Patents

Literature

39results about How to "Good strength and stiffness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

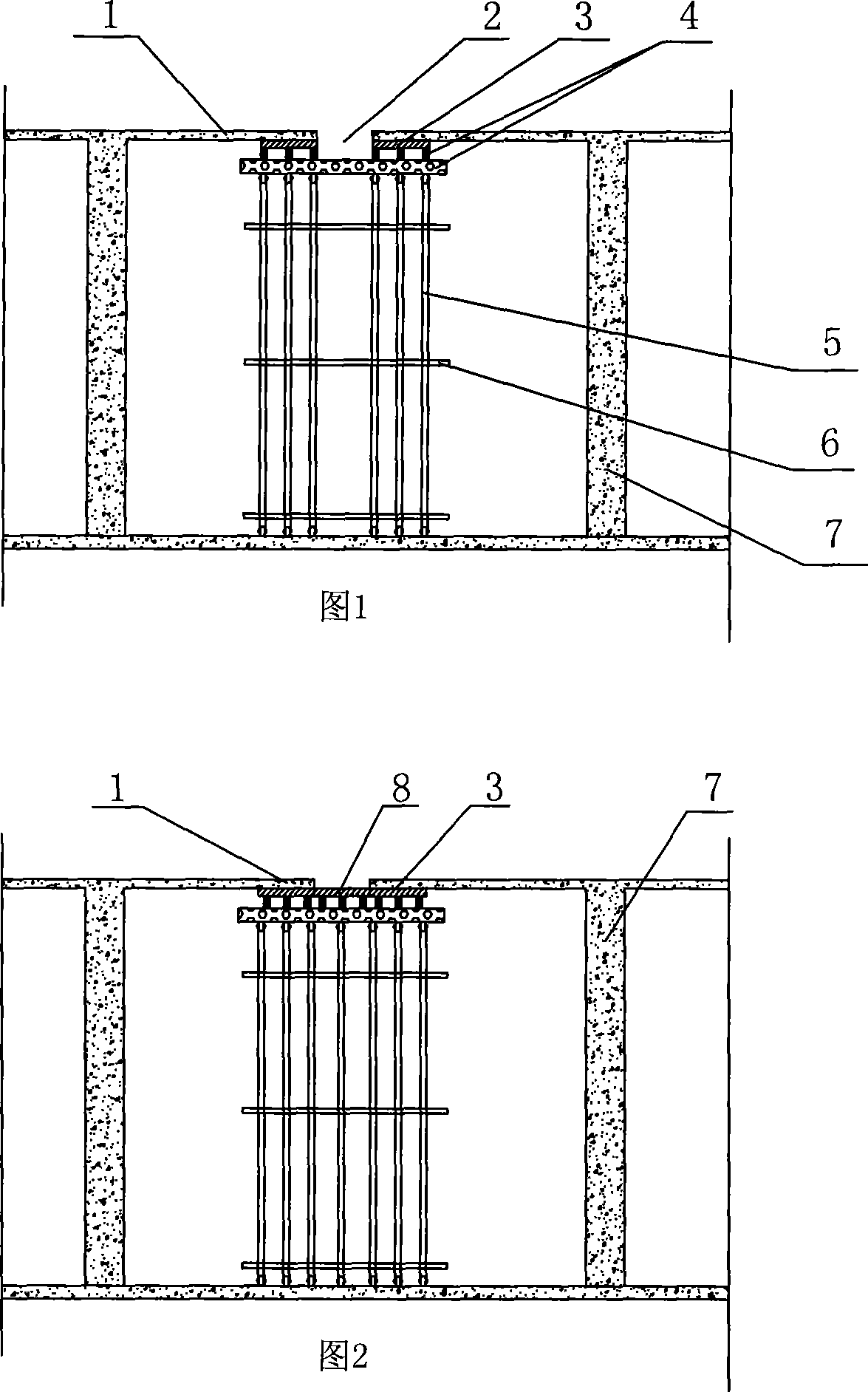

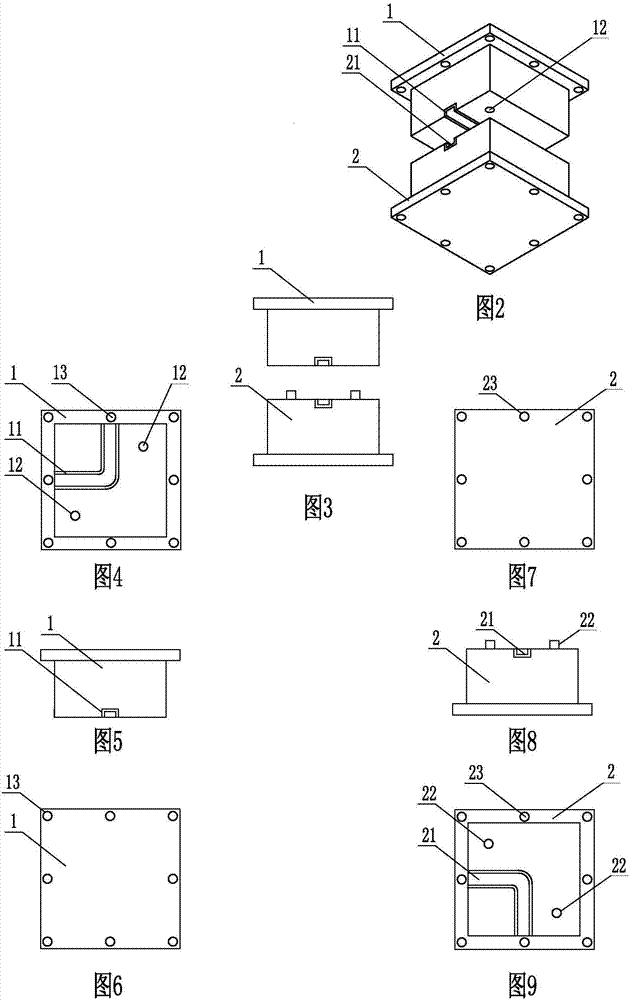

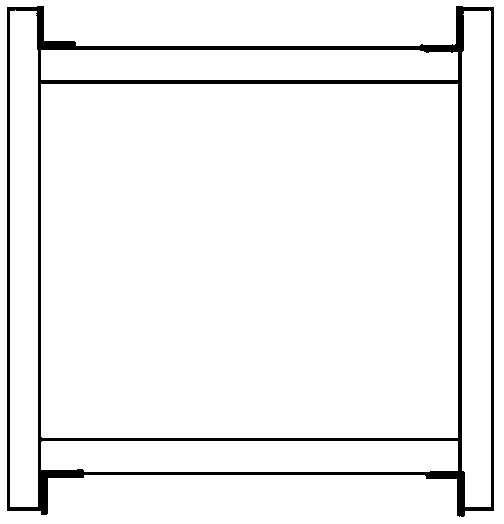

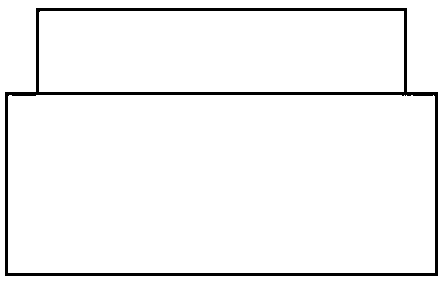

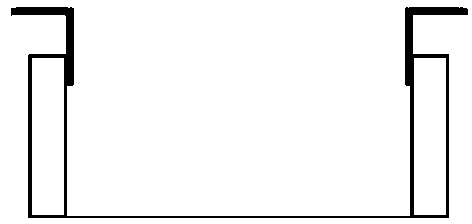

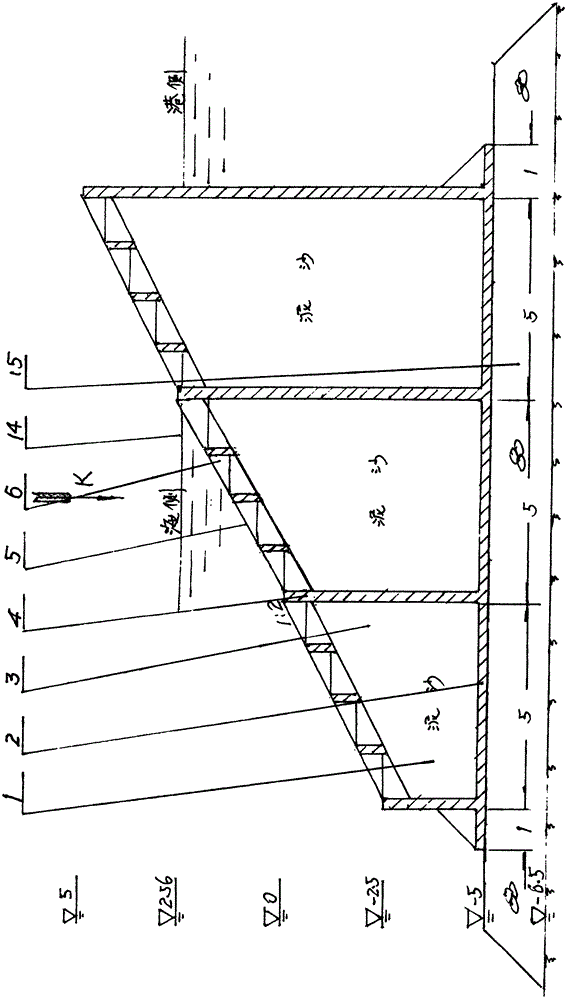

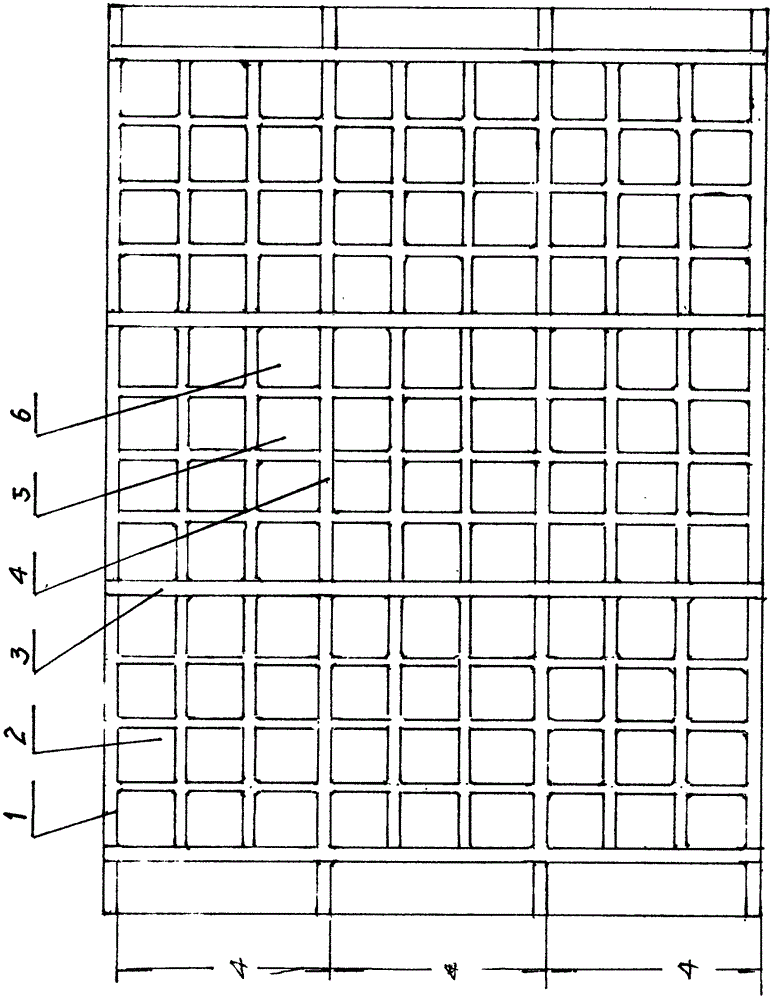

Construction method for after-pouring band beam-slab template

InactiveCN101144328AEasy to operateGood strength and stiffnessForms/shuttering/falseworksBuilding material handlingRebarConcrete beams

The invention relates to a construction method of a post-pouring strip beam slab template, and is characterized in that the invention comprises the following procedures in sequence: the axial line is rechecked, the beam slab template support is erected, the template of 800 mm-1000 mm width is erected on the both sides of the post-pouring strip, and the reinforcing bar is arranged, the template support becomes an independent system, a concrete beam slab is poured and cured, firstly, the template is removed after the strength of the pouring concrete beam slab reaches the requirement of the template removal, the template on the both sides of the post-pouring strip and the support are not removed, the roughening in the construction joint is cleaned and wetted, the post-pouring strip template is arranged, the epithelium elevation and the smoothness of the pouring strip template after being checked are fixed with the adjacent template at both sides. The invention ensures the wholeness of a post-pouring strip beam slab structure on the both sides, the performance quality of the concrete cast-in-situ at a concrete joint is effectively ensured, in particular to the clean water concrete. Because the method of the invention can not repeatedly remove the post-pouring strip template support system, the mass labor force is saved during the construction, and the construction speed is accelerated, as well as the engineering cost is reduced.

Owner:SHANDONG WANXIN CONSTR

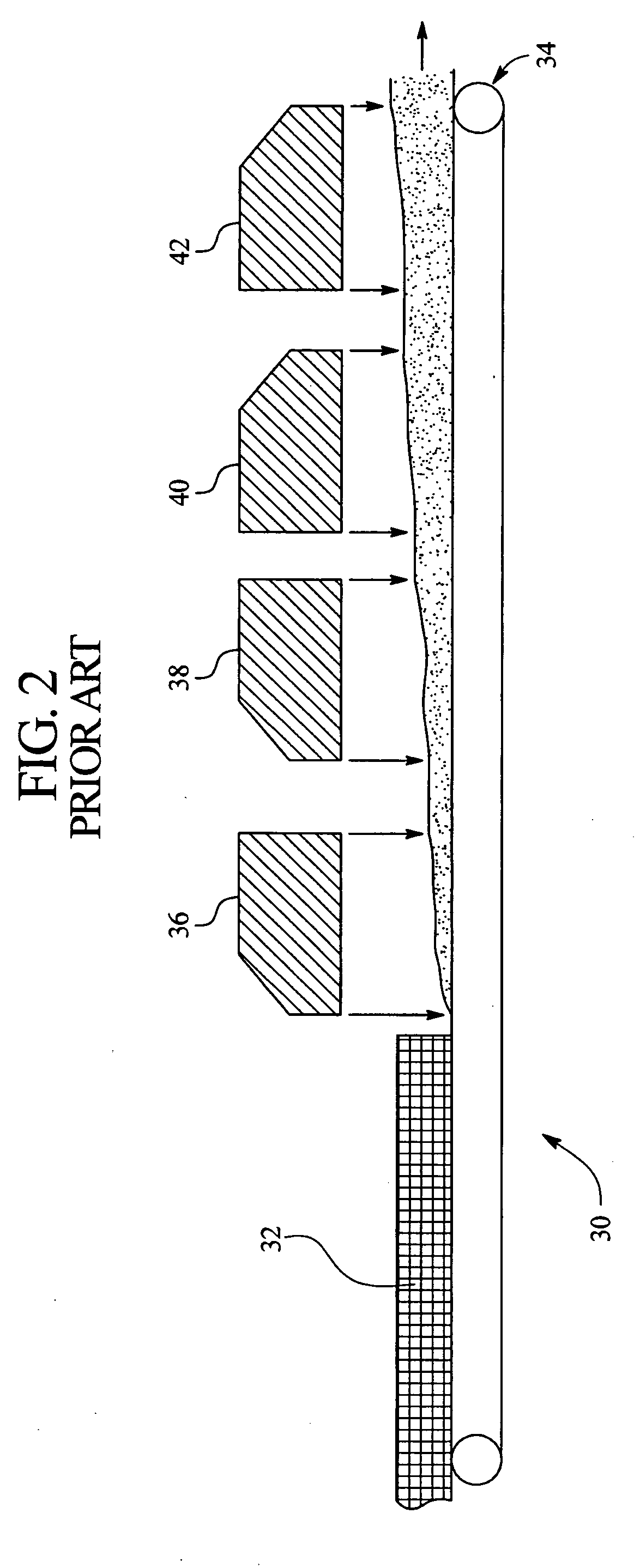

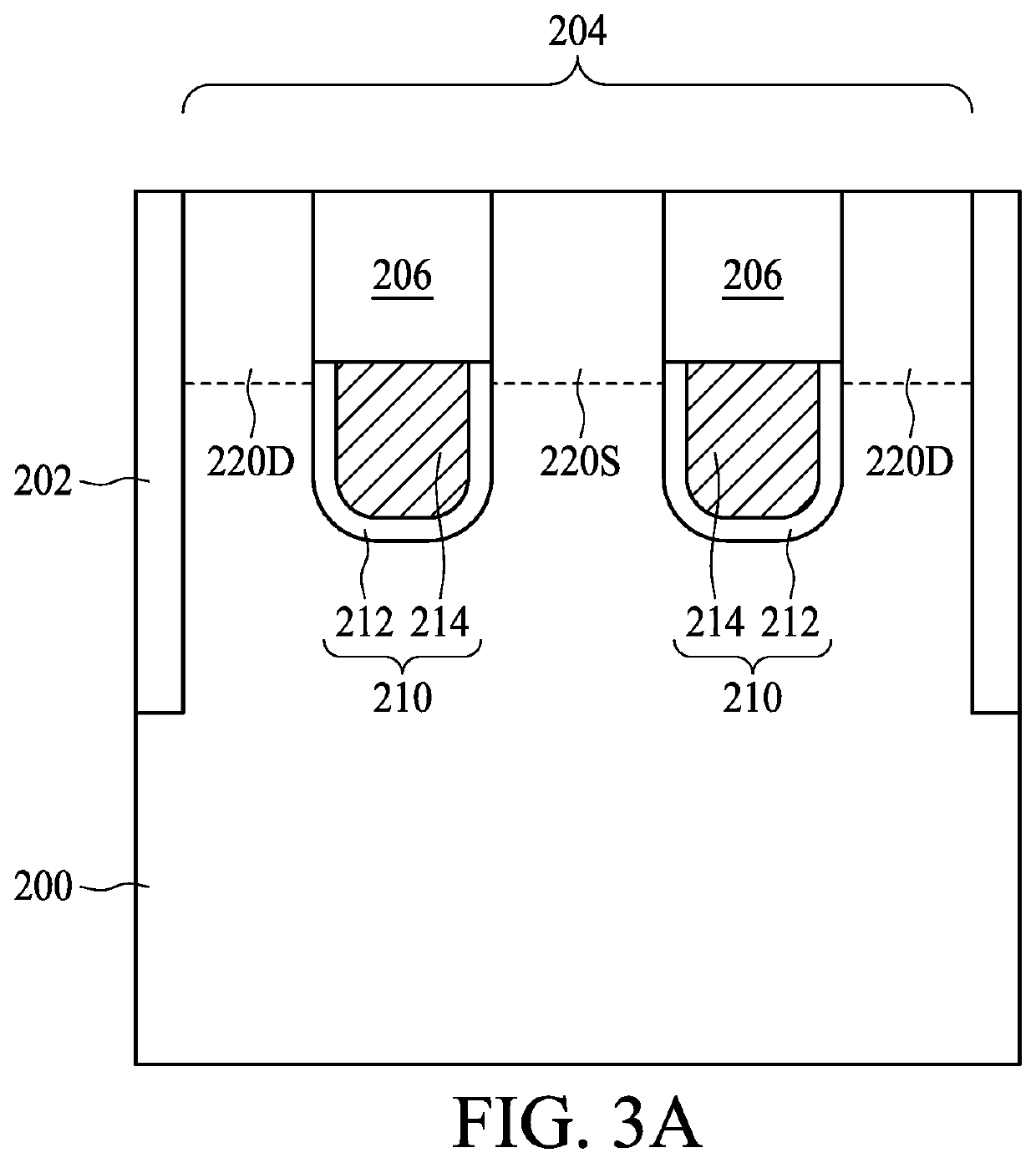

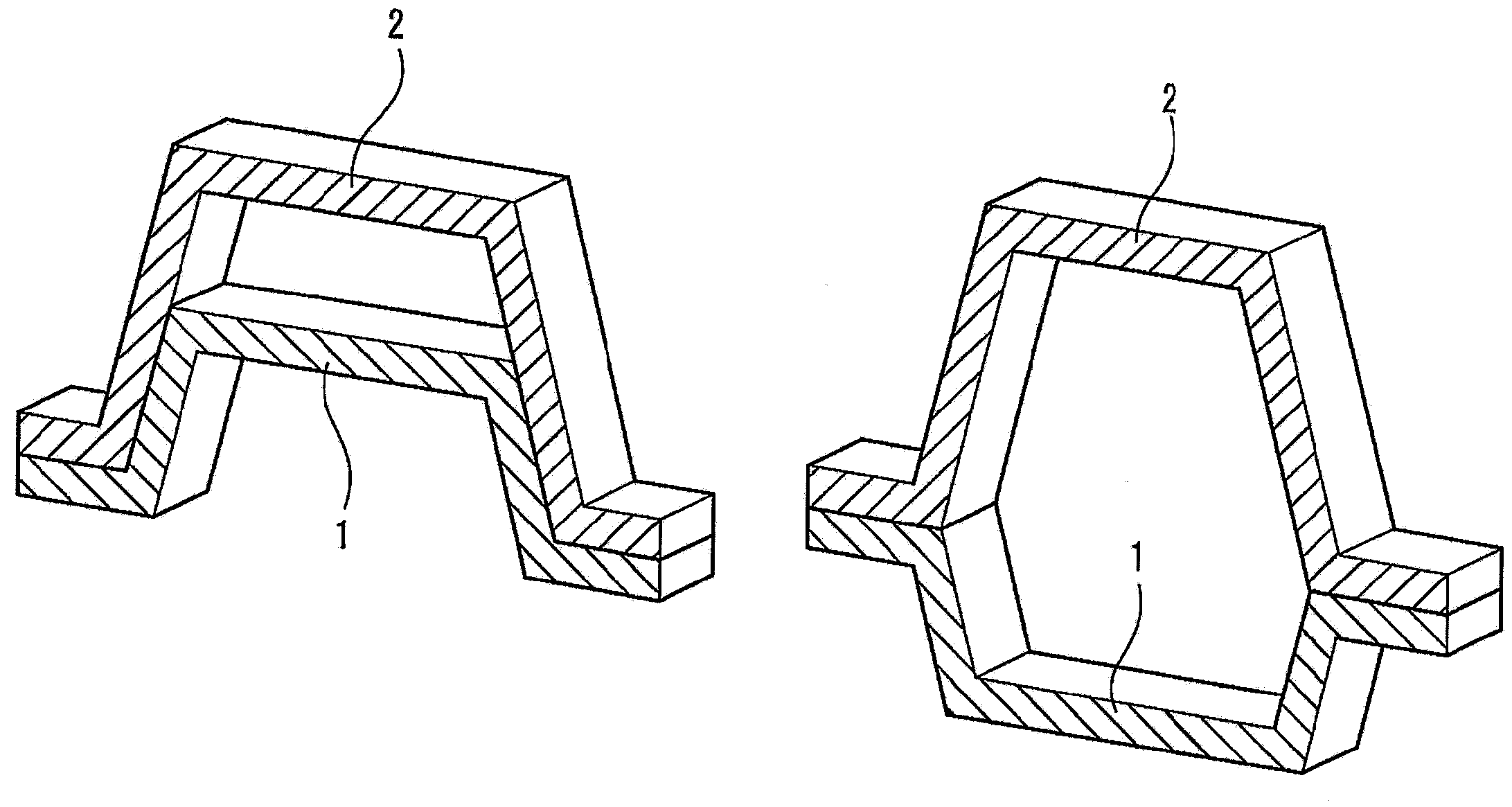

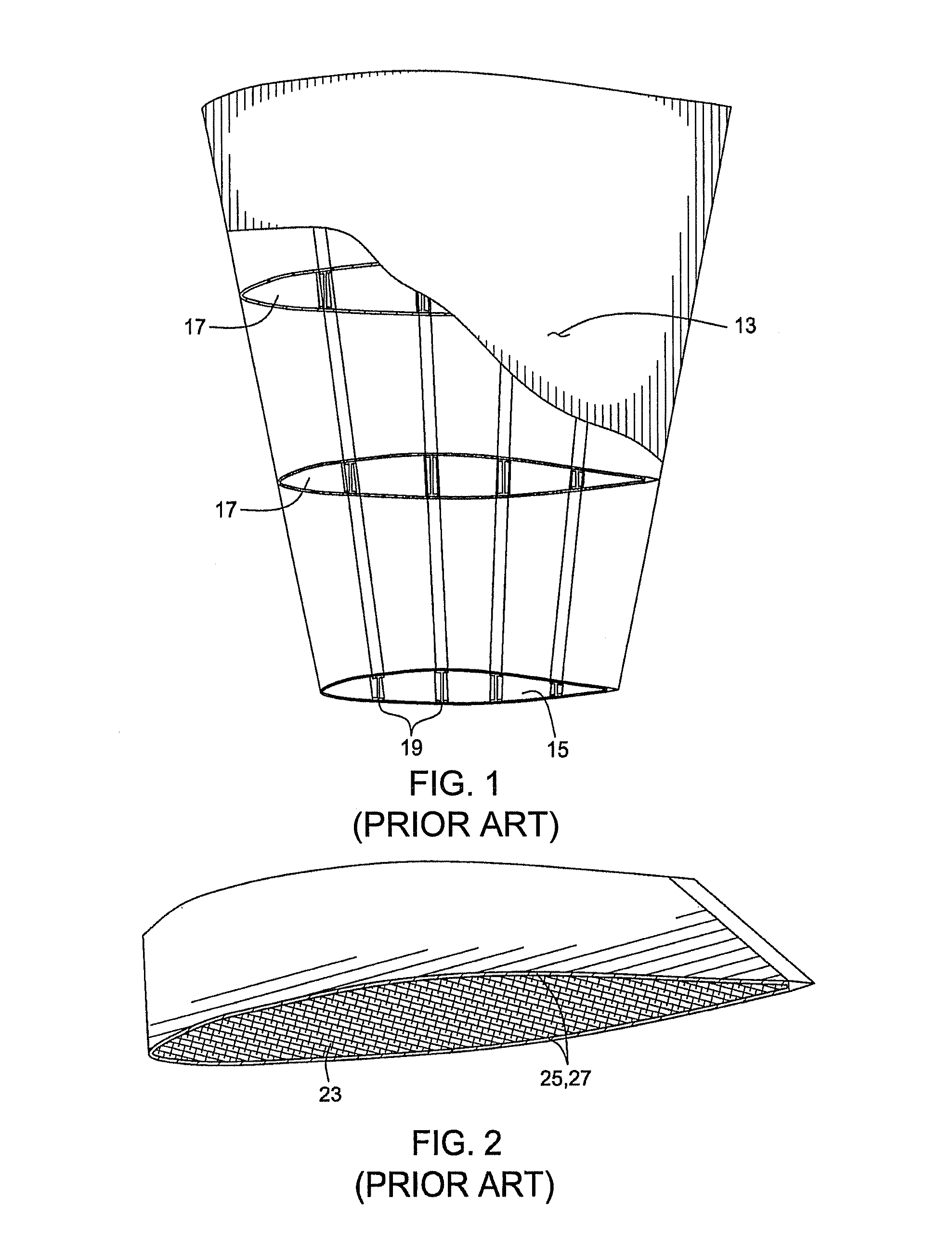

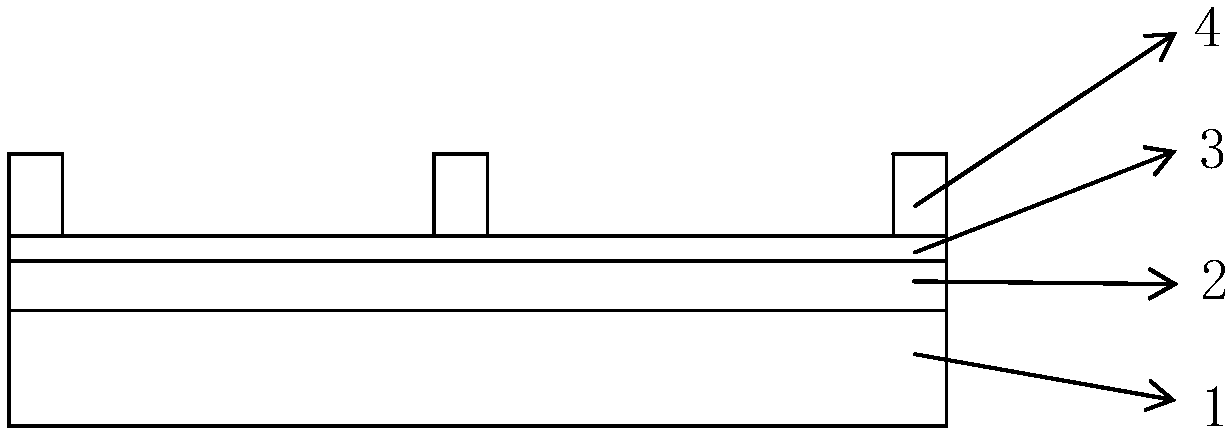

Layered microelectronic contact and method for fabricating same

InactiveUS7005751B2Eliminate requirementsGood strength and stiffnessPrinted circuit assemblingElectrically conductive connectionsDistal portionElectrical contacts

A microelectronic spring contact for making electrical contact between a device and a mating substrate and method of making the same are disclosed. The spring contact has a compliant pad adhered to a substrate of the device and spaced apart from a terminal of the device. The compliant pad has a base adhered to the substrate, and side surfaces extending away from the substrate and tapering to a smaller end area distal from the substrate. A trace extends from the terminal of the device over the compliant pad to its end area. At least a portion of the compliant pad end area is covered by the trace, and a portion of the trace that is over the compliant pad is supported by the compliant pad. A horizontal microelectronic spring contact and method of making the same are also disclosed. The horizontal spring contact has a rigid trace attached at a first end to a terminal of a substrate. The trace is free from attachment at its second end, and extends from the terminal in a direction substantially parallel to a surface of the substrate to the second end. At least a distal portion of the trace extending to the second end is spaced apart from the surface of the substrate. The spaced-apart distal portion is flexible in a plane parallel to the substrate.

Owner:FORMFACTOR INC

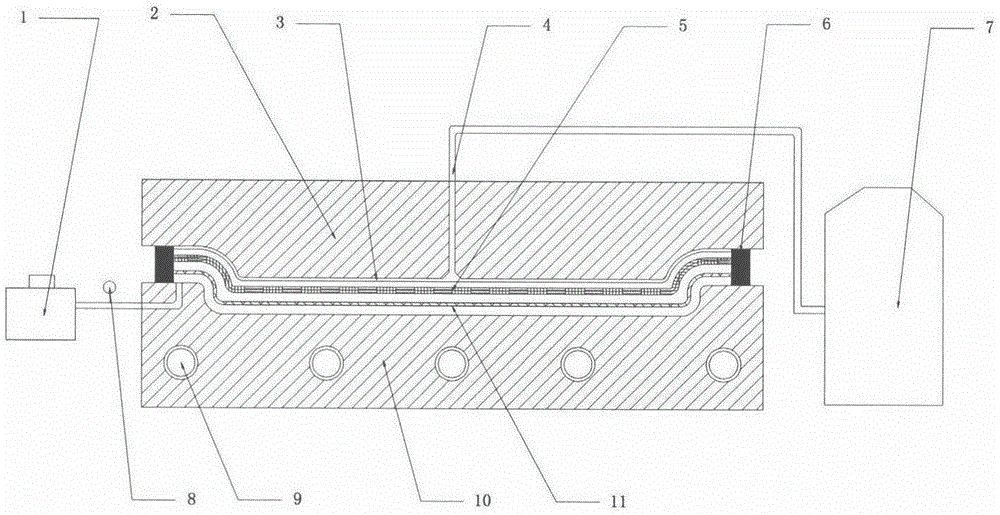

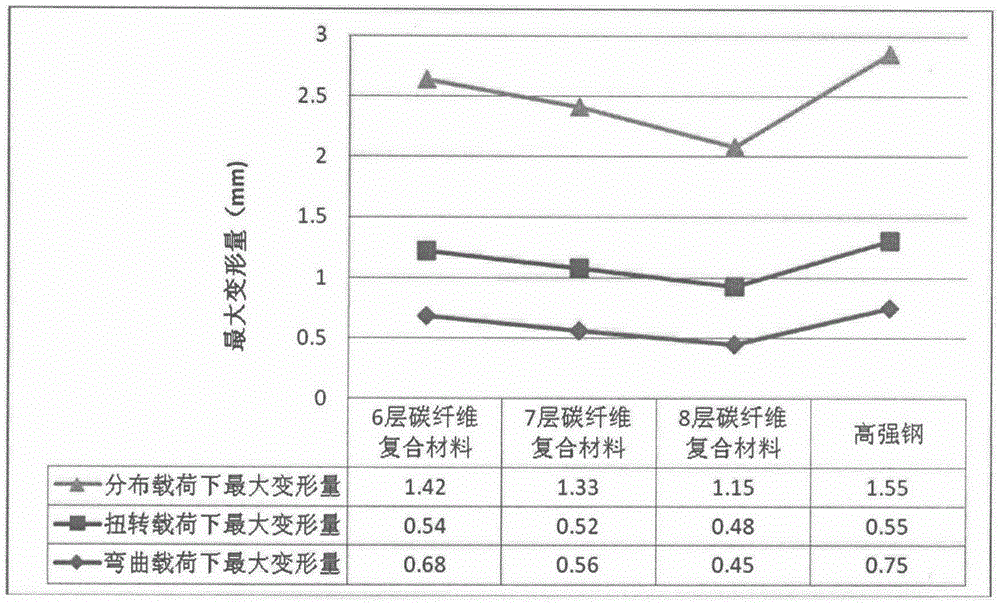

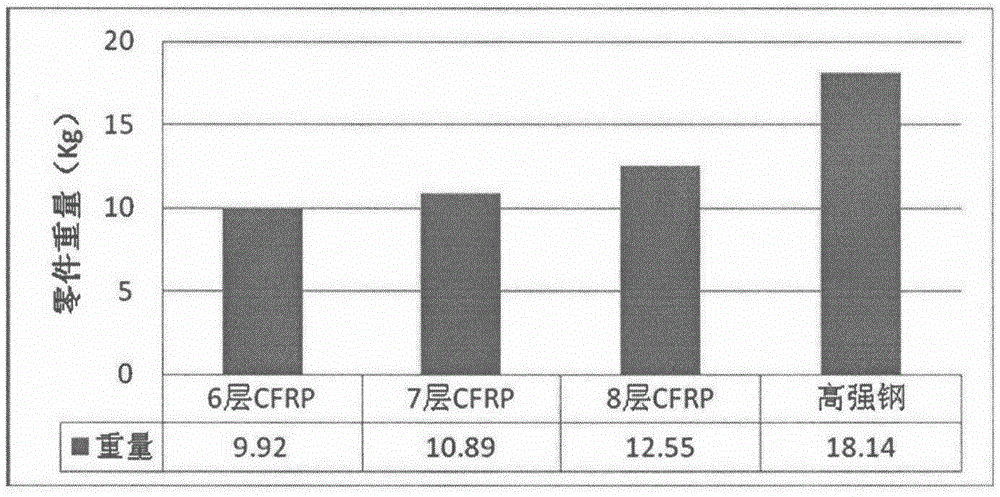

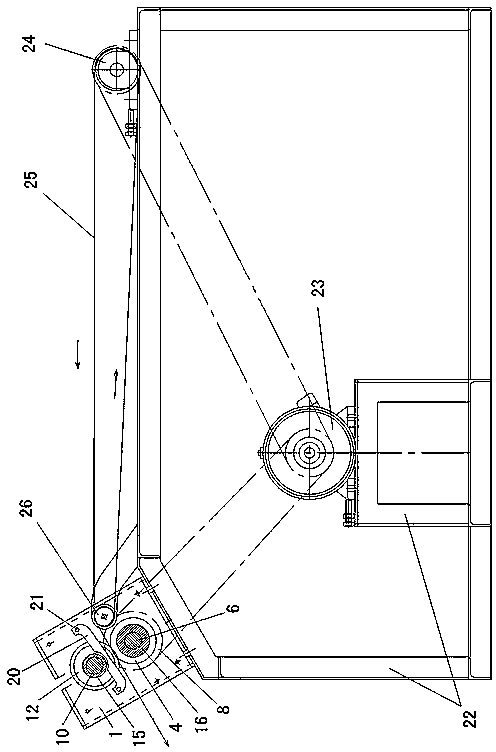

Manufacturing method of automobile engine cover made of carbon filer composite materials

InactiveCN105383070AGood strength and stiffnessLight in massDomestic articlesFibrous compositesUltimate tensile strength

The invention relates to the technology of machining manufacturing of automobile parts made of carbon filer composite materials, in particular to a manufacturing method of an automobile engine cover made of the carbon fiber composite materials. The manufacturing method is mainly applied to machining manufacturing of the engine cover made of the carbon fiber composite materials of different thicknesses. The process procedure includes the steps of clipping carbon fiber cloth, laying the carbon fiber cloth, arranging the multi-layer carbon fiber cloth into a die, conducting resin vacuum pouring, conducting vacuum heating and heat preservation, conducting demolding, taking out a workpiece and conducting trimming. The manufacturing method is characterized in that the carbon fiber cloth is clipped and designed, and the laid carbon fiber cloth layers in different shapes are put into the die and then subjected to resin pouring; and due to the fact that the thicknesses of the compositely formed engine cover made of the carbon fiber composite materials are different, the requirements for strength and rigidity of the engine cover are met, and the weight can be reduced.

Owner:丹阳如锦汽车部件有限公司

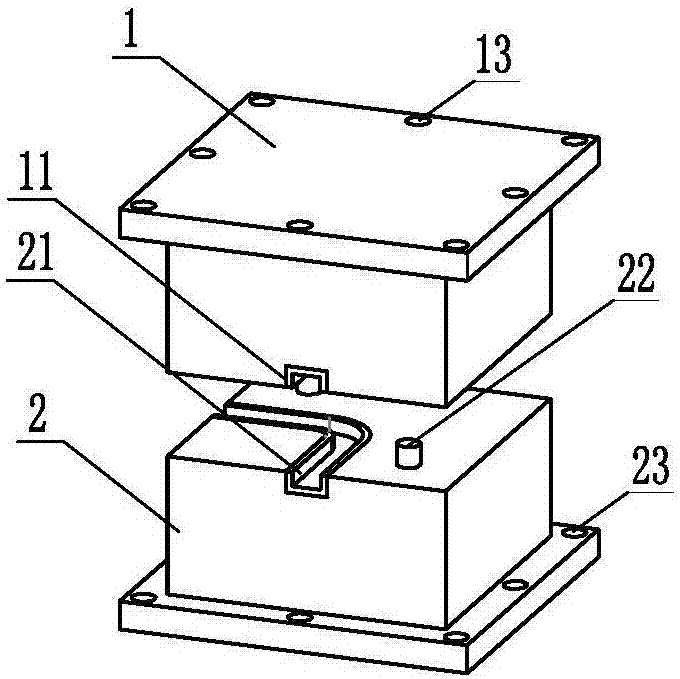

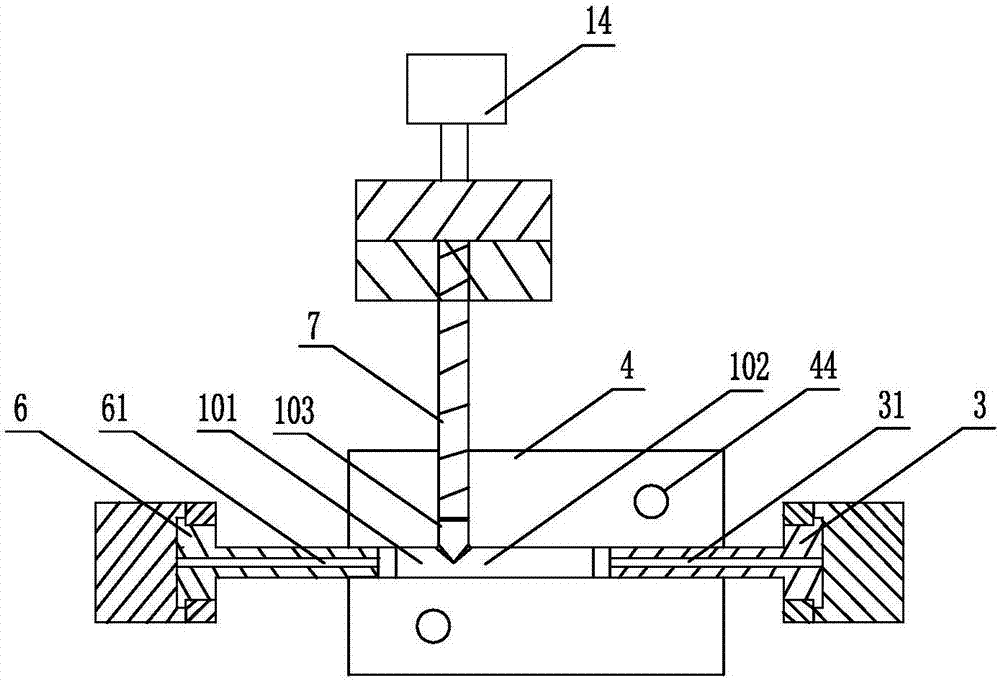

Thin-wall rectangular-cross-section pipe bending method

InactiveCN107052124AAchieving Precise FormingGuaranteed dimensional accuracyEngineeringHigh pressure

The invention provides a thin-wall rectangular-cross-section pipe bending method. The thin-wall rectangular-cross-section pipe bending method comprises the following steps that (1), a conventional pipe bending method is adopted, a thin-wall rectangular-cross-section pipe blank is bent in advance, and a pipe pre-bending piece with folds is obtained; (2), a corresponding shaping die is selected and installed on a pressure bulging pressing machine; (3), the pre-bending piece is installed to the shaping die and is connected with a high-pressure-oil oil way; (4), a high-pressure oil pump is started to eliminate air in the pipe pre-bending pipe, an exhausting hole is sealed, a pipe is filled with oil liquid; (5), pressure is exerted for bulging till the folds of the pipe pre-bending piece are eliminated; (6), pressure is relived, oil is discharged, and die sinking is performed. By means of the method, two types of process technologies are comprehensively utilized, on one hand, the advantage that the conventional bent pipe is easy to form is utilized, the blank is bent in advance in the first place, then the inner-high-pressure forming technology is utilized, high pressure is exerted on the interior of the pipe so that the pipe can be bulged and attached to the die to eliminate the folds, disadvantages of the conventional bent pipe are overcome, a thin-wall rectangular-cross-section pipe bending piece is formed accurately, forming quality and precision are high, the surface is neat and smooth, and the appearance is attractive.

Owner:柳州科瑞科技有限公司 +1

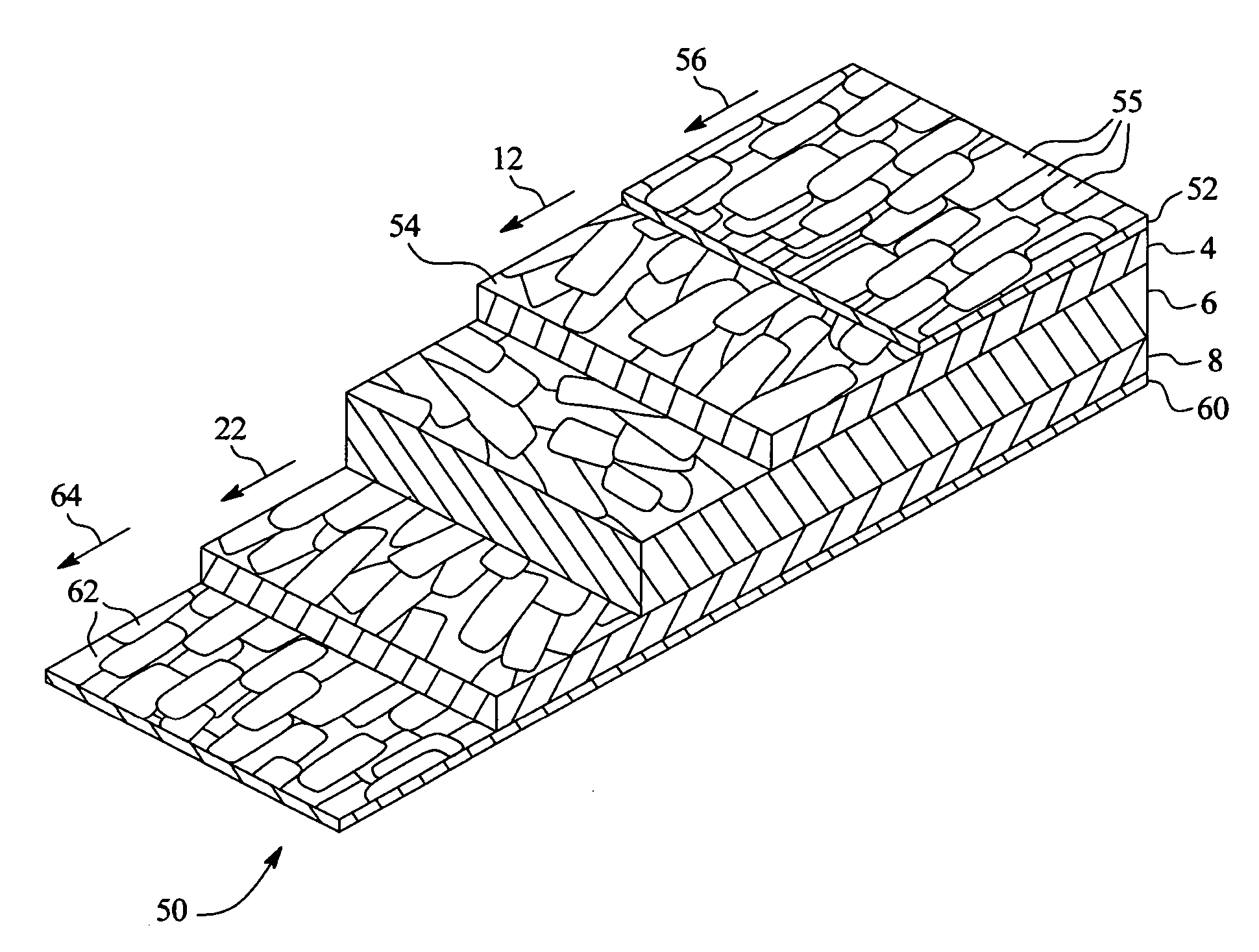

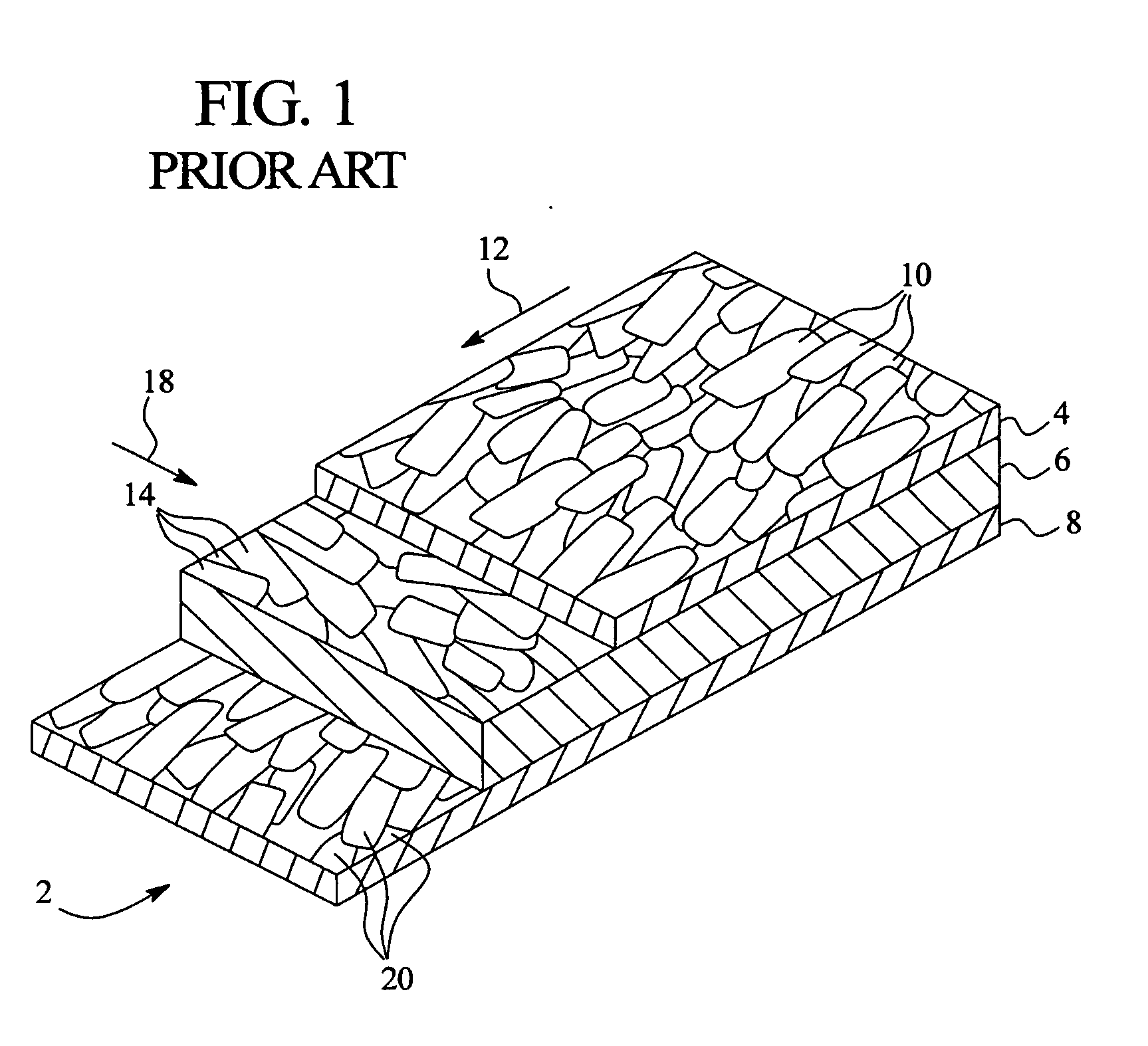

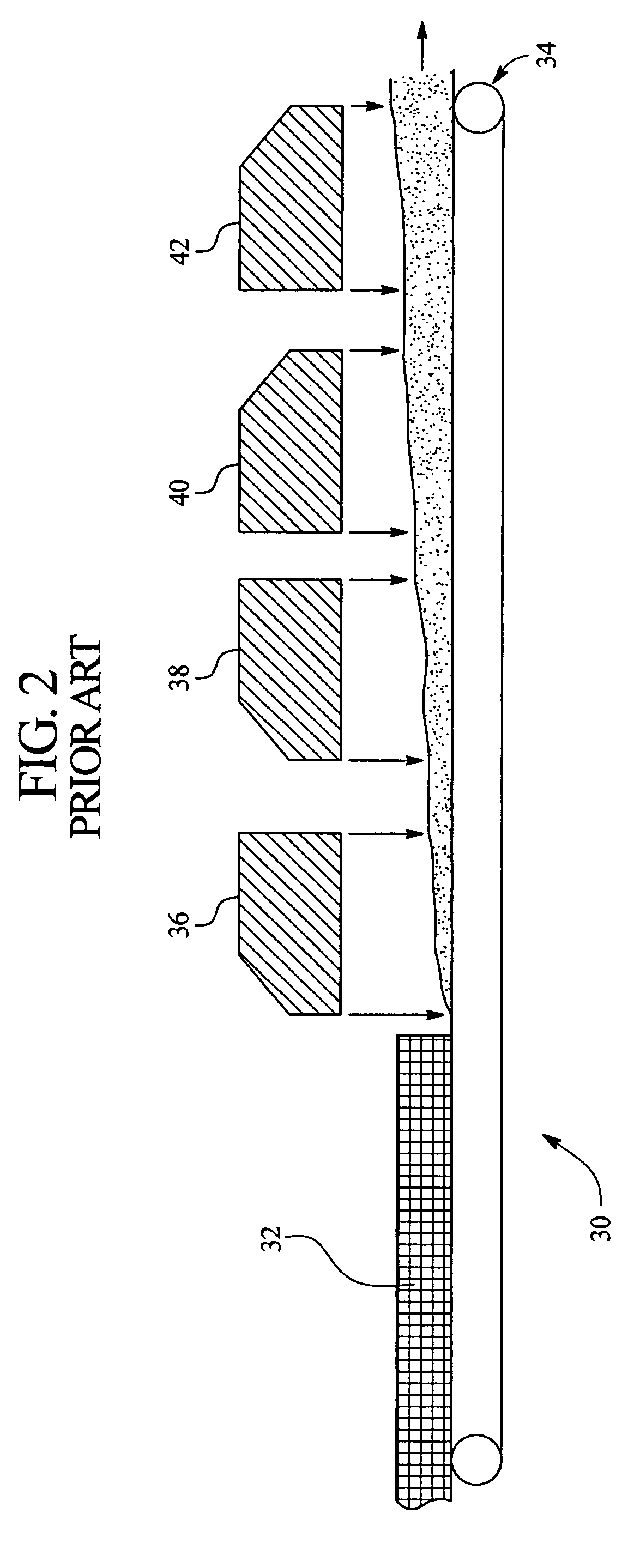

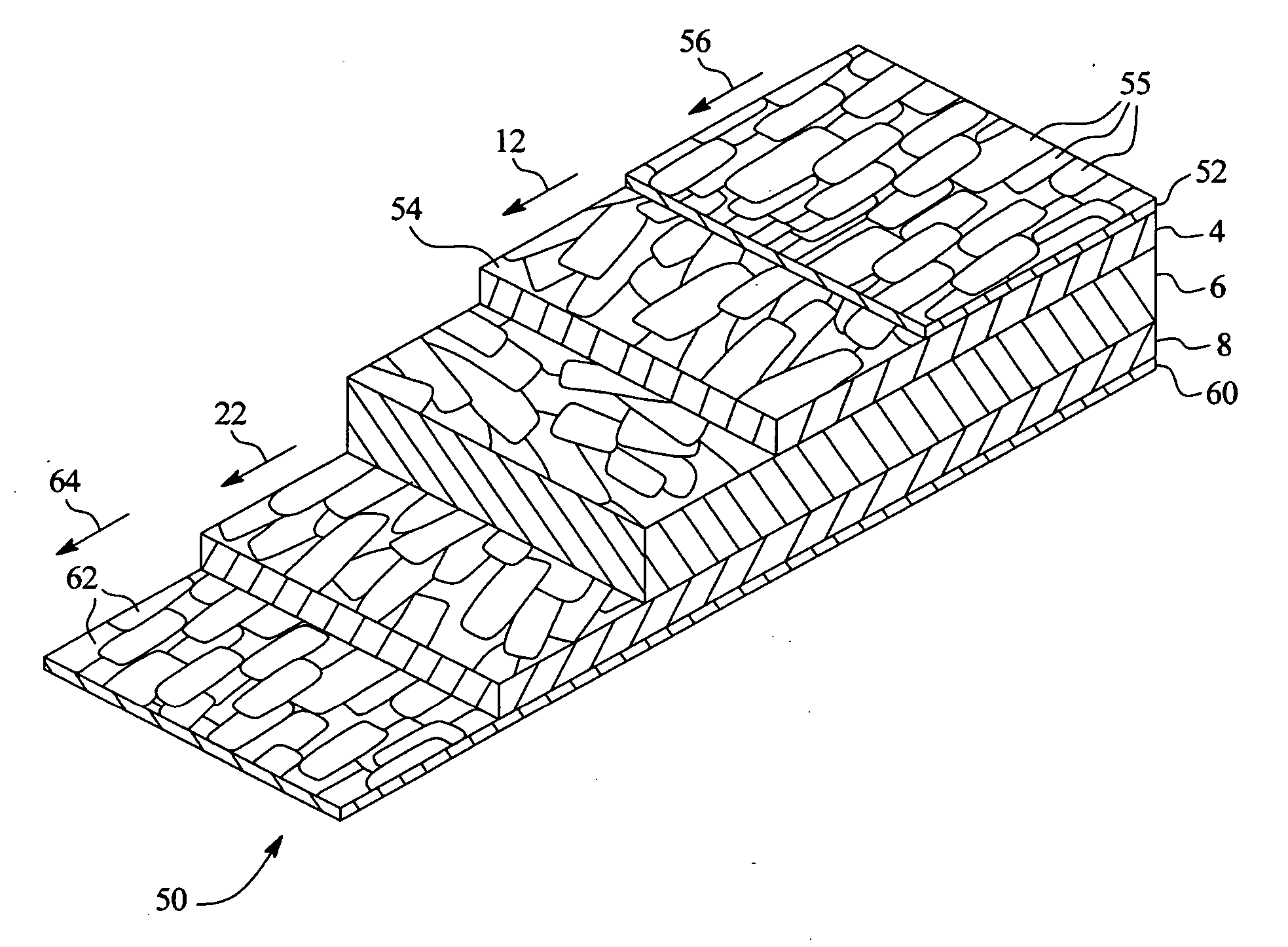

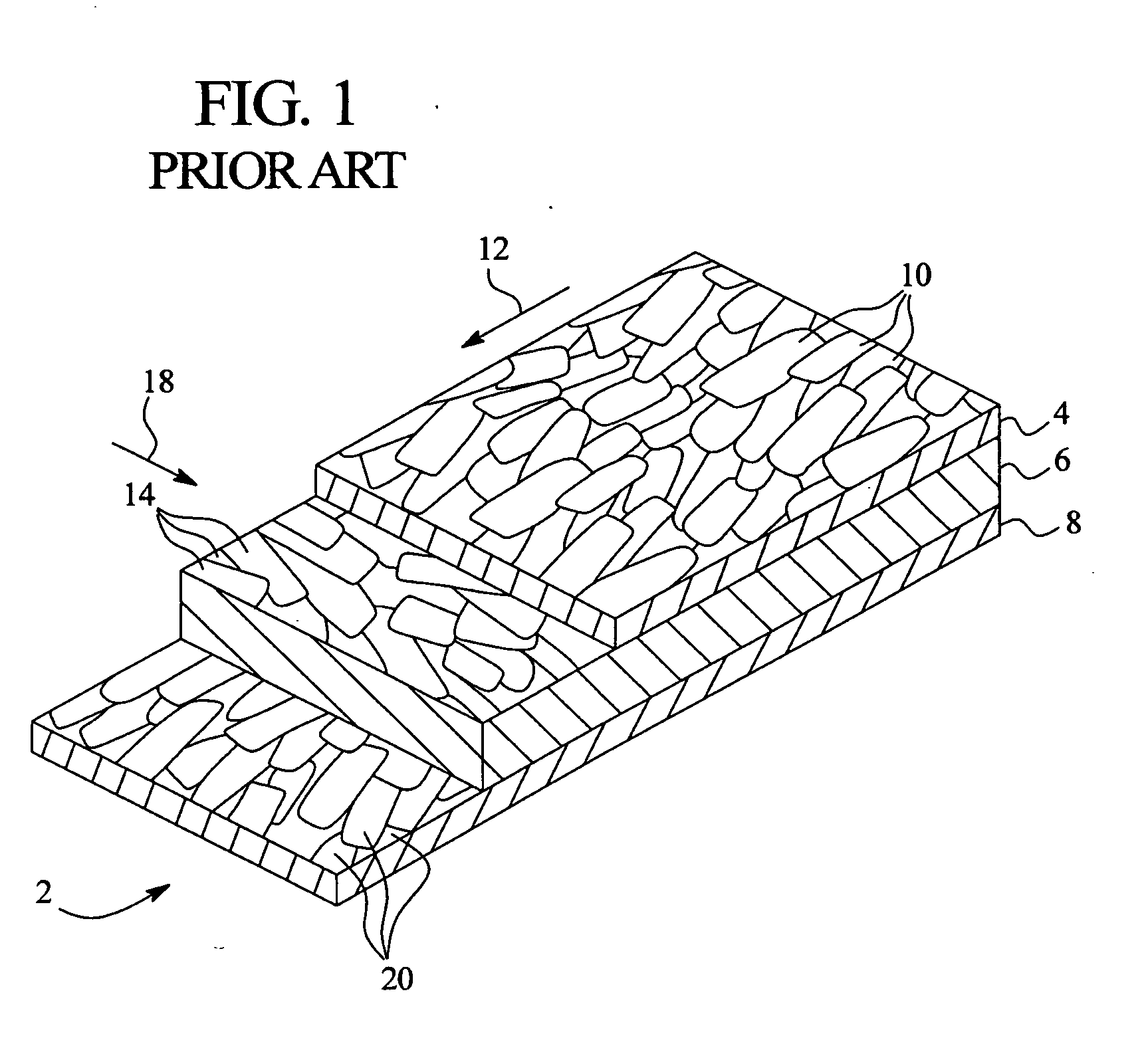

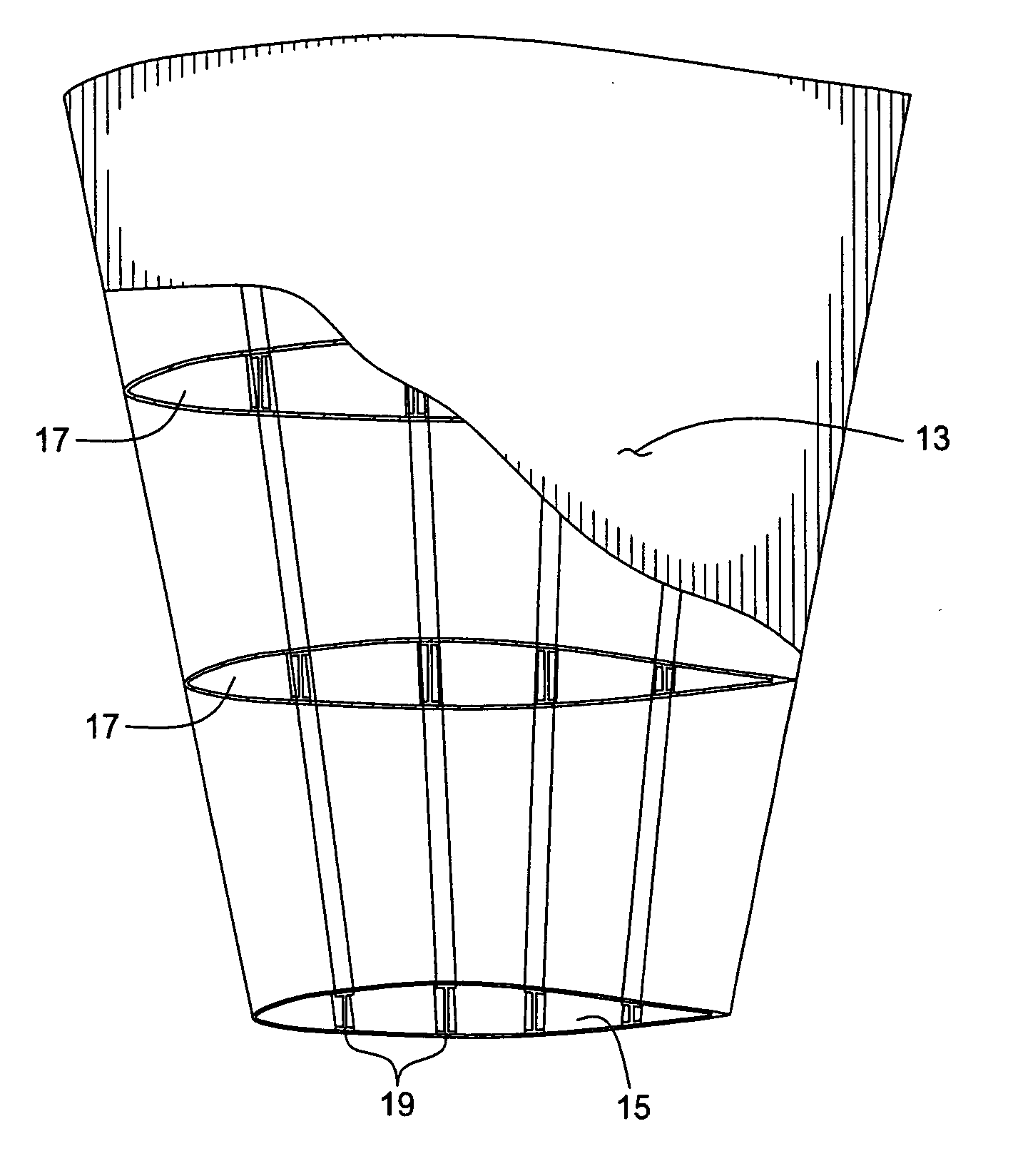

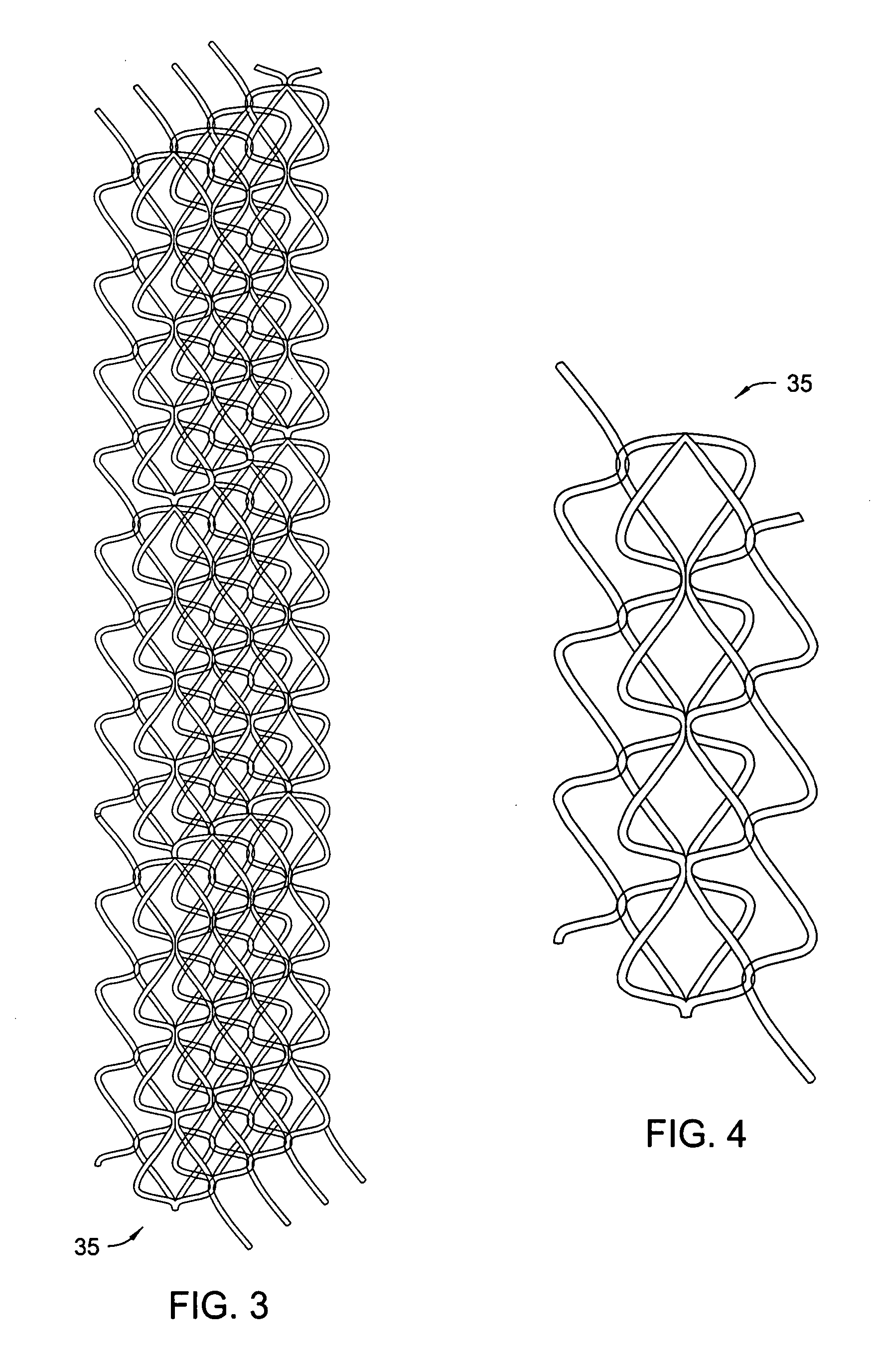

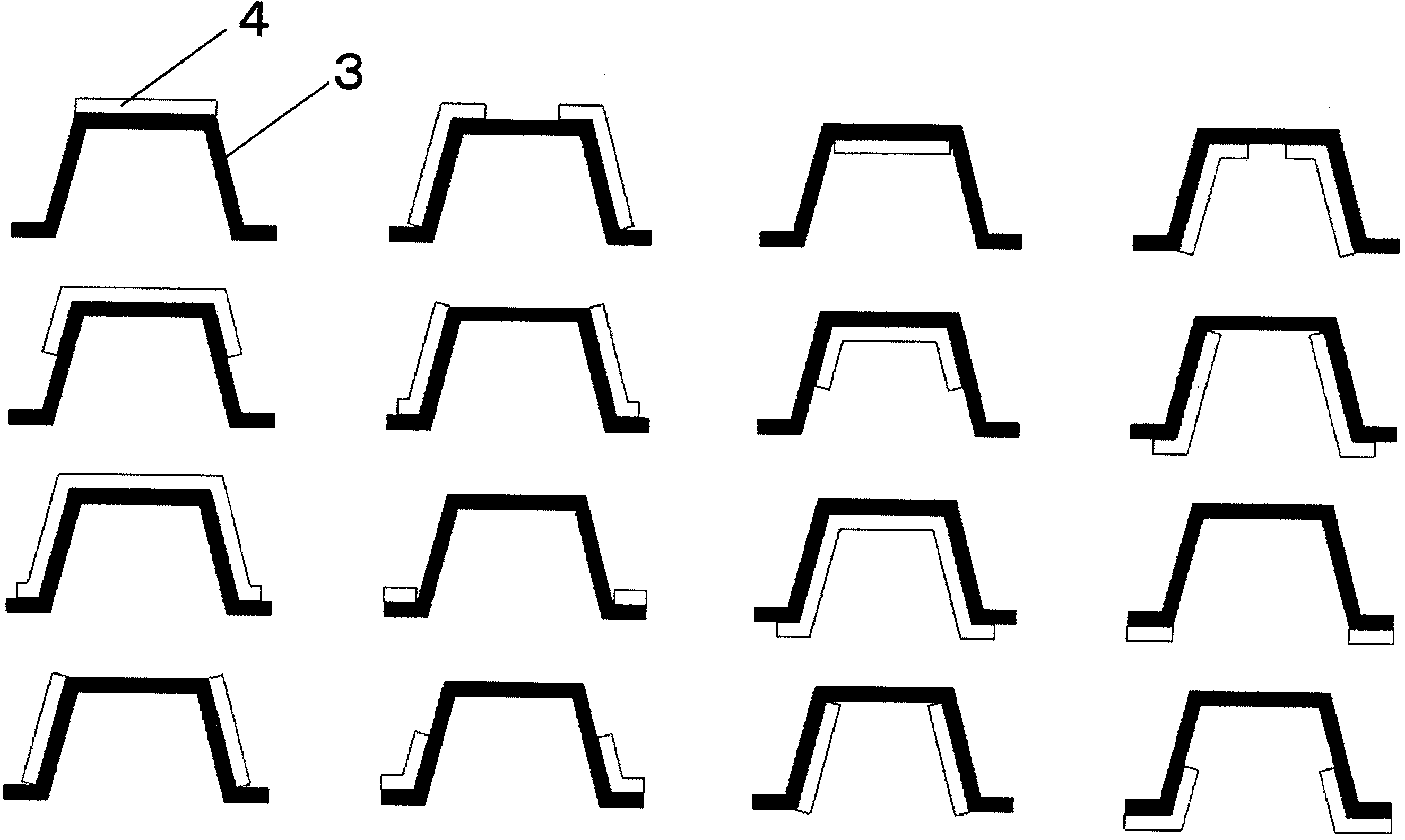

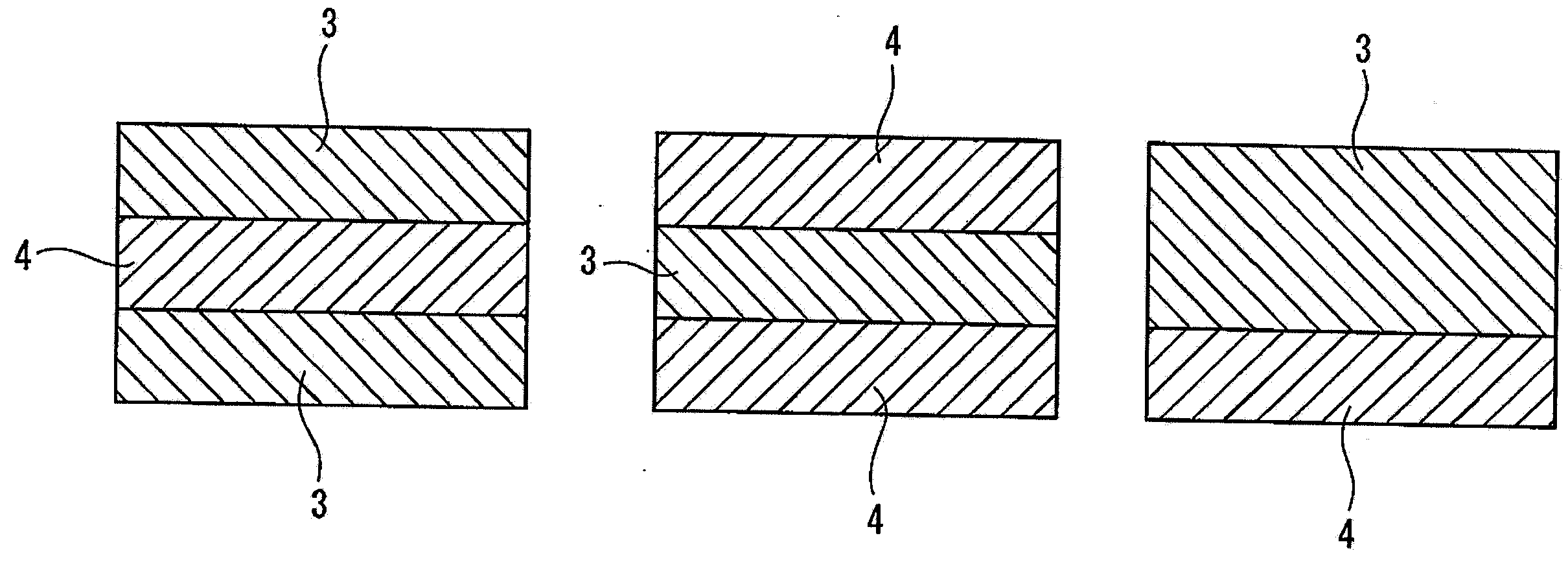

Oriented strand board panel having improved strand alignment and a method for making the same

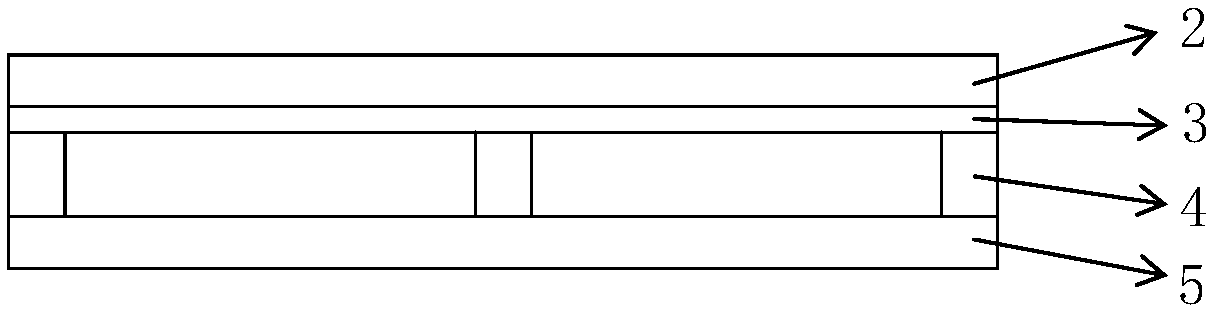

ActiveUS7547488B2Improved strand alignmentGood strength and stiffnessFibreboardCell electrodesSurface layerEngineering

An oriented strand board panel and a method for making the same are provided. The OSB panel has at least three layers, namely, a top surface layer, a core layer, and a bottom surface layer. A first cover layer may be provided on the top surface layer. Likewise, a second cover layer may be provided underneath the bottom surface layer. The first cover layer and / or the second cover layer may have a smaller strand angle, defined by an average deviation of strands from a longitudinal axis, than the top surface layer and the bottom surface layer. The smaller strand angles for the first cover layer and / or the second cover layer provide the OSB panel with greater stiffness and strength along the strong direction of the panel without significant compromise of strength and / or stiffness in the weak direction of the panel.

Owner:WEYERHAEUSER NR CO

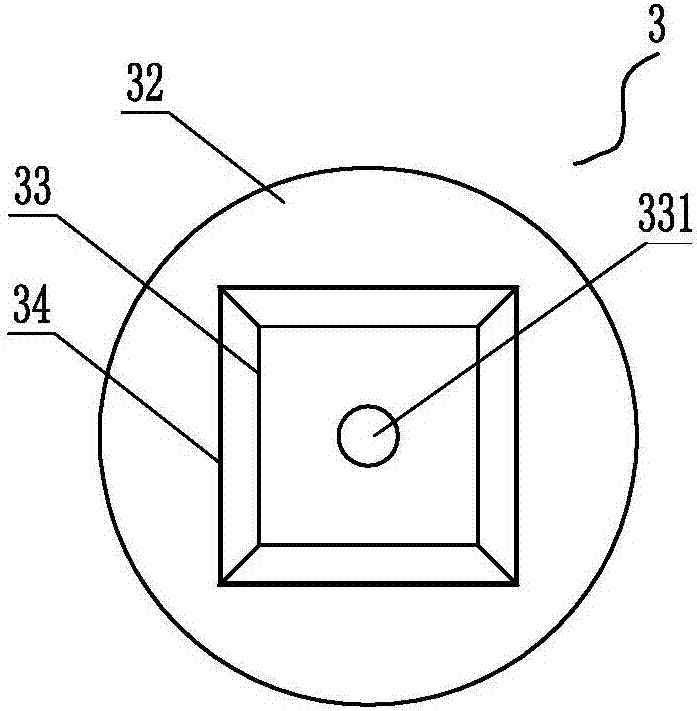

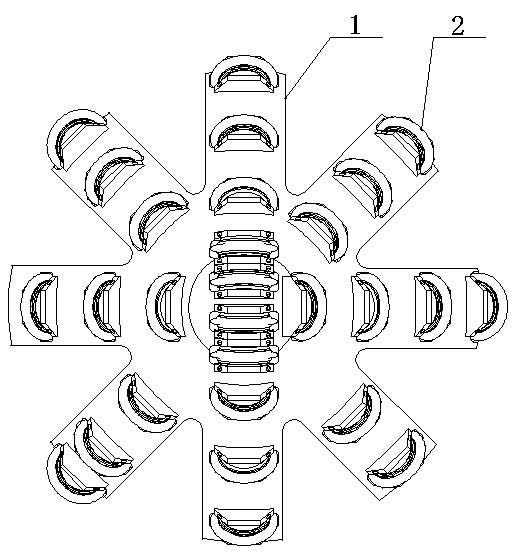

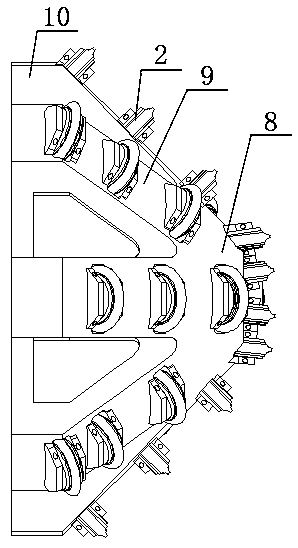

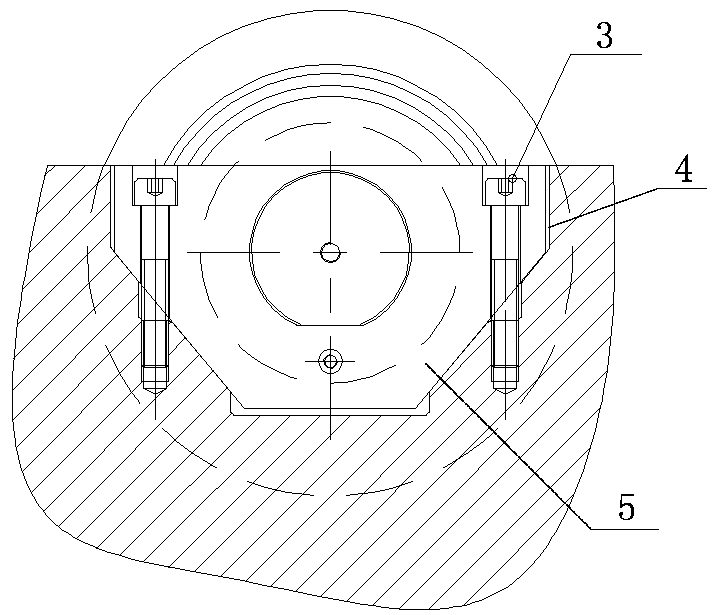

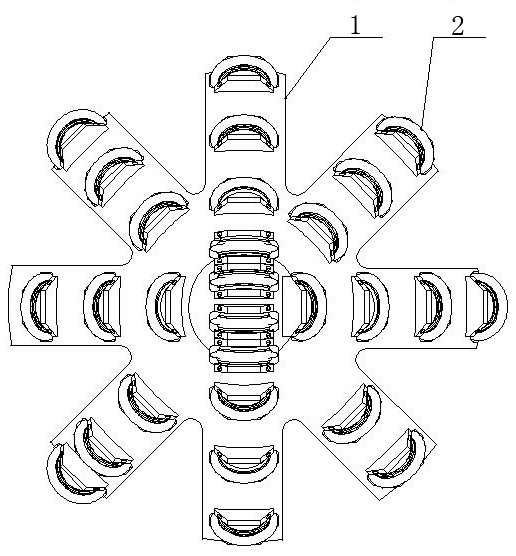

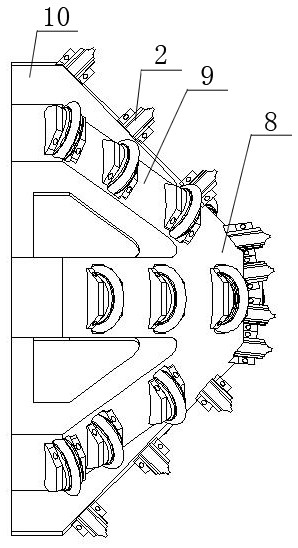

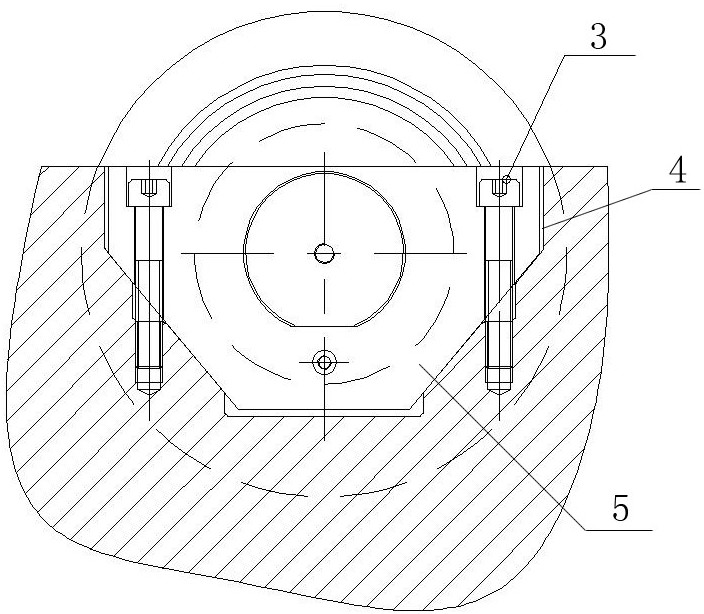

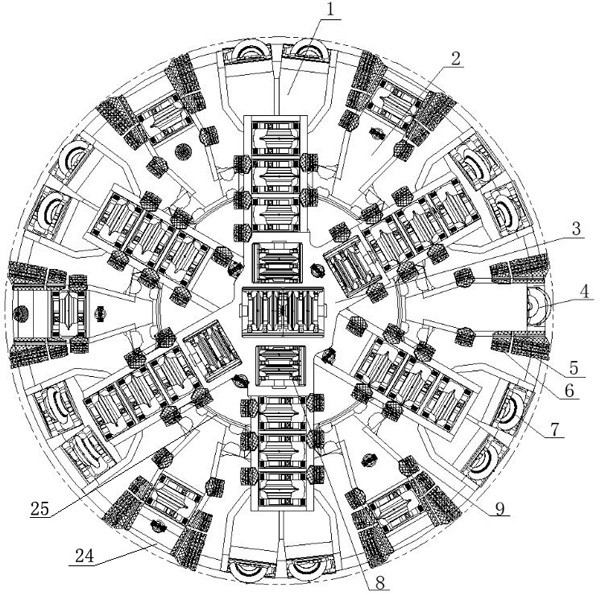

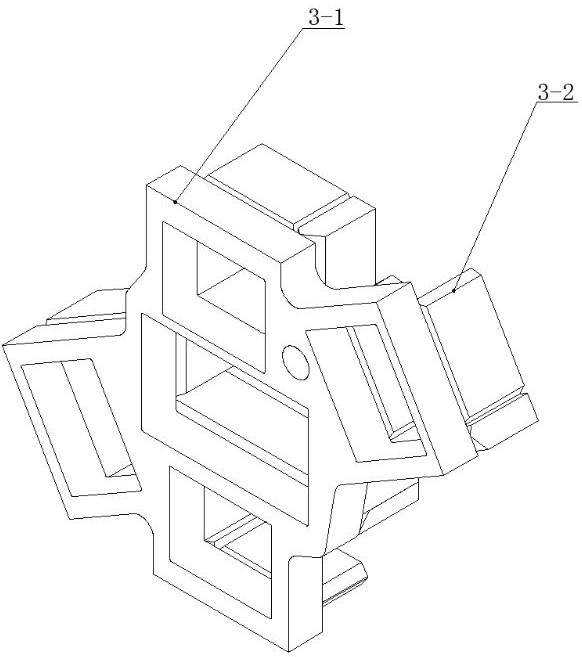

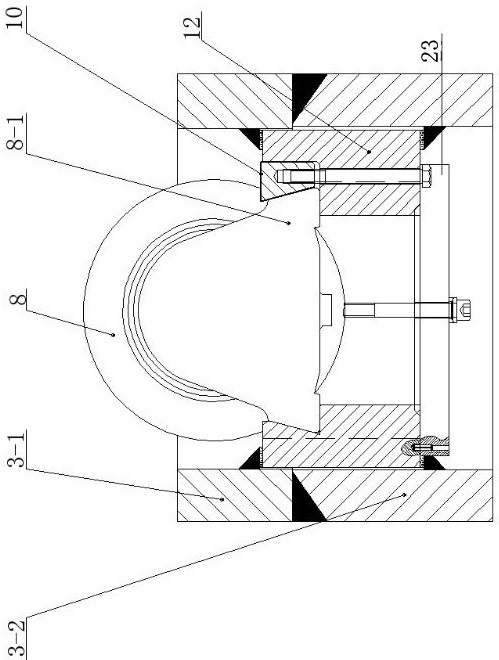

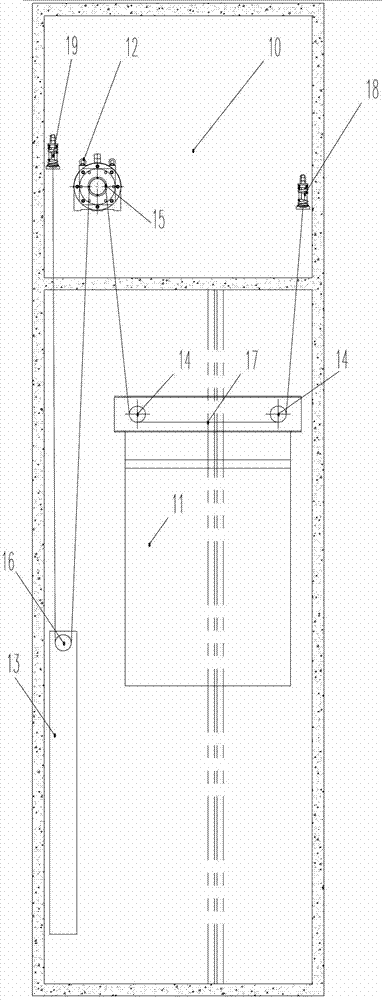

Hard rock cutterhead and cantilever heading machine comprising same

The invention provides a hard rock cutterhead and a cantilever heading machine comprising the same. The hard rock cutterhead comprises a conical cutterhead main structure; the cutterhead main structure comprises a head, spokes and a flange; the head is connected with the spokes, the spokes are connected with the flange, and the head and the spokes are provided with detachable cutters. The cantilever heading machine comprises the hard rock cutterhead. The hard rock cutterhead and the cantilever heading machine comprising the same have the advantages that the stress of the cutterhead structure is more uniform, the deformation resistance and break resistance are high, and the high-thrust high-rotation-speed excavating working condition can be borne; the cutterhead is formed by machining a complete plate or welding steel plates, and the overall strength and stiffness are better; the cutters adopt the form that end covers are located on cutter seat installation surfaces, and the rock breaking efficiency can be improved; a cutterhead center hobbing cutter can be drawn back when the cutterhead conducts swing cutting, and eccentric abrasion, cutting edge breaking and other abnormal damageoccurring to the center hobbing cutter are effectively avoided; hobbing cutters and toothed cutters are subjected to interchange installing, soft soil excavation can be achieved, and in addition, hardrock can be subjected to expanding excavation; and the cutterhead swings up and down as well as leftwards and rightwards, and round and special-shaped fracture surfaces can be excavated.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

Oriented strand board panel having improved strand alignment and a method for making the same

ActiveUS20060127634A1Improved strand alignmentIncrease stiffnessFibreboardCell electrodesSurface layerEngineering

An oriented strand board panel and a method for making the same are provided. The OSB panel has at least three layers, namely, a top surface layer, a core layer, and a bottom surface layer. A first cover layer may be provided on the top surface layer. Likewise, a second cover layer may be provided underneath the bottom surface layer. The first cover layer and / or the second cover layer may have a smaller strand angle, defined by an average deviation of strands from a longitudinal axis, than the top surface layer and the bottom surface layer. The smaller strand angles for the first cover layer and / or the second cover layer provide the OSB panel with greater stiffness and strength along the strong direction of the panel without significant compromise of strength and / or stiffness in the weak direction of the panel.

Owner:WEYERHAEUSER NR CO

Layered microelectronic contact and method for fabricating same

InactiveUS20060138677A1Good strength and stiffnessStep of become largePrinted circuit assemblingSemiconductor/solid-state device detailsDistal portionEngineering

A microelectronic spring contact for making electrical contact between a device and a mating substrate and method of making the same are disclosed. The spring contact has a compliant pad adhered to a substrate of the device and spaced apart from a terminal of the device. The compliant pad has a base adhered to the substrate, and side surfaces extending away from the substrate and tapering to a smaller end area distal from the substrate. A trace extends from the terminal of the device over the compliant pad to its end area. At least a portion of the compliant pad end area is covered by the trace, and a portion of the trace that is over the compliant pad is supported by the compliant pad. A horizontal microelectronic spring contact and method of making the same are also disclosed. The horizontal spring contact has a rigid trace attached at a first end to a terminal of a substrate. The trace is free from attachment at its second end, and extends from the terminal in a direction substantially parallel to a surface of the substrate to the second end. At least a distal portion of the trace extending to the second end is spaced apart from the surface of the substrate. The spaced-apart distal portion is flexible in a plane parallel to the substrate.

Owner:FORMFACTOR INC

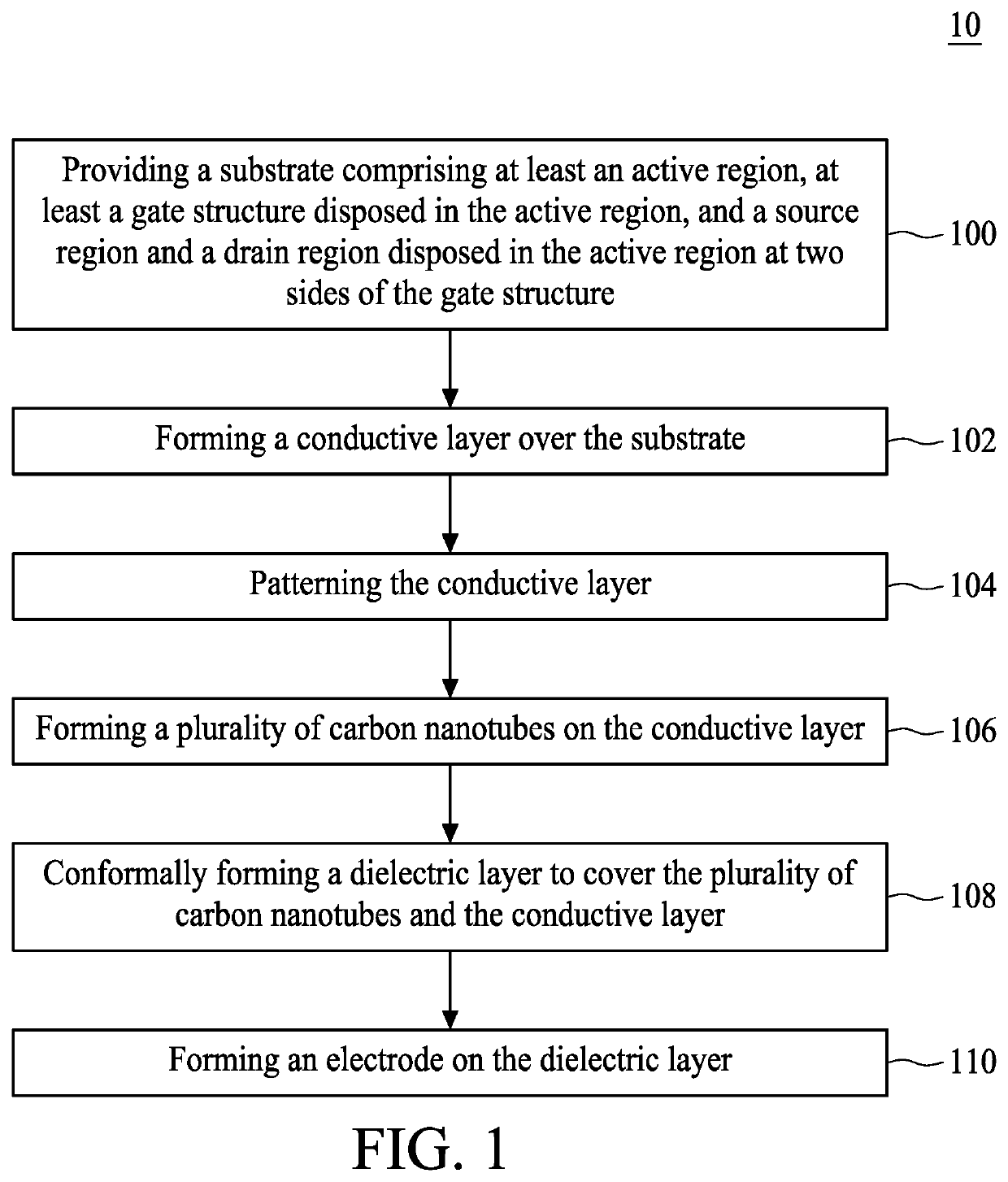

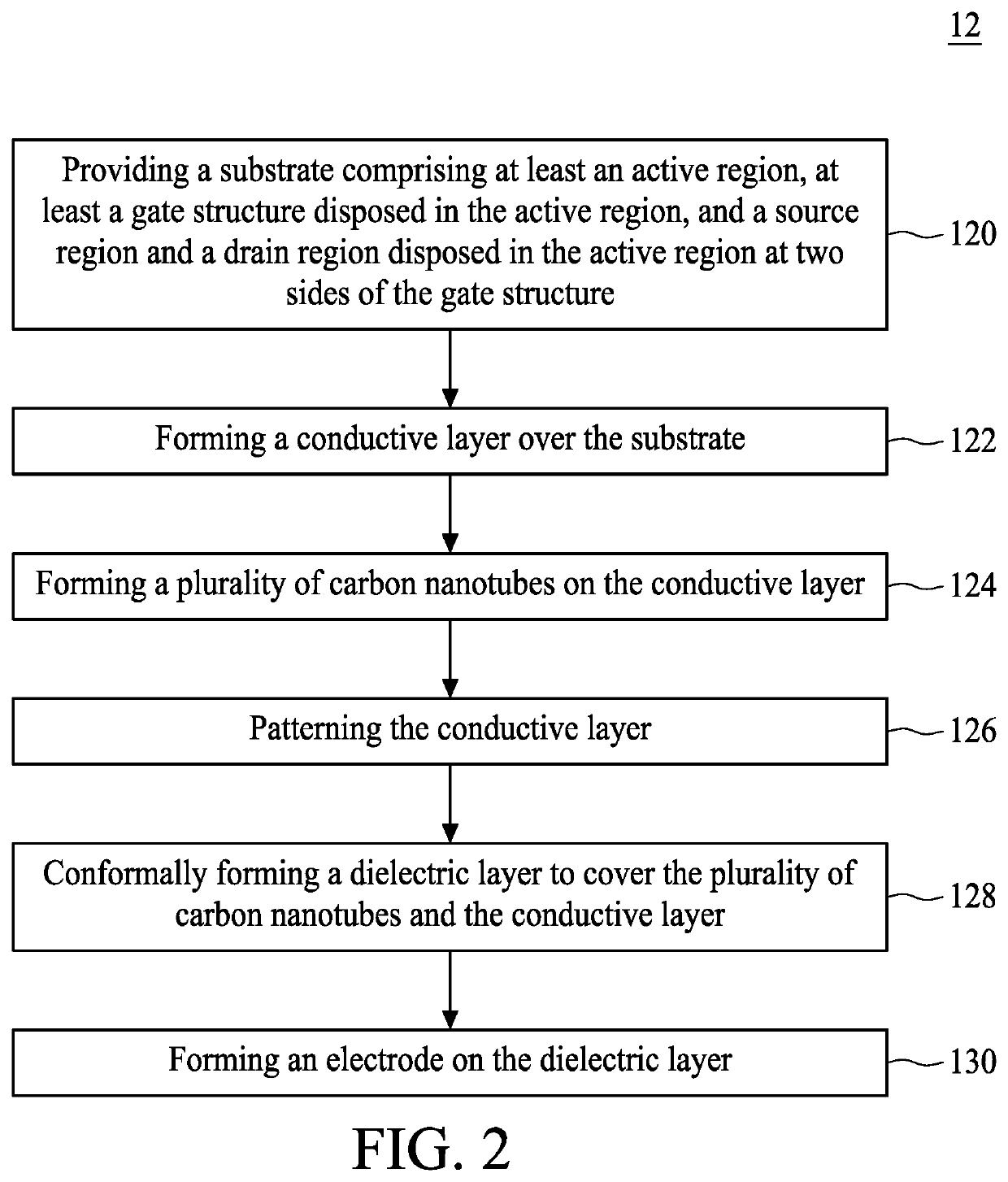

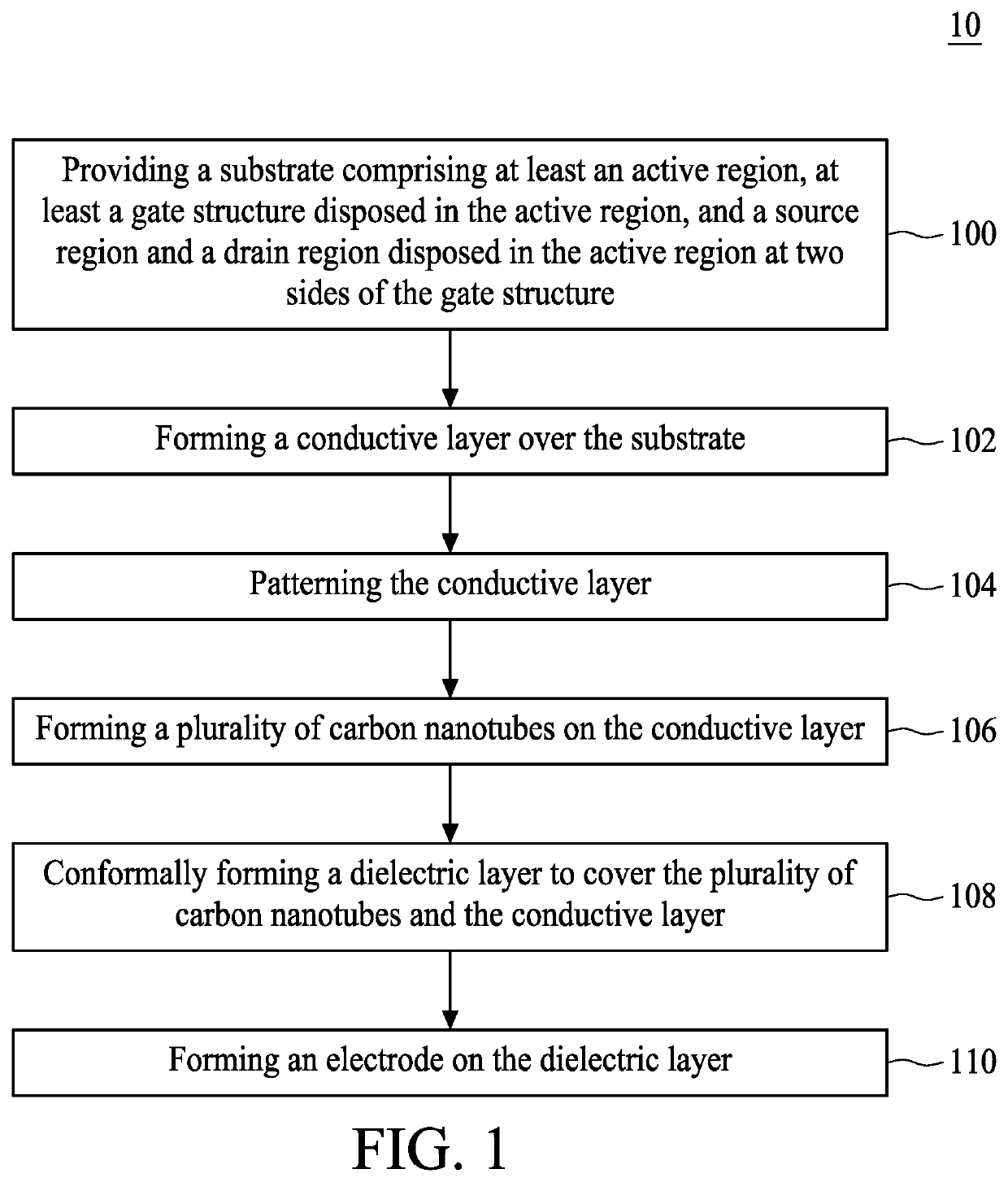

Dynamic random access memory structure and method for preparing the same

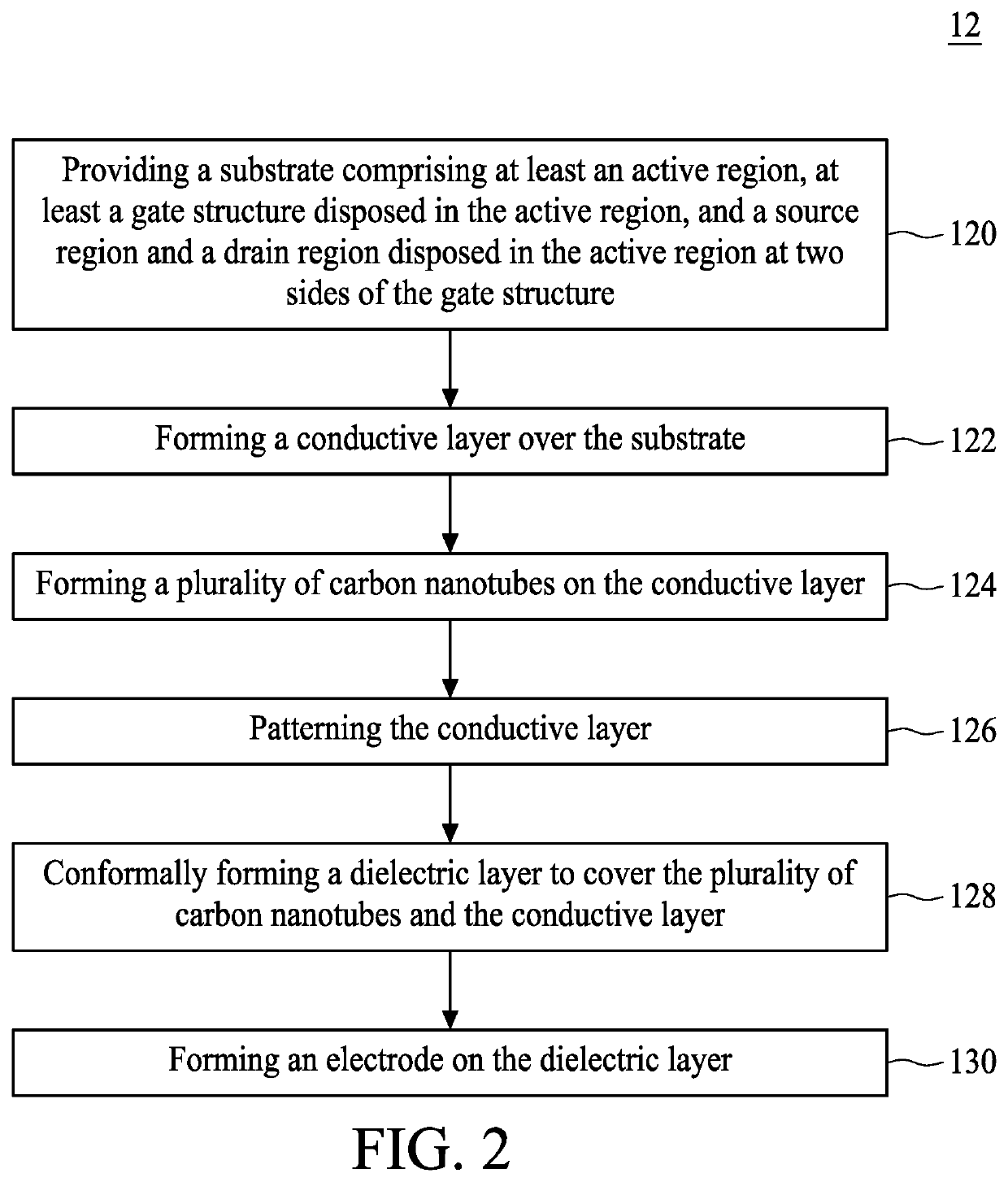

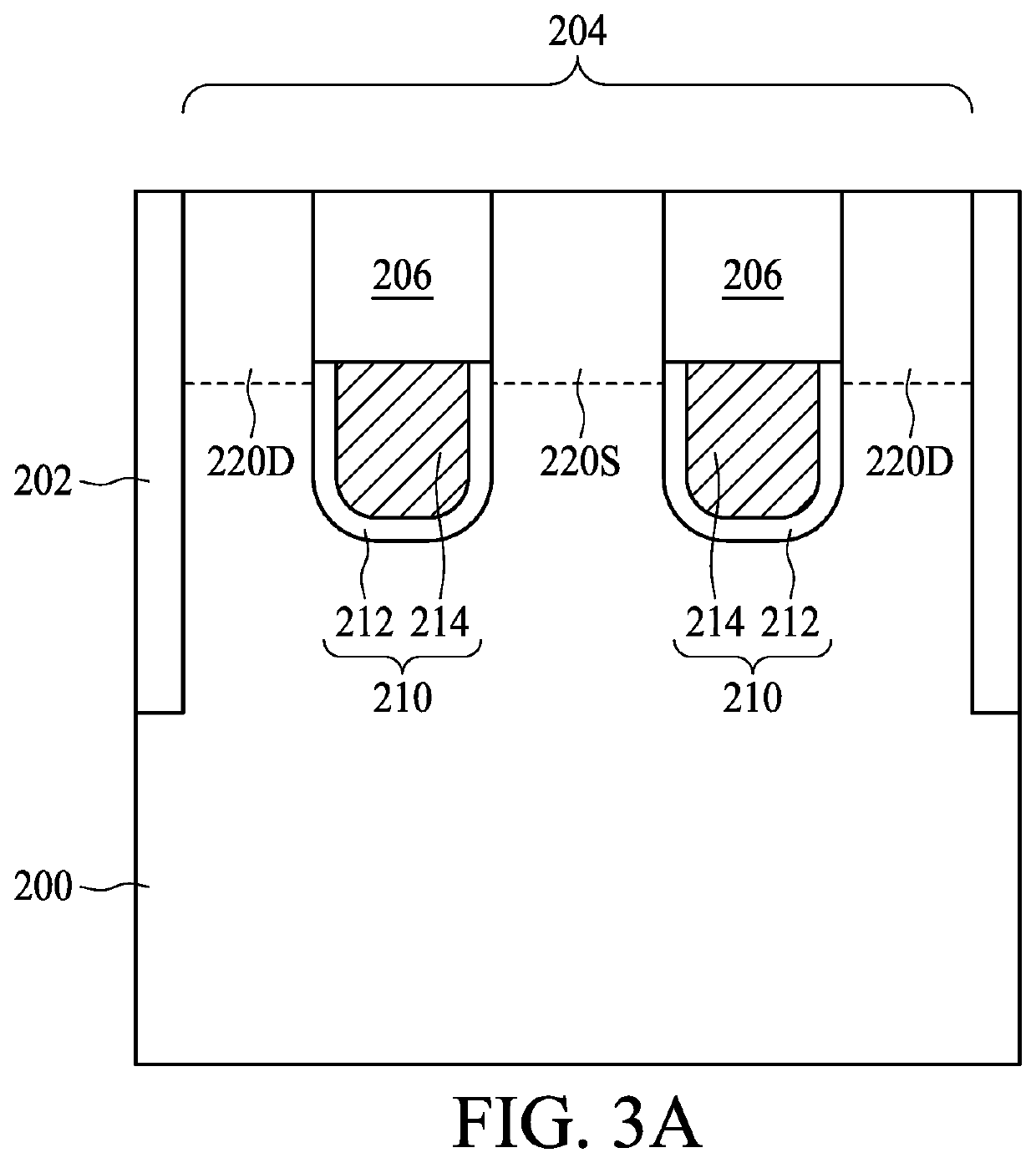

ActiveUS20200027884A1Large aspect ratioIncrease stiffnessTransistorMaterial nanotechnologyCarbon nanotubeEngineering physics

The present disclosure provides a DRAM cell structure. The DRAM cell structure includes a substrate, a gate structure disposed in the substrate, a source region and a drain region disposed in the substrate respectively at two sides of the gate structure, a landing pad disposed over the drain region, a plurality of carbon nanotubes disposed on the landing pad, a top electrode disposed over the plurality of carbon nanotubes, and a dielectric layer disposed between the top electrode and the plurality of carbon nanotubes.

Owner:NAN YA TECH

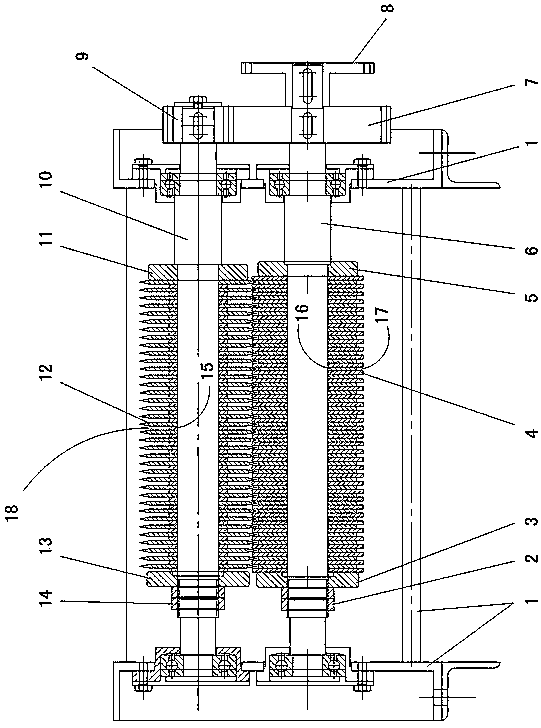

Kelp shredding cutter

InactiveCN103770138AFast shreddingGood strength and stiffnessMetal working apparatusEngineeringDrive shaft

The invention discloses a kelp shredding cutter. The kelp shredding cutter comprises a driving shaft and a driven shaft in mutual parallel; the driving shaft and the driven shaft are supported on two parallel supports by bearings; multiple round spacers are arranged on the driving shaft; a spacer gasket is arranged between adjacent spacers; multiple spacer gaps are formed at the periphery of each spacer; multiple round blades are arranged on the driven shaft; a blade gasket is arranged between adjacent blades; multiple blade gaps are formed at the periphery of each blade; the multiple blades are right inserted into the spacer gaps of the multiple spacers; an edge is arranged at the periphery of each blade; a check piece is inserted into each blade gap; the end of each check piece is sleeved on a hanging rod; two ends of the hanging rods are connected onto the supports. Compared with the prior art, the kelp shredding cutter has the advantage of capability of cutting thinner kelp silks, the width of each kelp silk achieves 1mm, the shredding speed is fast, the defect that the silks easily wrap a blade shaft is overcome, and the cutter is not deformed after being stressed and is good in strength and rigidity, long in service life, timesaving and laborsaving.

Owner:裴振军 +1

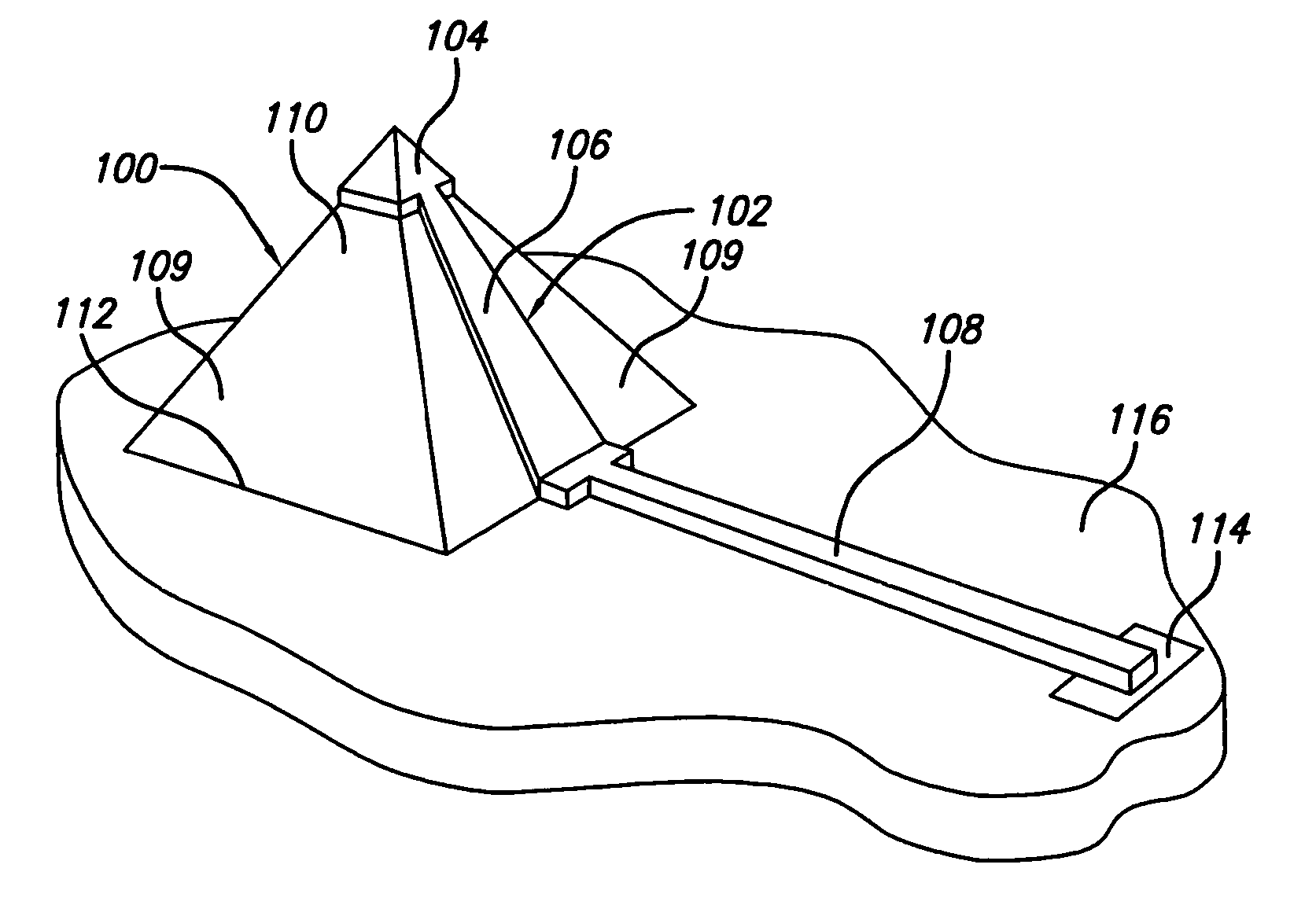

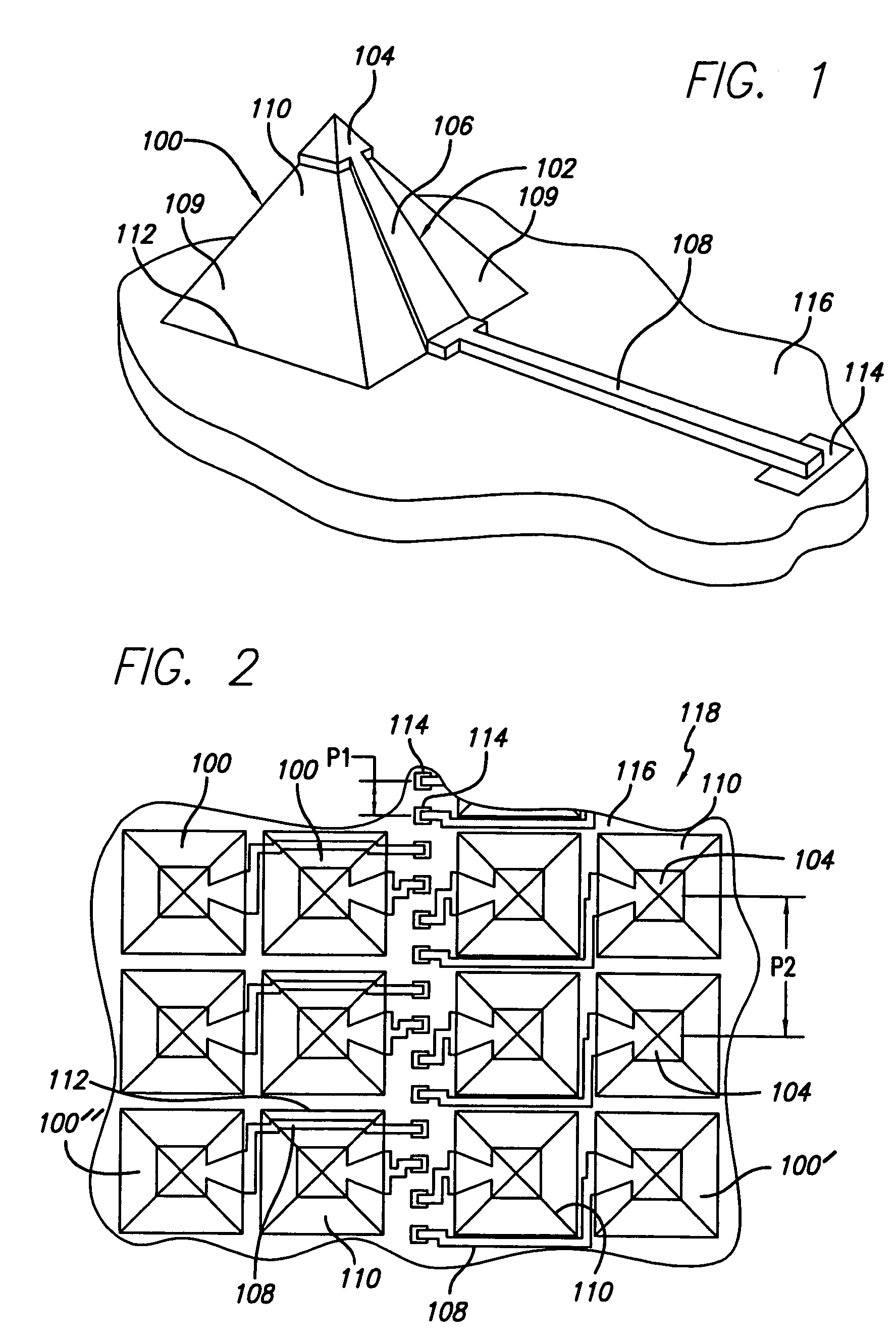

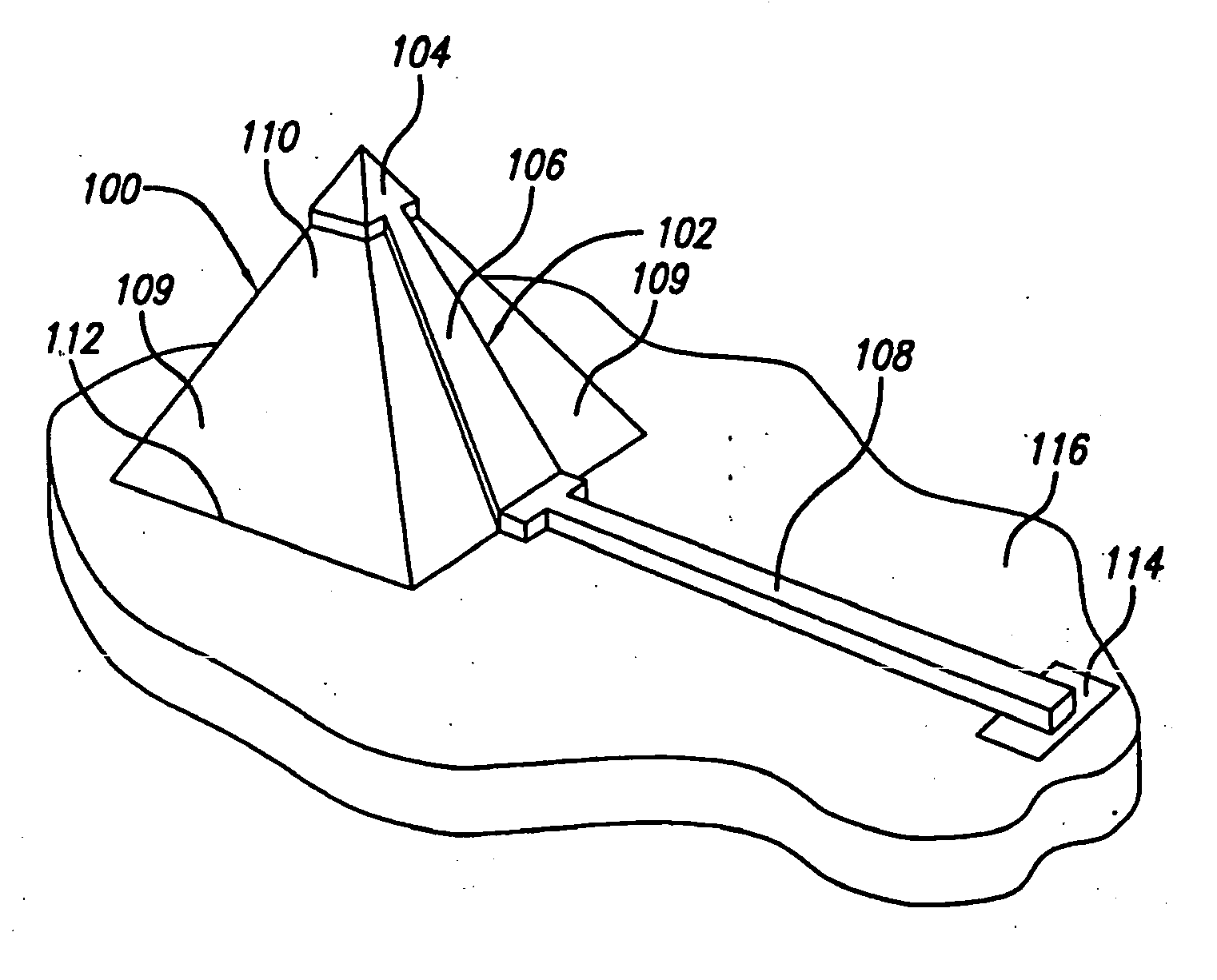

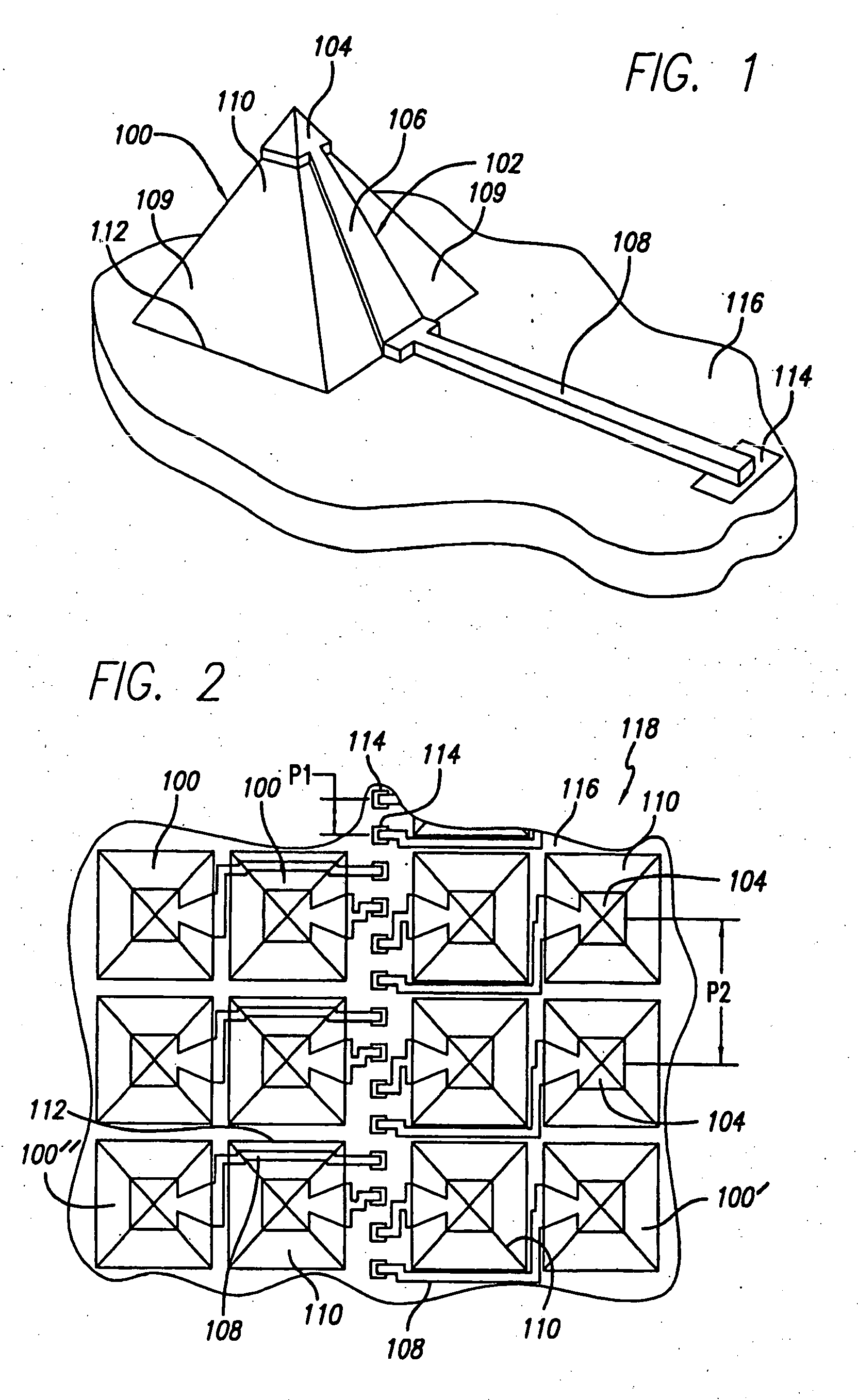

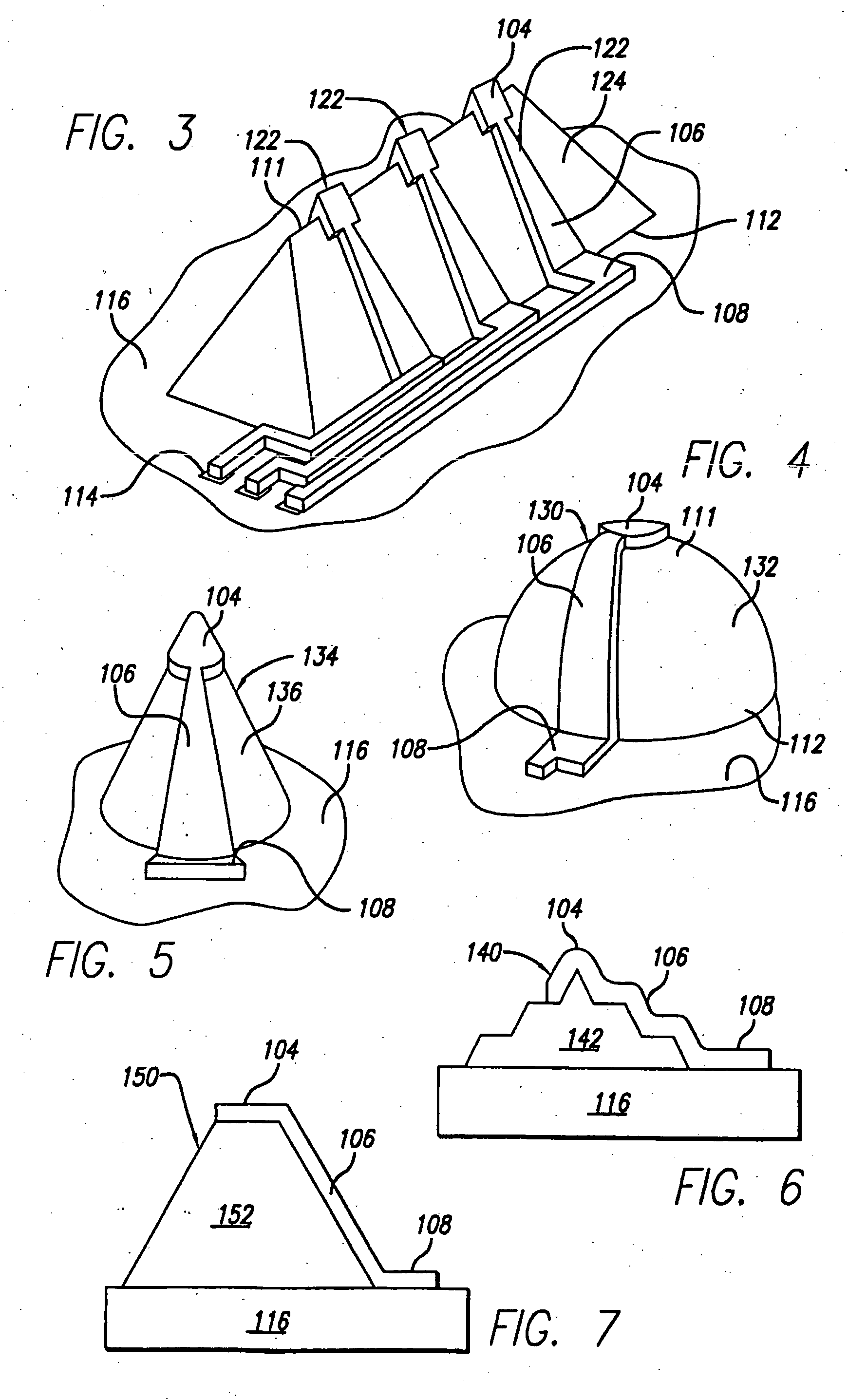

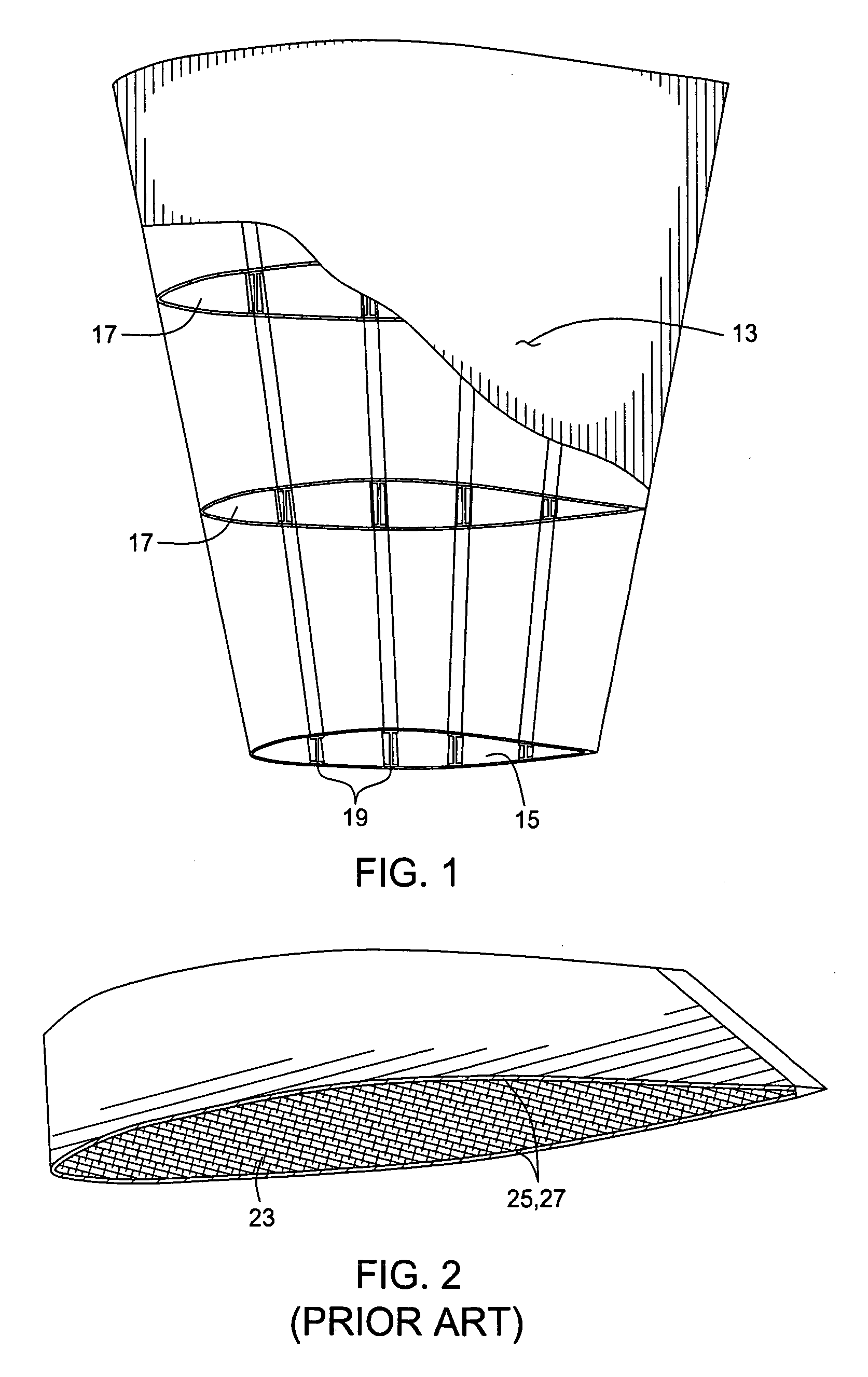

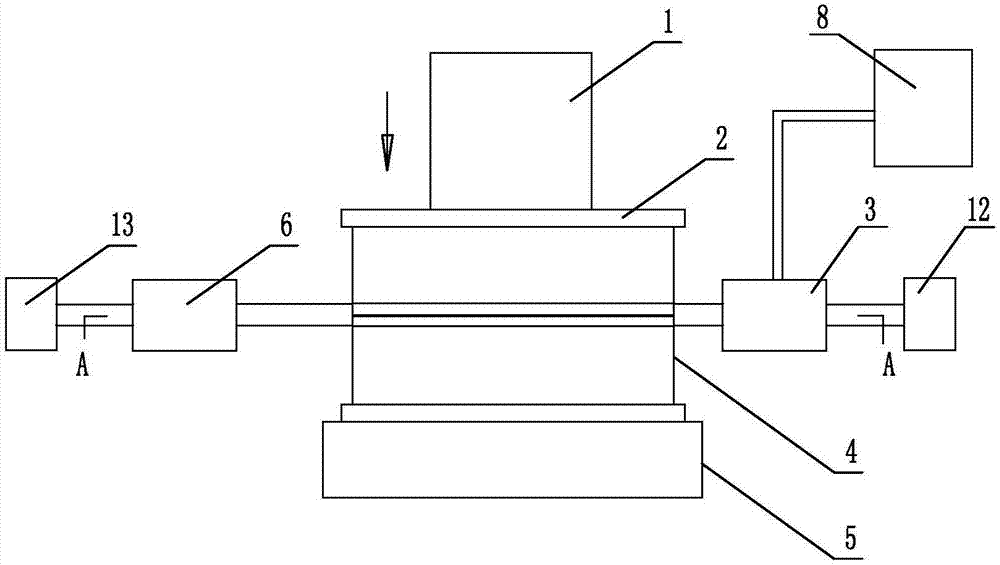

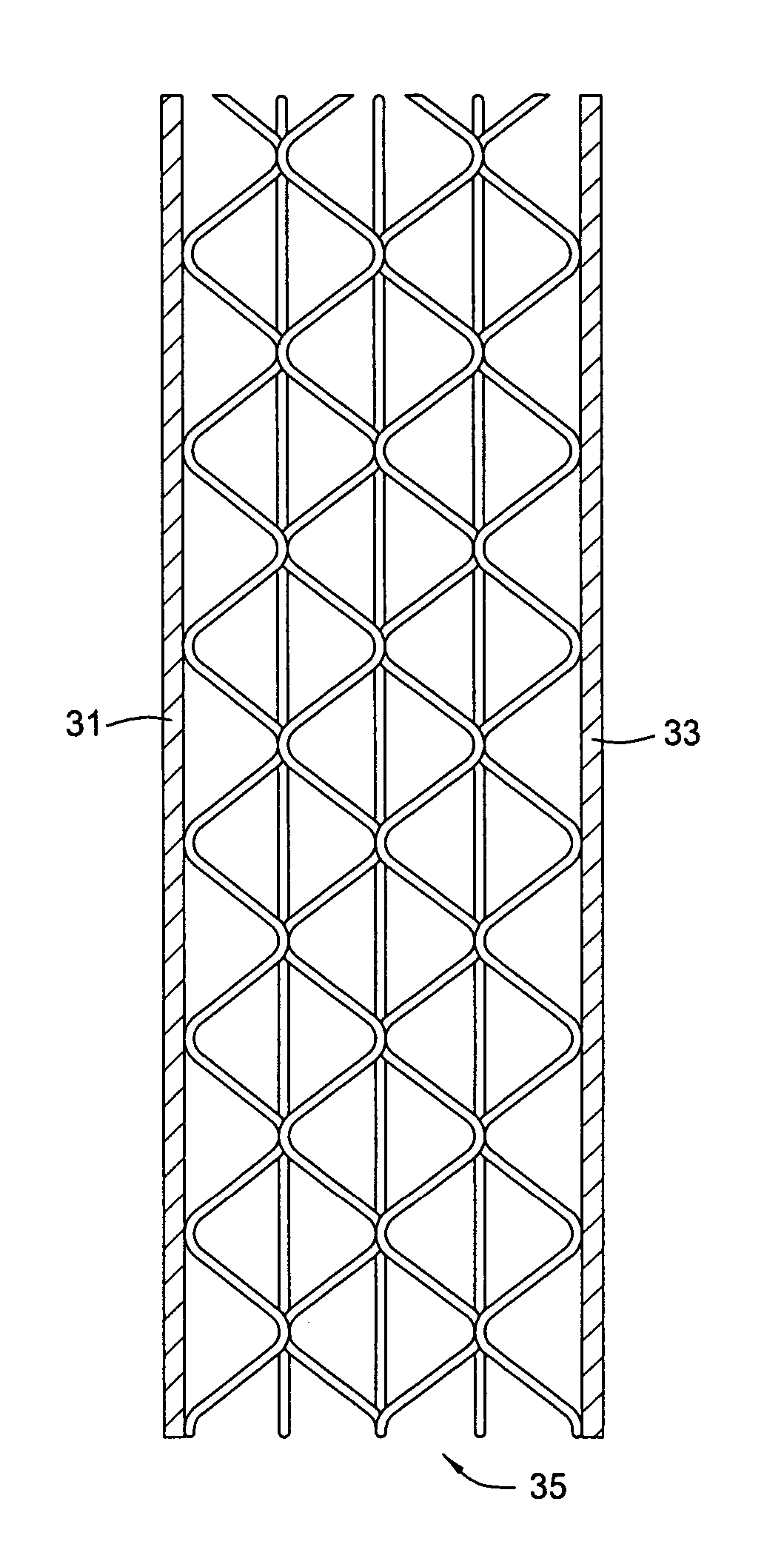

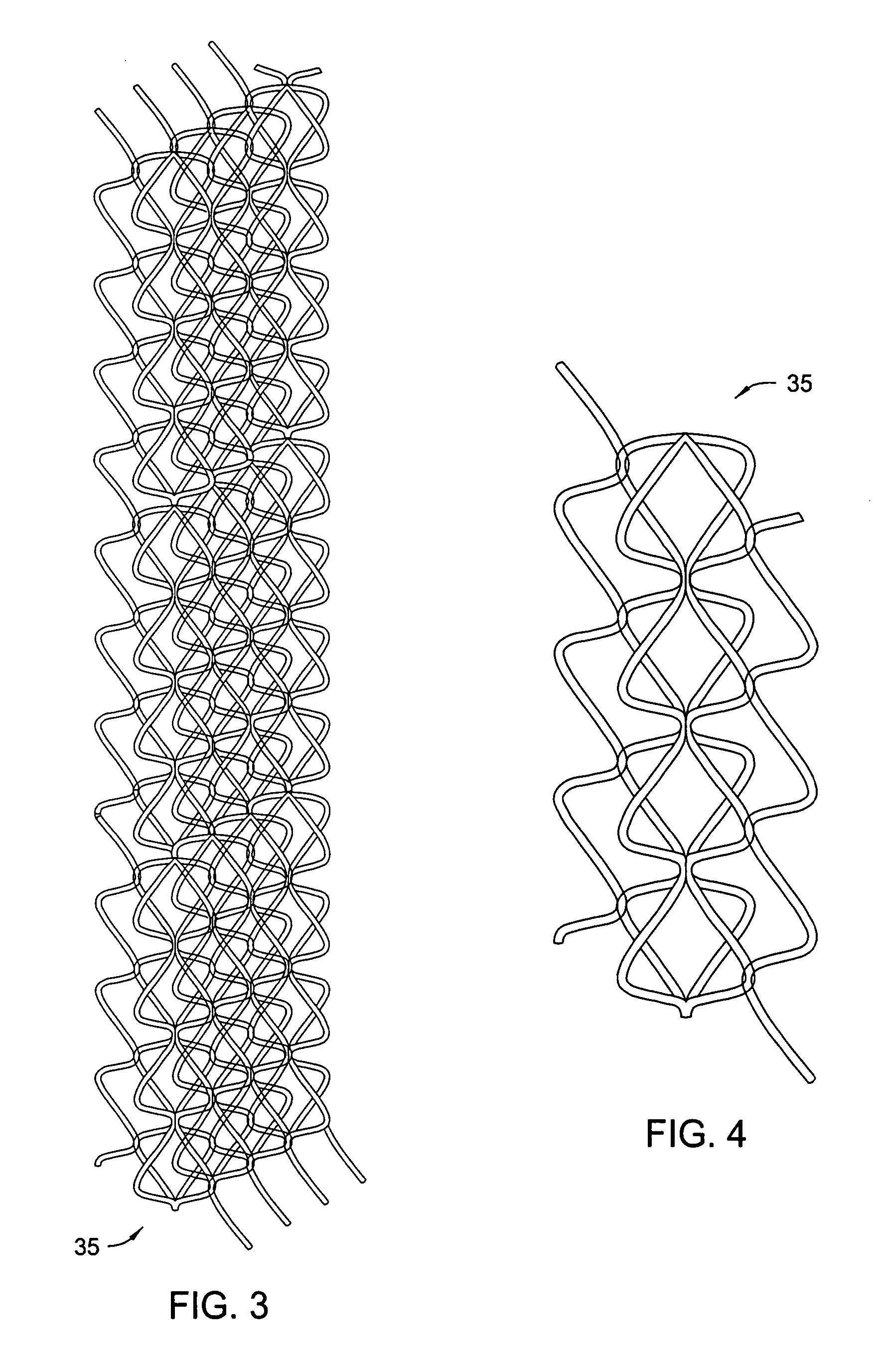

System, method, apparatus, and applications for open cell woven structural supports

An open cell or highly porous woven composite truss utilizes fibers of carbon, glass, ceramic, or the like that are woven together in a loom. The warps or tow are woven with the wefts, while the fibers are impregnated with resin. The resin impregnation step may be performed before or after the weaving step. The truss is then cured on the loom and later may be machined as needed. A rigid foam material may be used to stabilize the shape of the truss prior to curing and while machining. The foam may be later chemically dissolved or otherwise disposed of.

Owner:LOCKHEED MARTIN CORP

Forming device for faucet pipe body and method for forming faucet pipe body through forming device

A faucet pipe body forming device, including a hydraulic pressure generating system, a hydraulic bulging press, and an internal high-pressure forming die. The internal high-pressure forming die includes an upper die and a lower die. Die holes, including short and long end round die holes and vertically arranged manifold circular grooves, long and short end round die holes are installed with left and right push heads for tight sealing, the oil inlet channel of the right push head is connected with the high-pressure oil circuit, and the manifold is round A back pressure piston is installed in the die hole, and the left and right push heads and the back pressure piston are respectively connected with the left and right oil cylinders and the back pressure oil cylinder of the hydraulic bulging press. The method for manufacturing the faucet body includes the steps of: S1 using the internal high pressure forming technology to manufacture the semi-finished faucet body, S2. using the conventional bending process to form the finished faucet body. The design of the device is scientific, and the method of using the forming device to manufacture the complex-shaped faucet body fully utilizes the advantages of the internal high-pressure forming technology and the conventional pipe bending process, which can make the manifold end precisely formed, and the quality of the formed pipe body is good.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

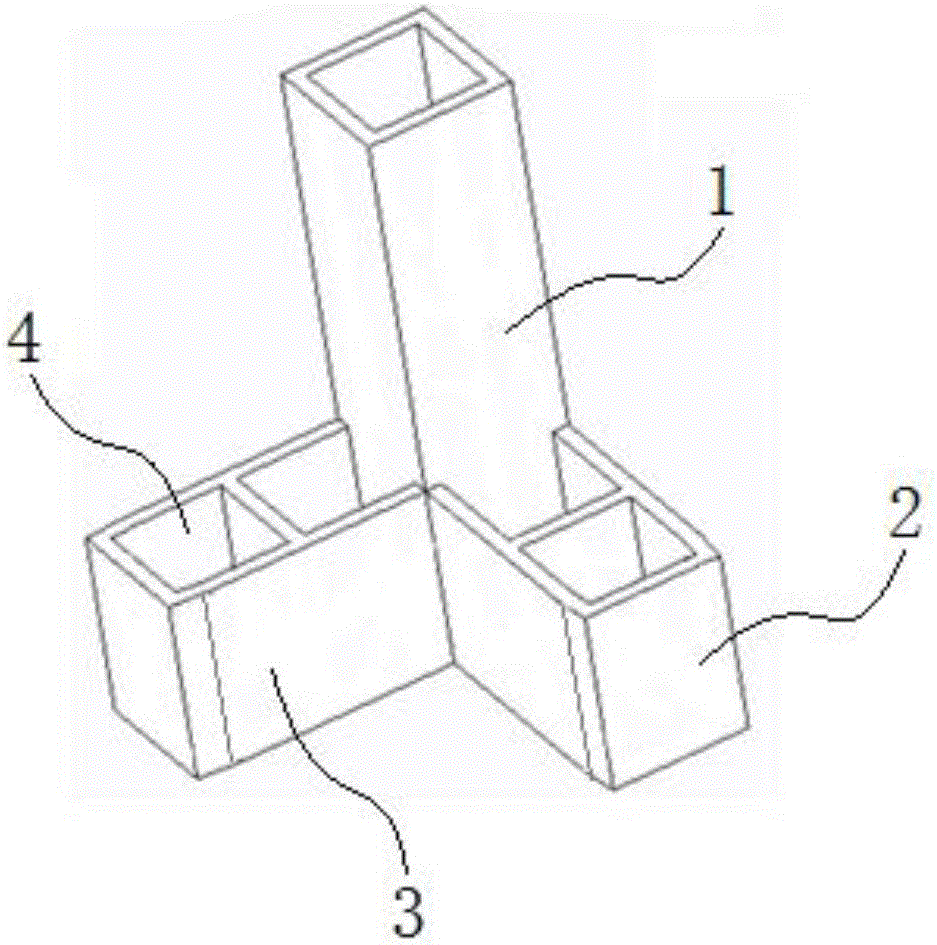

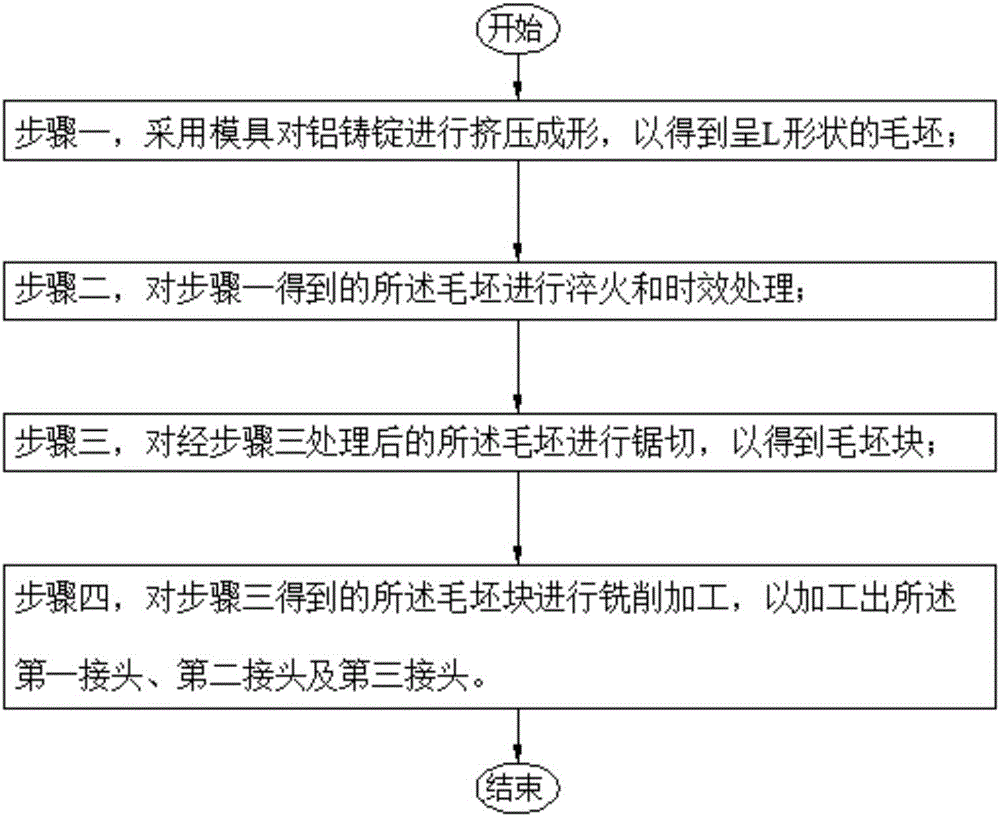

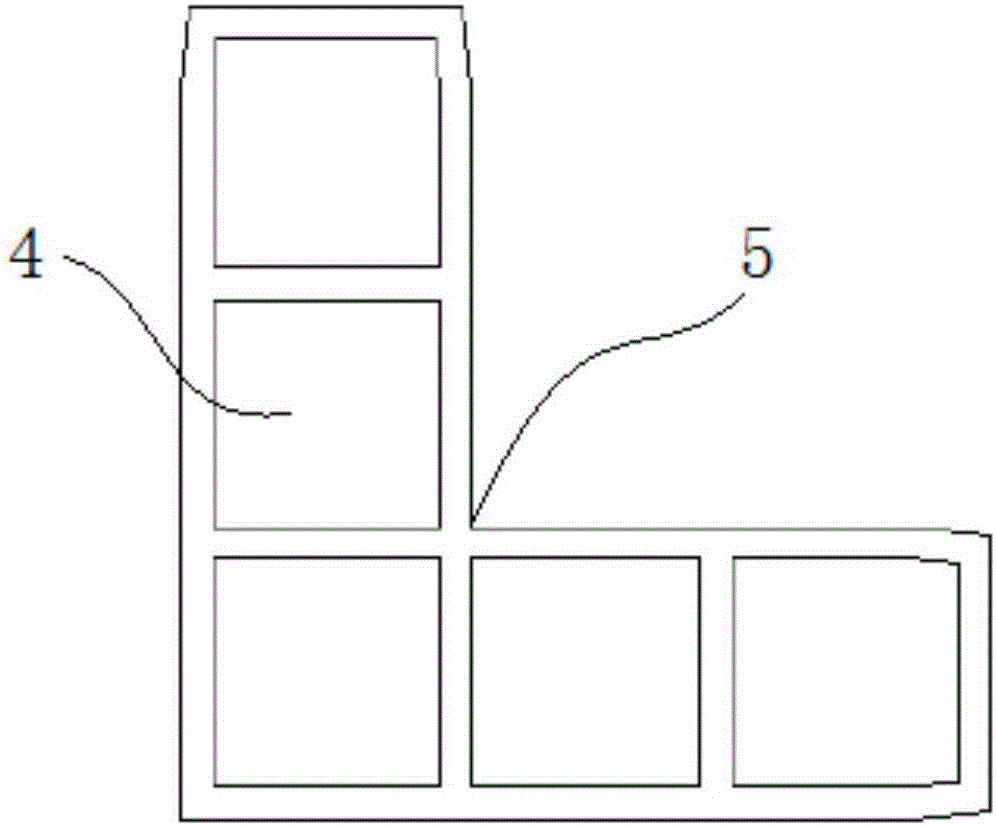

Three-way joint for aluminium materials and machining method thereof

The invention discloses a three-way joint for aluminium materials. The three-way joint comprises a first joint, a second joint and a third joint, wherein one end of the second joint is vertically connected with one end of the first joint; one end which is connected with the second joint, of the first joint, is further connected with one end of the third joint, and the third joint is vertical to the first joint and the second joint simultaneously; and the three joints are all made of the aluminium materials, and are integrally formed. A machining method for the three-way joint for the aluminium materials comprises the following steps: step 1, carrying out extrusion forming on an aluminium cast ingot by virtue of a die to obtain an L-shaped blank; step 2, carrying out quenching and ageing treatment on the blank; step 3, carrying out saw cutting the blank to obtain a blank block; and step 4, carrying out milling machining on the blank block to machine the first joint, the second joint and the third joint. The three joints of the three-way joint disclosed by the invention are integrally formed through the aluminium materials, have light weight and high rigidity and strength, and can also be recycled with the aluminium materials.

Owner:广西南南铝加工有限公司

Joined body of carbon fiber reinforced composite material

ActiveCN103402753AReduce weightGood strength and stiffnessSynthetic resin layered productsVehicle componentsCarbon fiber reinforced compositeFiber

Provided is a joined body wherein a reinforcing material having at least one layer of each of a random layer, wherein a chopped carbon fiber is randomly oriented in a thermoplastic resin, and a unidirectional material layer, wherein a continuous carbon fiber is disposed unidirectionally arranged within a thermoplastic resin, has been vibration-welded, in a manner so as to produce a hollow closed cross section, to a material to be reinforced that is open cross section and has at least one layer selected from the group consisting of the random layer and the unidirectional material layer.

Owner:TEIJIN LTD

Dynamic random access memory structure and method for preparing the same

ActiveUS10580778B2Large aspect ratioGood strength and stiffnessTransistorMaterial nanotechnologyCarbon nanotubeEngineering physics

The present disclosure provides a DRAM cell structure. The DRAM cell structure includes a substrate, a gate structure disposed in the substrate, a source region and a drain region disposed in the substrate respectively at two sides of the gate structure, a landing pad disposed over the drain region, a plurality of carbon nanotubes disposed on the landing pad, a top electrode disposed over the plurality of carbon nanotubes, and a dielectric layer disposed between the top electrode and the plurality of carbon nanotubes.

Owner:NAN YA TECH

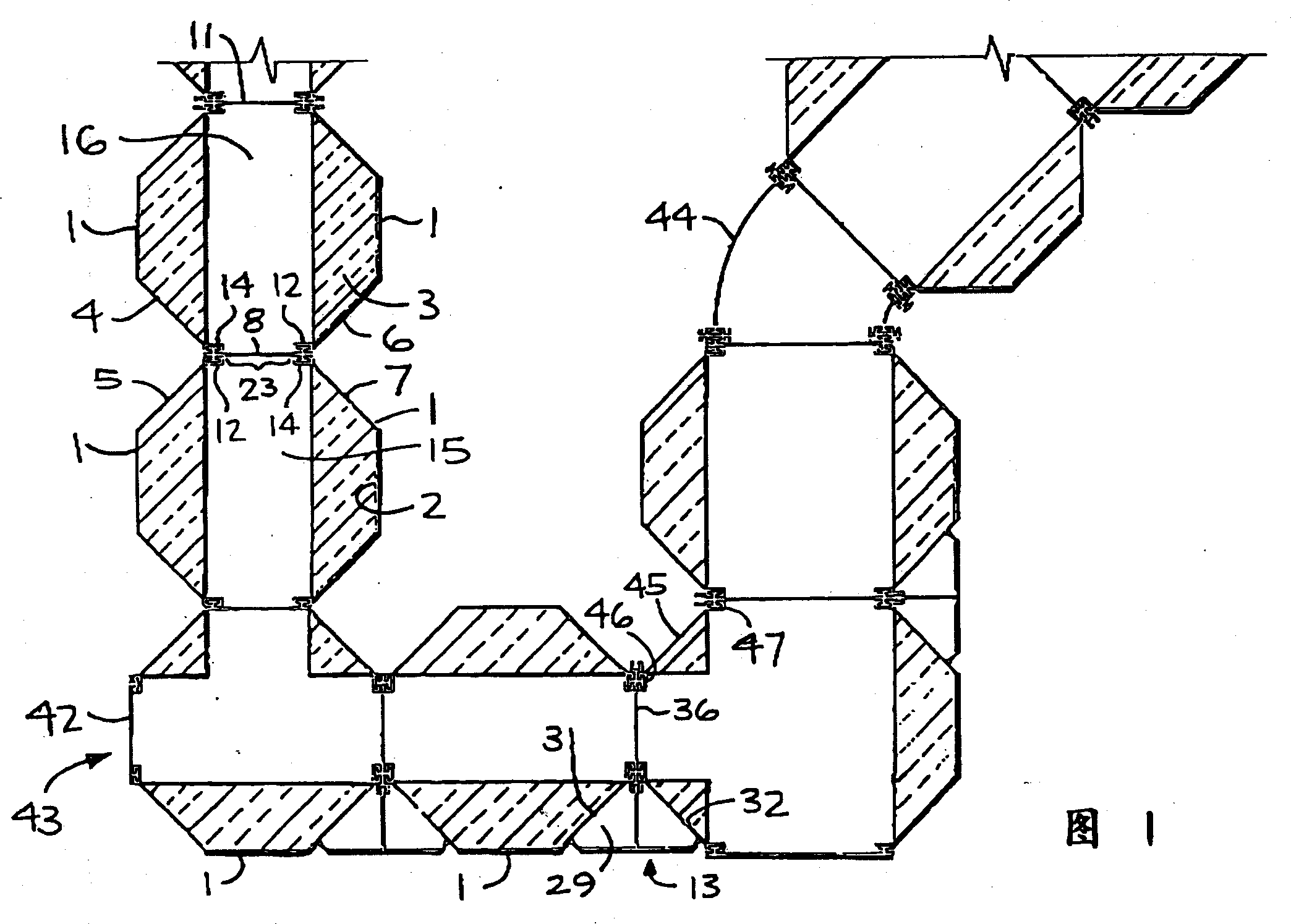

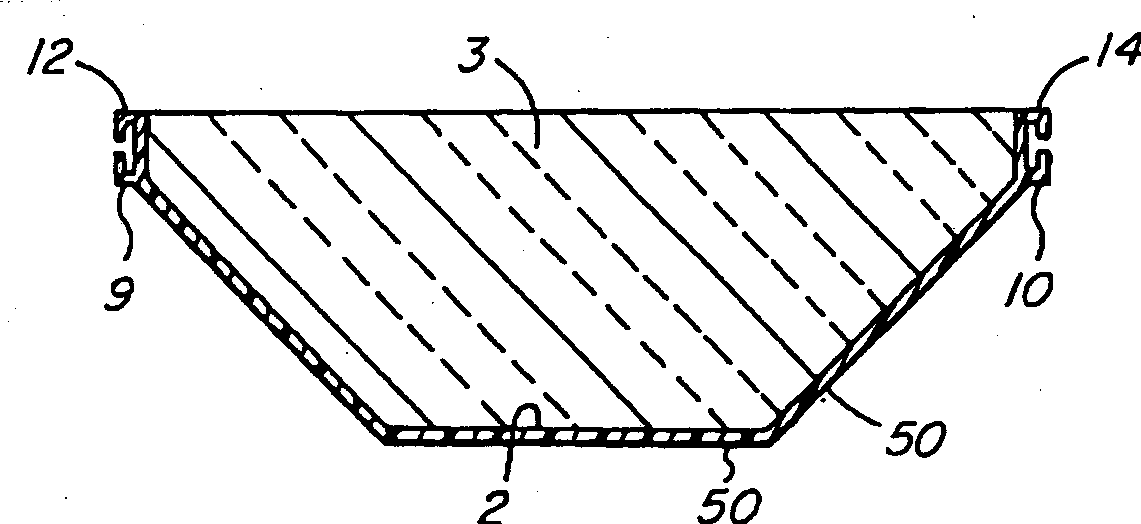

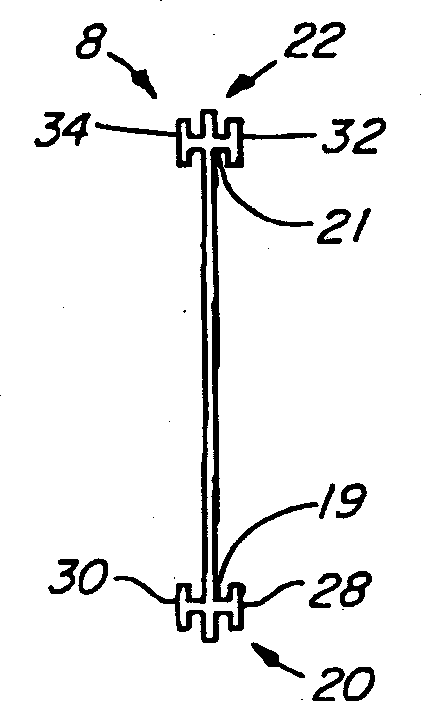

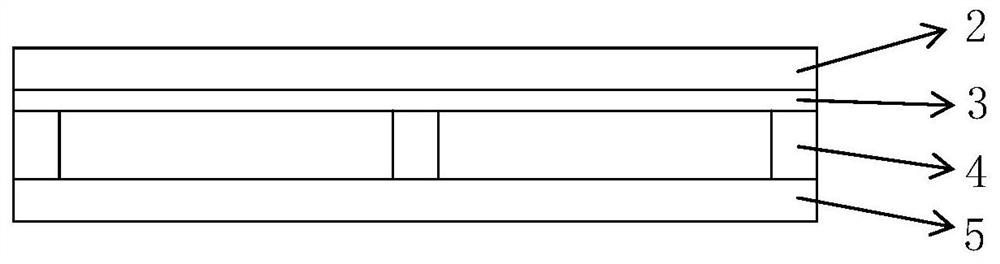

Modular formwork elements for pouring concrete to form vertical structure and assembling method

InactiveCN1086012CGood strength and stiffnessEasy to transport and assembleWallsBulkheads/pilesAerospace engineering

A modular assembly for creating formwork for casting vertical concrete structures is characterized by elongated, generally concave elements which are disposed in edge to edge relationship in two facing rows, and which are simultaneously retained in edge to edge relationship and in facing relationship by connecting members. The connecting members have spaced ribs allowing the flow of concrete across the plane of the connecting member.

Owner:弗朗西斯科·皮科尼

System, method, apparatus, and applications for open cell woven structural supports

ActiveUS7837919B2Good strength and stiffnessReduce in quantityWood working apparatusWingsGlass fiberFiber

An open cell or highly porous woven composite truss utilizes fibers of carbon, glass, ceramic, or the like that are woven together in a loom. The warps or tow are woven with the wefts, while the fibers are impregnated with resin. The resin impregnation step may be performed before or after the weaving step. The truss is then cured on the loom and later may be machined as needed. A rigid foam material may be used to stabilize the shape of the truss prior to curing and while machining. The foam may be later chemically dissolved or otherwise disposed of.

Owner:LOCKHEED MARTIN CORP

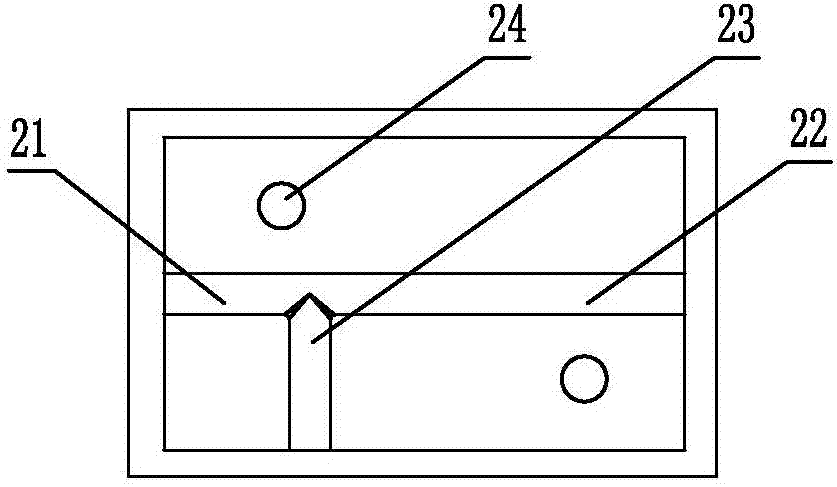

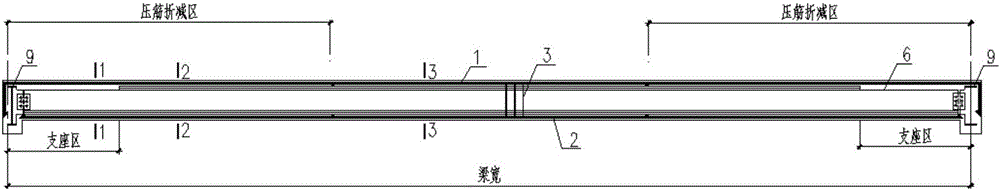

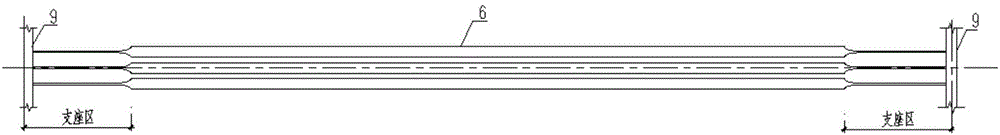

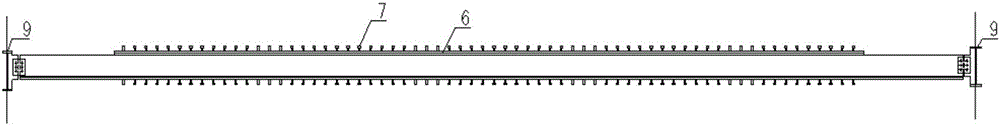

Adjustable support pad stone template

InactiveCN110593086AGood strength and stiffnessGood for positioning and stopping pulpBridge structural detailsEngineeringHeight difference

Owner:GANSU ROAD & BRIDGE CONSTR GROUP +1

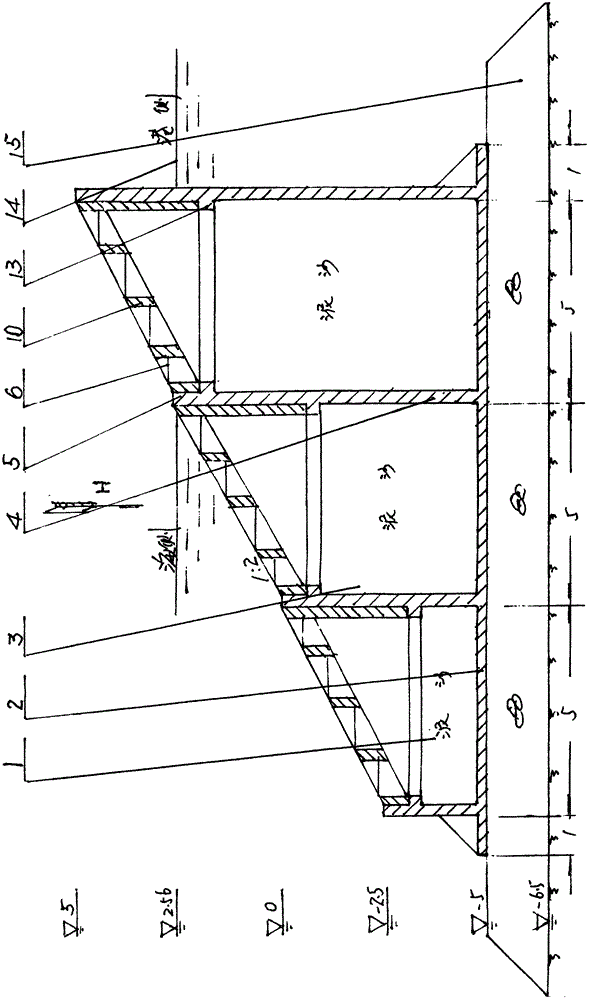

Slope-type caisson breakwater

InactiveCN104420441AImprove the protective effectGood strength and stiffnessBreakwatersQuaysReinforced concreteEngineering

The invention discloses a slope type caisson breakwater composed of a plurality of slope type caisson bodies arranged lengthways. The top portion of each slope-type caisson body is a caisson body levee crown slope surface rising from the seaside to the port side of the breakwater, the inclination of each caisson body levee crown slope surface is between 1:3 to 1:1, and each caisson body levee crown slope levee crown inclined surface of a caisson body surface is one to 4 times as high as waves. The slopes of slope-type caissons enable waves to break on the slope surfaces, most of wave energy is absorbed and dissipated during moving on slope surface, wave reflection is little, and the breakwater has high stability and good protecting effects. As a breakwater body is made of the slope type reinforced concrete caissons, building materials are saved, construction efficiency is high, manufacturing cost is low, investment is saved and construction period is shortened.

Owner:刘红静

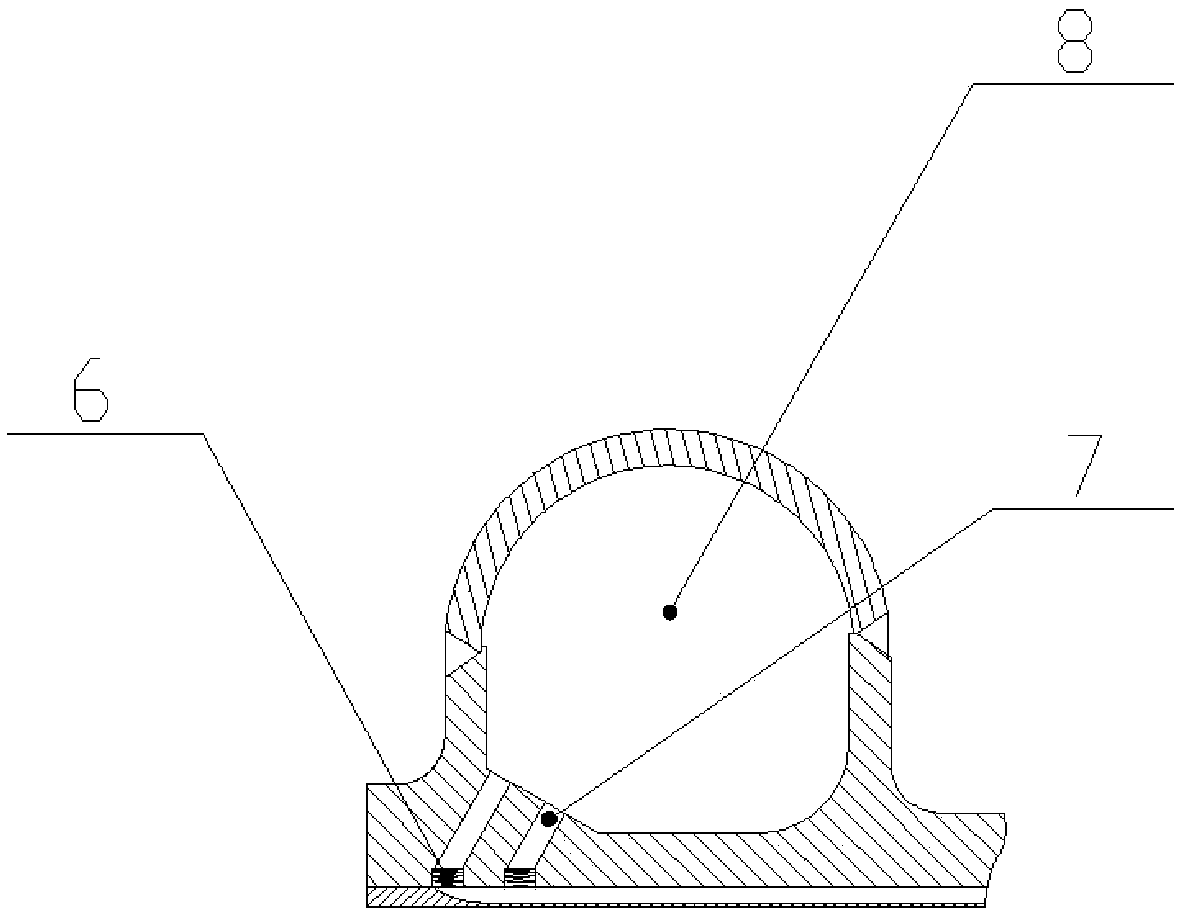

Thrust chamber body outer wall structure of liquid propellant rocket engine

PendingCN108825406ASolve processing problemsGood strength and stiffnessRocket engine plantsThrust chamberStructural engineering

The invention discloses a thrust chamber body outer wall structure of a liquid propellant rocket engine. The structure comprises an expansion section outer wall (2), a throat section outer wall (3), acylindrical section outer wall (4) and a liquid collecting ring upper cover (5); one end of the throat section outer wall (3) is connected with the expansion section outer wall (2), and the other endof the throat section outer wall (3) is connected with the cylindrical section outer wall (4); the cylindrical section outer wall (4) is provided with a radial hole (7) and a liquid collecting tank (6); the liquid collecting ring upper cover (5) is connected with the cylindrical section outer wall (4) to form a liquid collecting cavity (8); and the liquid collecting cavity (8) communicates with an external inner wall groove through the radial hole (7) and the liquid collecting tank (6) in sequence. The outer wall structure has the advantages of good assembly property, improvement of the dispersion welding line quality and the like; and meanwhile, the outer wall structure also achieves the function of a liquid collecting ring, is excellent in flowing uniformity and low in pressure loss, reduces the part number, and improves the reliability of a thrust chamber body part.

Owner:BEIJING AEROSPACE PROPULSION INST

A kind of hard rock cutterhead and cantilever tunneling machine including the cutterhead

ActiveCN110529139BThe structure is evenly stressedStrong resistanceTunnelsClassical mechanicsExcavator

The present invention proposes a hard rock cutterhead and a cantilever roadheader comprising the cutterhead. The hard rock cutterhead includes a conical cutterhead main structure, the cutterhead main structure includes a head, spokes and flanges, and the head and spokes The spokes are connected to the flange, the head and the spokes are provided with detachable cutters, and the cantilever boring machine includes the above-mentioned hard rock cutter head. The advantages of the invention: the cutterhead structure is more uniform in force, has a strong ability to resist deformation and damage, and can withstand high thrust, high speed and other driving conditions; the cutterhead is made of whole plate processing or steel plate welding, and the overall strength and rigidity are higher. Good; the cutter adopts the form that the end cover is located on the mounting surface of the cutter seat, which can improve the rock-breaking efficiency; the center hob of the cutter head can be retracted when the cutter head swings and cuts, effectively avoiding abnormalities such as eccentric grinding and edge chipping of the center hob Damage problem; the interchangeable installation of the hob and toothed cutter can excavate not only soft soil but also hard rock; the cutter head can swing up and down, left and right, and can excavate circular and special-shaped sections.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

Quick manufacturing process for carbon fiber reinforced paste resin

The invention relates to a quick manufacturing process for carbon fiber reinforced paste resin. The quick manufacturing process mainly comprises the following steps of: processing a PS foam board, sequentially performing extrusion-coating on an epoxy paste resin material, a carbon deposition fiber reinforced resin layer and adhesive support, removing the PS foam board to support, position and process a surface, which is separated from the PS foam mould, of the epoxy paste resin material, and performing surface treatment on the processed surface to obtain a final workpiece. Automobile carts manufactured by the quick manufacturing process are short in processing time and are high in processing precision, and processed parts can be modified by many times to meet requirements of a developer. Compared with conventional injection-molding and stamping, the quick manufacturing process greatly shortens development time, reduces cost, and meets physical properties needed, and therefore, a quickand precise process route is provided for developing and repairing automobile part products.

Owner:天津康普斯特科技发展有限公司

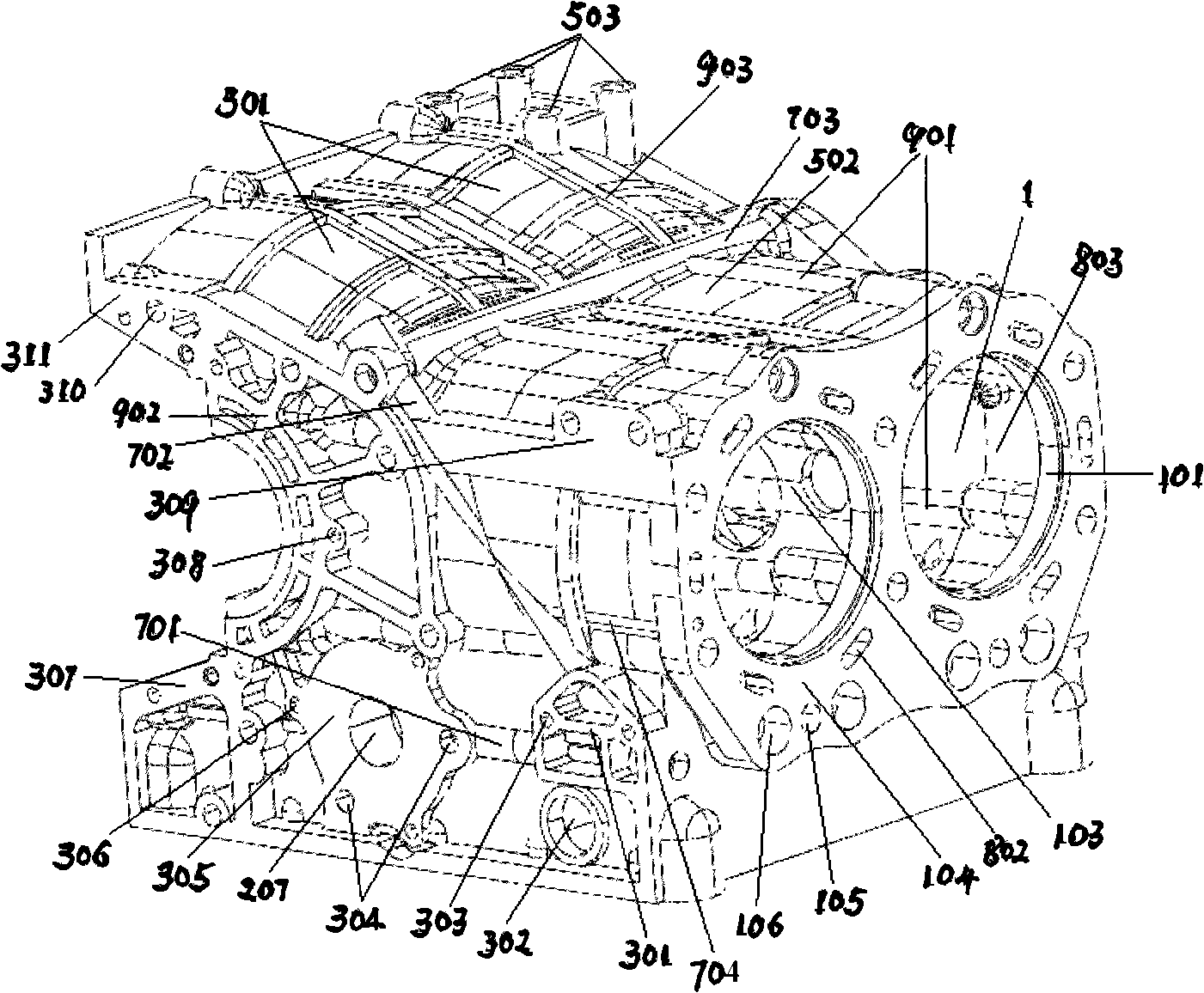

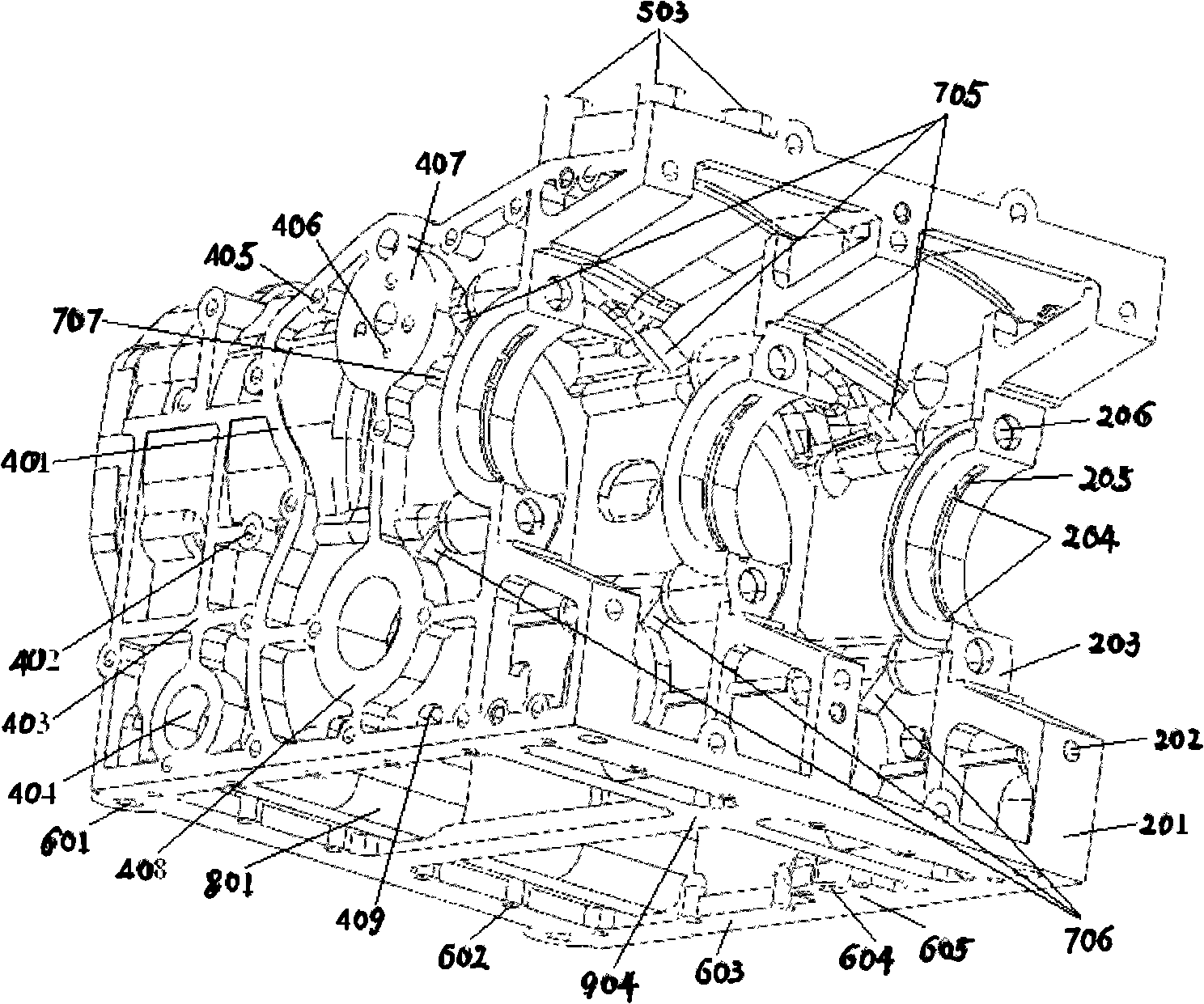

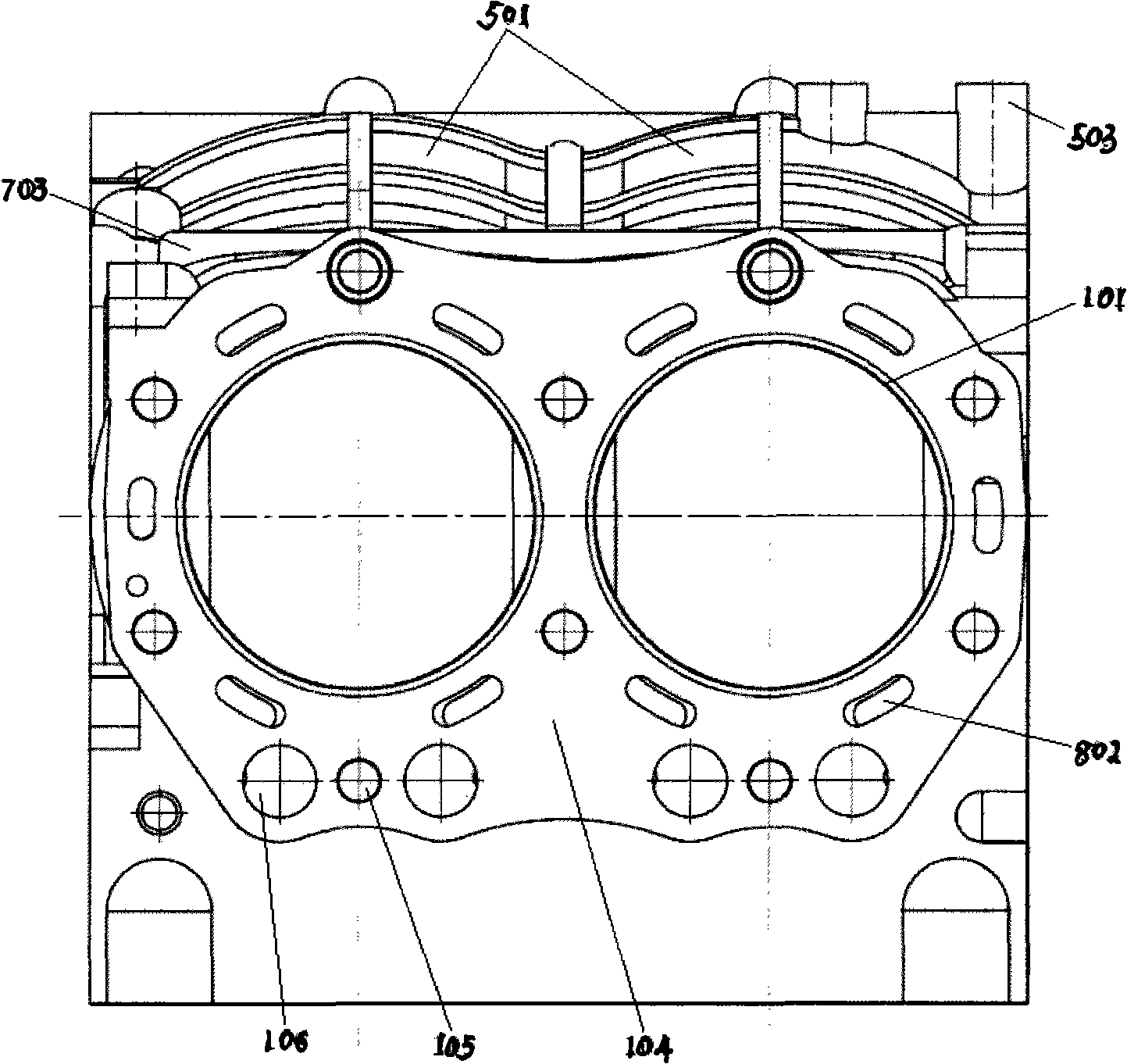

New generation horizontal single-double cylinder diesel airframe

InactiveCN101255827ABody structure is compactGood strength and stiffnessCylinder headsCylindersLubricationFlywheel

The present invention relates to a new horizontal diesel engine body, especially a horizontal single-cylinder or double-cylinder diesel engine body employing gantry structure, which belongs to field of diesel engine. Wherein, the front end of horizontal gantry single or twin cylinder diesel engine is a cylinder, the back end is a gantry globoidal crankcase, the left end is a flywheel end and related mounting surface, the right end is a gear chamber surface and related accessory mounting surface, the top end is a mounting surface of the gasoline tank, the bottom is an oil pan mounting surface and a cooling water chamber, five oil channels are provided in the engine body, the specific compulsory cooling water chamber is provided outside the cylinder cooling water cover (namely between handspike and oil pan mounting surface) on bottom of engine body, a reinforce rib is provided on engine body. The gantry horizontal diesel engine body employs a gantry type globoidal crankcase, the cover of crankcase and the engine body respectively are single part, the crankcase cover of the engine body and the crankcase are connected at mounting surface of the crankcase cover by a bolt. The present invention has merits of compact structure, good intension and rigidity, high carrying capacity of headstock, good reliability, good cooling efficiency because of cooling water chamber on bottom of engine body, short oil channels, good lubrication efficiency and low cost.

Owner:KUNMING UNIV OF SCI & TECH +1

A multi-mode shield machine cutterhead and its shield machine

ActiveCN110985027BEvenly distributedThe structure is evenly stressedTunnelsMechanical engineeringPhysics

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

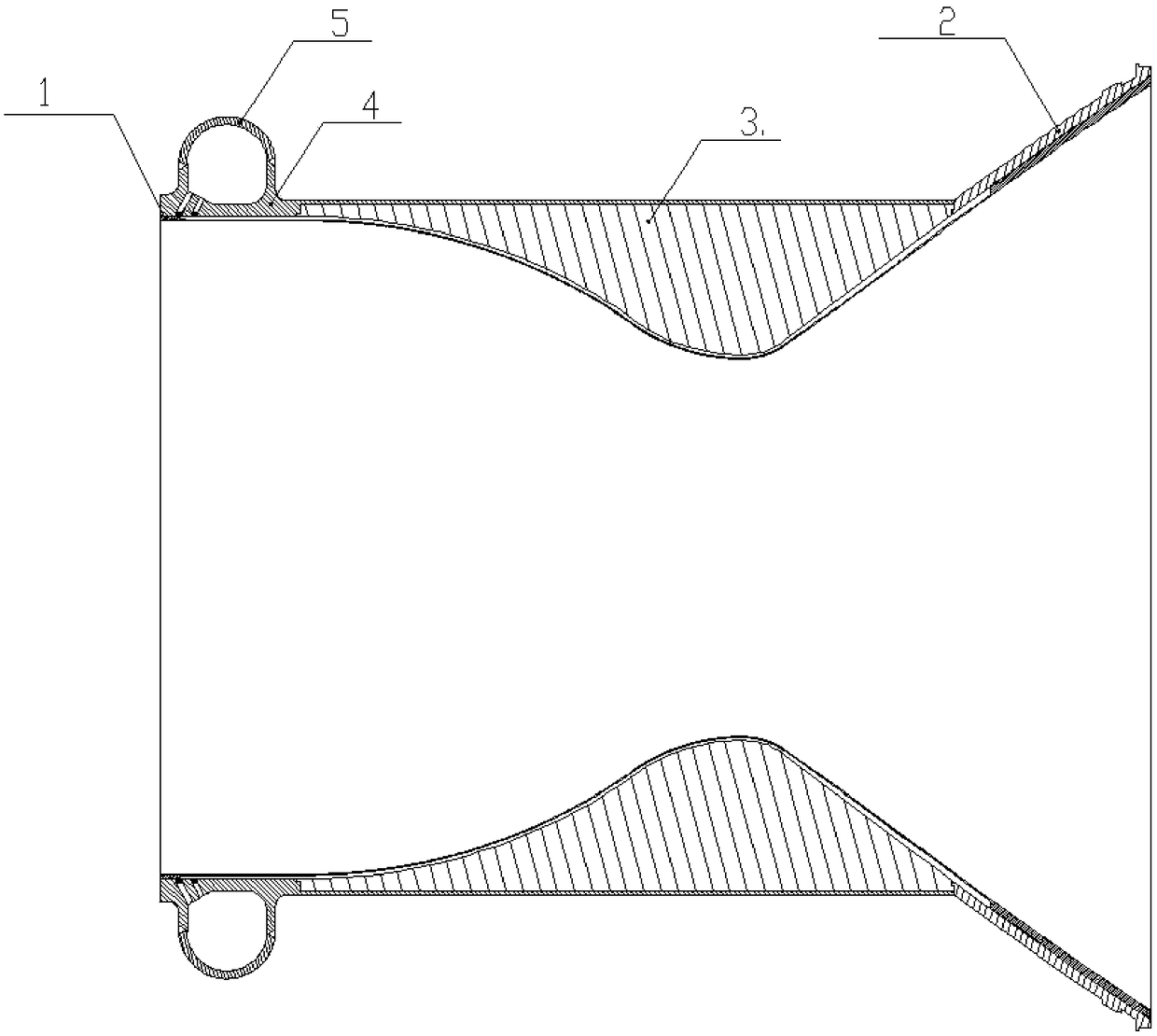

Elevator traction system

ActiveCN103171953AGood strength and stiffnessImprove securityBuilding liftsLoad carryingTraction system

The invention discloses an elevator traction system. The elevator traction system comprises guiding pulleys which are arranged on an elevator lift car frame, an elevator main engine and a counterpoise, and composite steel belts which successively pass through the guiding pulleys, wherein the guiding pulleys are in an integrated structure of a pulley and a bearing main shaft, a guiding groove which is formed in a bearing main shaft is formed in the bearing main shaft, and the guiding groove is a groove with a flat base. On one hand, the elevator traction system solves the problems that the composite steel belts are in line deflection and load carrying capacity is uneven, on the other hand, the elevator traction system further solves the problems of inability to slip caused by an oversize friction coefficient by adopting the composite steel belts with a concave shape and a protruding shape and a rope sheave, so that the elevator traction system is authentically suitable for long term operation of the elevator. The elevator traction system has the advantages of being good in rigidity and intensity by adopting a wheel axle integrated structure, high in safety coefficient, compact in structure, capable of ensuring that an elevator device and an elevator complete machine structure are simplified, thereby reducing occupied space of the elevator device to an elevator well, and effectively saving well space.

Owner:GUANGZHOU GUANGRI ELEVATOR IND

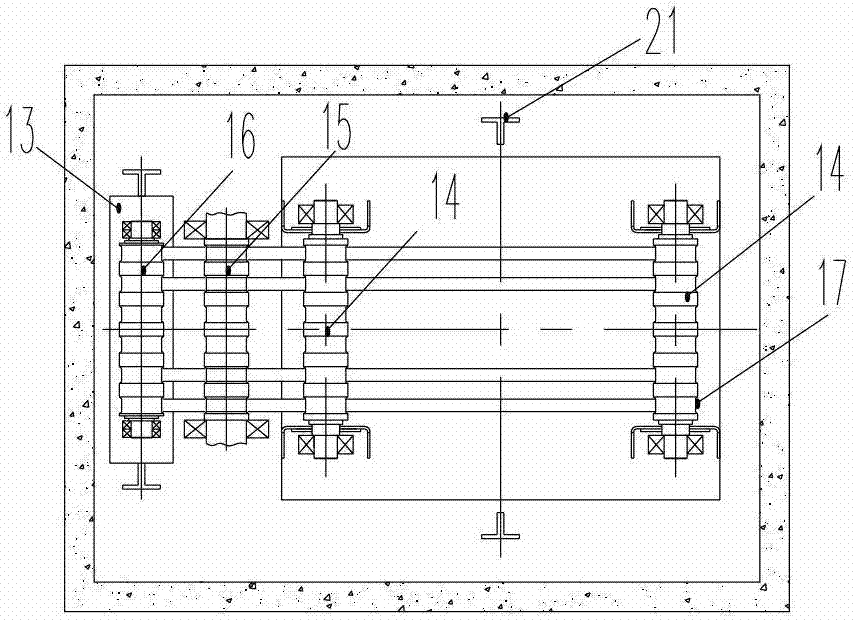

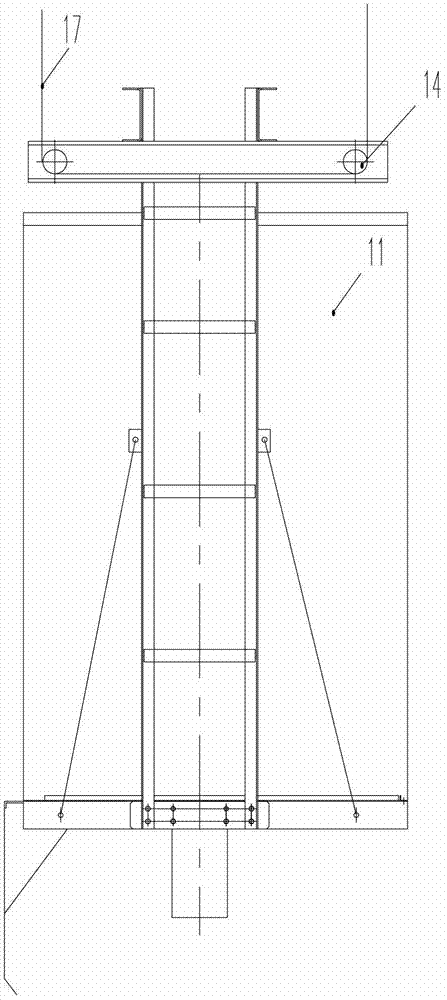

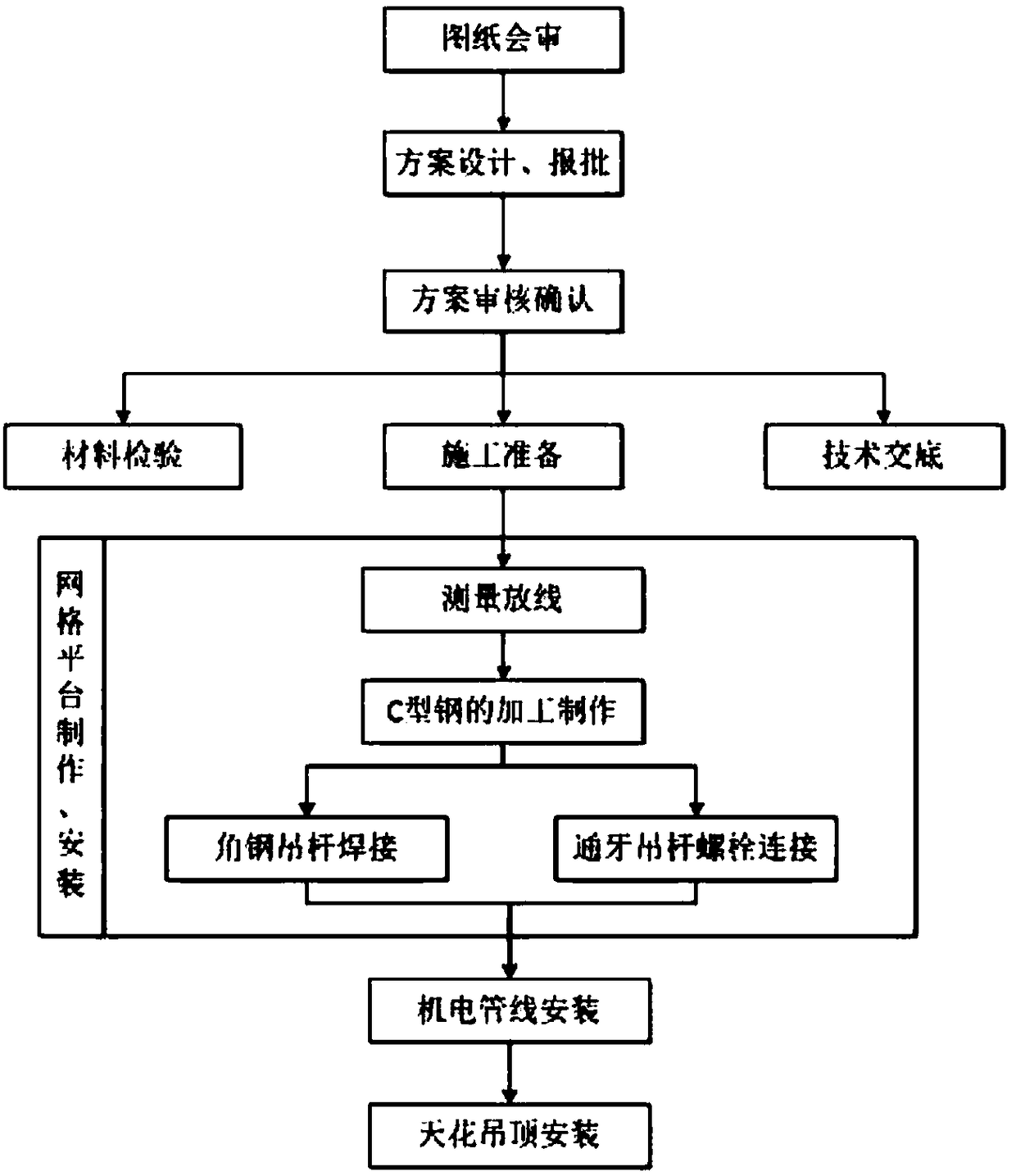

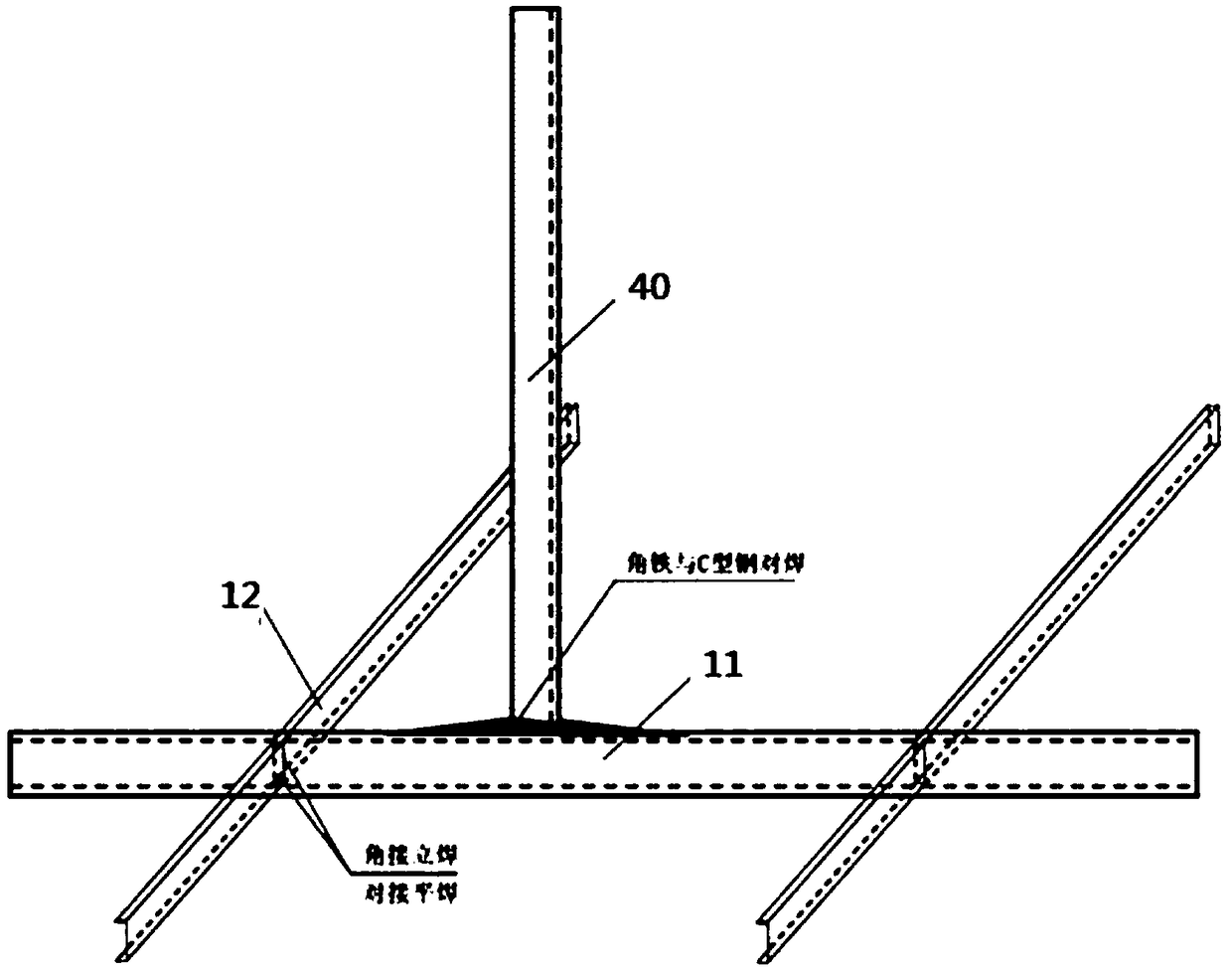

Tall and large workshop self-made grid platform used as electromechanical pipeline and construction method of platform

The invention discloses a tall and large workshop self-made grid platform used as an electromechanical pipeline and a construction method of the platform. The platform comprises a C sectional steel truss and punched CL sectional steel, the C sectional steel truss comprises longitudinal C sectional steel and transverse C sectional steel, and a closed end, opposite to an open end, of the punched CLsectional steel is fixedly connected to a roof steel structure main beam through right-angled tube bundles and antiskid nuts; the open end of the punched CL sectional steel is connected to one end ofgalvanized angle steel through a first L-shaped frame, a connecting plate and bolts; the longitudinal C sectional steel is electrically welded to the other end of the galvanized angle steel; the lowerportion of the C sectional steel truss is connected with an air pressure pipe, a fire service pipe, a wire groove and a wire tube through connecting rods, and the lower portion of the C sectional steel truss is connected to a ceiling by adopting a first through-thread suspension rod. By adopting the self-made grid platform, the dense installation of roof brackets is reduced, extension brackets are made by using the grid platform, the problems of installation and fixation of wire grooves, pipelines and air ducts in a large space are solved, and the platform also can be used as a suspended ceiling keel.

Owner:GUANGZHOU MECHANICAL & ELECTRICAL INSTALLATION

High-temperature-resistant corrosion-resistant diaphragm core material

The invention relates to a high-temperature-resistant corrosion-resistant diaphragm core material. The material is characterized in that by weight, 55-65% of ethylene-propylene-diene monomer rubber and 0.8-1.5% of dicumyl peroxide (DCP) are weighed and evenly mixed at normal temperature, then the mixture is added into a first feed inlet of a double-screw extruder for mixing, 10-15% of naphthenic oil is injected after mixing, and then 25-30% of polypropylene and 8-13% of talcum powder are evenly mixed and added into a second feed inlet of the double-screw extruder to be extruded and granulated.The material has the advantages that temperature resistance and corrosion resistance are high, physical property indexes of the material are hardly reduced at a high temperature, and solid-liquid separation work under a relatively high temperature environment can be achieved.

Owner:HENAN DAZHANG FILTER EQUIP CO LTD

Combined sectional steel concrete beam

InactiveCN106381955AIncrease the use of spaceGuaranteed structural bearing capacityLoad-supporting elementsSurface layerConcrete beams

The invention provides a combined sectional steel concrete beam. The combined sectional steel concrete beam comprises combined sectional steel, concrete and connecting nodes, wherein reasonable spacing is kept between the combined sectional steel and the outer surface layer of the concrete through configuration; the combined sectional steel and frame beam sectional steel are kept in consistent upper flange top elevation through configuration; the spacing between central axes distributed by secondary beams of the combined sectional steel concrete beam is 2 to 3 times of beam width. Compared with a method of increasing the sectional dimension of a building structure, the combined sectional steel concrete beam provided by the invention has the advantages that the beam height can be well controlled while the structure bearing capacity and the applicability are ensured, and more using space of a building is ensured.

Owner:SHANGHAI NUCLEAR ENG RES & DESIGN INST CO LTD

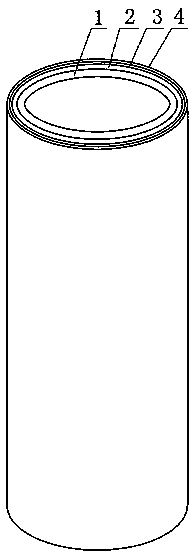

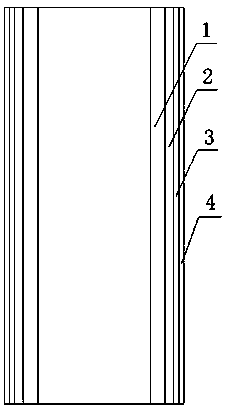

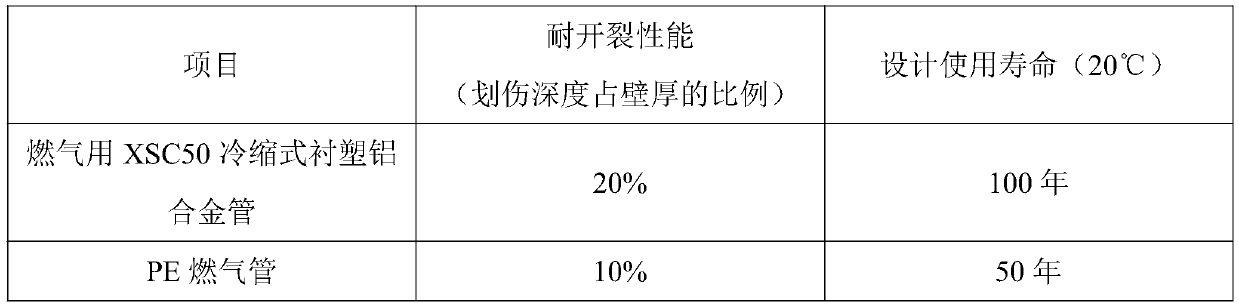

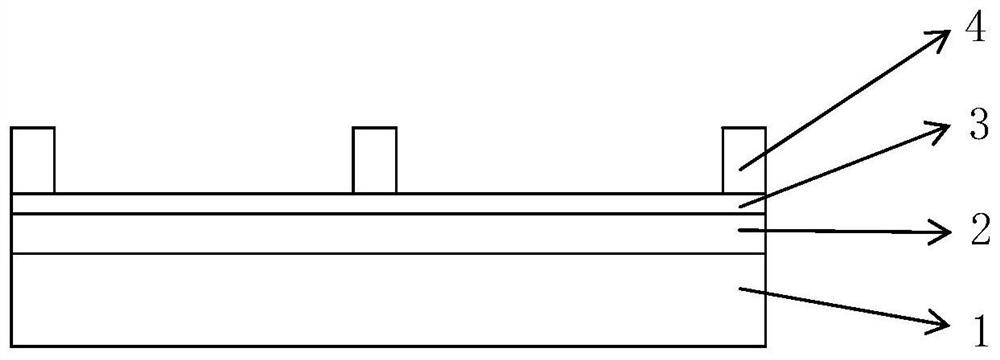

Xsc50 cold-shrinkable plastic-lined aluminum alloy pipe for gas, piping system and preparation method

ActiveCN106523807BHigh mechanical strengthImprove toughnessCorrosion preventionPipe protection against corrosion/incrustationAdhesiveHigh adhesion

The invention relates to the technical field of pipes, in particular to an XSC50 cold shrinkage type lining plastic aluminum alloy pipe and pipeline system used for fuel gas and a manufacturing method. The XSC50 cold shrinkage type lining plastic aluminum alloy pipe is composed of an XSC50 resin pipe layer, an aluminum pipe layer, an oxidation film protection layer and a high-adhesive-force oxidation-corrosion-prevention layer which are sequentially arranged from inside to outside. The XSC50 resin pipe is used as the raw material, and therefore the manufactured XSC50 cold shrinkage type lining plastic aluminum alloy pipe can be high in mechanical strength, good in tenacity, quite good in strength rigidity in a high-temperature environment, high in heatproof grade and suitable for working under various environments. Meanwhile, the aluminum pipe and the XSC50 resin pipe are connected in a seamless manner through cold shrinkage and can be firmly combined without adhesives; due to the adoption of the XSC50 resin pipe layer of a certain thickness, the aluminum pipe layer of a certain thickness, the oxidation film protection layer of a certain thickness and the high-adhesive-force oxidation-corrosion-prevention layer of a certain thickness, the strength of the manufactured pipeline reaches about 5.5 MPa at the temperature being 70 DEG C within 50 years; and meanwhile the manufacturing cost is controlled. The manufacturing method is simple, and the manufactured XSC50 cold shrinkage type lining plastic aluminum alloy pipe is excellent in performance and has important significance in promoting application and development of fuel gas pipes.

Owner:成都蕴达管业有限公司

Rapid Parts Process of Carbon Fiber Reinforced Paste Resin

The invention relates to a quick manufacturing process for carbon fiber reinforced paste resin. The quick manufacturing process mainly comprises the following steps of: processing a PS foam board, sequentially performing extrusion-coating on an epoxy paste resin material, a carbon deposition fiber reinforced resin layer and adhesive support, removing the PS foam board to support, position and process a surface, which is separated from the PS foam mould, of the epoxy paste resin material, and performing surface treatment on the processed surface to obtain a final workpiece. Automobile carts manufactured by the quick manufacturing process are short in processing time and are high in processing precision, and processed parts can be modified by many times to meet requirements of a developer. Compared with conventional injection-molding and stamping, the quick manufacturing process greatly shortens development time, reduces cost, and meets physical properties needed, and therefore, a quickand precise process route is provided for developing and repairing automobile part products.

Owner:天津康普斯特科技发展有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com