A high-efficiency all-back-electrode solar cell

A technology of solar cells and solar panels, applied in the field of solar cells, can solve the problems of reducing the effective area of solar cells, reducing the power generation and conversion efficiency of solar cells, and achieving the effect of increasing power generation and conversion efficiency and increasing the area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

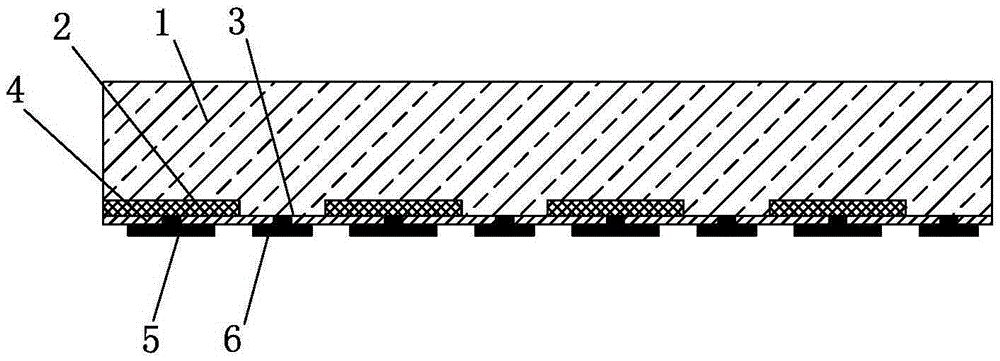

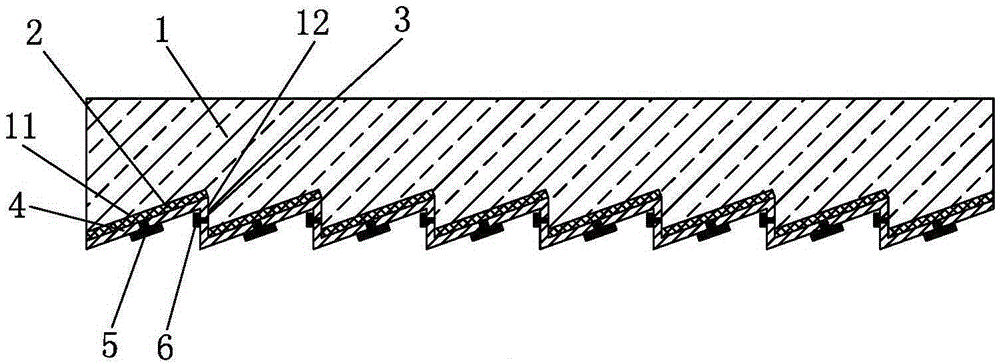

[0014] Attached below figure 2 The present invention is described further:

[0015] A high-efficiency full back-electrode solar cell, the solar cell includes a solar cell panel 1 arranged on the outer layer, the bottom of the solar cell panel 1 is provided with alternate zigzag stepped surfaces with long and short sides 11 and 12, and the long side 11 is provided with The PN junction diffusion layer 2 forms the substrate electrode layer 3 on the short side 12, and the protective layer 4 is arranged at the bottom of the PN junction diffusion layer 2, and the PN junction diffusion layer electrodes 5 are respectively arranged outside the protective layer 4 under the long side 11 and the short side 12. , Substrate electrode 6 .

[0016] In order to increase the illuminated area of the PN junction diffusion layer 2 and reduce the absorption of the incident sunlight by the substrate electrode, the short side 12 is arranged perpendicular to the surface of the solar cell panel 1, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com