Pile foundation protection structure and protection method

A protective structure and pile foundation technology, which is applied in the field of pile foundations, can solve problems such as riprap accumulation, and achieve the effects of convenient maintenance, stability assurance, and simple implementation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

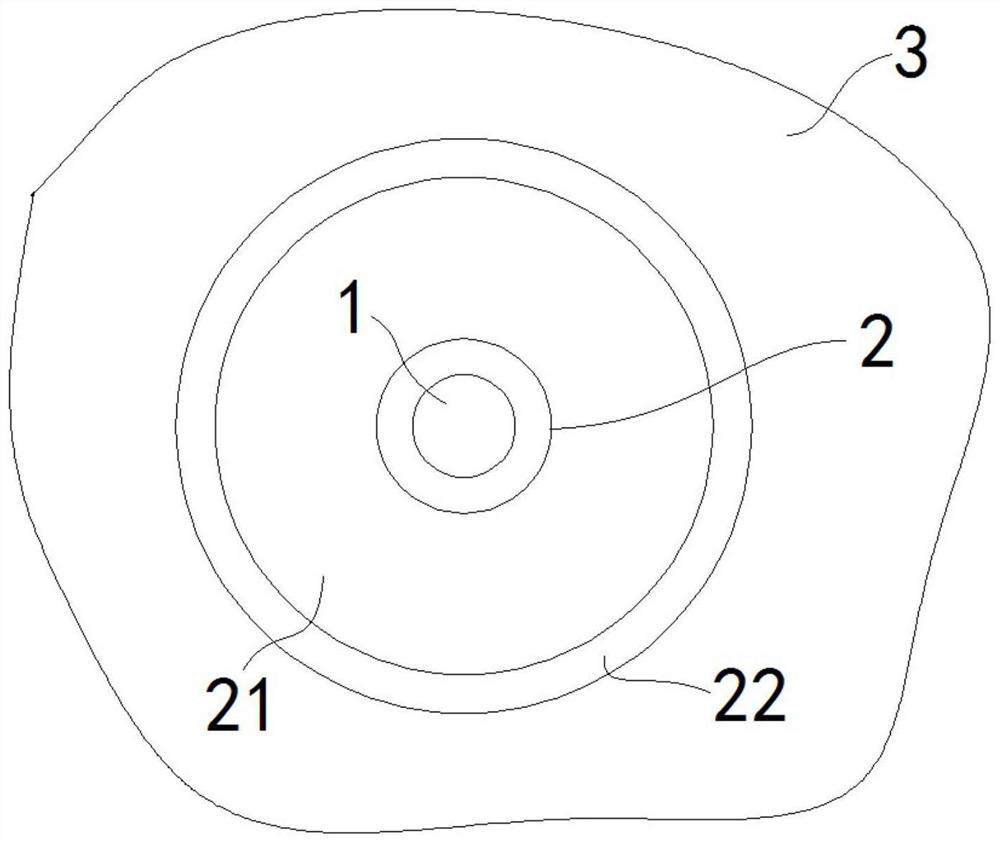

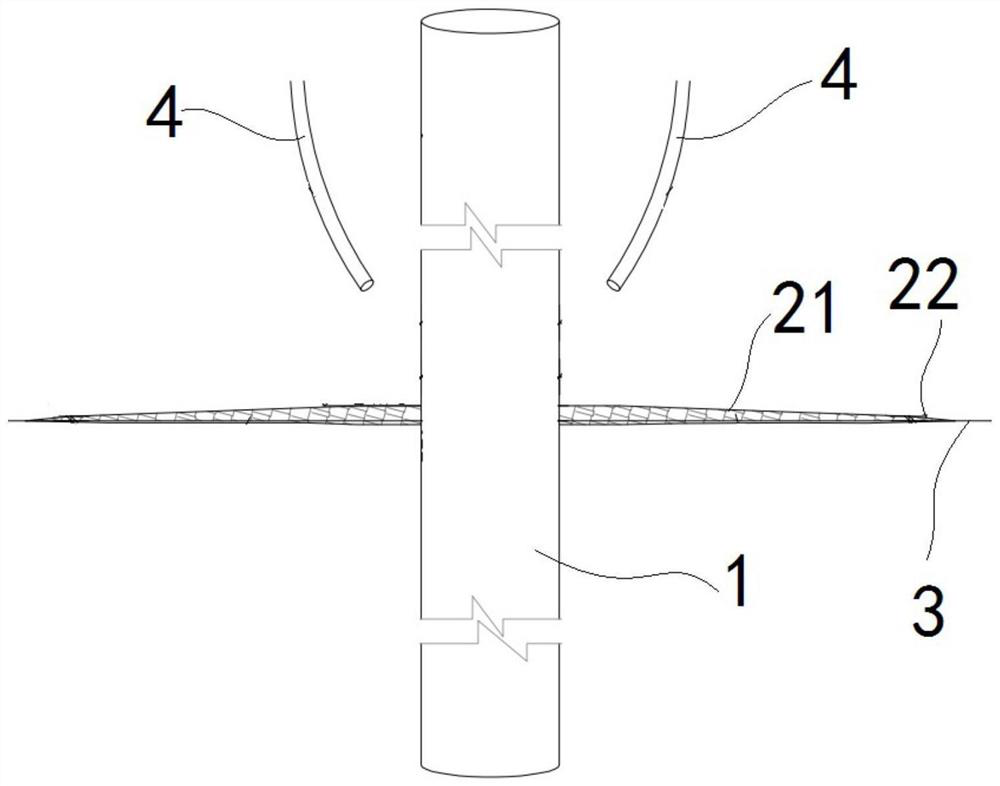

[0037] This embodiment provides a specific implementation of the pile foundation protection structure, such as figure 1 and figure 2 As shown, by laying a solidified soil layer 2 around the pile foundation 1, the solidified soil layer 2 is in contact with the seabed 3 and laid above the seabed 3, the solidified soil layer 2 can be closely attached to the mud surface of the seabed 3, wherein, The solidified soil layer 2 comprises mud and curing agent, and the mud makes the solidified soil layer 2 have a certain fluidity, and the solidified soil layer 2 and the materials such as secondary minerals in the mud surface of the seabed 3 can undergo a series of hydration, The hydrolysis reaction produces a large number of various hydration gel products, which will cement and wrap the fine particles in the mud surface, making them aggregate, and cement the loose soil into a whole with a certain strength, and then in the A solidified soil layer 2 with a certain strength is formed arou...

Embodiment 2

[0046] The present embodiment provides a specific implementation of the protection method. In the present application, the diameter of the pile foundation 1 is 6.9m. After the pile foundation 1 is inserted on the seabed 3, use mud and curing agent to make solidified soil, mud and The mass ratio of the curing agent ranges from 11.4% to 13.9%. Among them, in this embodiment, 12.5% of the solidified soil is used for mixing to obtain a solidified soil whose slump meets the requirements, and then the blow-fill pipe 4 The outlet end extends to the pile foundation 1 and is inserted above the root of the seabed 3 to fill with solidified soil. After the solidified soil is filled around the pile foundation 1, it flows under the influence of its own gravity. With the continuous filling of the solidified soil, the solidified soil The area of the soil around the pile foundation 1 becomes larger and larger until the distance between the edge of the solidified soil and the outer periphera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com