Ultra-wide cutter device for soft films

A soft rubber and cutting knife technology, applied in metal processing and other directions, can solve the problems of easy accidents, limited cutting width, dangerous operation, etc., and achieve the effect of fast cutting speed, neat cutting and reducing industrial accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

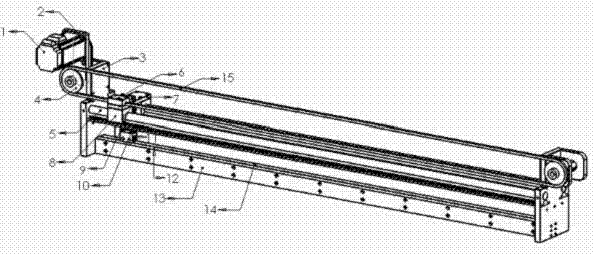

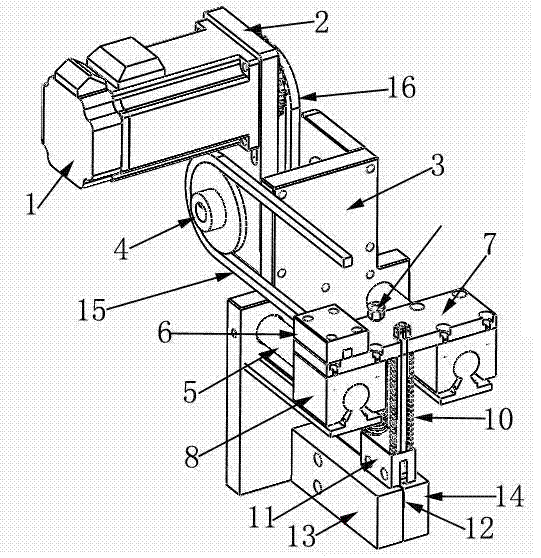

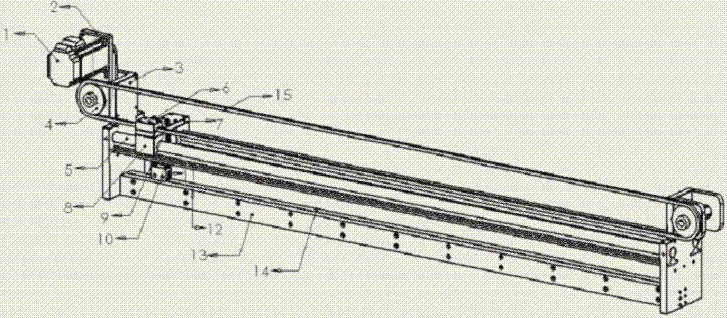

[0016] refer to figure 1 , figure 2 As shown, an ultra-wide soft rubber cutter device includes two slide rail fixing plates 3, the one slide rail fixing plate 3 is connected with a driving device, and two slide rail fixing plates 3 are connected with two Linear guide rod 5, front tool holder 13, rear tool holder 14 and tungsten steel blade 12, the tungsten steel blade 12 is sandwiched between the front tool holder 13 and the rear tool holder 14, the slide rail fixing plate 3 each is provided with a transmission sprocket 4, the transmission sprocket 4 is connected with a transmission chain 15, each of the linear guide rods 5 is connected with a linear slider 8, and the two linear sliders 8 are connected with sliding A block pressing plate 7, the slider pressing plate 7 is connected with a pressing chain block 6, the transmission ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com