A continuous printing cardboard cutting processing equipment

A technology for printing cardboard and processing equipment, which is applied to paper/cardboard containers, papermaking, container manufacturing machinery, etc. It can solve the problems of uneven cutting of cardboard, low precision of cardboard, and slow cutting speed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

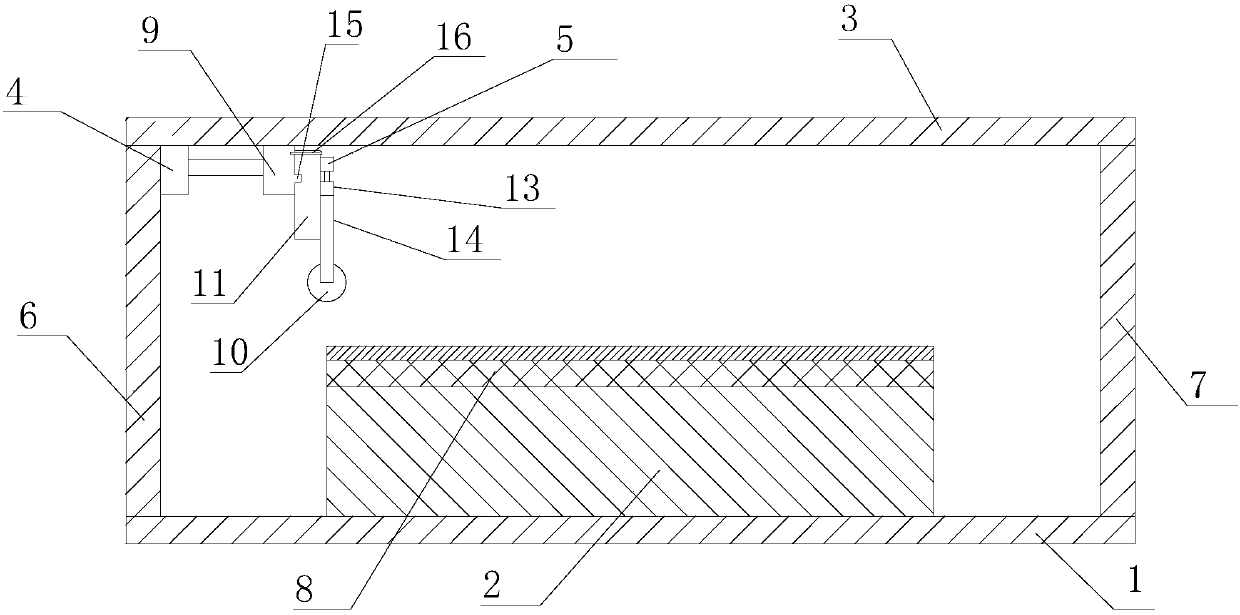

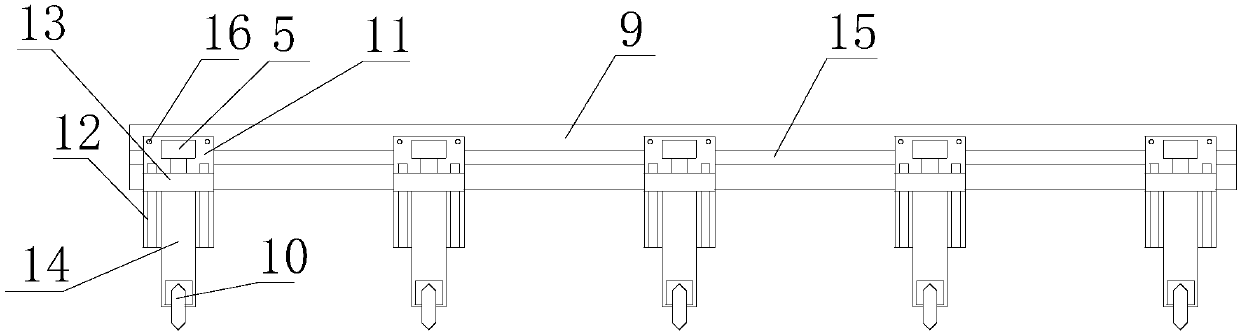

[0022] refer to figure 1 , figure 2 , the present invention proposes a continuous printing cardboard cutting processing equipment, including a base 1, a workbench 2, a first driving mechanism, a mounting frame 3, a cutting mechanism, a second driving mechanism 4, a third driving mechanism 5, a monitor and a control institutions, where:

[0023] The base 1 is arranged horizontally, and the two ends of the base 1 are provided with a first side frame 6 and a second side frame 7 oppositely arranged along the vertical direction.

[0024] The workbench 2 is arranged on the base 1, and the workbench 2 is provided with a conveying roller group 8, and the discharge end of the conveying roller group 8 is provided with a detection station.

[0025] The first driving mechanism is connected with the conveying roller set 8 for driving the conveying roller set 8 to rotate.

[0026] The installation frame 3 is located above the base 1 and parallel to the base 1 , and the two ends of the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com