Elevator traction system

A traction system and elevator technology, applied in the elevator field, can solve the problems of difficult to guarantee rigidity and strength, high cost, limited application, etc., and achieve the effect of saving hoistway space, good rigidity and strength, and high safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

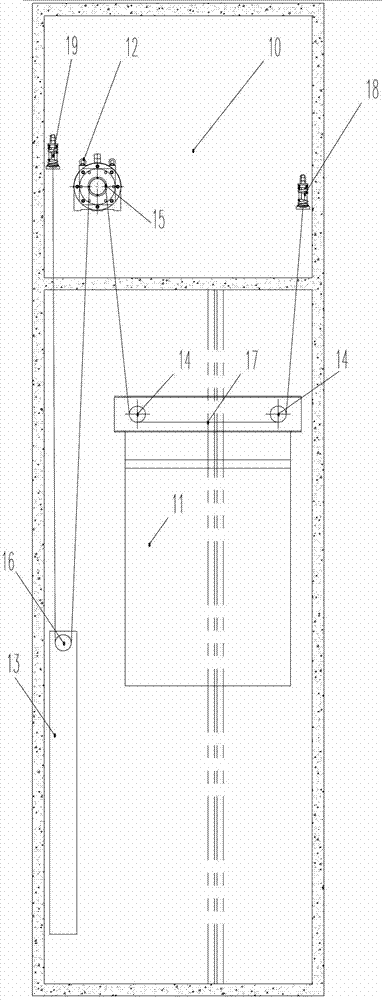

[0032] The present invention is an elevator traction system 10, such as figure 1 , including the guide pulleys 14, 15, 16 respectively located on the elevator car frame 11, the elevator main frame 12 and the counterweight 13, and the guide pulleys 14, 15, 16 are designed through improvement, and can be well used for flat type The guide of composite steel belt 17. Owing to adopting composite steel belt 17 as suspension and traction assembly, composite steel belt 17 is made up of multi-strand steel wire rope, and the diameter of steel wire rope can be less than 2mm, and then the diameter of guide pulley 14,15,16 can be 80mm, what present embodiment design is 95mm. The reduction of the diameter of the guide pulley enables the pulley and the load-bearing main shaft to be integrated. That means that the elevator car frame 11, the elevator main frame 12 and the counterweight 13 only need to assemble a pulley shaft (that is, the load-bearing main shaft), and the pulley shaft is pr...

Embodiment 2

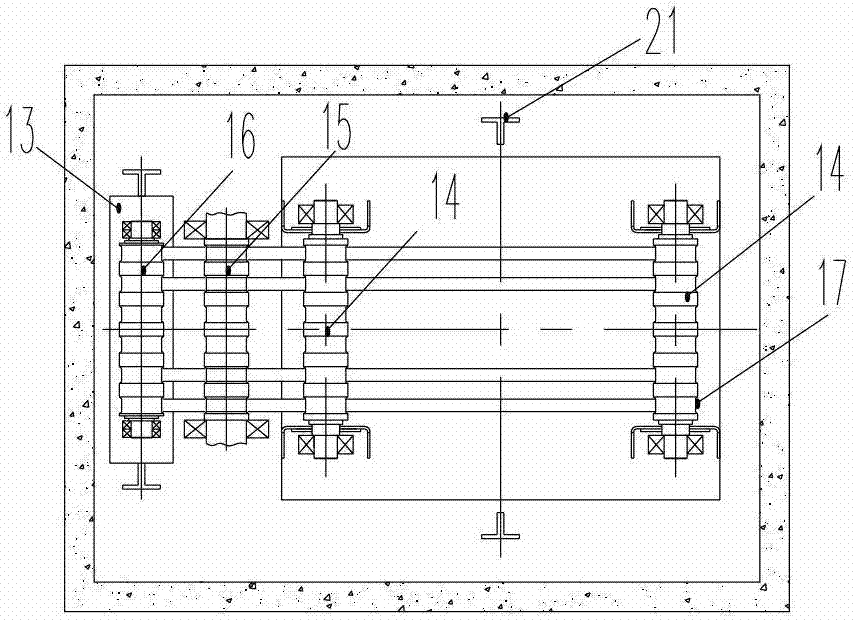

[0041] Such as Figures 9 to 11 Shown is a layout plan with a machine room structure. There are two guide pulleys 20 transition between the guide pulley 15 of the elevator main engine 12 and the guide pulley 14 of the car frame 11, and the guide pulleys 14 are respectively placed on the top of the elevator car frame 11. The front and rear positions on the elevator can realize the simplification of the structure of the elevator system. Simultaneously, the composite steel belts 17 on the car side and the counterweight side can be placed vertically without offset angle, which greatly improves the running effect of the elevator.

[0042] Other structures are with embodiment 1.

Embodiment 3

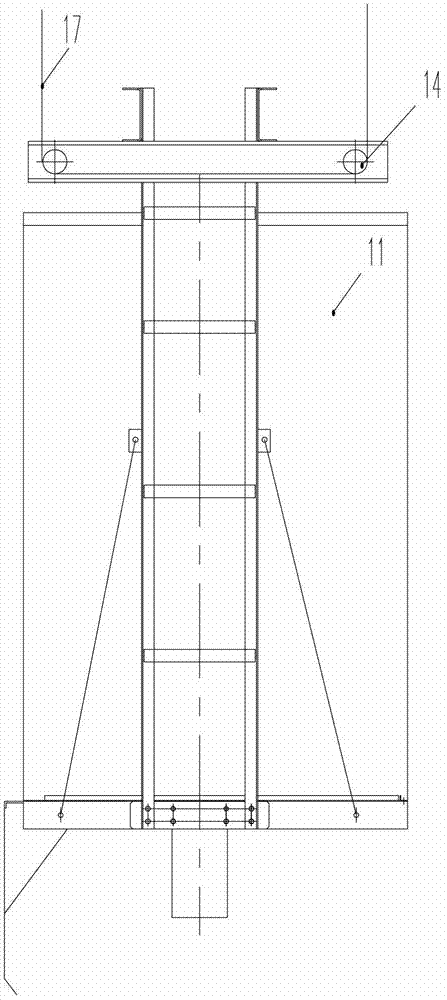

[0044] Such as Figures 12 to 14 In order to be provided with the layout scheme of the machine room structure, there are two guide pulleys 20 transition between the guide pulley 15 of the elevator main frame 12 and the guide pulley 14 of the car frame 11, and the guide pulley 14 of the car frame 11 is placed on the car frame 11. The middle of the upper beam realizes the simplification of the structure of the elevator system. Simultaneously, the composite steel belts 17 on the car side and the counterweight side can be placed vertically without offset angle, which greatly improves the running effect of the elevator. In addition, a guide pulley 14 is also saved on the car frame 11, reducing the cost of the elevator.

[0045] Other structures are with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com