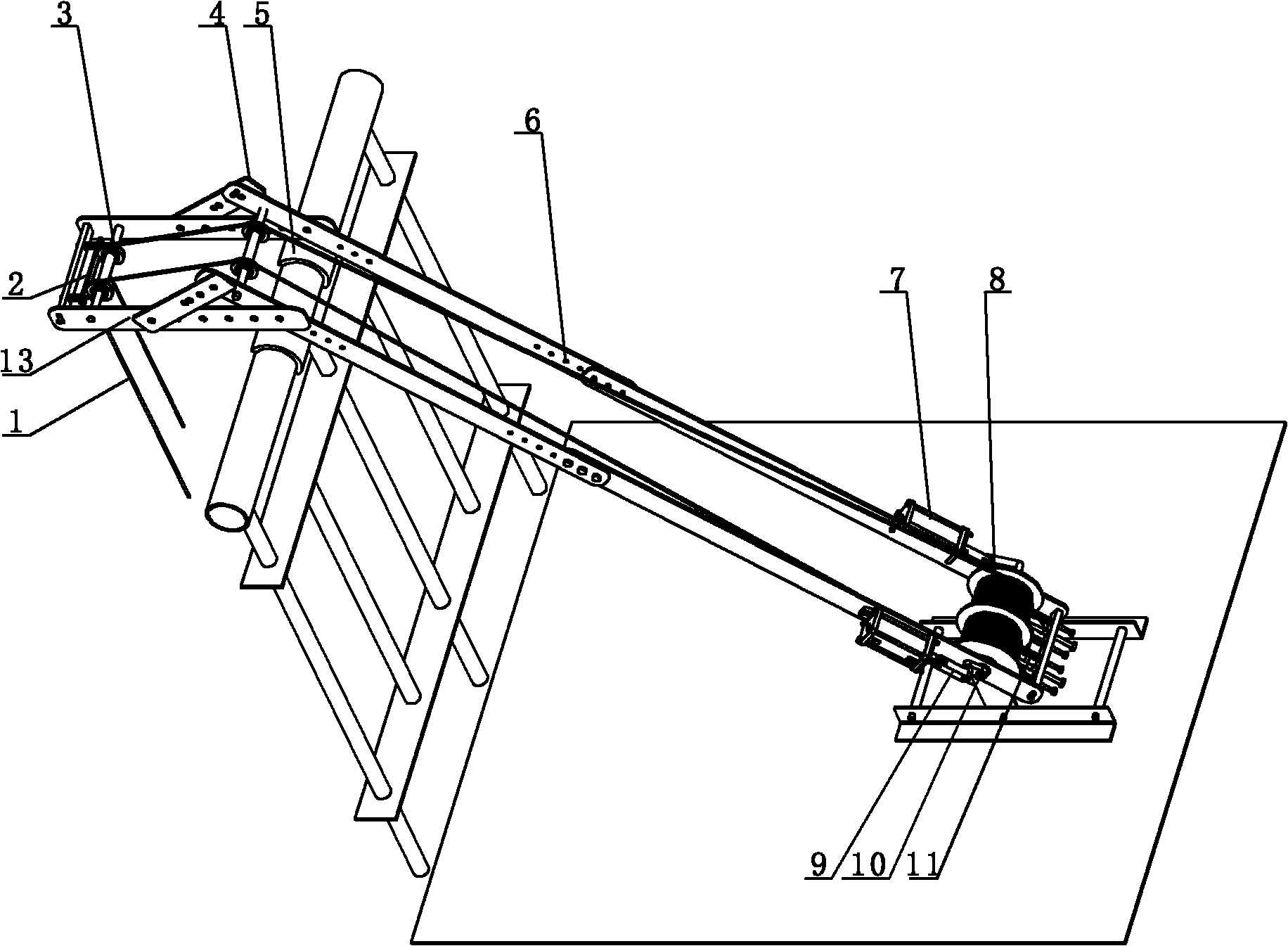

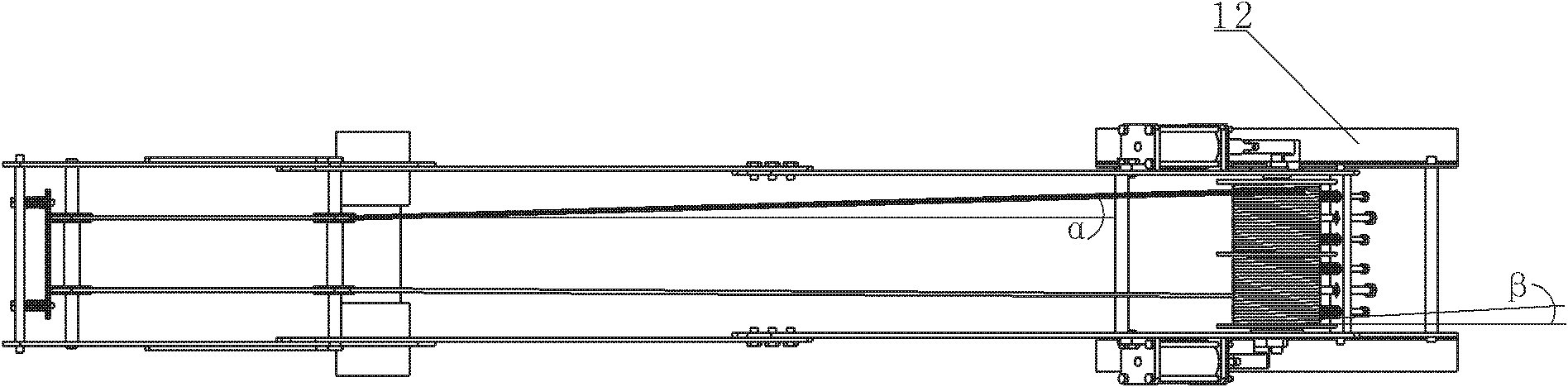

Efficient whole-rod type sugarcane combine-harvester

InactiveCN105432232AReduce the rate of broken headsIncrease productionHarvestersEngineeringMotor drive

The invention discloses an efficient whole-rod type sugarcane combine-harvester. The combine-harvester comprises a tail removal device located on a harvester frame, two or more straightening devices with the outer roller space adjustable, two or more root cutting devices with the space adjustable, a conveying device, a loading and unloading device, a traveling mechanism with the space between a left wheel and a right wheel adjustable and a harvester frame structure with the ground clearance adjustable; the tail removal device comprises a leaf smashing roller and a leaf smashing motor driving the leaf smashing roller to rotate, leaf smashing strips and tail tip clamping rods are arranged at the peripheral circle of the leaf smashing roller alternately, and the tail tip clamping rods are used for beating away tail tips of sugarcane; each straightening device comprises a ground attachment awl and a straightening roller arranged above the corresponding ground attachment awl, each ground attachment awl scoops up the sugarcane on the ground and delivers the sugarcane to the corresponding straightening roller, and each straightening roller aligns the sugarcane and lifts the sugarcane to the operation scope of the corresponding root cutting device. The efficient whole-rod type sugarcane combine-harvester has the advantages of being simple in procedure, extremely high in efficiency, reasonable in structure and reliable in work, and the same machine can be used for multiple purposes.

Owner:韦瑞峯

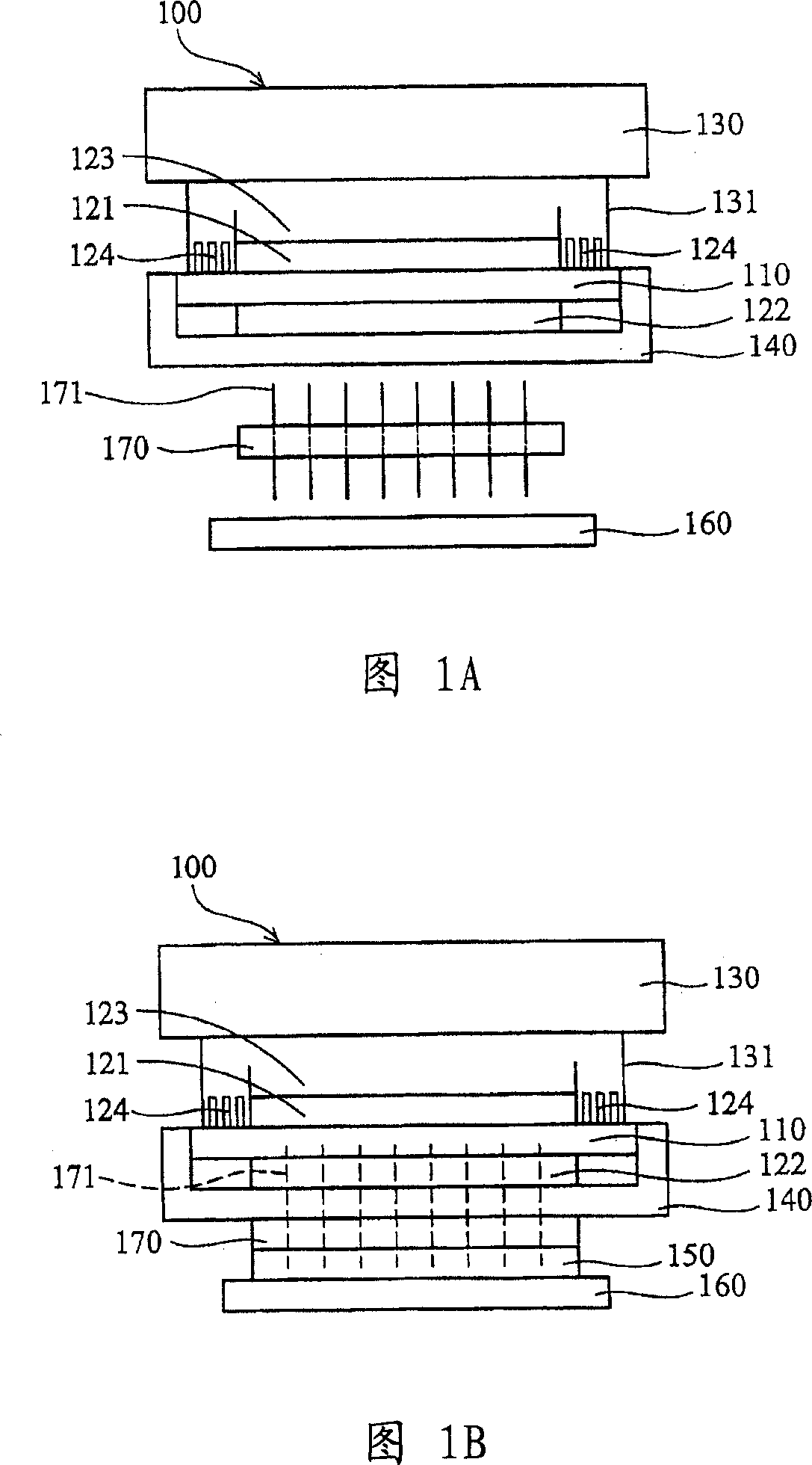

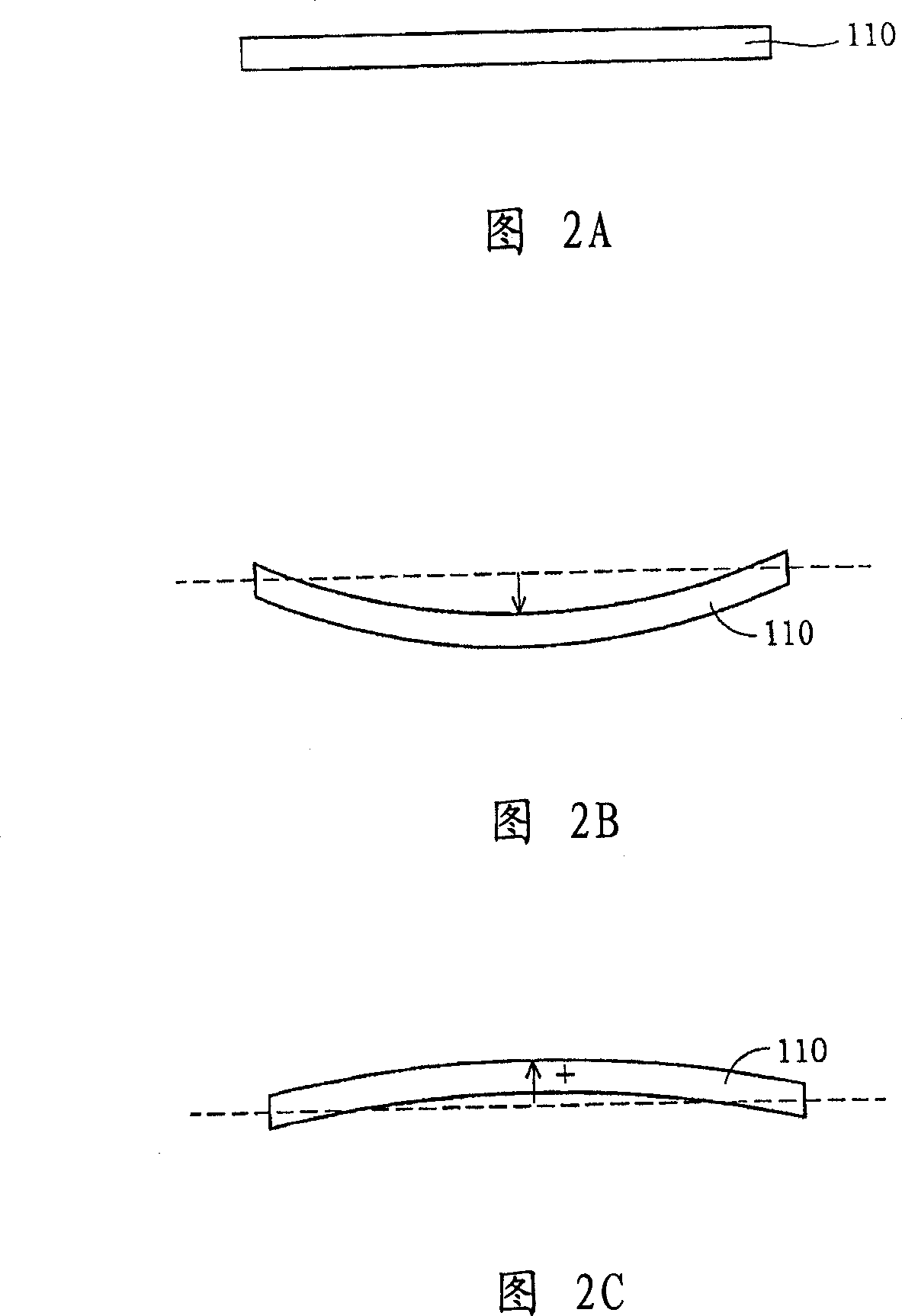

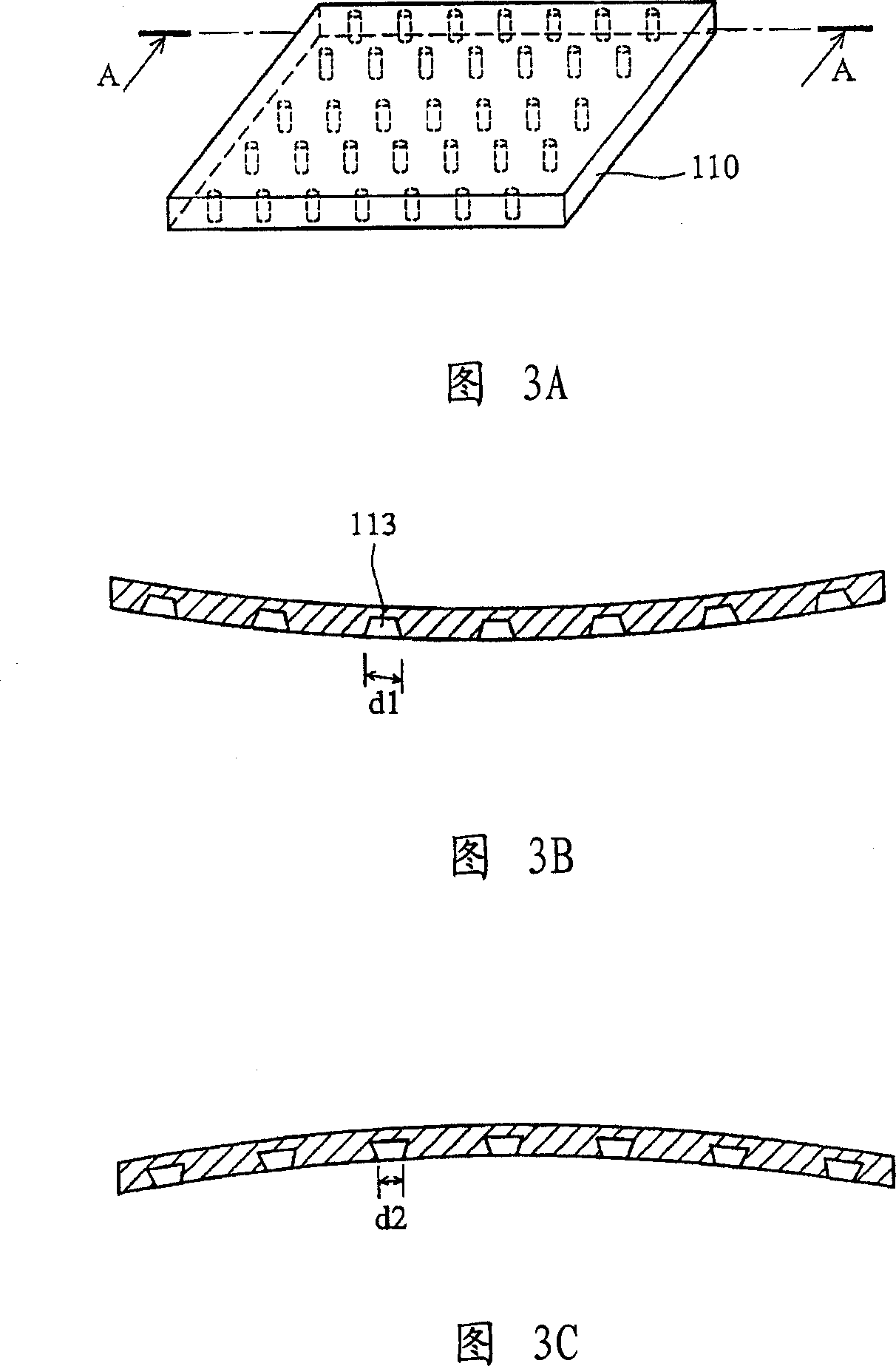

Semiconductor machine

InactiveCN1763926AEnough widthInsert smoothlySemiconductor/solid-state device testing/measurementStable stateSemiconductor package

The semiconductor machine bench comprises a printed circuit board with first and second surfaces, a heat source to stable provide heat for the first liquid near circuit board to heat the board, and a regulating device to control the temperature of first surface to under the second surface and make the board deformation achieve rapidly stable state.

Owner:POWERCHIP SEMICON CORP

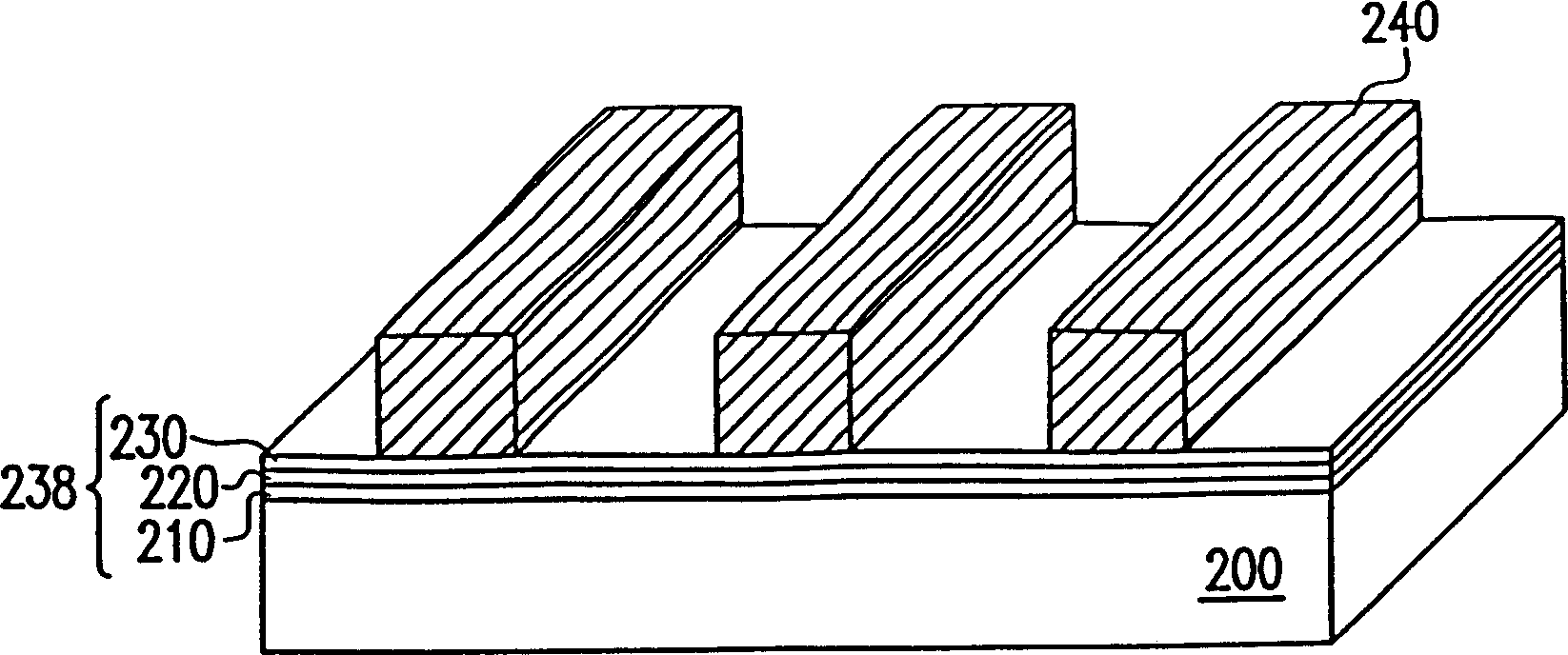

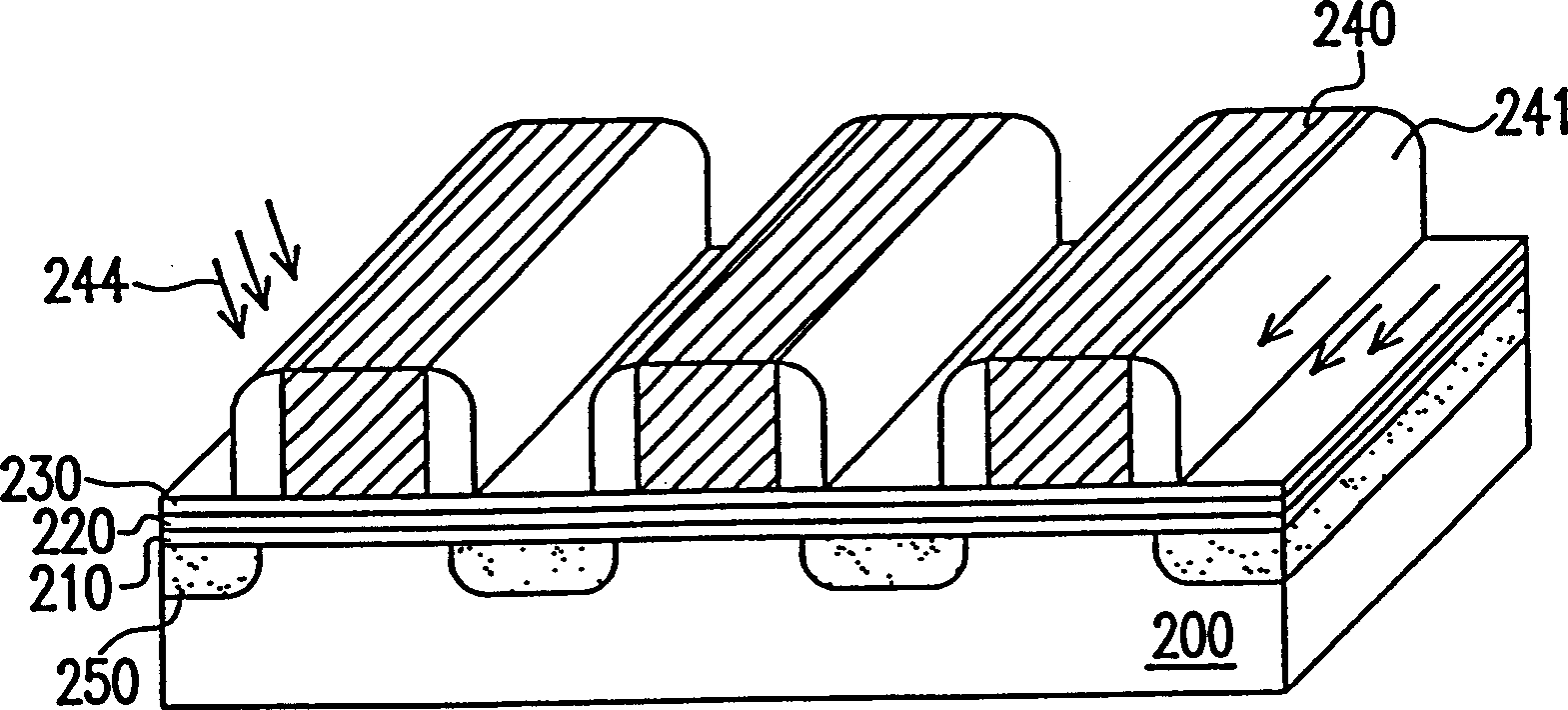

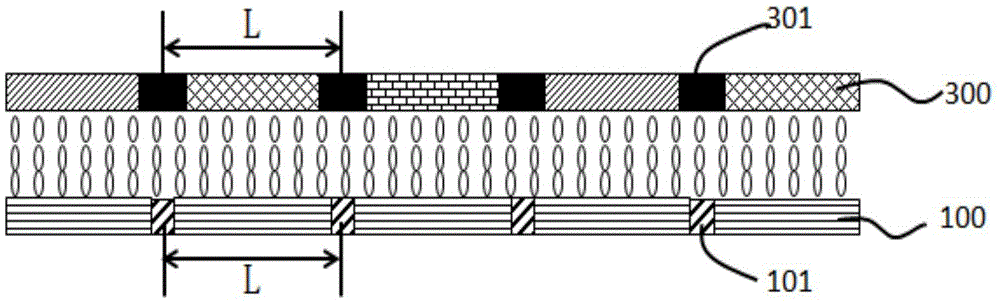

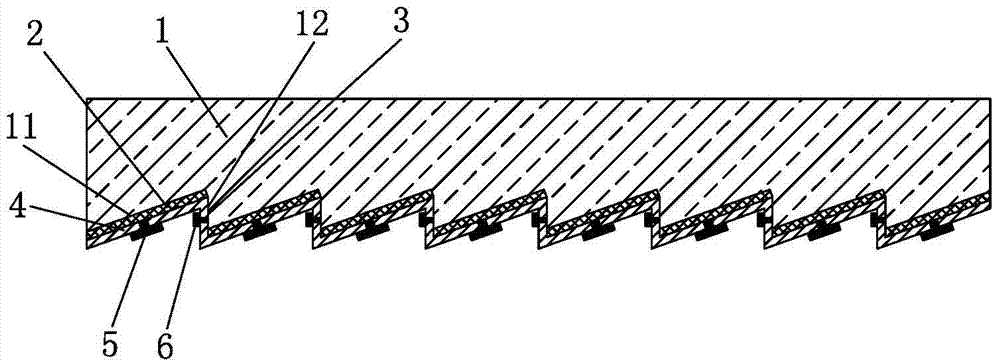

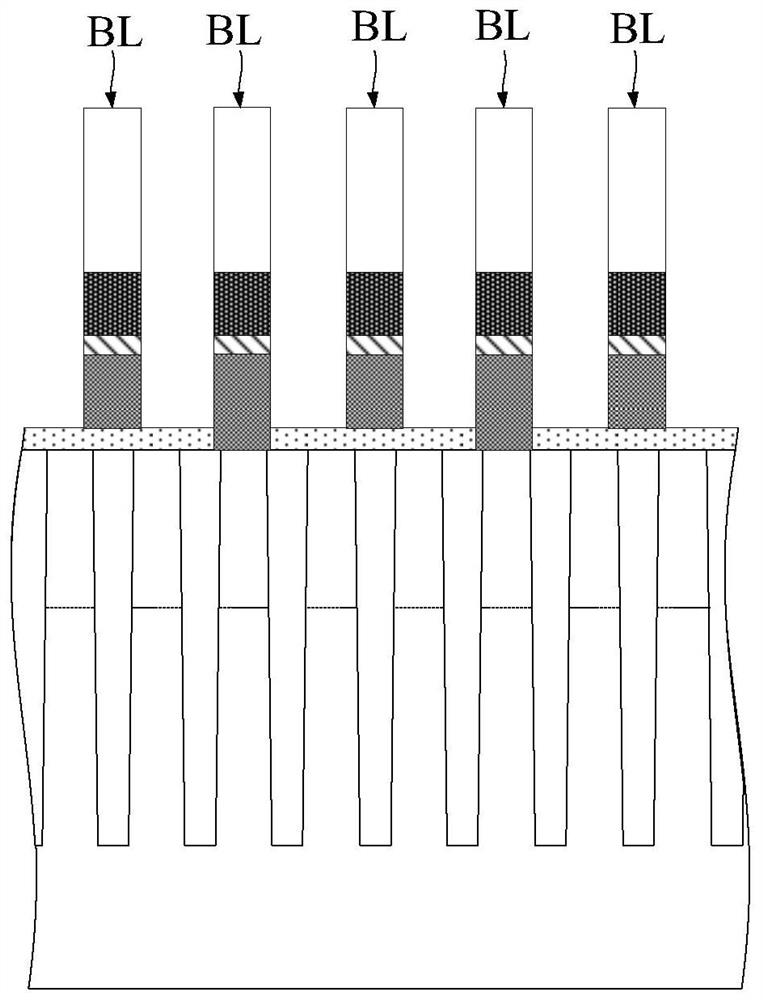

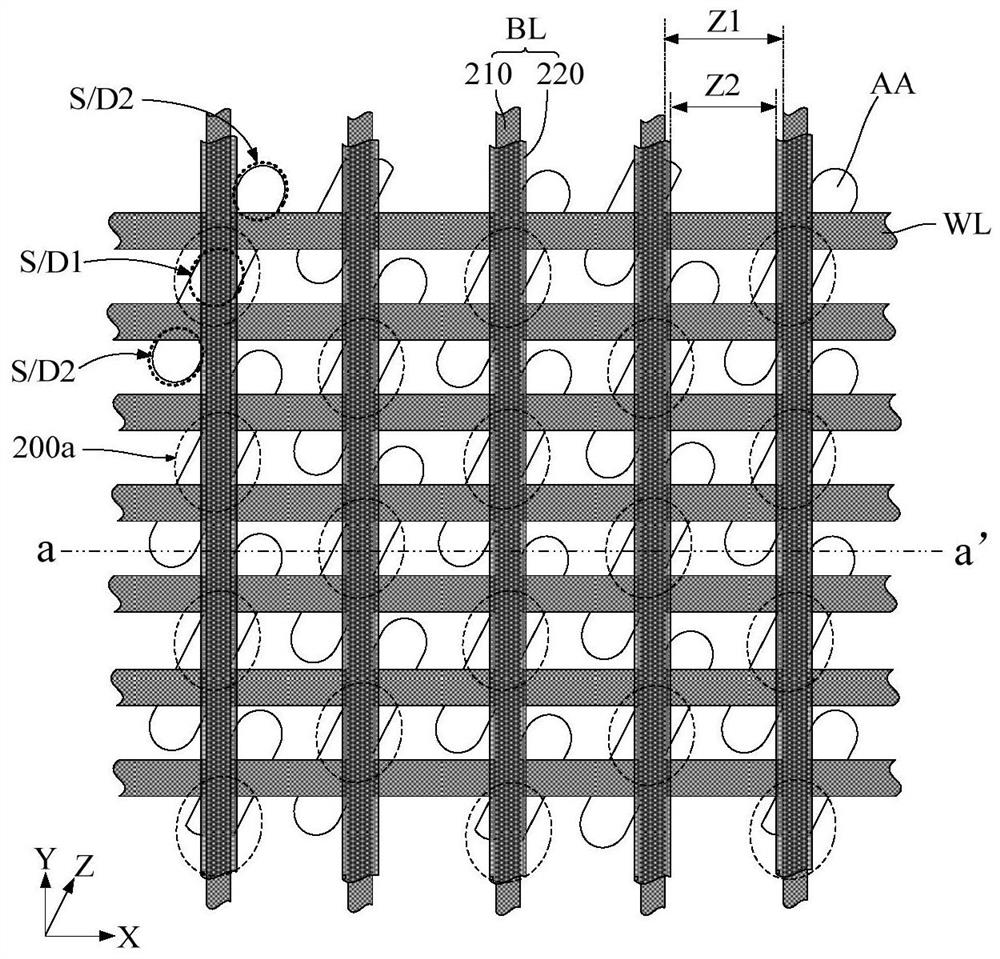

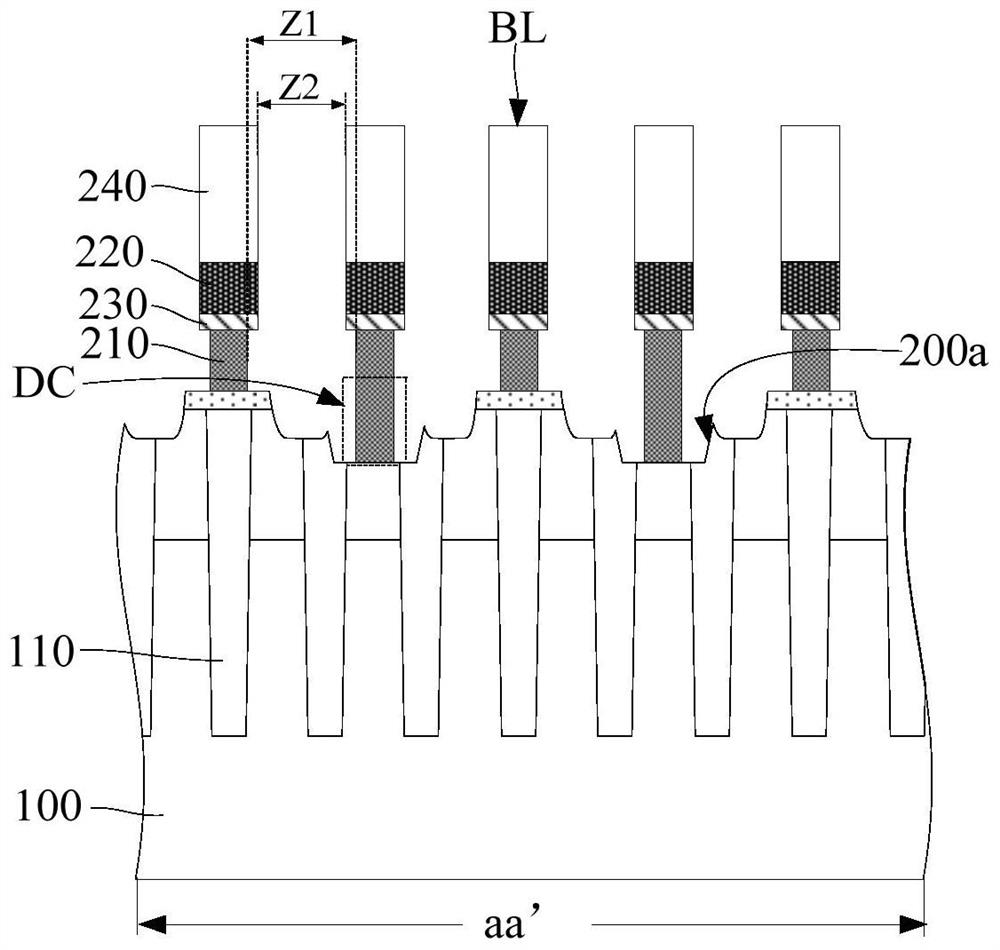

Memory and forming method thereof

ActiveCN111640743AImprove transmission performanceIncrease bottom sizeTransistorSemiconductor/solid-state device manufacturingBit lineMechanical engineering

The invention provides a memory and a forming method thereof. According to the bit lines in the memory, the width size of the first conductive layer is smaller than that of the second conductive layerabove the first conductive layer, so that the bottom interval size between the adjacent bit lines is larger than the top interval size of the adjacent bit lines. Thus, on the basis that the width size of the second conductive layer is met to guarantee the transmission performance of the bit lines, the bottom interval size between the adjacent bit lines is increased, and the bottom size of the storage node contact part filled between the adjacent bit lines can be further increased.

Owner:FUJIAN JINHUA INTEGRATED CIRCUIT CO LTD

A device and a method for labelling containers through label cases

ActiveCN103129787AEnough widthAvoid collisionLabelling non-rigid containersLabelling short rigid containersEngineeringLabelling

The invention describes a device and a method for labelling containers through label cases. The label cases implement relative movements directed from sections at the bottom sides of the containers towards sections at the opening sides of the containers so as to occupy the related labelling positions on the containers to be labelled, thereby enabling the containers to be held in the air during the labelling process and thus realizing the specifically compact device for labelling.

Owner:KRONES AG

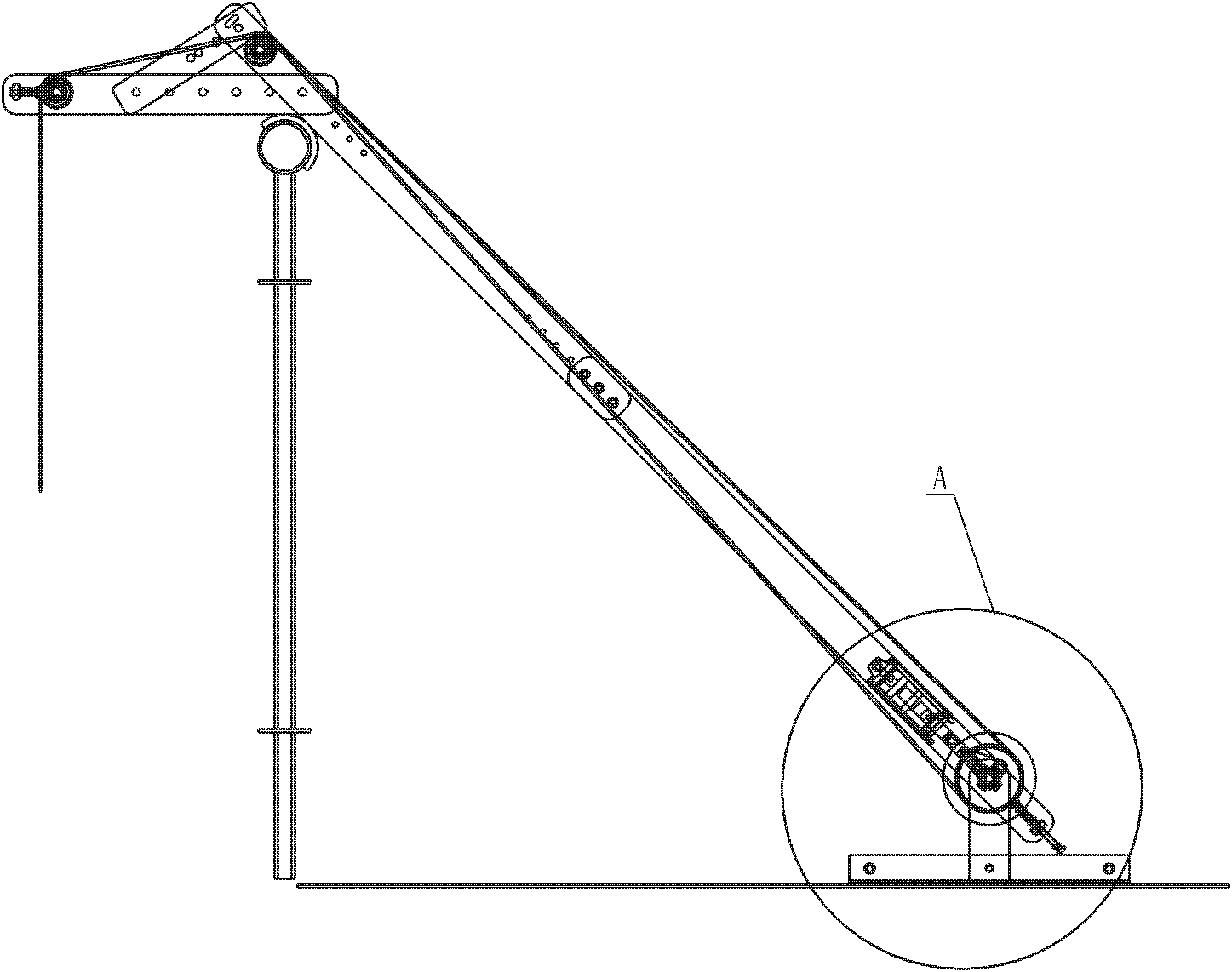

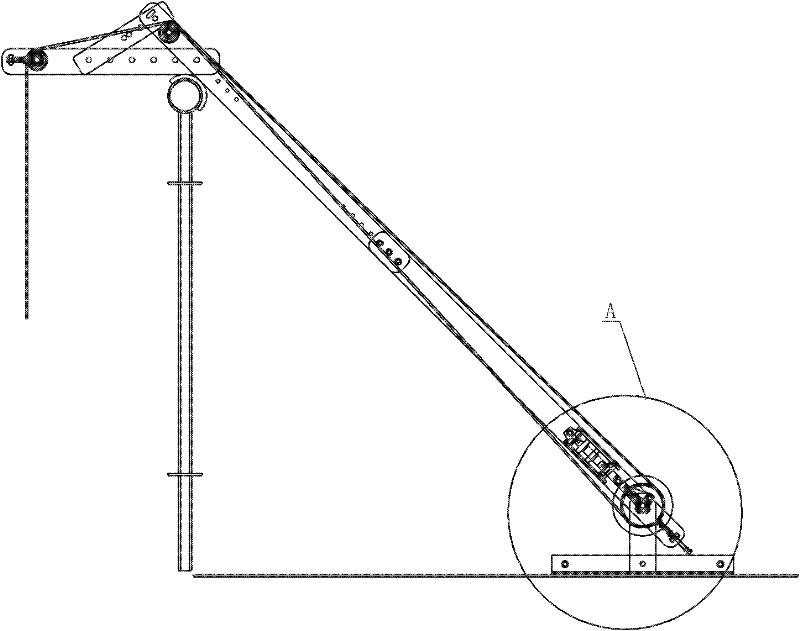

Reciprocating descent control device

The invention discloses a reciprocating descent control device. A rotating shaft is arranged on a bracket and is provided with a winding drum; a steel wire rope is wound on the winding drum around a pulley; a damping cylinder is arranged on the bracket close to the rotating shaft; a piston of the damping cylinder is connected with the rotating shaft through a crank slider mechanism; and a small hole is formed on the piston. The preferable scheme of the invention is that: the reciprocating descent control device is provided with two damping cylinders, and a rotation angle of the crank slider mechanism which is connected with the damping cylinders is staggered for 90 degrees. Therefore, the dead center of the crank slider mechanism is avoided, the speed is steady during descent control, and the winding of the steel wire rope due to the speed change is avoided. The reciprocating descent control device is not controlled by a user at all during use, can realize continuous descent control, and has the advantages of steady operation, safety and reliability, and low production cost.

Owner:HUBEI THREE GORGES POLYTECHNIC

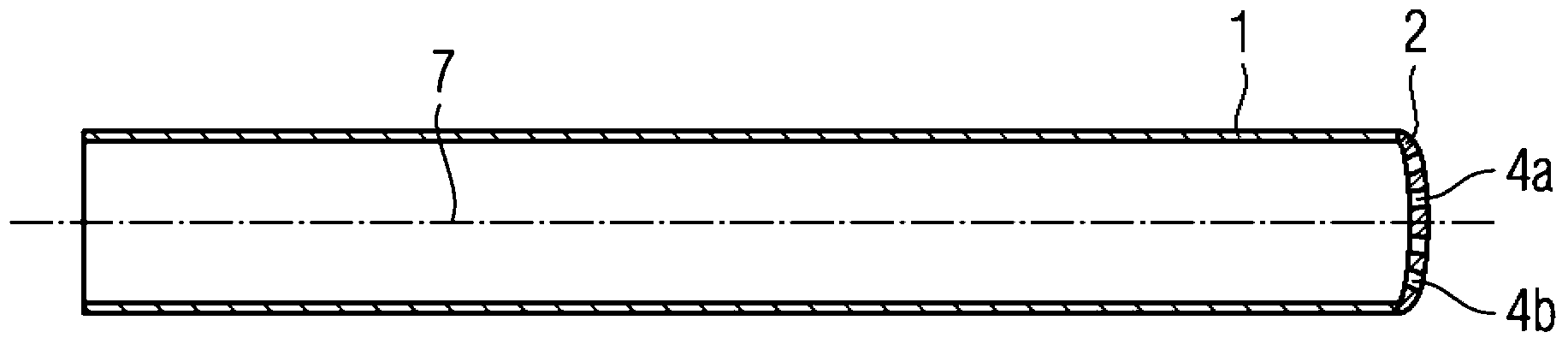

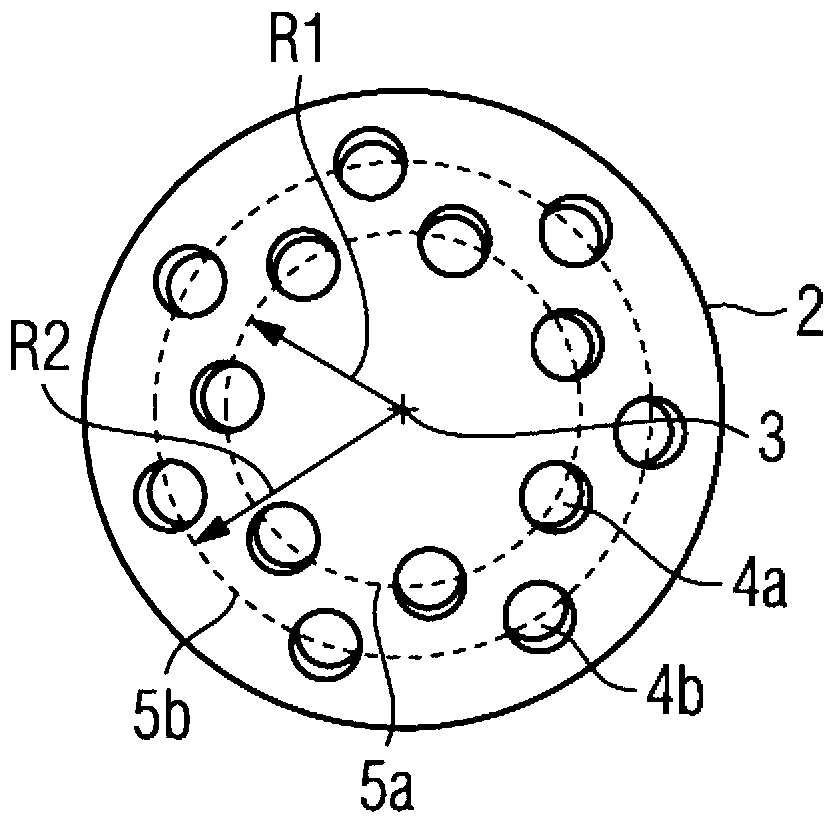

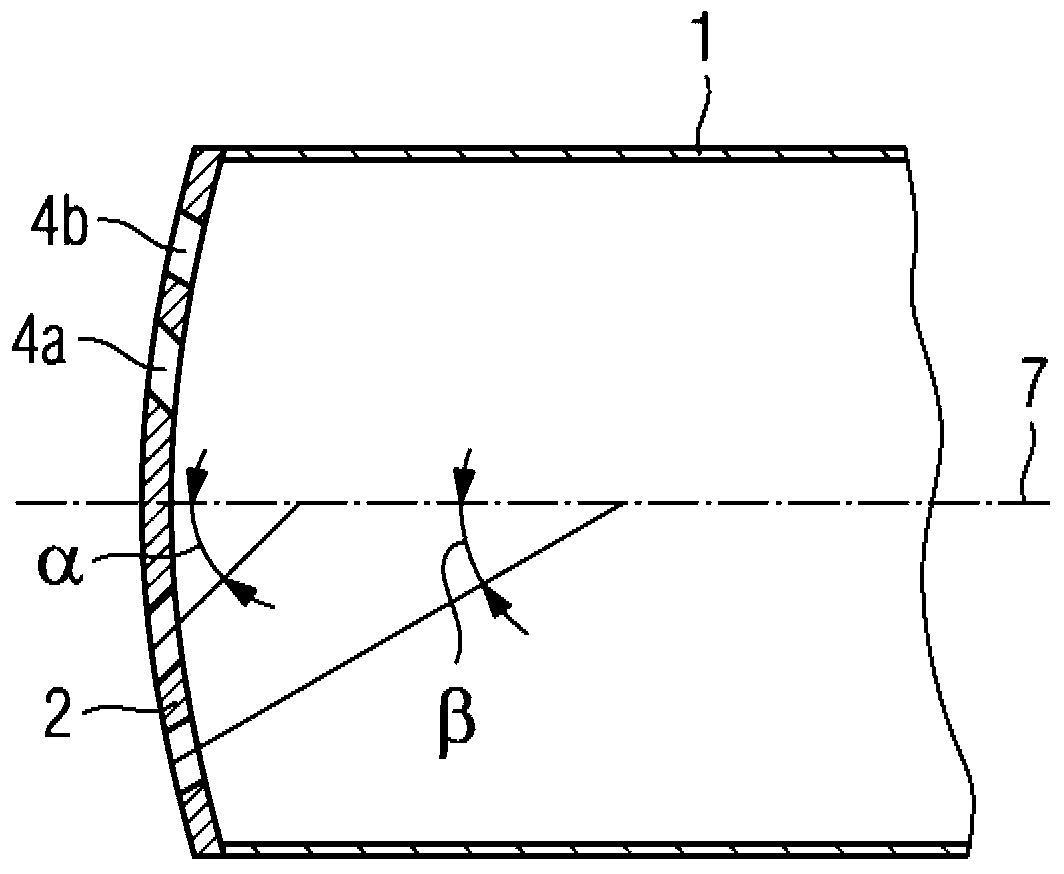

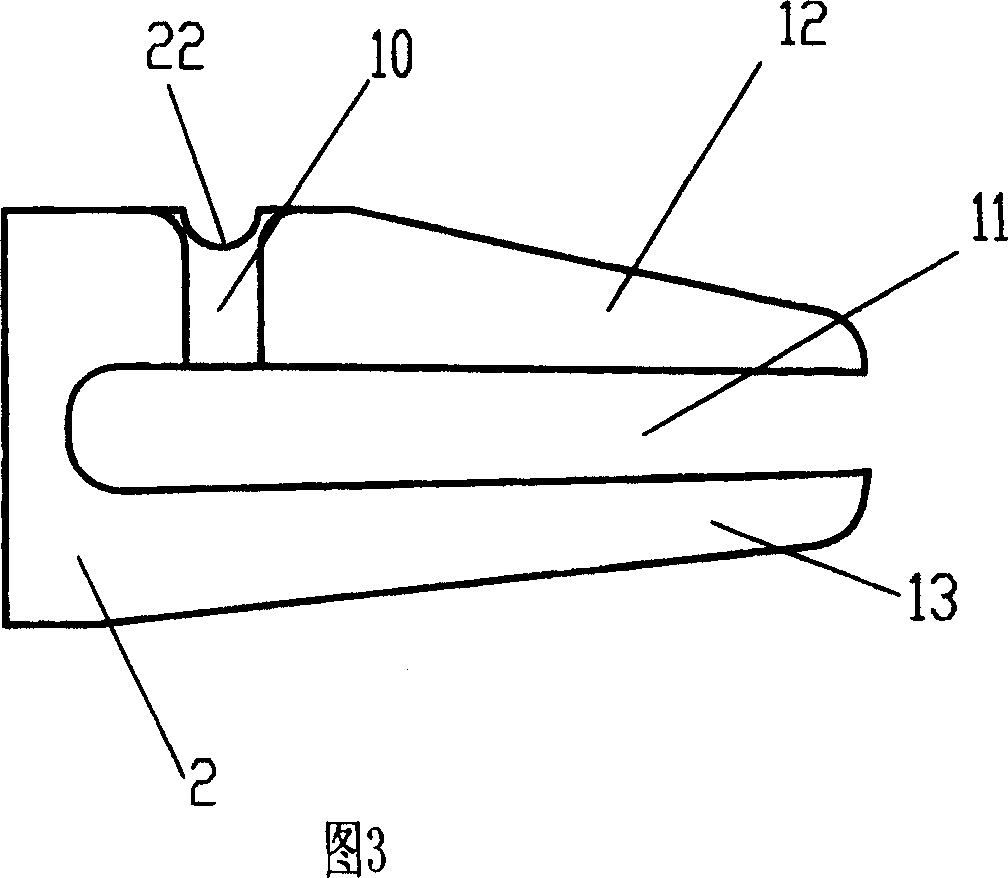

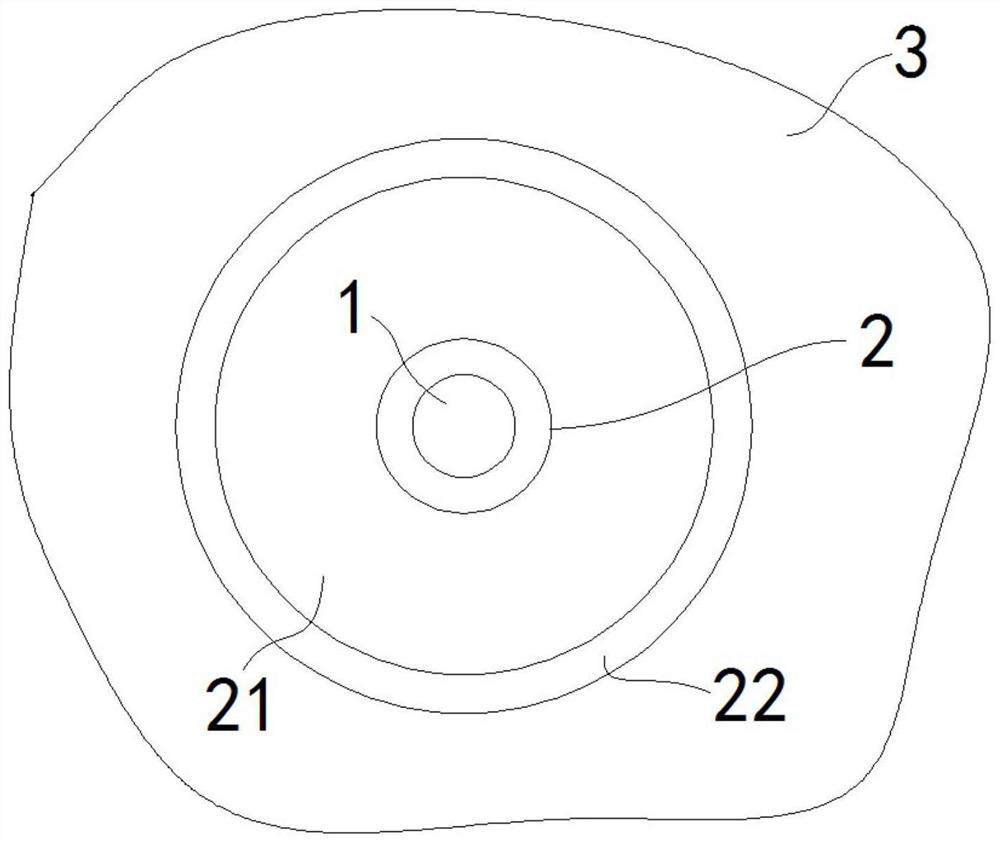

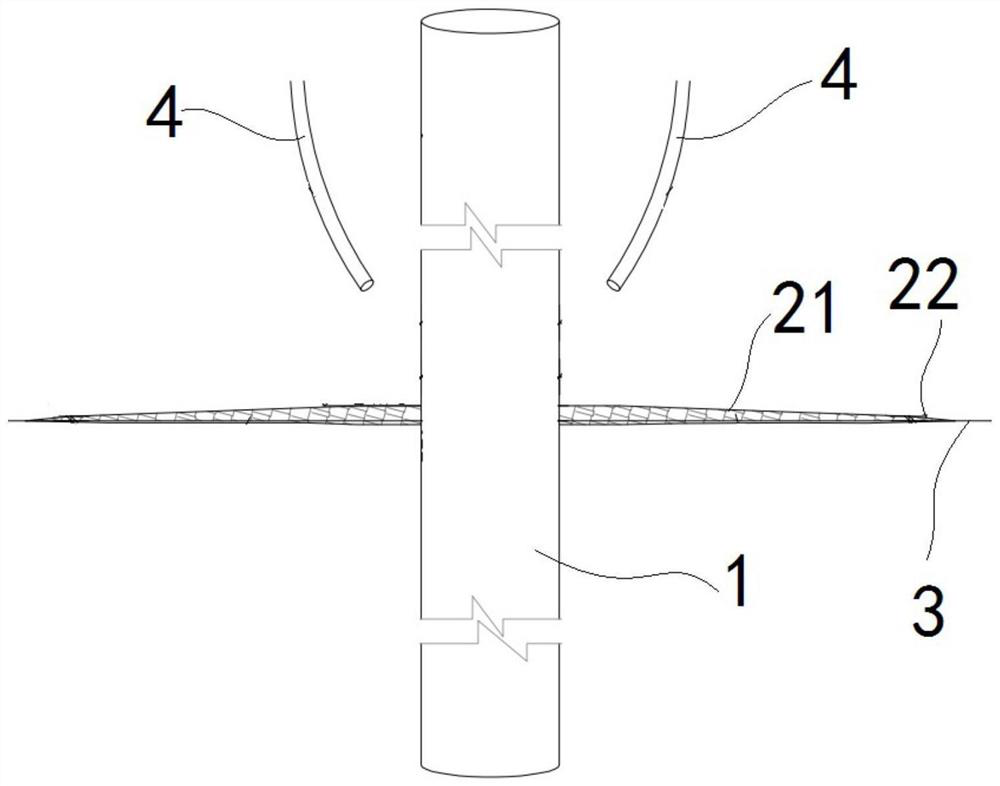

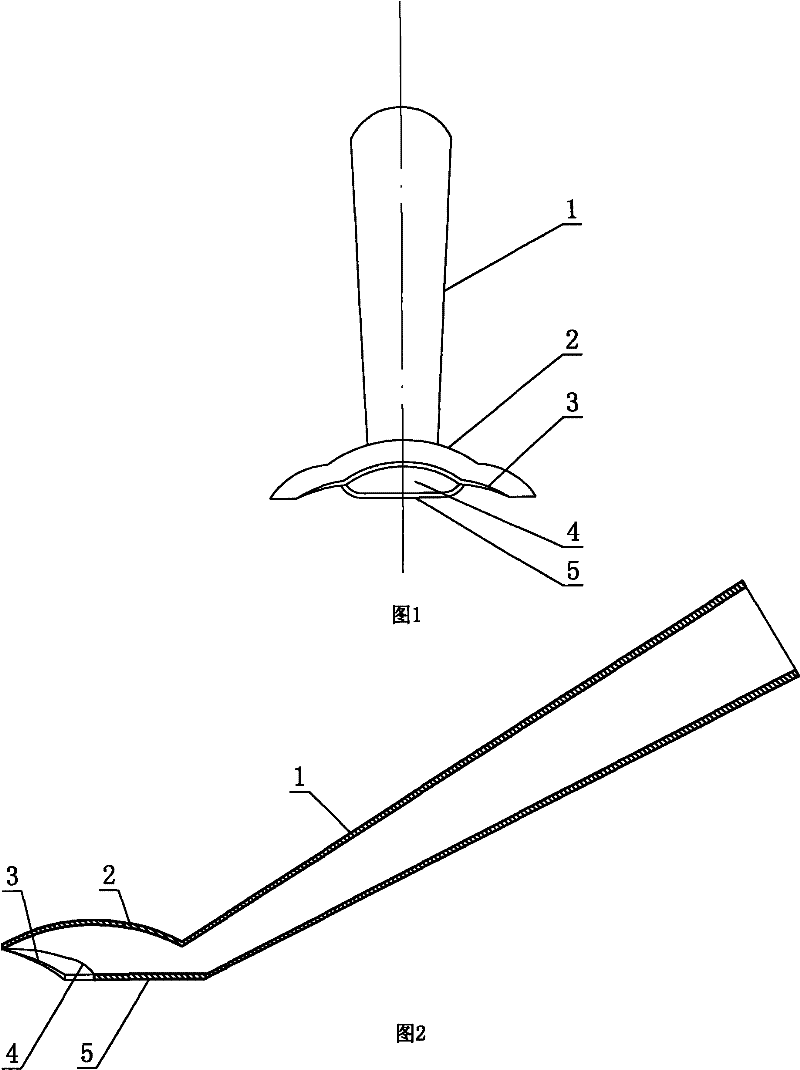

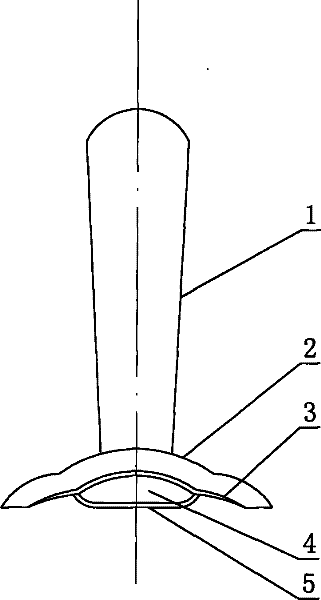

Gas-turbine combustion chamber with fuel nozzle, burner with such a fuel nozzle and fuel nozzle

InactiveCN103270369AExtended service lifeEnough widthTurbine/propulsion fuel supply systemsContinuous combustion chamberCombustorCombustion chamber

The invention relates to a gas-turbine combustion chamber with a fuel nozzle comprising a cylindrical nozzle tube (1), into which a fluid is made to flow, and a convexly formed nozzle cover (2), which is arranged downstream of the nozzle tube (1) and has a central point (3), wherein the nozzle cover (2) has a number of through-openings (4a, 4b), through which the fluid that is made to flow into the nozzle tube (1) leaves, wherein the through-openings (4a, 4b) are arranged at different radial distances (R1, R2) from the central point (3) on at least two circular lines (5a, 5b).

Owner:SIEMENS AG

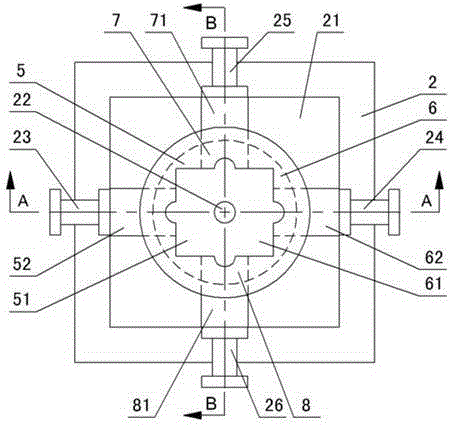

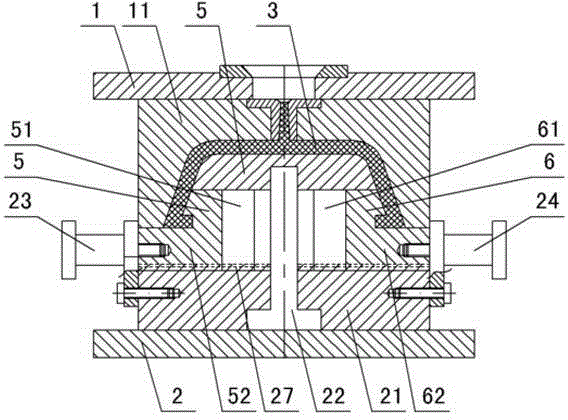

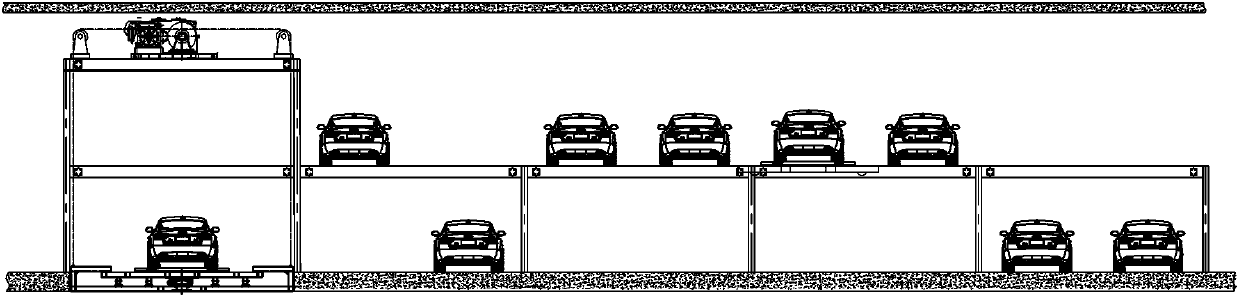

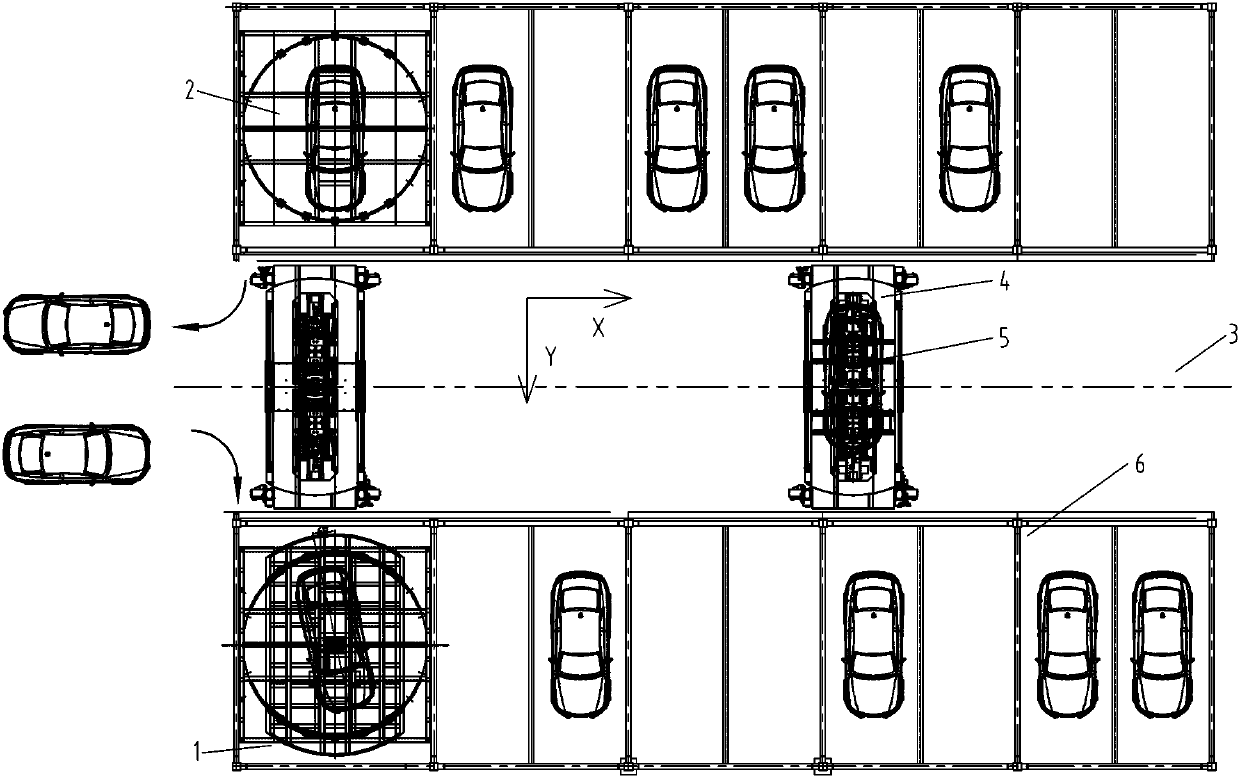

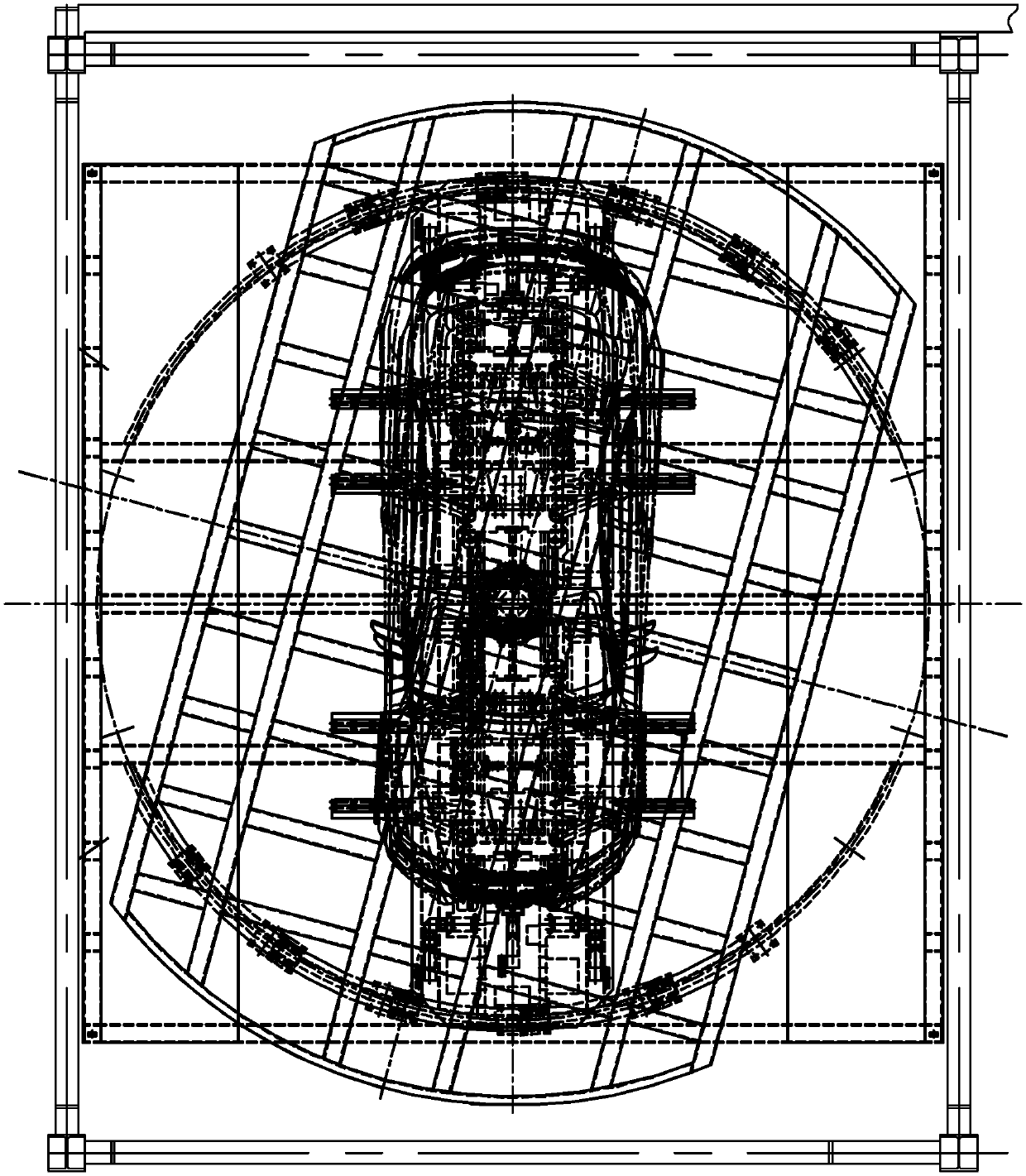

Underground intelligent garage with rotating tray and use method

The invention discloses an underground intelligent garage with a rotating tray and a use method. The garage comprises a vehicle storage area on one side of a vehicle entrance, a vehicle taking area isarranged on the opposite side of the vehicle storage area, a middle channel is arranged between the vehicle storage area and the vehicle taking area, parking spaces are arranged on the two sides of the middle channel, lifting devices for lifting vehicles are arranged on garage tops of the vehicle storage area and the vehicle taking area, a rotating device used for rotating vehicles is arranged ona lifting tray of the lifting device in the vehicle storage area, a transfer device used for moving the vehicles on a flat layer garage is included, a holding type vehicle carrying device used for clamping and lifting the vehicles is carried on the transfer device, the vehicles driven into the tray can be automatically rotated to be aligned, in cooperation with the transfer device and the vehiclecarrying device, automatic parking of the vehicles can be achieved, parking efficiency is improved, and operation difficulty of a driver is reduced.

Owner:WUHAN ZHIXIANG ROBOT CO LTD

Electrostatic adsorption adhesive tape and preparation method thereof

PendingCN107903835APrevent edgeEnough widthProtein adhesivesInorganic adhesivesPolymer scienceAdhesive belt

The invention discloses an electrostatic adsorption adhesive tape which comprises a protective layer, wherein an adhesive region located in the middle is arranged on the side surface of one side of the protective layer; protection regions are respectively arranged on two sides of the adhesive region; an adhesive layer made of an adhesive is arranged in the adhesive region; smooth electrostatic adsorption surfaces are arranged in the protective regions. The invention further discloses a preparation method of the electrostatic adsorption adhesive tape. The preparation method comprises the following steps: (a) preparation of an adhesive material: respectively covering the two sides of the adhesive material with release paper; (b) primary slitting or slicing; (c) compounding: compounding multiple long-strip type adhesive materials obtained by cutting on the electrostatic adsorption surfaces of the protective layer, and reserving a gap between two adjacent adhesive material strips, whereinthe width of each gap is twice the set width of each protective region; or compounding the sliced adhesive materials on the adhesive region of the protective layer in an arraying manner, and reservinga gap between two adjacent adhesive material slices, wherein the width of each gap is twice the set width of each protective region; (d) secondary slitting; (e) winding or stacking.

Owner:ZHEJIANG HAICHUANG MEDICAL DEVICE CO LTD

Needle fixing device of needle selecting equipment

InactiveCN1920145AEnough widthGuaranteed StrengthWeft knittingWarp knittingSyringe needleBiomedical engineering

The invention relates to a needle fixer of needle selector, which comprises the middle plate with pin groove and needle groove that vertical and connected, two outer cover plates fixed at two side surfaces of middle plate, the needle inserted into the needle groove, the positioning pin inserted into the pin groove to lock said needle, and a driving plate connector for fixing two outer cover plates to another end of middle plate; one end of said needle has head, and middle has should needle rod, while another end has trapezium cut relative to the pin groove; the positioning pin is formed by the flexible bolt spring whose upper end has pin tail and lower end has two external protrusions in reversed U shape; said positioning pin can through the longitudinal guide groove when compressing two flexible bolt springs, and open when inserted into the trapezium cut, to lock the needle. The invention has accurate position and long service life.

Owner:SUZHOU PANT PIEZOELECTRIC TECH

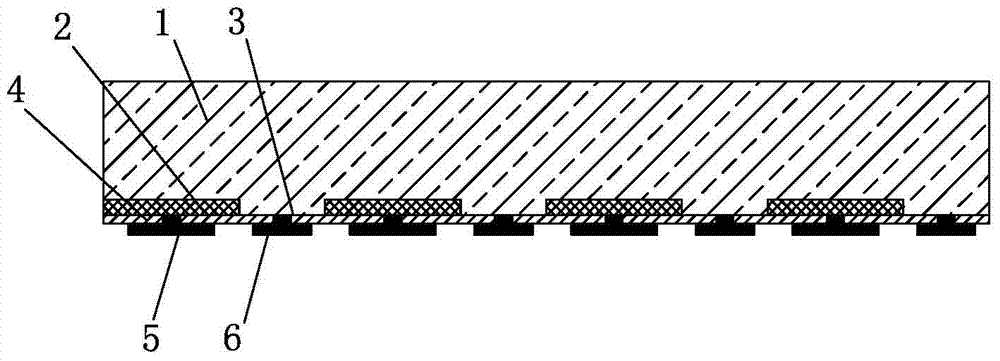

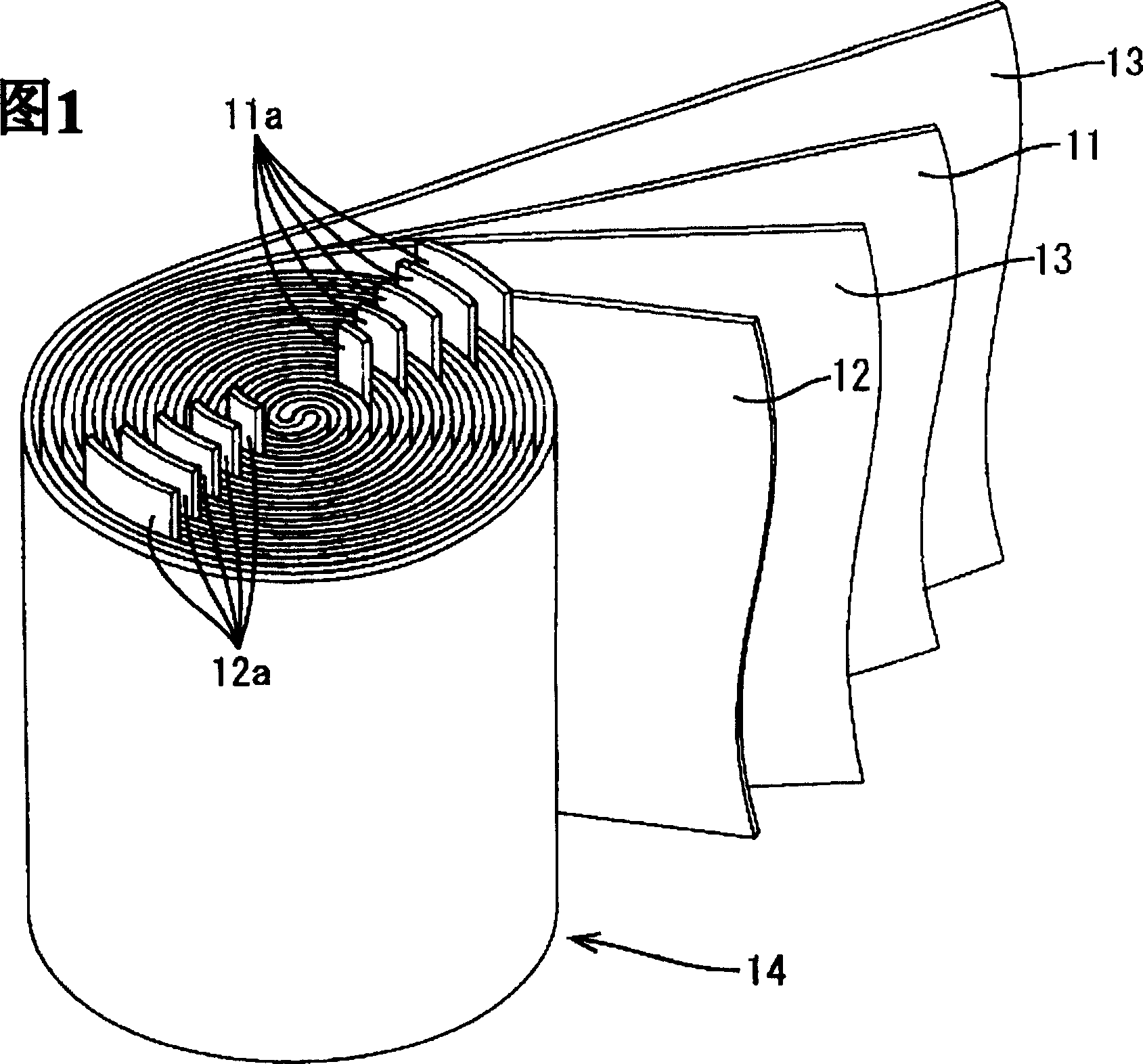

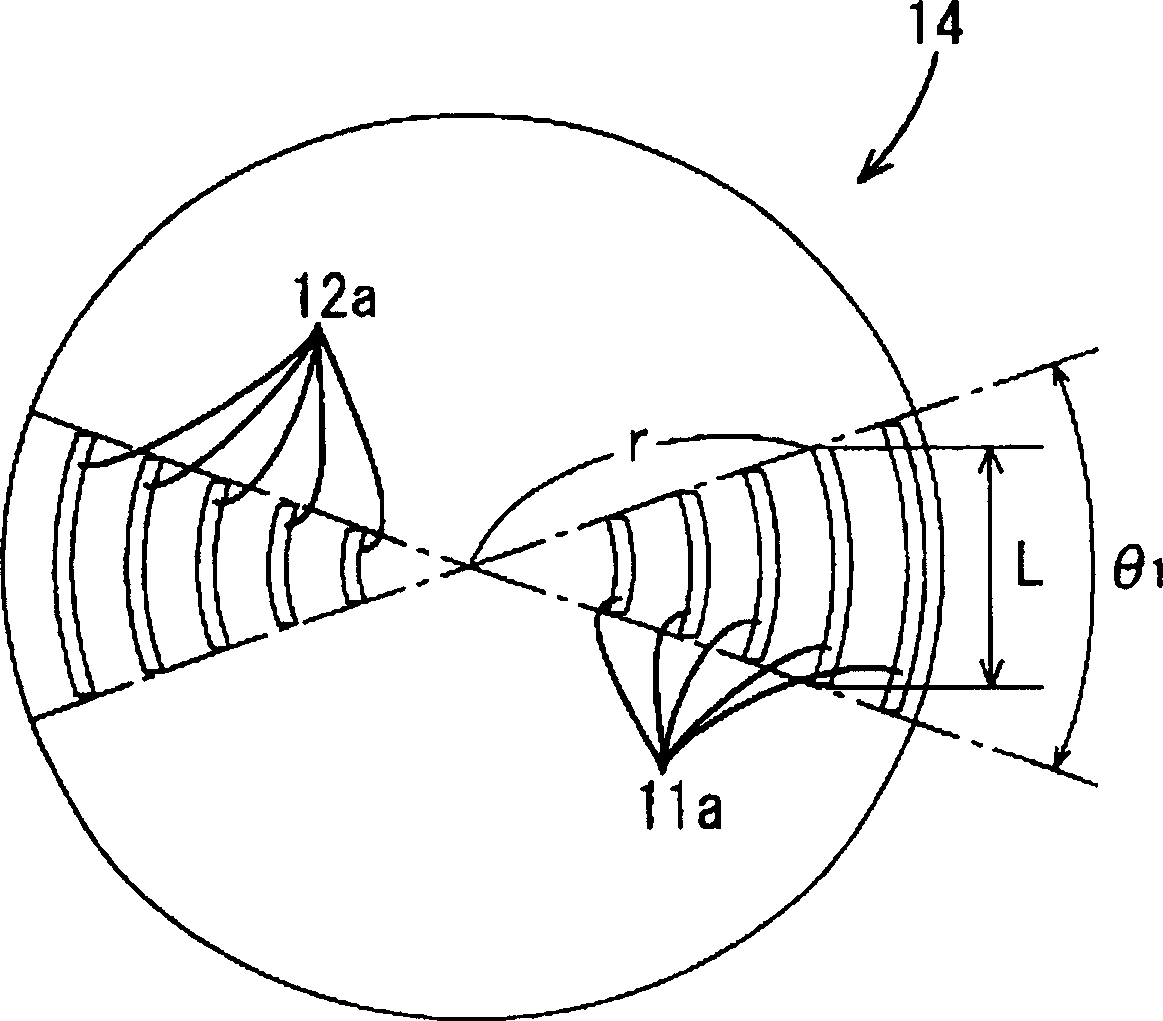

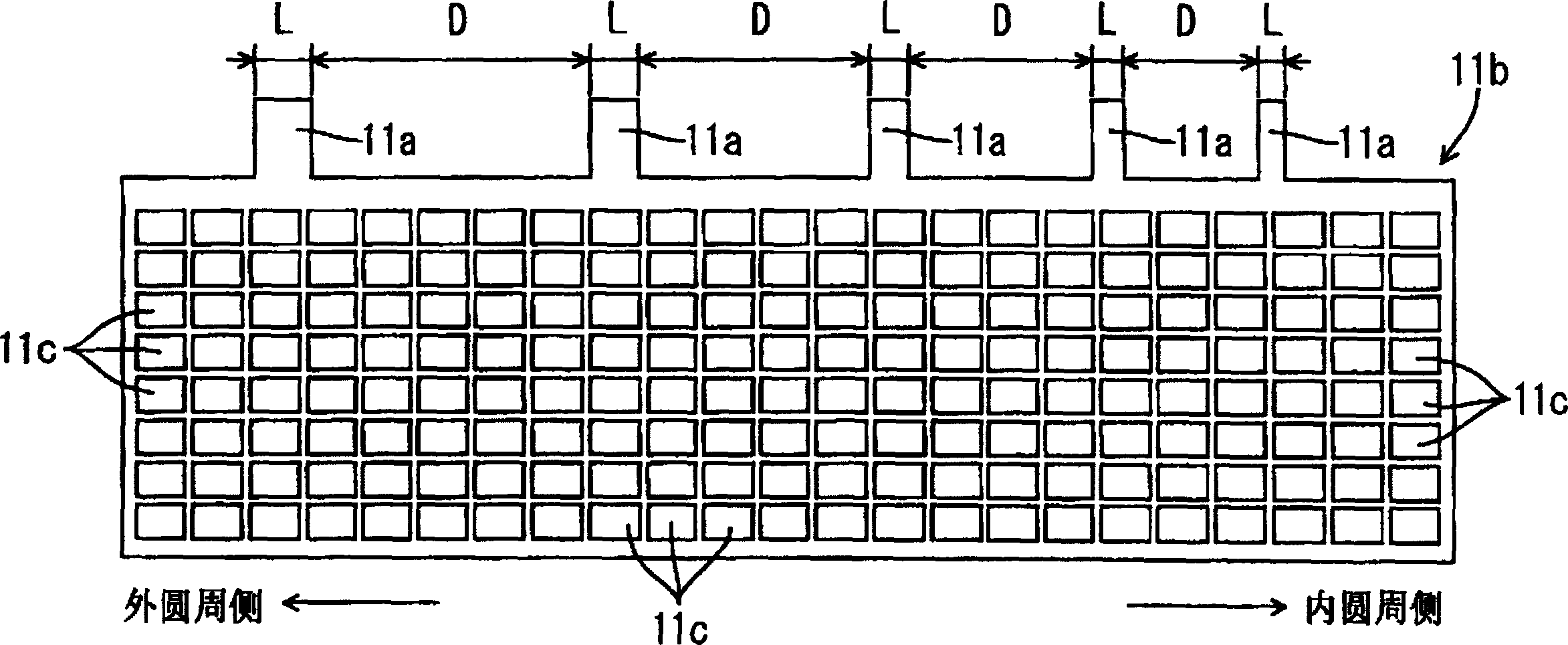

Cell

InactiveCN1237634CEnough widthQuality improvementFinal product manufactureElectrode carriers/collectorsElectricityDischarge current

A battery comprising an electricity-generating element comprising a strip-form positive electrode (11), a strip-form negative electrode (12), and a strip-form separator (13), said positive electrode and said negative electrode being spirally wound through said separator and said positive electrode and said negative electrode respectively having current collecting lugs (11a,12a) protruding from a side thereof, wherein the pitches of the current collecting lugs become longer toward the outer periphery side, and the at least one current collecting lug that located on the outer side has a larger width than that located on the inner side. In this battery, the electricity-generating element has at least one current collecting lug which has a larger width than the adjacent current collecting lug located on the inner side thereof. Consequently, although the current collecting lugs in an outer region are located at a longer pitch and the area to be covered by each current collecting lug in that region is wide, charge / discharge current can sufficiently flow through the active material throughout the whole area in that region. Therefore, charge / discharge current can evenly flow through the electrodes including their inner and outer parts, whereby the active materials can have an even reaction distribution.

Owner:GS YUASA INT LTD

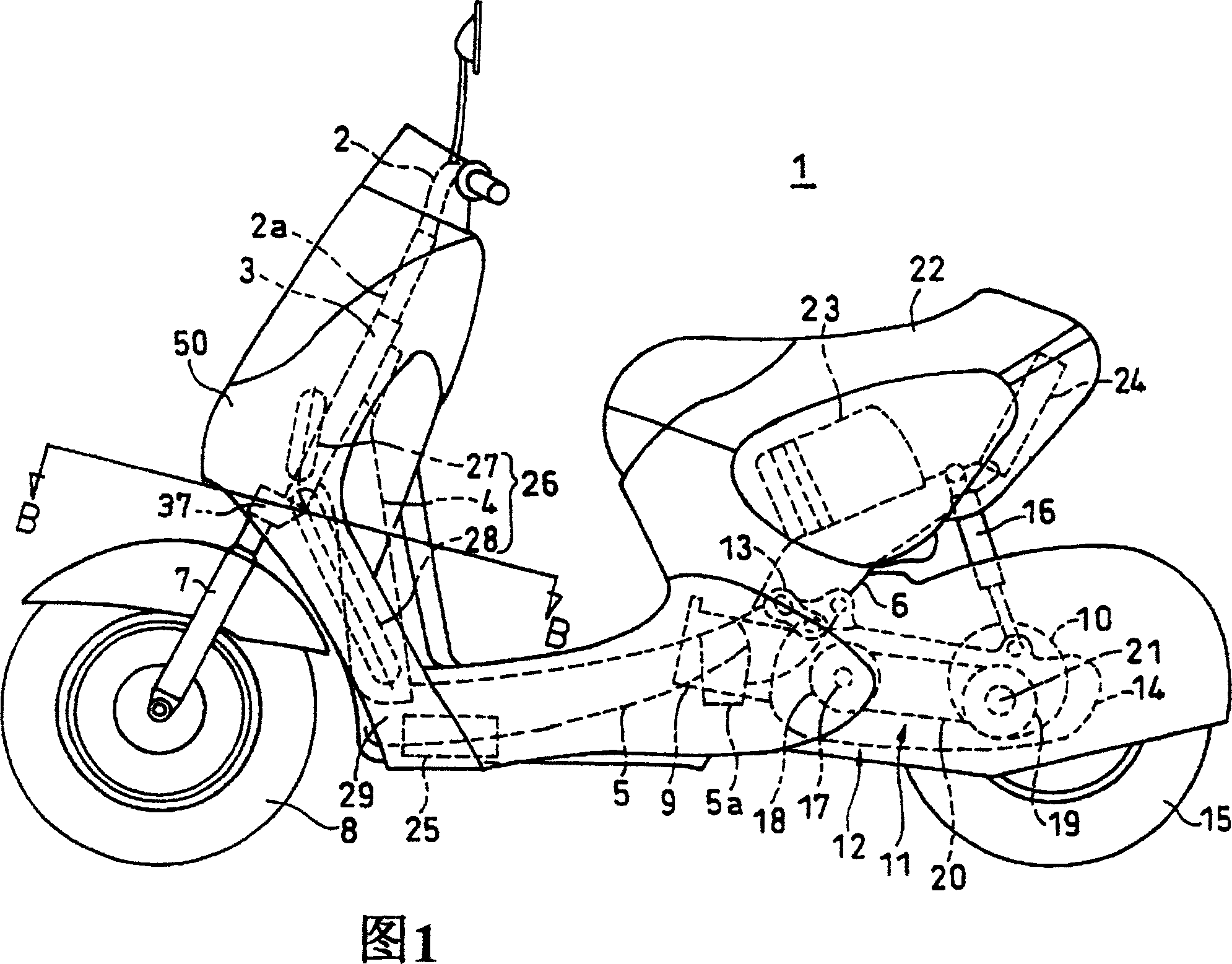

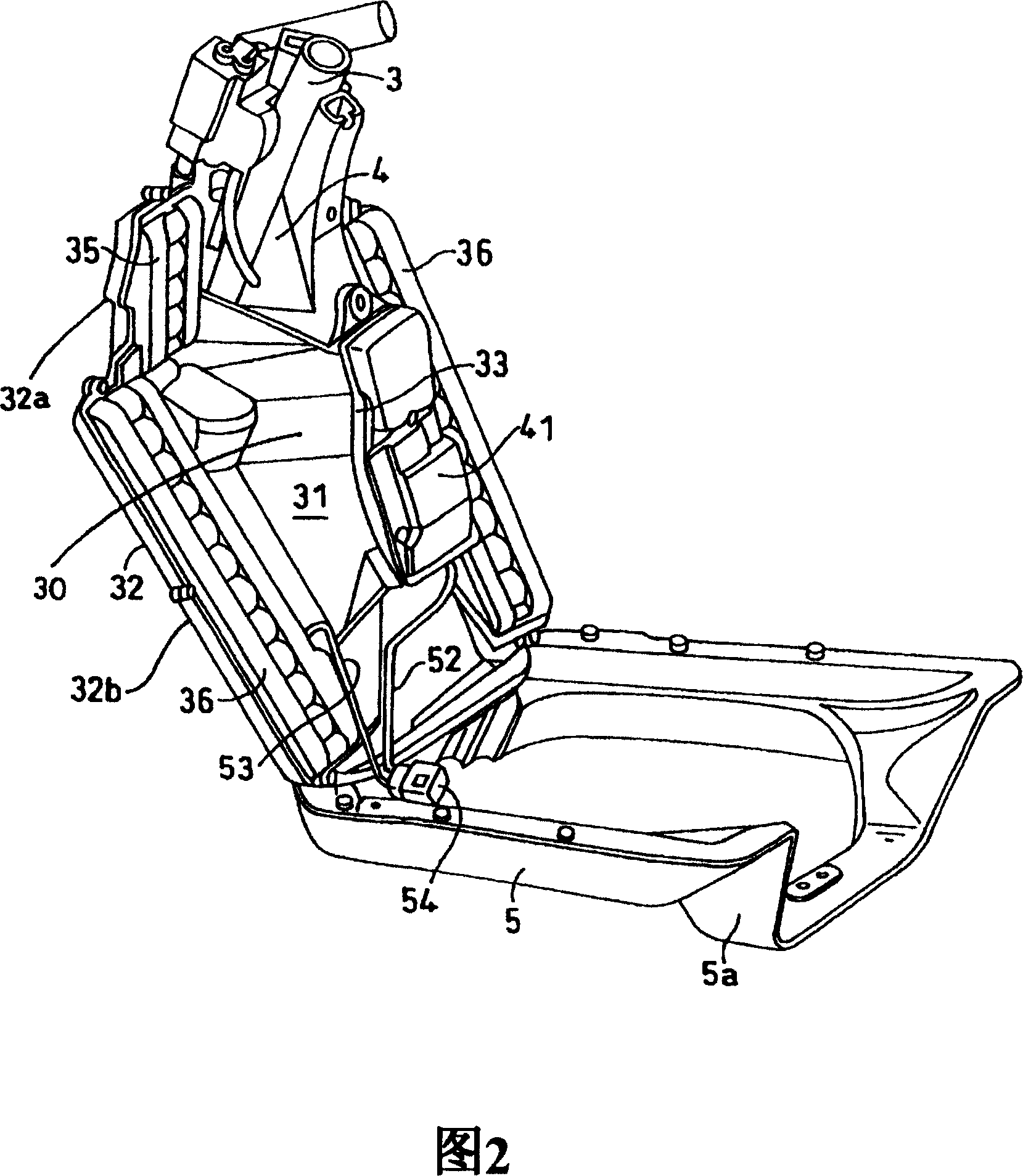

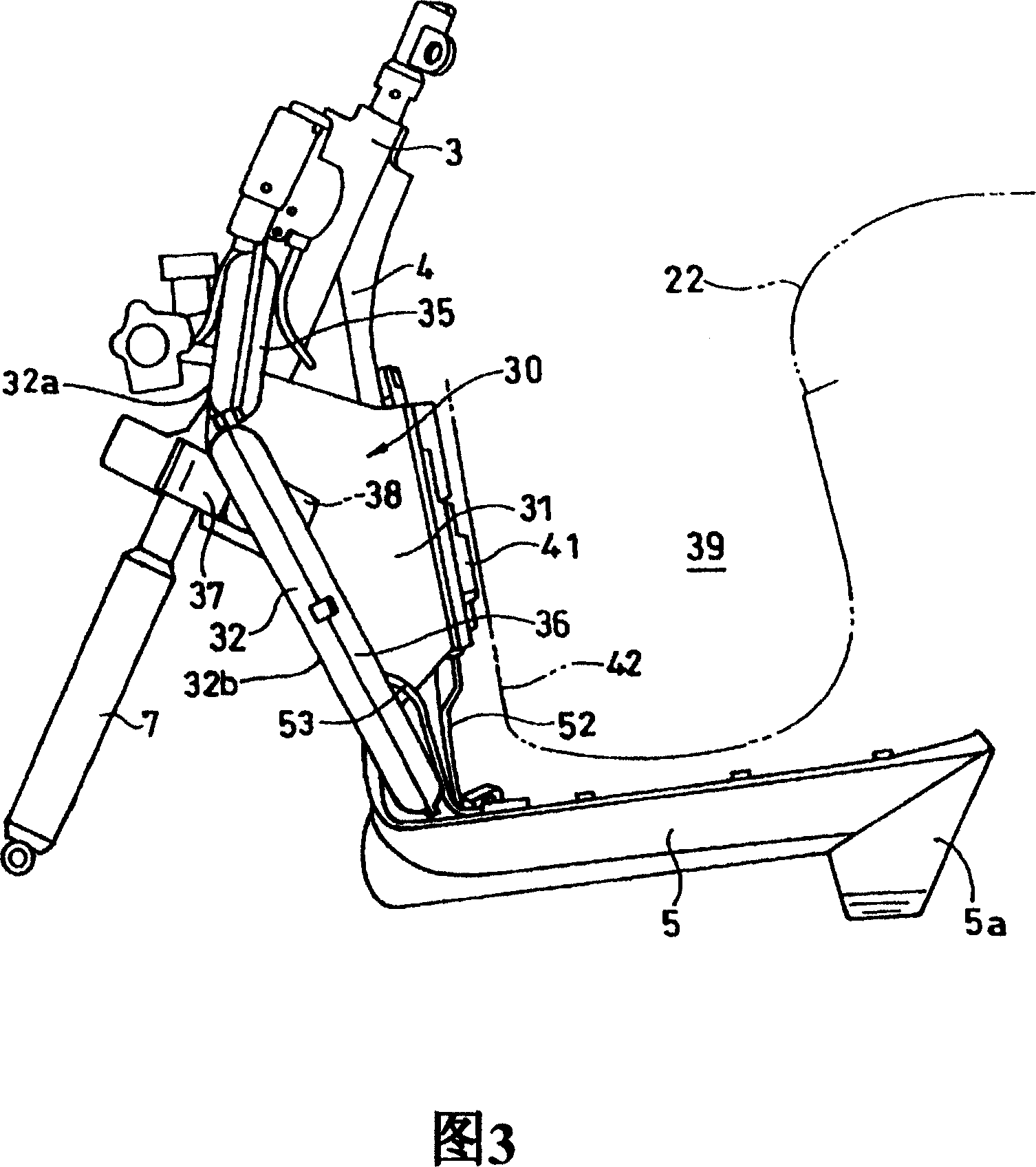

Battery holder of electric vehicle

InactiveCN100344473CAchieve large capacitySecure spaceElectric propulsion mountingCycle equipmentsVehicle frameElectrical battery

PROBLEM TO BE SOLVED: To effectively utilize space by improving layout of a battery for a motor of a motorized two-wheeled vehicle and improve cooling effect of the battery.SOLUTION: A battery assembly body (battery) 26 is disposed by dividing an upper part 27 and a lower part 28. The upper part 27 is disposed on the side part of a head pipe 3 and the lower part 28 is disposed on the side part of a down frame 4. Especially, the lower part 28 is disposed on the outer side than a front fork 7 to approach the vehicle body front part. An inlet port 43 of traveling wind is formed on a cowl in front of the battery assembly body 26. An exhaust port 44 exhausting the traveling wind is provided on an inner cover 42.

Owner:HONDA MOTOR CO LTD

A high-efficiency all-back-electrode solar cell

InactiveCN103762258BIncrease power generationImprove conversion efficiencyPhotovoltaic energy generationSemiconductor devicesGenerating capacitySolar cell

The invention relates to the technical field of solar cells, in particular to an efficient all back electrode type solar cell. The solar cell comprises a solar panel arranged on the outer layer, wherein a zigzag stepped surface with long edges and short edges arranged alternately is arranged on the bottom of the solar panel, each long edge is provided with a PN junction diffusion layer and a diffusion layer electrode, and each short edge is provided with a substrate electrode. Due to the fact that the PN junction diffusion layers are arranged on the zigzag long edges, the contact area between a P region and an N region, namely the area of a PN junction region is increased as much as possible. Besides, due to the fact that the substrate electrode layers are arranged on the short edges of the stepped surface, the short edges are arranged to be perpendicular to the surface of the solar panel as far as possible, so that solar rays shining on the solar panel can almost completely shine on the PN junction diffusion layers. In this way, the area of the PN junction diffusion layers can be increased, solar rays can be fully absorbed, sufficient width is guaranteed for the substrate electrode layers, and then the electric generating capacity and conversion efficiency of the solar cell are improved to the greatest extent.

Owner:DONGGUAN POLYTECHNIC

Reciprocating descent control device

The invention discloses a reciprocating descent control device. A rotating shaft is arranged on a bracket and is provided with a winding drum; a steel wire rope is wound on the winding drum around a pulley; a damping cylinder is arranged on the bracket close to the rotating shaft; a piston of the damping cylinder is connected with the rotating shaft through a crank slider mechanism; and a small hole is formed on the piston. The preferable scheme of the invention is that: the reciprocating descent control device is provided with two damping cylinders, and a rotation angle of the crank slider mechanism which is connected with the damping cylinders is staggered for 90 degrees. Therefore, the dead center of the crank slider mechanism is avoided, the speed is steady during descent control, andthe winding of the steel wire rope due to the speed change is avoided. The reciprocating descent control device is not controlled by a user at all during use, can realize continuous descent control, and has the advantages of steady operation, safety and reliability, and low production cost.

Owner:HUBEI THREE GORGES POLYTECHNIC

Pile foundation protection structure and protection method

PendingCN111926806AGuaranteed stabilityLiquidProtective foundationWind motor supports/mountsSoil scienceStructural engineering

The invention provides a pile foundation protection structure and a protection method, and belongs to the technical field of pile foundations. The pile foundation protection structure comprises a pilefoundation and a solidified soil layer. The pile foundation is suitable for being inserted in a seabed. The solidified soil layer is laid around the pile foundation and makes contact with the pile foundation, and furthermore, the solidified soil layer is suitable for being arranged on the upper portion of the seabed while making contact with the seabed. According to the pile foundation protectionstructure, the solidified soil layer is laid around the pile foundation, the solidified soil layer makes contact with the seabed and is laid on the upper portion of the seabed, the solidified soil layer can be tightly attached to the mud surface of the seabed, scouring pits are prevented from being formed around the pile foundation by water scouring, the stability of the pile foundation is guaranteed, the scheme is easy and convenient to implement, and maintenance is convenient.

Owner:HUADIAN HEAVY IND CO LTD

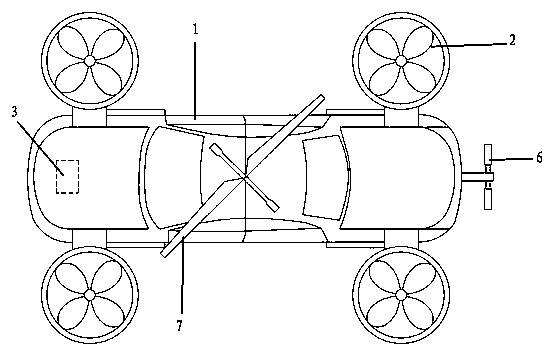

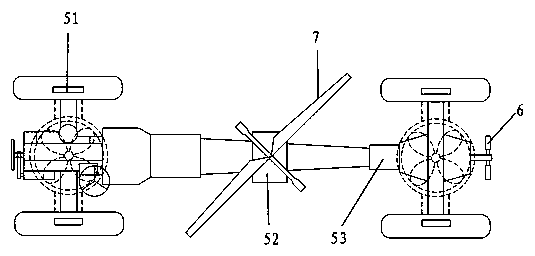

Aerocar

InactiveCN108284721ASmall sizeFlexible flightFuselagesAir-flow influencersElectric machineryPropeller

The invention discloses an aerocar comprising a car body, an engine, rotors, a motor, a mechanical transmission mechanism, an electromotor, a spiral propeller and a spiral lifting device, wherein theengine and the rotors are arranged inside the car body, the rotors are movably connected with rotor turning mechanisms, the motor, the mechanical transmission mechanism and the electromotor are arranged on wheels and connected with the engine, the motor and the rotors are connected with each other, the spiral propeller is fixedly installed at the tail portion of the car body and is connected withthe electromotor, and the spiral lifting device is fixedly arranged at the top of the car body. When the aerocar is not in flight, the rotors are arranged in cavities of the front and rear parts of the car body, and opening and withdrawal of the rotors are realized by a rotor rotation mechanism. Two groups of the rotors are arranged in an up-down stack-up mode, and thus the aerocar is small in size and can conveniently fly. The enough width of the rotors can ensure the power of flight, and the rotors are opened and positioned at both sides of the car body. The spiral lifting device is arrangedat the top portion of the car body and provides secondary lift power for the aerocar, thereby enhancing the flying stability of the aerocar.

Owner:FOSHAN SHENFENG AVIATION SCI & TECH

Semiconductor machine

InactiveCN100353516CEnough widthInsert smoothlySemiconductor/solid-state device testing/measurementStable stateSemiconductor package

Owner:POWERCHIP SEMICON CORP

Concealable seat back

ActiveCN105291922BIn line with engineering design principlesEnough widthBack restsVehicle with living accommodationLiving roomMechanical stability

The invention discloses a concealable seat back, which comprises a rear fixed plate, a front back plate whose upper end is hinged to the rear fixed plate, a support plate whose outer end is hinged to the inner side of the back plate, and the support plate At least one notch is formed on the plate, and the limit guide plate is hinged in the notch, and the other end of the limit guide plate is hinged with the rear fixing plate. The beneficial effect of the invention is that the structure is simple, the mechanical stability is high, the front backboard has a hidden effect after being folded, and the space can be saved. At the same time, after the front backboard is pulled out, a comfortable backrest inclination and a reasonable seat depth will be formed, which conforms to the principle of ergonomic design; when the front backboard is folded, it can not only save space, but also pull out the front backboard The depth of the seat surface covered by the time is released, so that the seat surface forms a sufficient width, has the function of a bed, and can be widely used in seats or sofas, especially for occasions with high space requirements, such as small living rooms or RVs, etc. .

Owner:刘章巨 +1

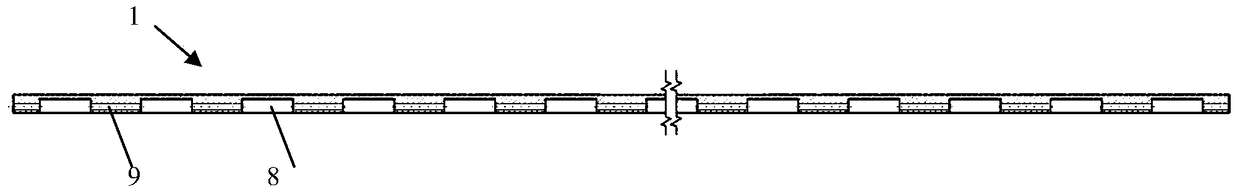

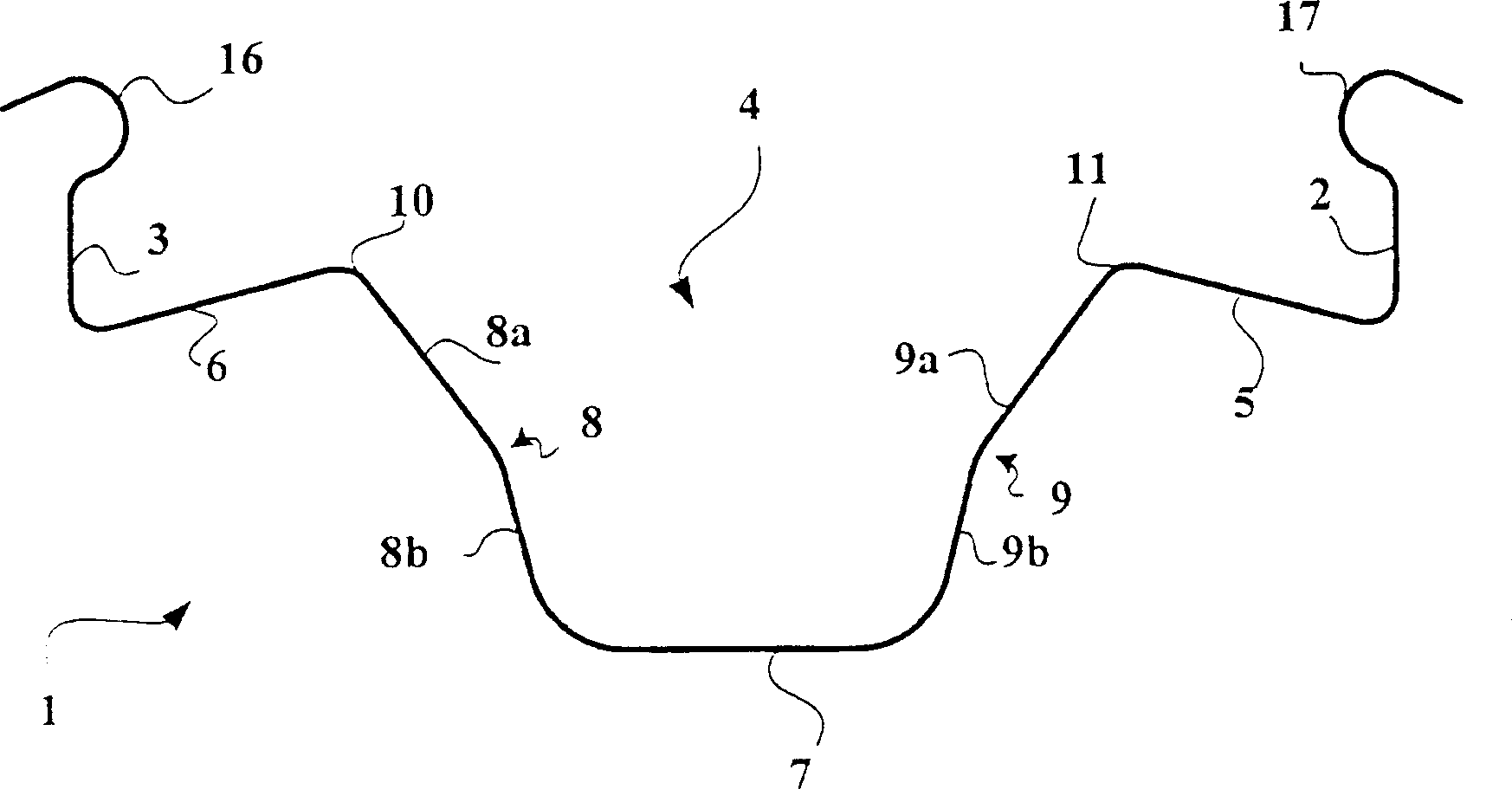

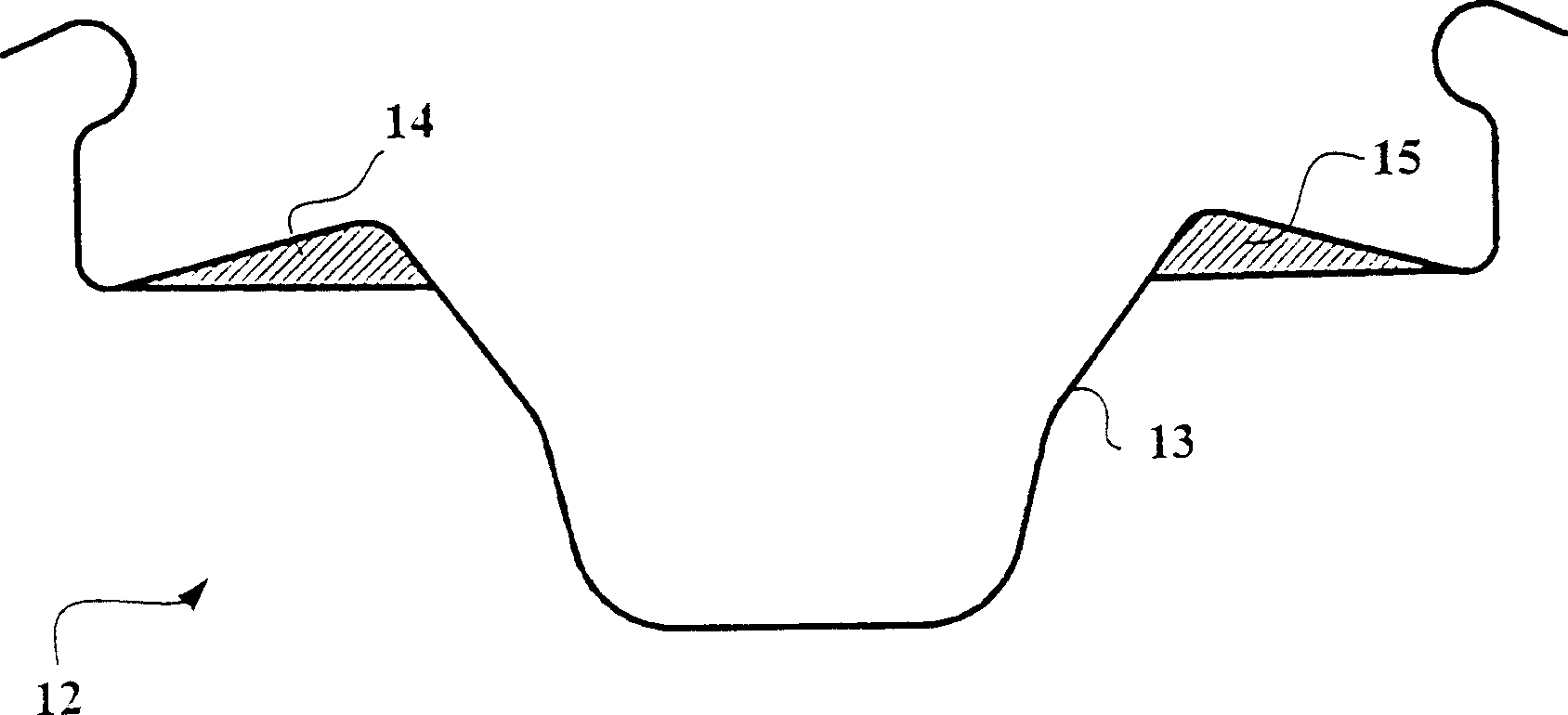

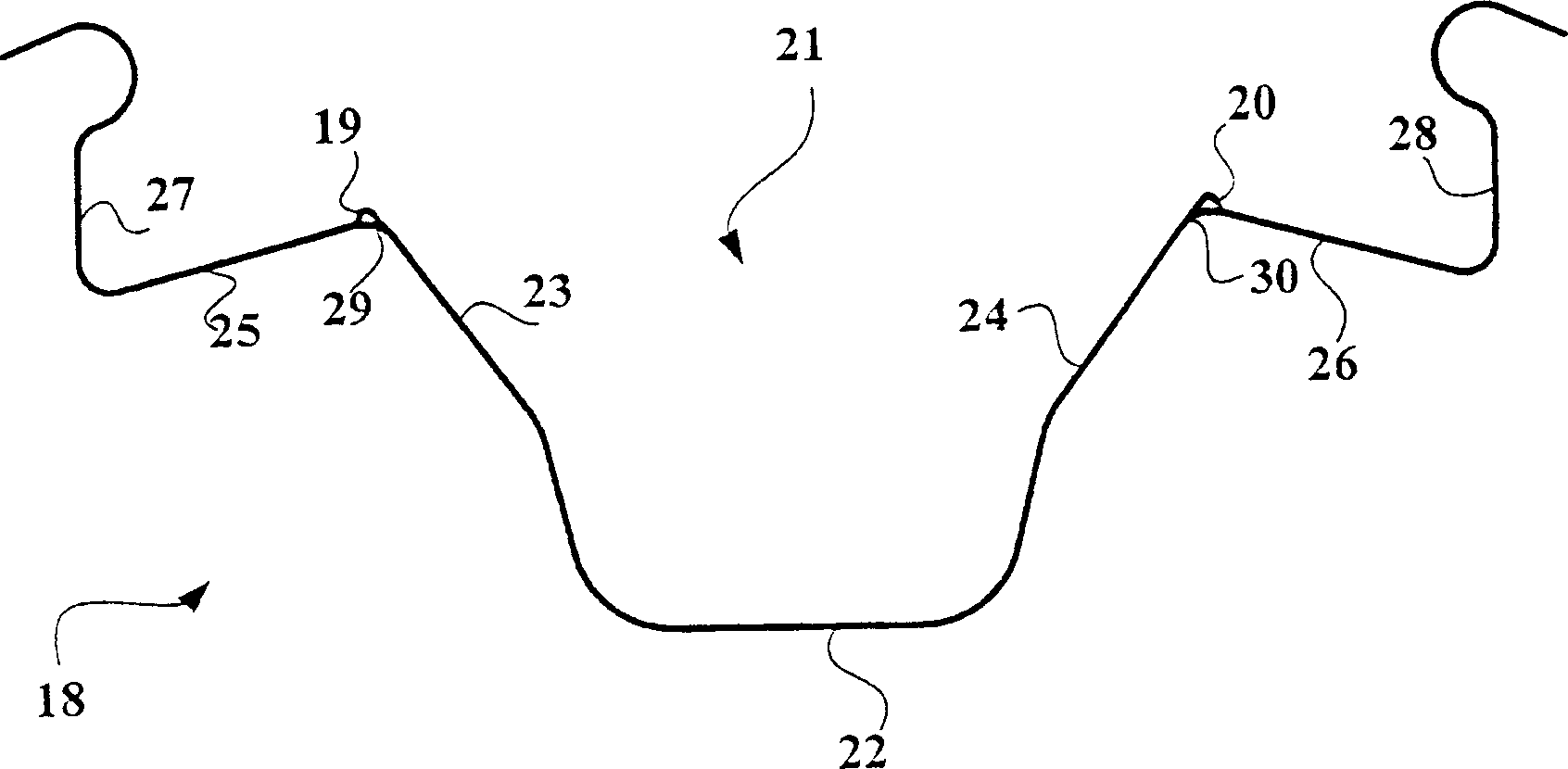

Cycle rim and tubeless mounting assembly for cycle

InactiveCN1277700CReduce tensionHas the function of anti-seatingWithout separate inflatable insertsRimsRadial planeFlange

The invention relates to a rim for cycles, more particular for bicycles. The invention is also aimed at a tubeless mounted assembly consisting of the said rim and of a tire having in particular two flexible bead wires. According to the invention, the rim consists of two flanges, attached to two seats, intended to receive the beads of a tire, separated from each other by a mounting groove, and, according to the profile of the rim in a radial plane, the bead seats have a generatrix, the axially outer end of which is on a circle of smaller diameter than the diameter of the circle on which the axially inner end is situated, the said generatrix forming an angle with the axis of rotation of the tire of between 15 and 45 degrees.

Owner:MICHELIN & CO CIE GEN DES ESTAB MICHELIN +1

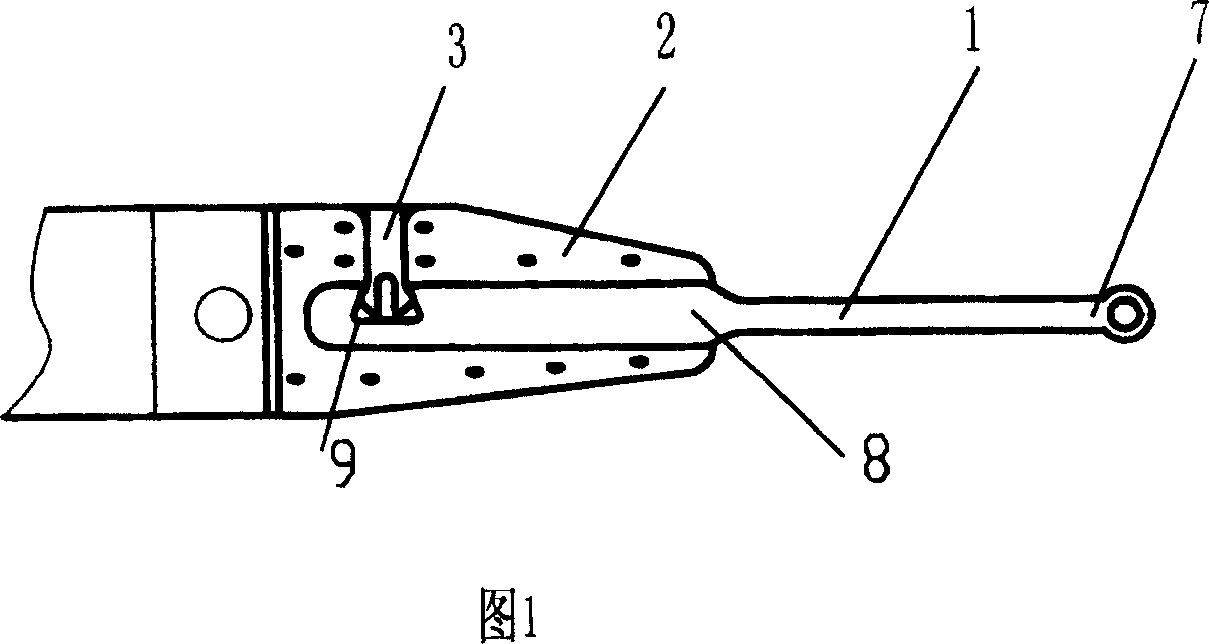

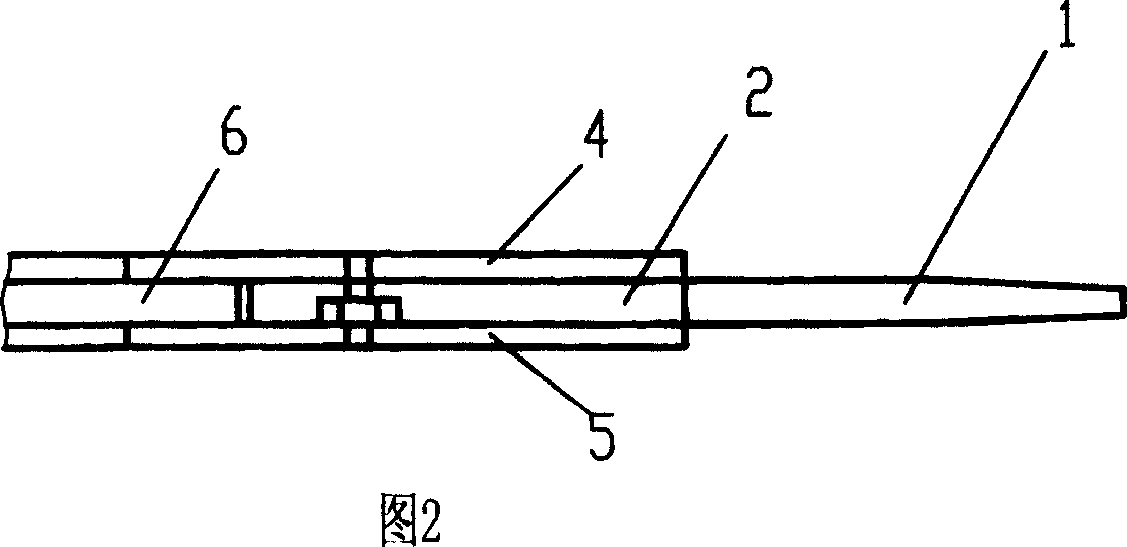

Fixed-angle extrusion glass cement glue-flowing tube

InactiveCN101761220BEnsure uniform thicknessEasy to operateBuilding constructionsEngineeringCircular segment

The invention relates to a glue gun accessory, in particular to a fixed-angle extrusion glass cement glue-flowing tube. The fixed-angle extrusion glass cement glue-flowing tube comprises a casing handle, a top shell, taped fins and a glue outlet, wherein the lower end of the casing handle is provided with the arc top shell which is integrated with the casing handle, the top shell and a positioning plate which is arranged below the top shell and is integrated with the casing handle commonly constitute the half-elliptic glue outlet of which the major axis of section is horizontal; the angle between the positioning plate and the axial lead of the casing handle is 20-45 degrees; and two taped fins which are integrated with the top shell are arranged on the two sides of the top shell and the taped fins are arc shells. The top shell and the taped fins of the invention can be used to extrude glass cement to form the adhesive tape with bowed section, thus further increasing the sealing effectof the glass cement to the joints of the curtain wall.

Owner:NINGBO YINZHOU YUNFAN ENG CONSULTING

Fixed-angle extrusion glass cement glue-flowing tube

InactiveCN101761220AEnsure uniform thicknessEasy to operateBuilding constructionsLong axisEngineering

The invention relates to a glue gun accessory, in particular to a fixed-angle extrusion glass cement glue-flowing tube. The fixed-angle extrusion glass cement glue-flowing tube comprises a casing handle, a top shell, taped fins and a glue outlet, wherein the lower end of the casing handle is provided with the arc top shell which is integrated with the casing handle, the top shell and a positioning plate which is arranged below the top shell and is integrated with the casing handle commonly constitute the half-elliptic glue outlet of which the major axis of section is horizontal; the angle between the positioning plate and the axial lead of the casing handle is 20-45 degrees; and two taped fins which are integrated with the top shell are arranged on the two sides of the top shell and the taped fins are arc shells. The top shell and the taped fins of the invention can be used to extrude glass cement to form the adhesive tape with bowed section, thus further increasing the sealing effect of the glass cement to the joints of the curtain wall.

Owner:NINGBO YINZHOU YUNFAN ENG CONSULTING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com