Cycle rim and tubeless mounting assembly for cycle

A technology for installing components and rims, which is applied in the field of rickshaws, especially the installation components of bicycles, and rickshaws. It can solve the problems of bead falling off and detachment, and achieve the effect of ensuring inflation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The figures are not shown to scale for ease of understanding.

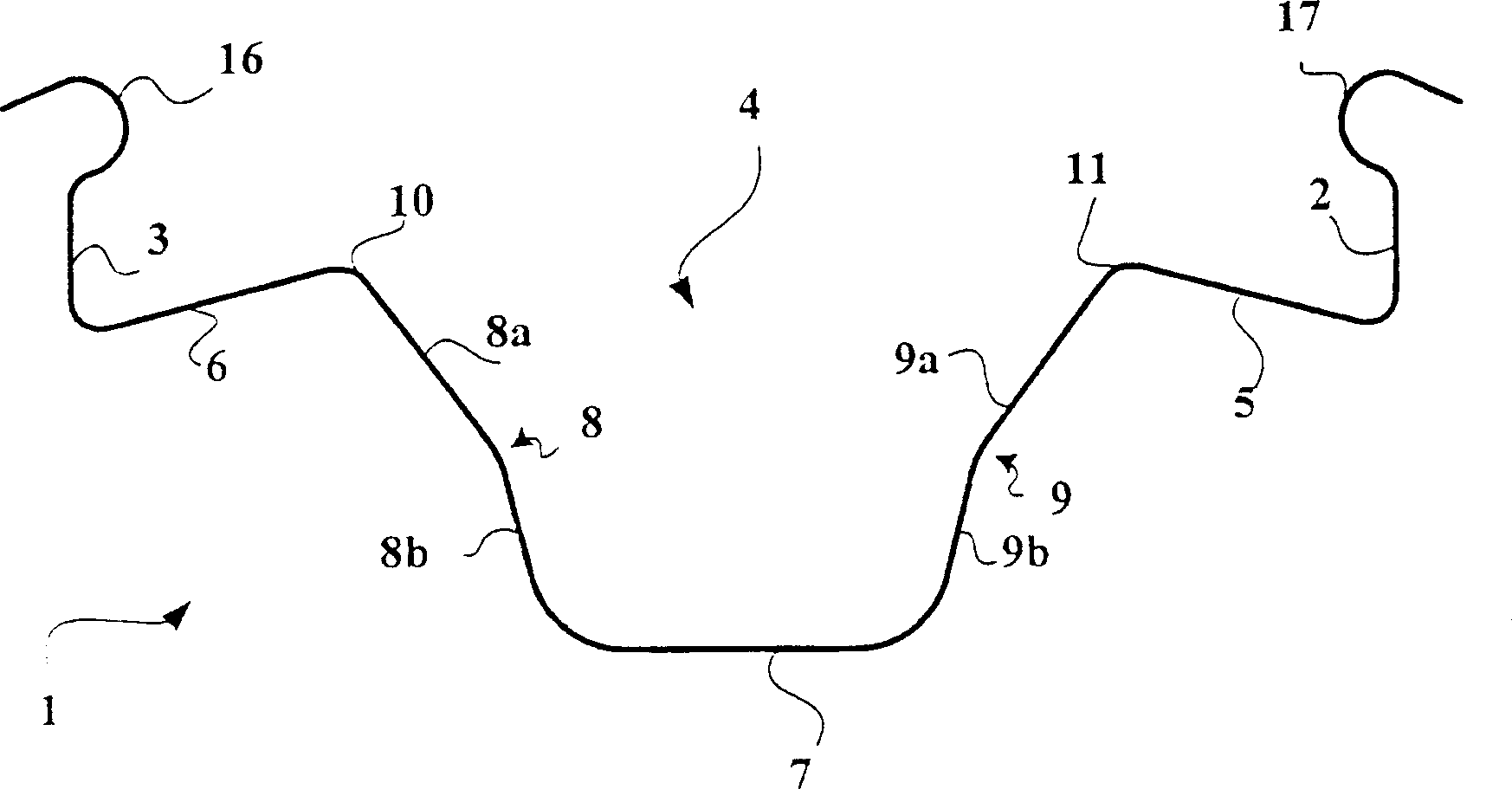

[0052] figure 1 A schematic diagram of a radial section of a rim 1 according to the invention is shown. The rim comprises two flanges 2 , 3 at the outer ends, which connect the groove 4 via the bead seats 5 , 6 . The orientation of the flanges 2 and 3 is substantially parallel to the annular midplane. The bead seats 5 and 6 form an angle of about 20° with the axis of rotation. On the one hand, the groove 4 comprises a groove bottom 7 and two side walls 8, 9 which are generally inclined compared to the rims normally used for bicycles. These walls 8 and 9 according to the invention are as figure 1 Shown is made in two parts; first, the lower part 8b, 9b, which forms an angle of about 30° and is centered on the annular midplane, and the second or upper part 8a, 9a, which forms an angle of about 65° corner and centered on the midplane of the ring. In the upper part said flange further comprises hook mea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com