Xsc50 cold-shrinkable plastic-lined aluminum alloy pipe for gas, piping system and preparation method

A technology for aluminum alloy pipes and gas, which is applied in the direction of pipes/pipe joints/fittings, pipes, rigid pipes, etc. It can solve the problems of insufficient strength and rigidity at high temperature, low heat resistance level, and restrictions on the use environment, and achieve good strength and rigidity. High heat resistance and good toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solution of the present invention will be further described in detail below in conjunction with specific examples, but the protection scope of the present invention is not limited to the following description.

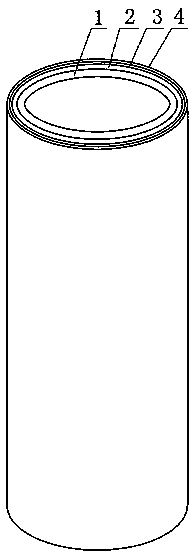

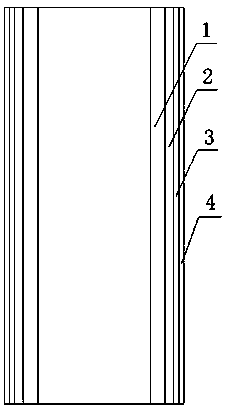

[0026] Such as figure 1 and figure 2 As shown, the XSC50 cold-shrinkable plastic-lined aluminum alloy tube for gas is composed of XSC50 resin tube layer 1, aluminum tube layer 2, oxide film protection layer 3 and high adhesion anti-oxidation and corrosion layer 4, which are arranged in sequence from the inside to the outside. The thickness of the XSC50 resin tube layer 1 is x, the thickness of the aluminum tube layer 2 is y, the thickness of the oxide film protection layer 3 is 9-11 μm, the thickness of the anti-oxidation corrosion layer 4 with high adhesion is 20-25 μm, and the thickness of the 2.5mm ≥x:y≤3mm.

[0027] Preferably, the 1.25mm≤x≤2.1mm, 0.5mm≤y≤0.7mm.

[0028] Preferably, the thickness of the XSC50 resin tube layer 1 is 1.7mm-1.9...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tack-free time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com