Gas-turbine combustion chamber with fuel nozzle, burner with such a fuel nozzle and fuel nozzle

A gas turbine and fuel nozzle technology, applied in gas fuel burners, burners, combustion chambers, etc., can solve problems such as shortening the service life of fuel nozzles, and achieve good cooling effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

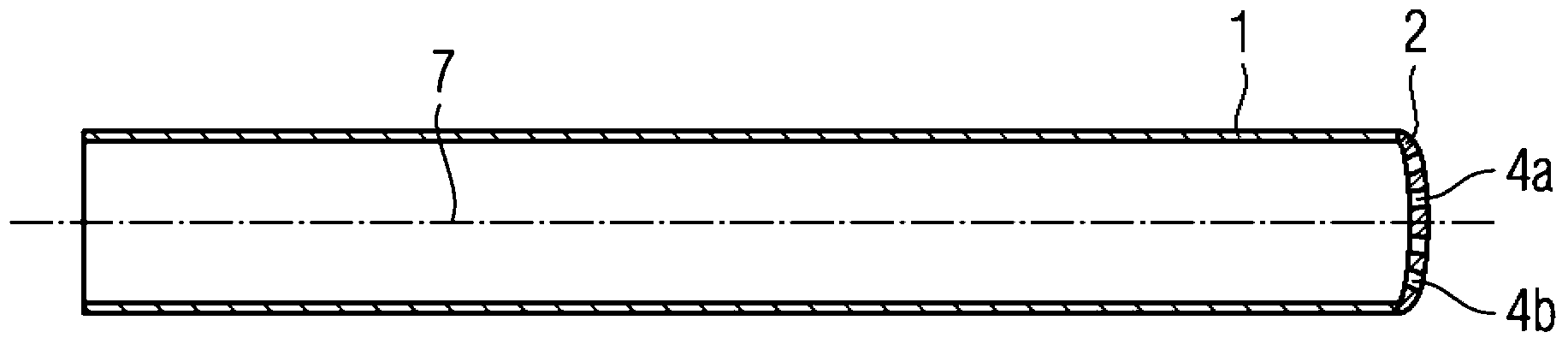

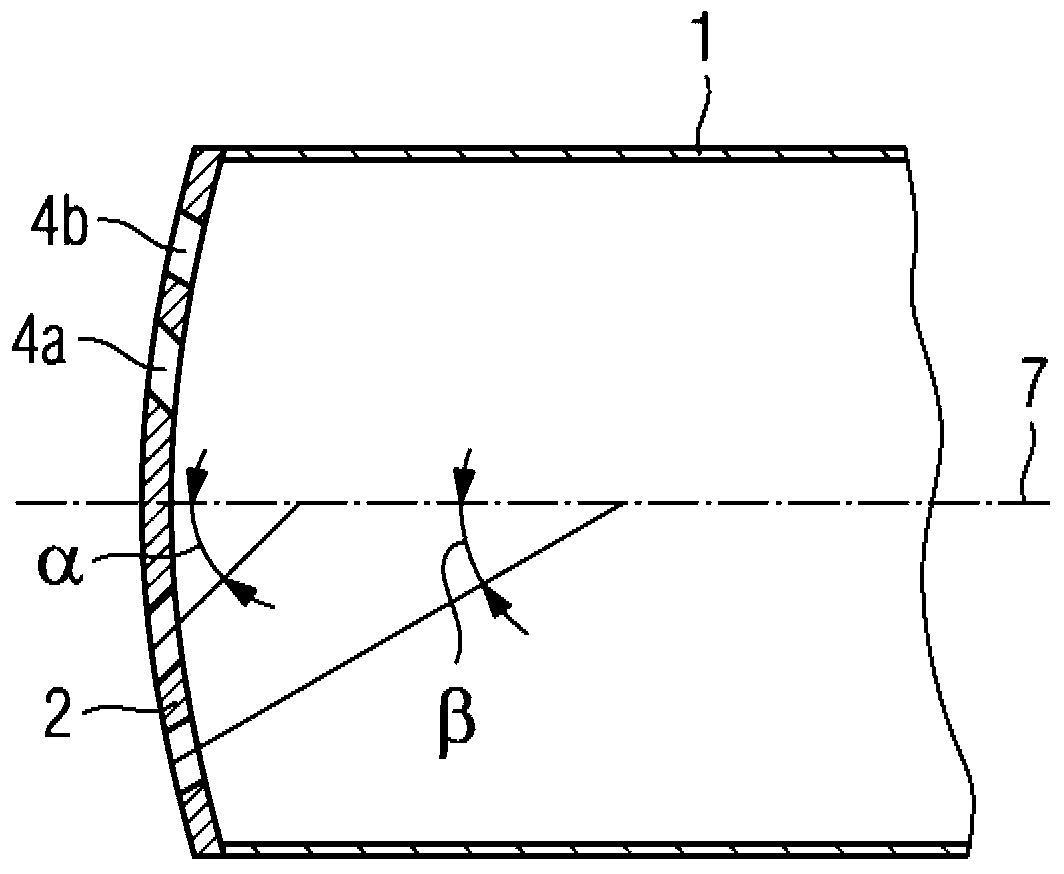

[0019] figure 1 A fuel nozzle with a cylindrical nozzle tube 1 and a convex nozzle cover 2 is shown. The fuel nozzle 1 has a cylinder axis 7 . A fluid, in particular fuel, is introduced into the fuel nozzle 1 and then exits through the through-openings 4a, 4b to a downstream, not shown combustion chamber.

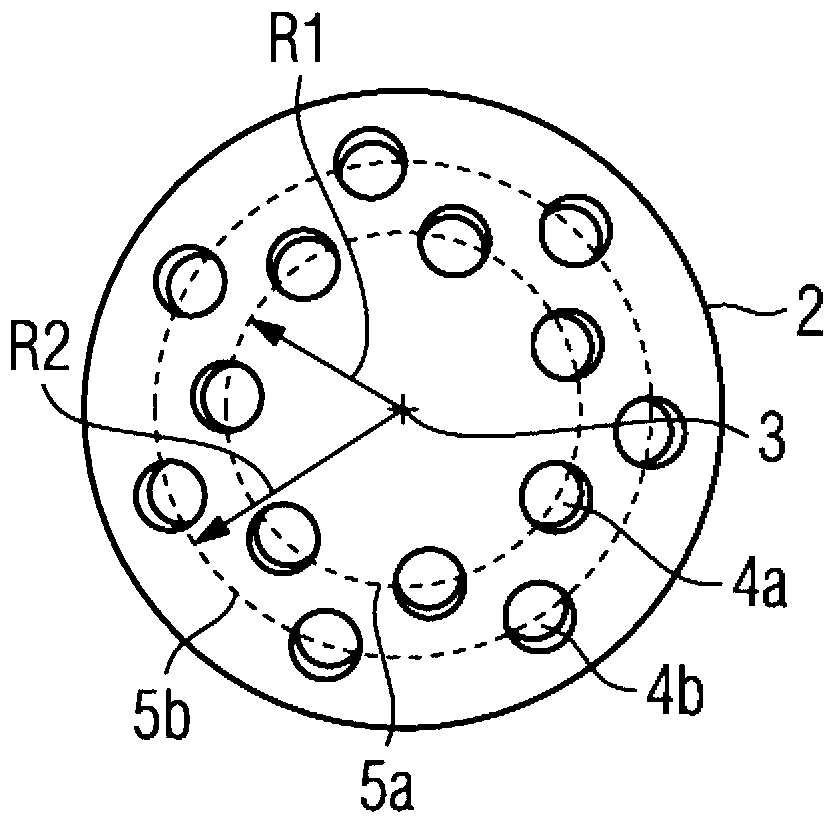

[0020] figure 2 The nozzle cover 2 is shown viewed from the front. The nozzle cover 2 has a center point 3 . Furthermore, the nozzle cover 2 has a plurality of throughflow openings 4a, 4b. The through-openings 4 a , 4 b are arranged on at least two annular lines 5 a , 5 b at different radial distances R1 , R2 from the center point 3 . Wherein, the through hole 4a is arranged on a circular line 5a whose distance from the center point 3 is a radius R1. At this time, the ring line 5a having the smaller radius R1 is referred to as the radially inner ring line 5a. In contrast to the nozzles of the prior art, multiple fuels or (if the fuels are premixed) multiple fuel-ai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com