A printing cardboard cutting device with pre-pressing function

A technology of printing cardboard and cutting device, applied in metal processing and other directions, can solve the problems of poor product quality, low processing efficiency, low cardboard accuracy, etc., and achieve the effects of fast cutting speed, high work efficiency and high processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

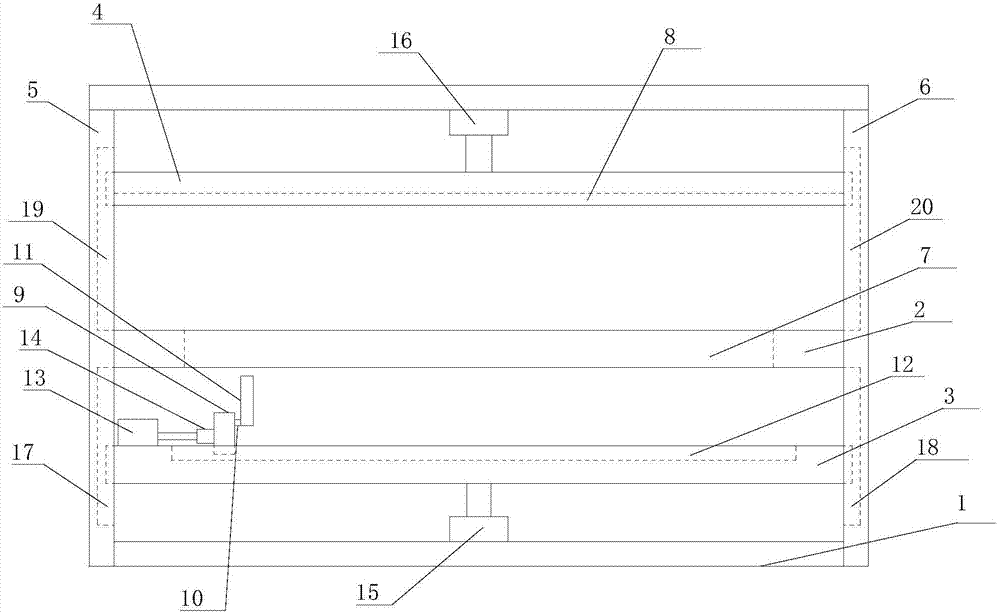

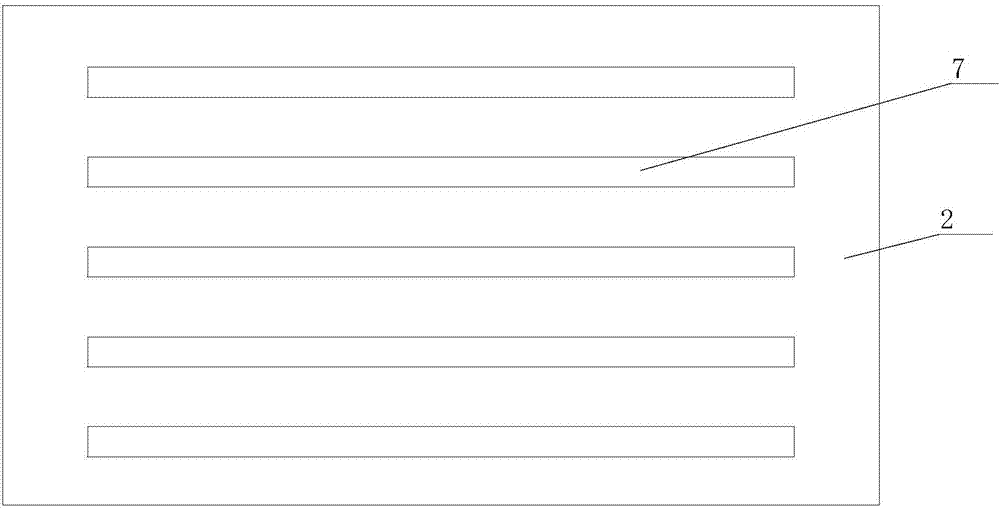

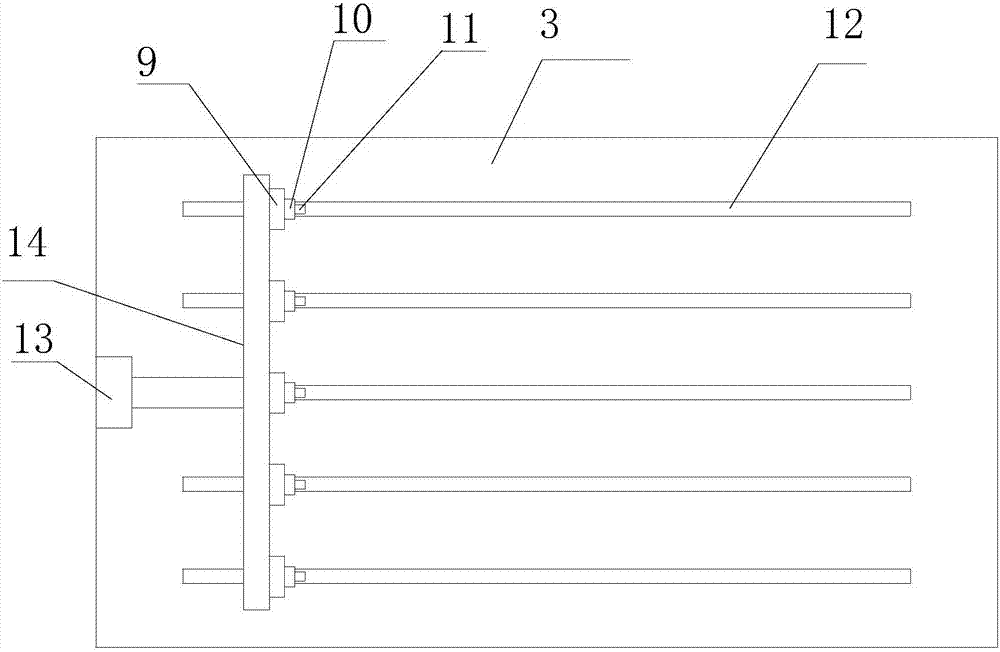

[0023] Such as figure 1 , figure 2 , image 3 , Figure 4 , figure 1 It is a structural schematic diagram of a printing cardboard cutting device with a pre-pressing function proposed by the present invention; figure 2 It is a schematic structural diagram of the first workbench of a printing cardboard cutting device with a pre-pressing function proposed by the present invention; image 3 It is a structural schematic diagram of the second workbench and the cutting knife assembly of a printed cardboard cutting device with pre-pressing function proposed by the present invention; Figure 4 It is a structural schematic diagram of a pre-compression plate of a printed cardboard cutting device with a pre-compression function proposed by the present invention.

[0024] refer to figure 1 , figure 2 , image 3 , Figure 4 , the present invention proposes a printing cardboard cutting device with a pre-compression function, including a base 1, a first workbench 2, a second workb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com