New generation horizontal single-double cylinder diesel airframe

A diesel engine, a new generation of technology, applied in the direction of machines/engines, cylinders, cylinder heads, etc., can solve the problems of complex machining process, large structure size, low bearing capacity, etc., and achieve good fluidity and cooling effect, strength and rigidity Good, strong bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

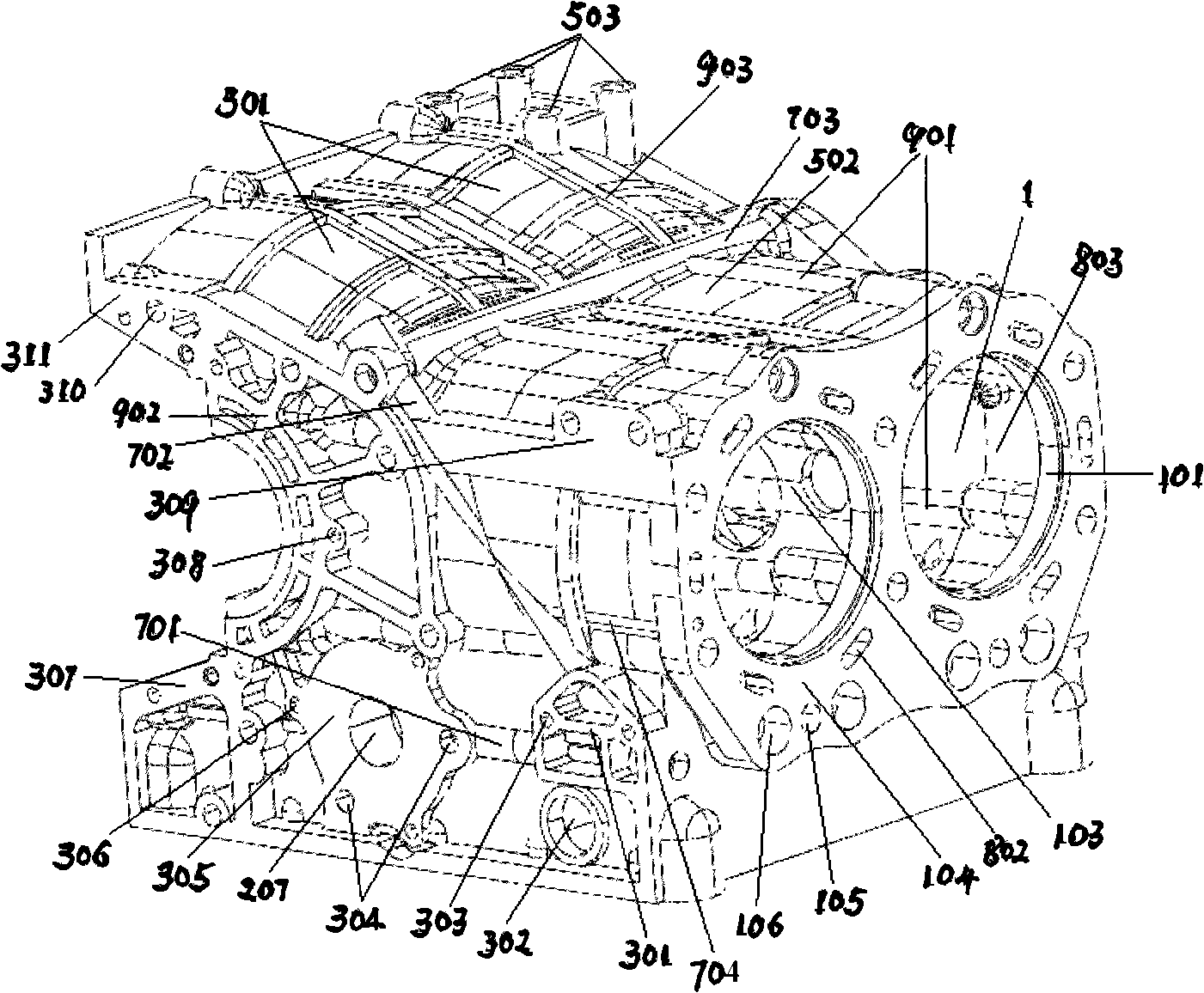

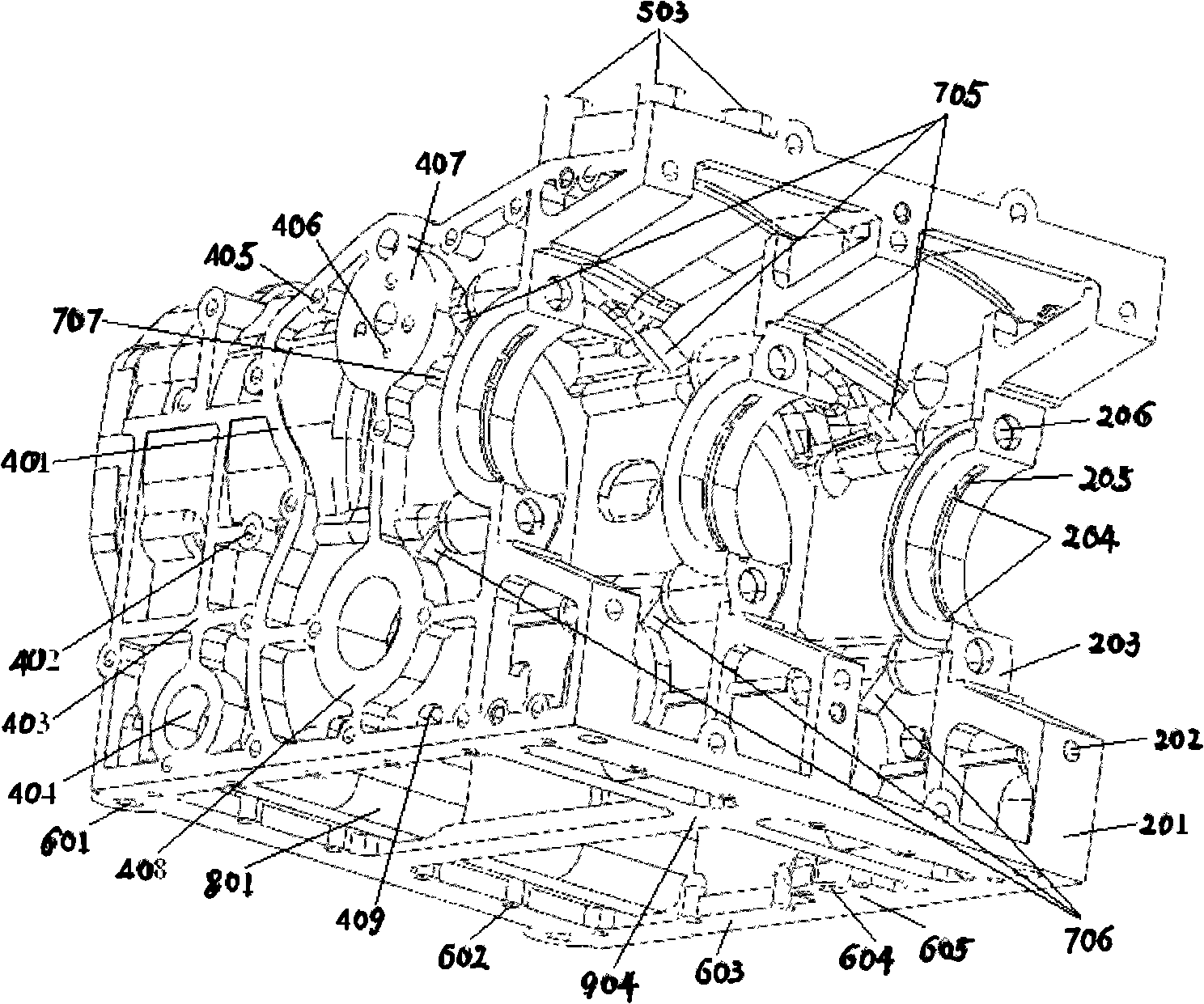

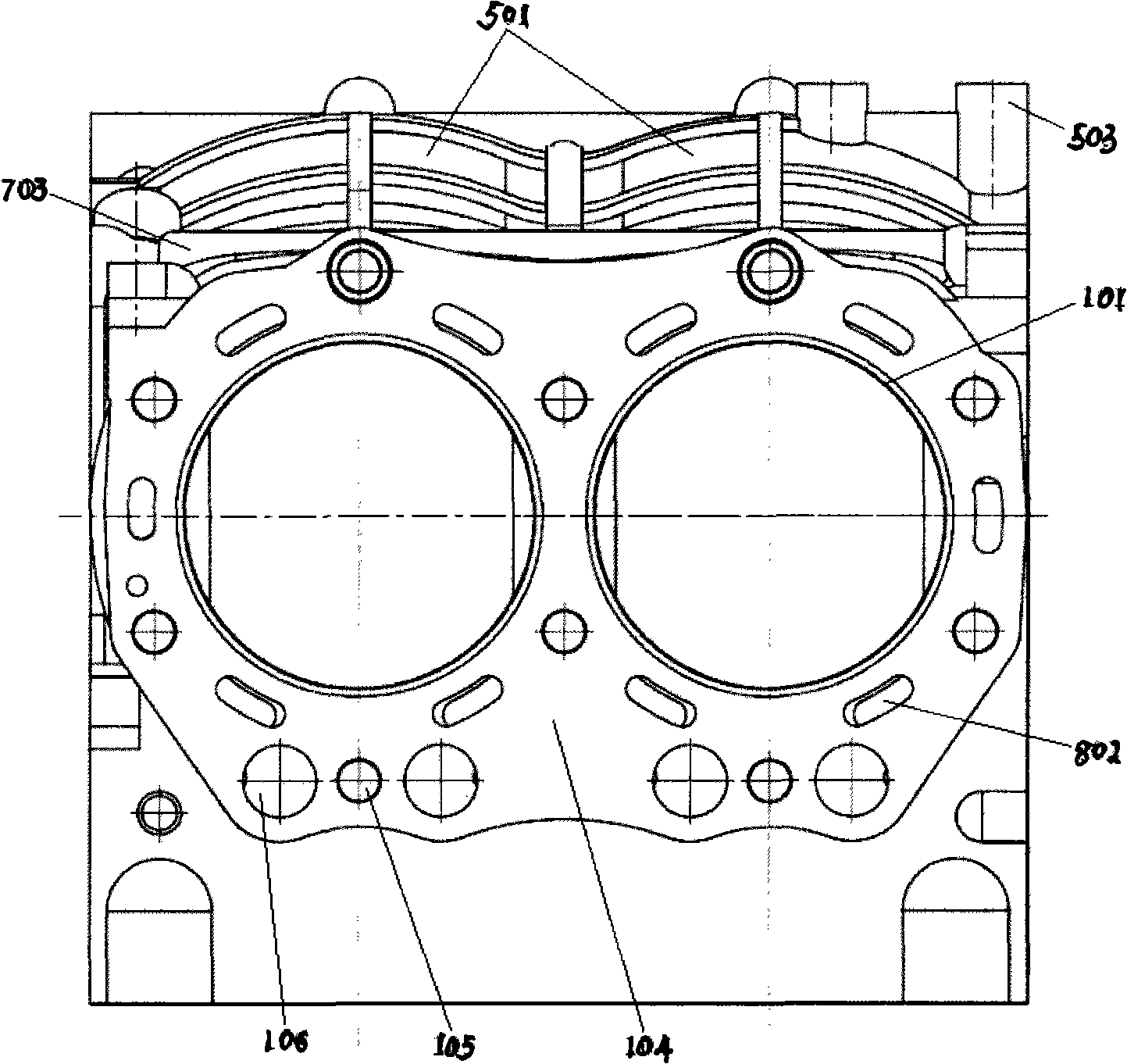

[0050] The overall shape of the new generation of horizontal single- and double-cylinder diesel engines is a hexagonal body, which consists of cylinders, crankcases, cooling water chambers, lubricating oil passages, connecting holes and various attachment mounting surfaces. The front end of the horizontal diesel engine body is the cylinder (1), the rear end is the gantry type curved surface crankcase (2), the left end of the body (3) is the flywheel end face and the mounting surface of related accessories, and the right end (4) of the body is the gear chamber surface (401) And related accessories mounting surface, the body upper end (5) is the fuel tank mounting surface, and the body lower end (6) is the oil pan mounting surface (603) and the cooling water cavity (801).

[0051] A main oil passage (7) is arranged on the body, and four lubricating oil passages (704, 705, 706, 707) are designed inside the body, and the main oil passage and the four oil passages communicate with e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com