Inner annular backoff demoulding mechanism for injection mould cavity piece

A technology of demoulding mechanism and inner ring, which is applied in the field of inner ring undercut ejection mechanism of injection mold cavity parts, which can solve the problems of low product yield, small width of inner ring undercut, easy deformation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

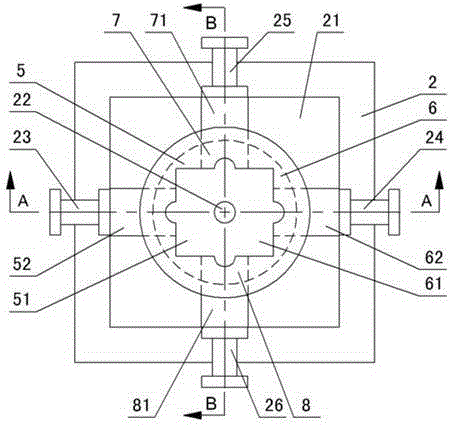

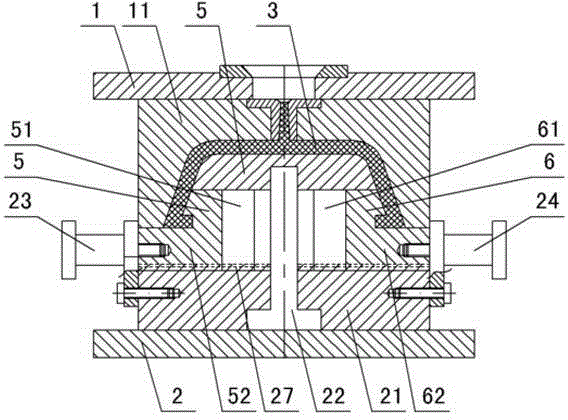

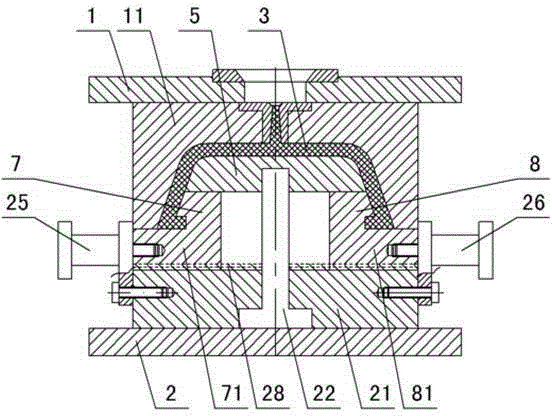

[0015] The invention relates to a ring-shaped undercut stripping mechanism in an injection mold cavity body, such as figure 1 — Figure 9 As shown, it includes an upper doubler plate 1 and a lower doubler plate 2, a cavity 11 is set under the upper doubler plate, a sliding seat 21 is set on the lower doubler plate, a core is set on the sliding seat, and there is an injection molding between the core and the cavity. The plastic part 3 is formed with an inner annular undercut 31 under the plastic part. It is characterized in that: the support column 22 is set in the slide seat 21, and the left oil cylinder 23, the right oil cylinder 24, the front oil cylinder 25 and the outer side of the slide seat 21 are installed. Rear oil cylinder 26, sliding seat 21 is shaped on left and right slide rails 27 and front and rear slide rails 28, and described mold core comprises the main mold core 4 of top, is provided with left inner core pulling 5, right inner core pulling 6, The front inner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com