Medical fiber material preparation machine

A fiber material and preparation machine technology, which is applied in the cutting of textile materials, textiles and papermaking, metal processing, etc., can solve the problems of difficult to remove the surface of finished medical fiber cotton cloth, and achieve the effect of avoiding the accelerated cutting speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] For example figure 1 -example Figure 5 Shown:

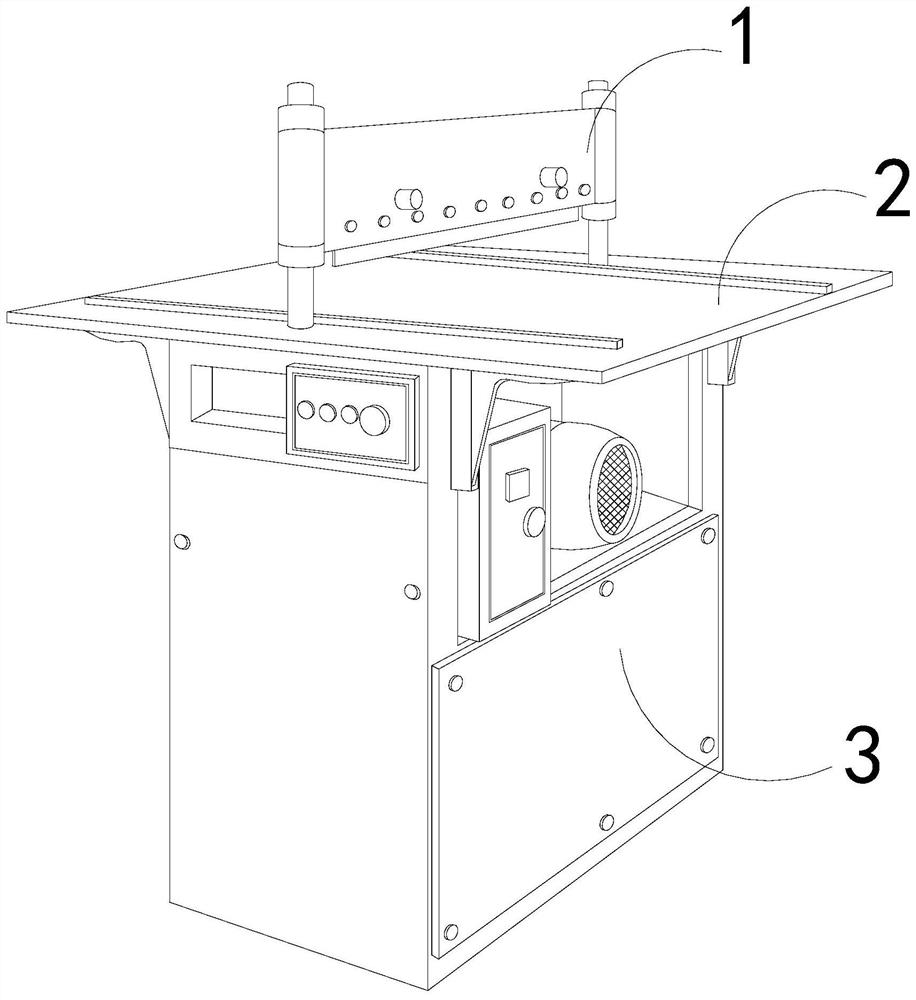

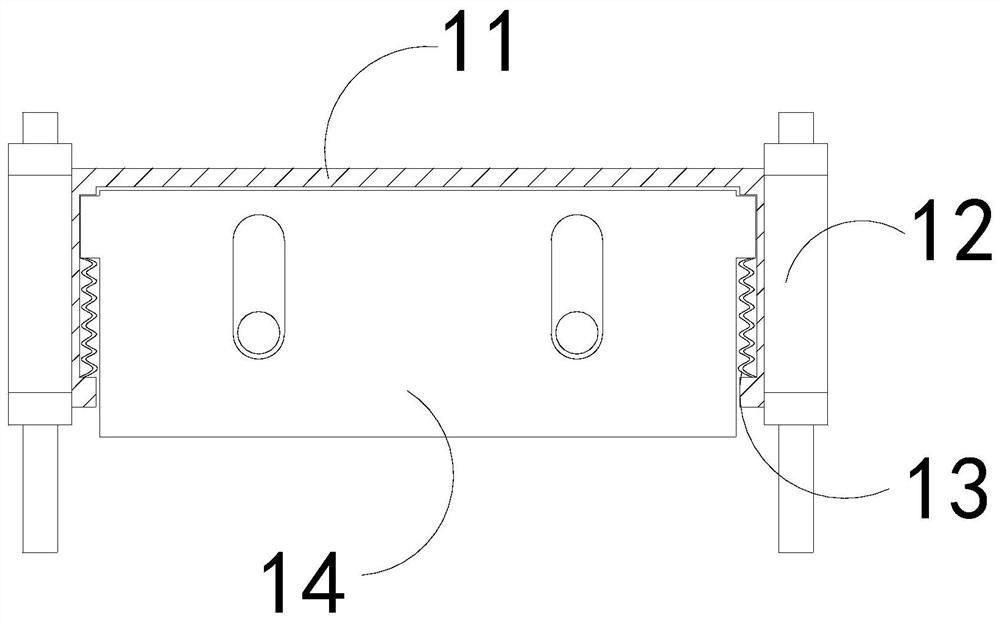

[0029] The present invention provides a medical fiber material preparation machine, the structure of which includes a cutting mechanism 1, an operating table 2, and a base 3, the bottom of the operating table 2 is welded to the top of the base 3, and the cutting mechanism 1 is installed on the operating table 2; the cutting mechanism 1 includes a frame 11, a support rod 12, a pullback bar 13, and a knife 14. The frame 11 is embedded between two support rods 12, and the pullback bar 13 is installed on Between the switch knife 14 and the inner wall of the frame 11 , the switch knife 14 is movably engaged with the inner wall of the frame 11 .

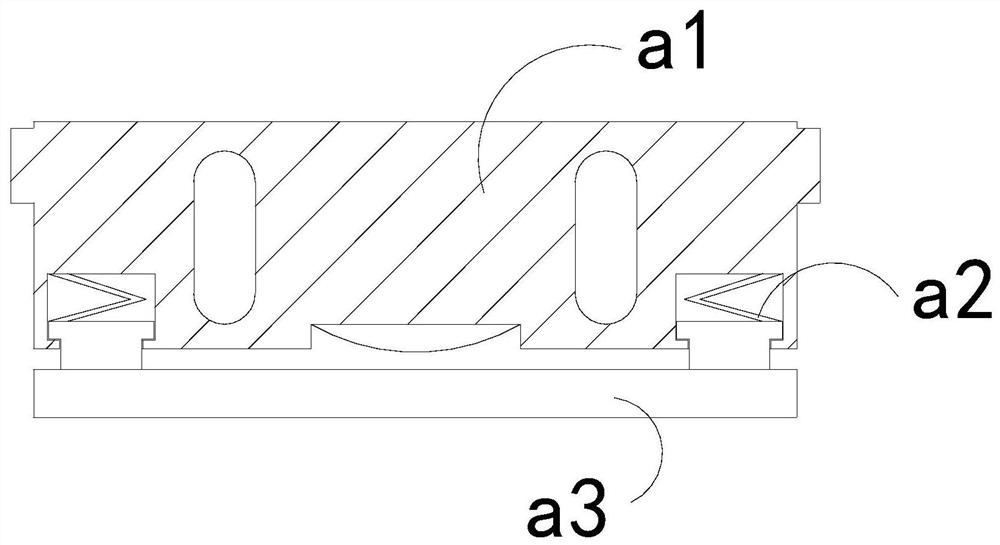

[0030] Wherein, the switch knife 14 includes a blade surface a1, an elastic piece a2, and a cutting piece a3. The elastic piece a2 is installed on the upper end of the inner wall of the knife surface a1 and the top position of the cutting piece a3. The inner wall of the inner wall ...

Embodiment 2

[0036] For example Image 6 -example Figure 9 Shown:

[0037]Wherein, the knife surface a1 includes a connecting strip c1, a receiving plate c2, a force receiving block c3, and a buffer piece c4. The connecting bar c1 is installed between the upper end of the force receiving block c3 and the upper end of the inner wall of the receiving plate c2. The force-bearing block c3 cooperates with the inner wall of the receiving plate c2, and the buffer sheet c4 is fixed on the inner wall of the receiving plate c2. The buffer sheet c4 adopts an arc-shaped convex structure made of spring steel, and the buffer sheet c4 can The impact force when the stressed block c3 shrinks is buffered.

[0038] Wherein, the force receiving block c3 includes an upper connection plate c31, a suction block c32, a lower swing plate c33, and a suction block c34. The suction block c32 is embedded in the inner position of the lower swing plate c33, and the lower swing plate c33 and the suction block The bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com