Glazing including a network of conductive wires

A glass, door and window technology, used in printing, printing devices, electric heating devices, etc., can solve problems such as damage to the optical quality of glass doors and windows

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

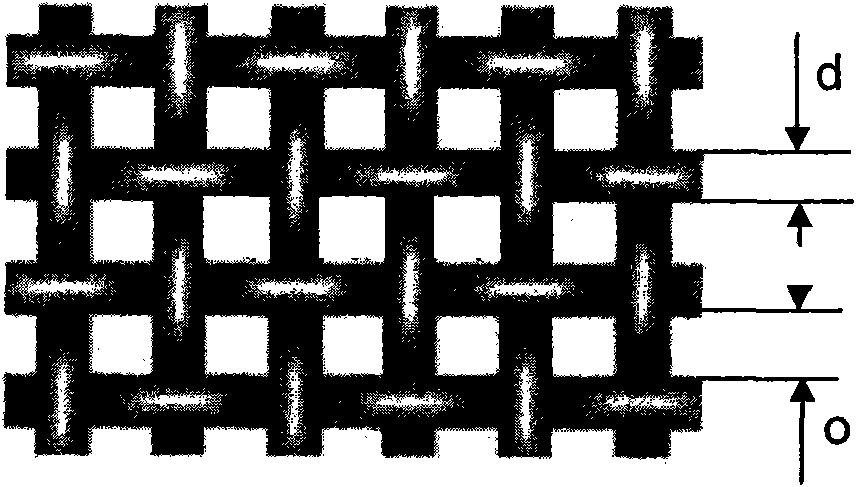

[0057] figure 1 A model showing fabrics that can be used for screen printing applications. The fabric shown shows equally sized, regularly interlaced warp wires 1 and weft wires 2 . The mesh diameter O is usually on the order of the diameter d of the fabric wire. The opening is square as shown.

[0058] Depending on the application, the fabric exhibits other characteristics such as different warp and weft threads, meshes that vary according to the screen area, etc.

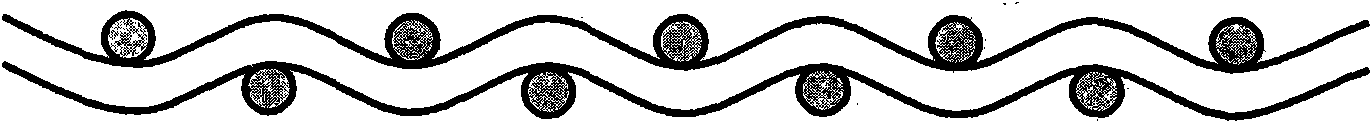

[0059] figure 2 The configuration of wires 1 and 2 in the fabric is shown in cross-section. This figure shows in particular the structural configuration of the screen fabric surface in an enlarged manner. It is obvious that the enlarged surface of the wire is not flat but conforms to the undulations of the wire. The configuration of the surface takes into account the size of the wires, the mesh, and the tension of the fabric.

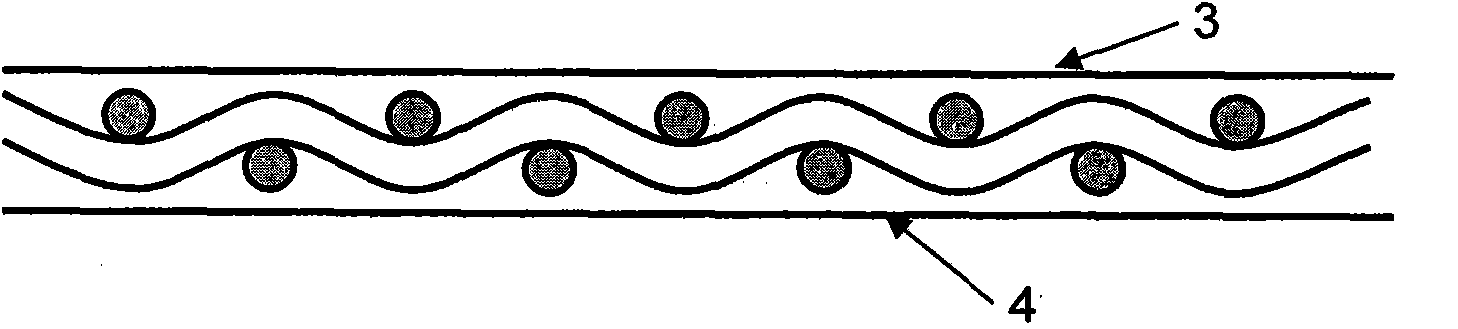

[0060] image 3 Fabric covered with photosensitive coating 3 is shown. Regula...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistance | aaaaa | aaaaa |

| Roughness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com