Fixed-angle extrusion glass cement glue-flowing tube

An extrusion type, glass glue technology, applied in the direction of construction, building construction, etc., can solve the problems of cumbersome operation, poor sealing effect, waste of glass glue, etc., and achieve the effects of improving sealing effect, saving materials, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

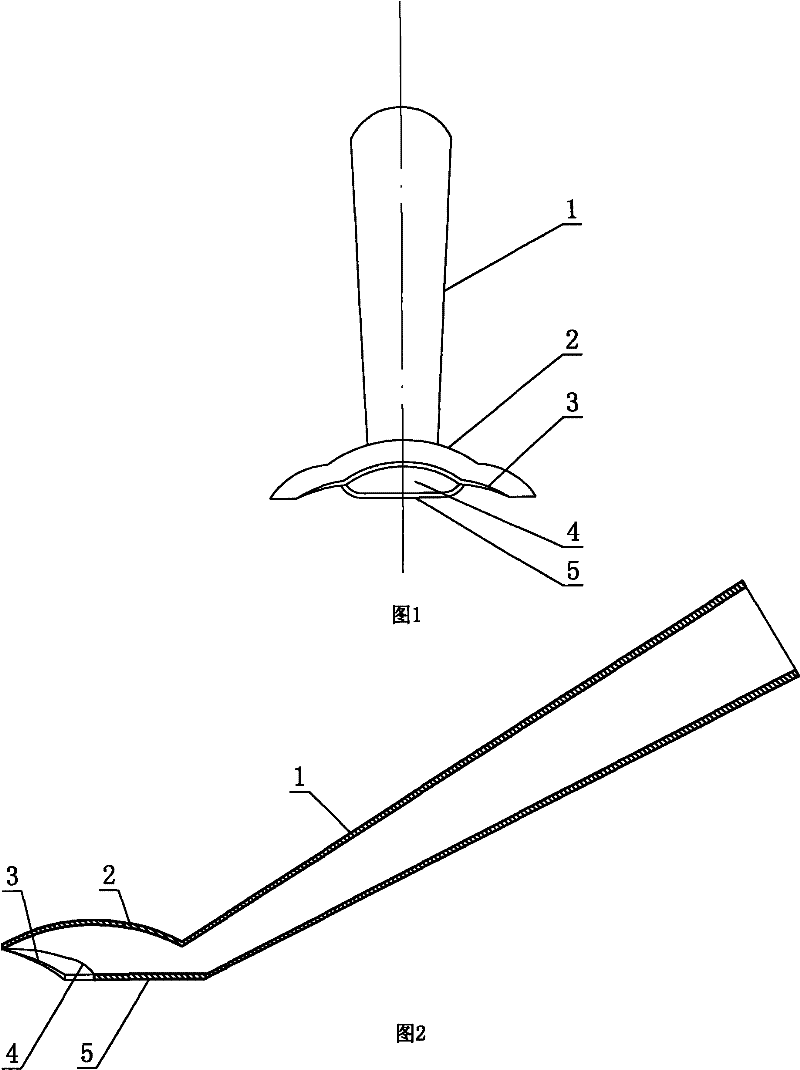

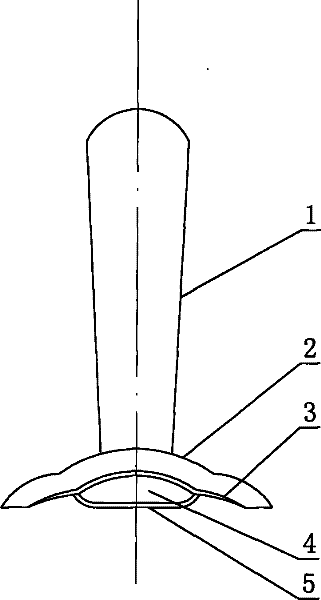

[0012] The fixed-angle extrusion type glass glue outlet hose is composed of a sleeve handle 1, a top shell 2, a glue flap 3 and a glue outlet 4. Wherein, the sleeve handle 1 is a tapered cylinder with a large upper part and a smaller lower part. The lower end of the sleeve handle 1 is an arc-shaped top shell 2 integrated with the sleeve handle 1. The handle 1 is an integral positioning plate 5 which jointly forms a semi-elliptical glue outlet 4 whose cross-section is a long axis and a horizontal direction. The positioning plate 5 is a flat plate, and the positioning plate 5 forms an included angle of 20° with the axis line of the sleeve handle 1 . Both sides of the top shell 2 are two glued flaps 3 integral with the top shell 2. The glued flaps 3 are arc-shaped shells. The distance in the vertical direction of the bottom is 1 mm. When glueing, first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com