Manufacture of non-volatile memory

A non-volatile, manufacturing method technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as interference, affecting normal operation, serious problems, etc., to achieve interference reduction, gate line width reduction, The effect of increasing distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

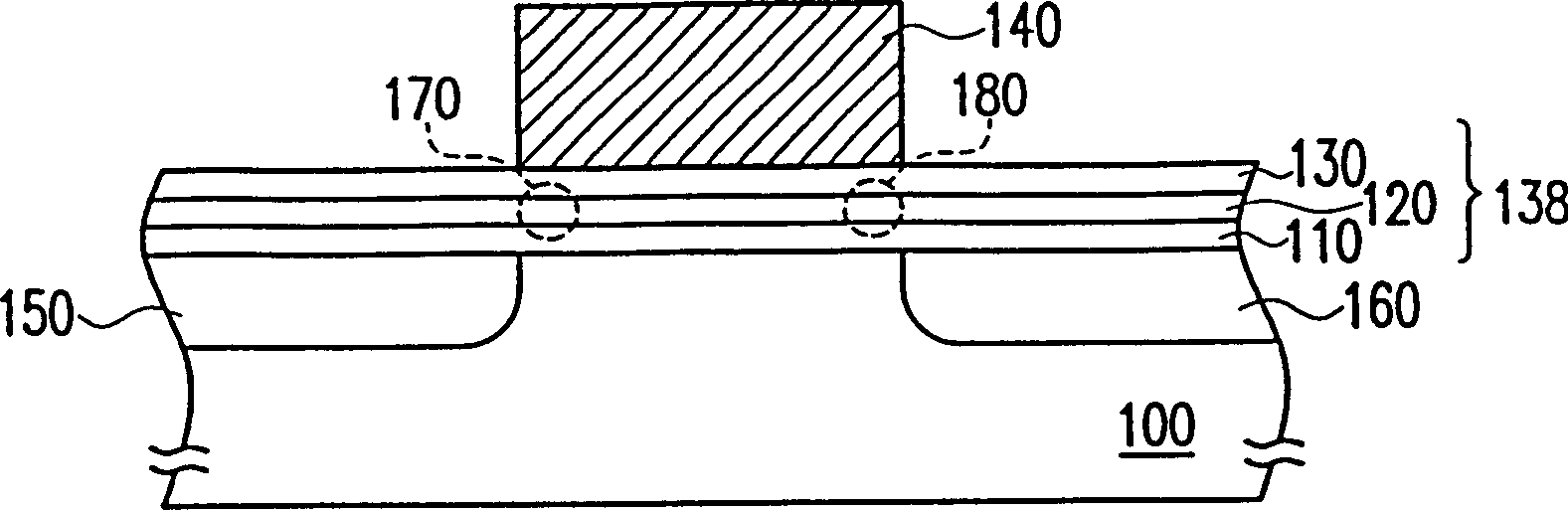

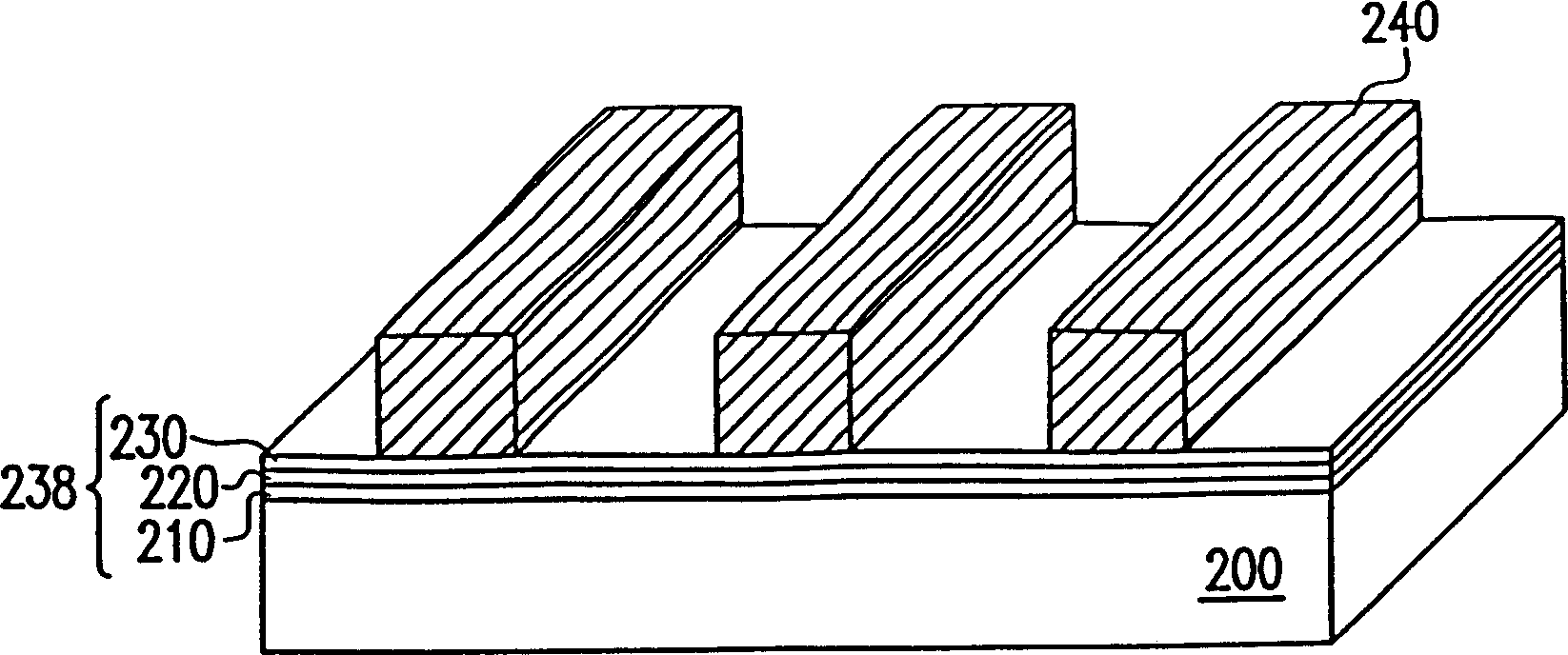

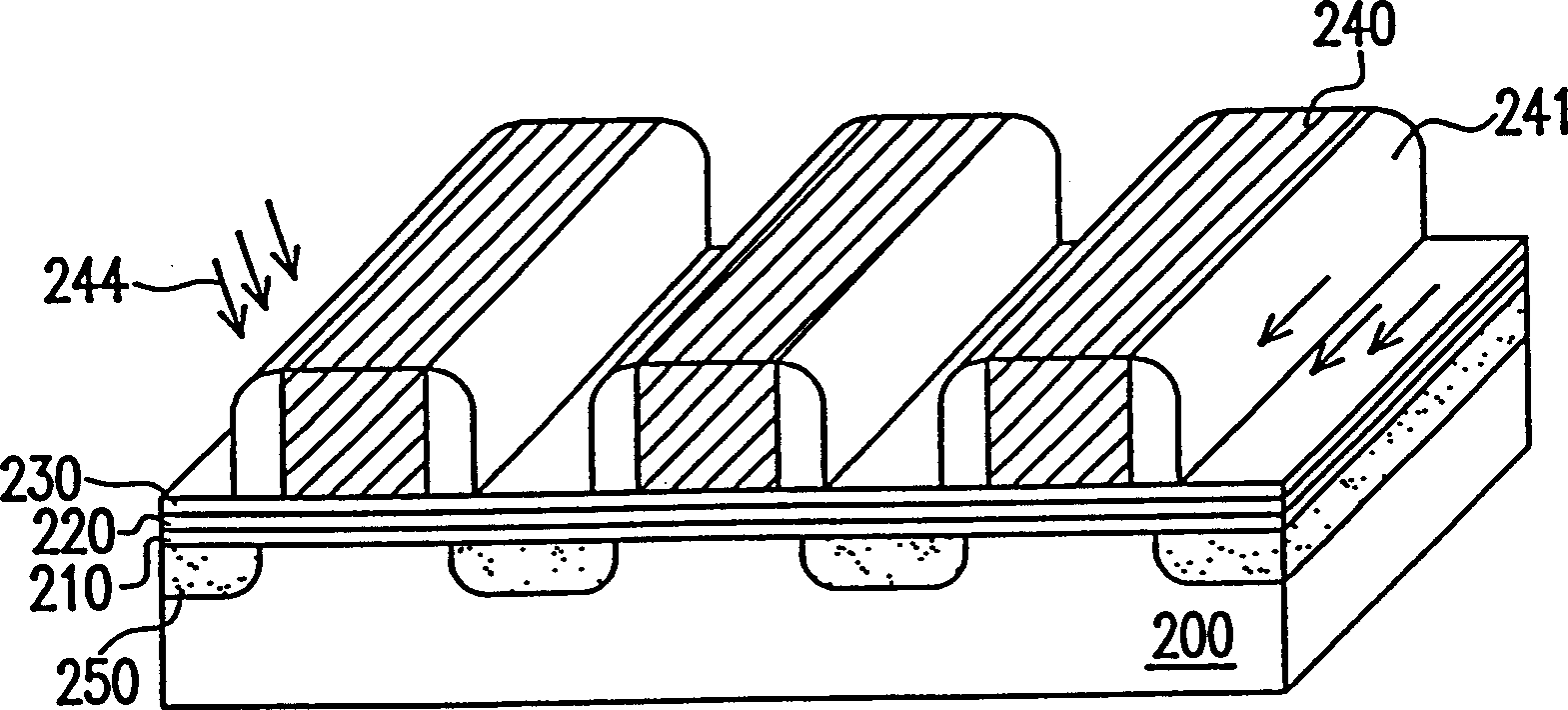

[0022] This preferred embodiment takes the manufacturing process of SONOS memory as an example, and uses Figure 2A ~ Figure 2E As an aid, the method of manufacturing the nonvolatile memory of the present invention will be described.

[0023] Please refer to Figure 2A First, a substrate 200 is provided, and then a silicon oxide layer 210 , a silicon nitride layer 220 , and a silicon oxide layer 230 are sequentially formed on the substrate 200 , and these three are collectively referred to as a charge trap layer 238 . Among them, the formation method of the silicon oxide layer 210 is preferably Thermal Oxidation, the formation method of the silicon nitride layer 220 is, for example, low-pressure chemical vapor deposition (LPCVD), and the formation method of the silicon oxide layer 230 is, for example, nitrogen oxide the surface of silicon oxide layer 220. Next, a strip-shaped conductive layer 240 parallel to each other is formed on the substrate 200 , which is the precursor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com