Electrostatic adsorption adhesive tape and preparation method thereof

An electrostatic adsorption and adhesive tape technology is applied in the field of electrostatic adsorption adhesive tape and its preparation. and durability, the effect of improving the bonding stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

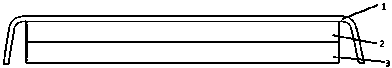

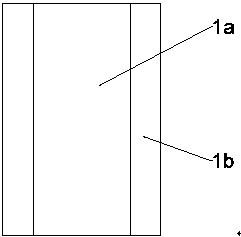

[0033] Such as figure 1 Shown is a schematic structural view of Embodiment 1 of the electrostatic adsorption adhesive tape of the present invention. The electrostatic adsorption adhesive tape of this embodiment comprises a protective layer 1 made of a flexible material, one side surface of the protective layer 1 is provided with an adhesive area 1a located in the middle, and protective layers are respectively provided on both sides or around the adhesive area 1a. In area 1b, an adhesive layer 2 made of adhesive is provided in the adhesive area 1a, and a smooth electrostatic adsorption surface is provided in the protection area 1b. The protection area 1b in this embodiment is arranged on both sides of the bonding area 1a.

[0034] Further, the adhesive layer 2 is made of industrial adhesive or medical adhesive. When the adhesive layer 2 is made of industrial adhesive, the electrostatic adsorption tape of this embodiment can be made into OPP, BOPP, EVA, foam Cotton base tape, ...

Embodiment 2

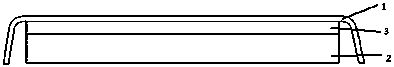

[0040] Such as image 3Shown is a schematic structural view of Embodiment 2 of the electrostatic adsorption adhesive tape of the present invention. The electrostatic adsorption adhesive tape of this embodiment comprises a protective layer 1 made of a flexible material, one side surface of the protective layer 1 is provided with an adhesive area 1a located in the middle, and protective layers are respectively provided on both sides or around the adhesive area 1a. In area 1b, an adhesive layer 2 made of adhesive is provided in the adhesive area 1a, and a smooth electrostatic adsorption surface is provided in the protection area 1b. The adhesive layer of this embodiment is made of medical adhesive. At this time, the electrostatic adsorption tape of this embodiment also includes a functional layer 3 , and the functional layer 3 is located on the side of the adhesive layer 2 facing away from the protective layer 1 . The width of the functional layer 3 and the adhesive layer 2 in t...

Embodiment 3

[0043] Such as Figure 4 Shown is a schematic structural view of Embodiment 3 of the electrostatic adsorption adhesive tape of the present invention. The electrostatic adsorption adhesive tape of this embodiment comprises a protective layer 1 made of a flexible material, one side surface of the protective layer 1 is provided with an adhesive area 1a located in the middle, and protective layers are respectively provided on both sides or around the adhesive area 1a. In area 1b, an adhesive layer 2 made of adhesive is provided in the adhesive area 1a, and a smooth electrostatic adsorption surface is provided in the protection area 1b. The adhesive layer of this embodiment is made of medical adhesive. At this time, the electrostatic adsorption tape of this embodiment also includes a functional layer 3, and the functional layer 3 is located between the adhesive layer 2 and the protective layer 1, and the functional layer 3 The width of the functional layer 3 is greater than the wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com