An automatic packaging system for workpieces

An automatic packaging and workpiece technology, applied in packaging, packaging protection, transportation and packaging, etc., can solve the problems of low production efficiency and large labor costs, and achieve the effects of high production efficiency, convenient operation and stable operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

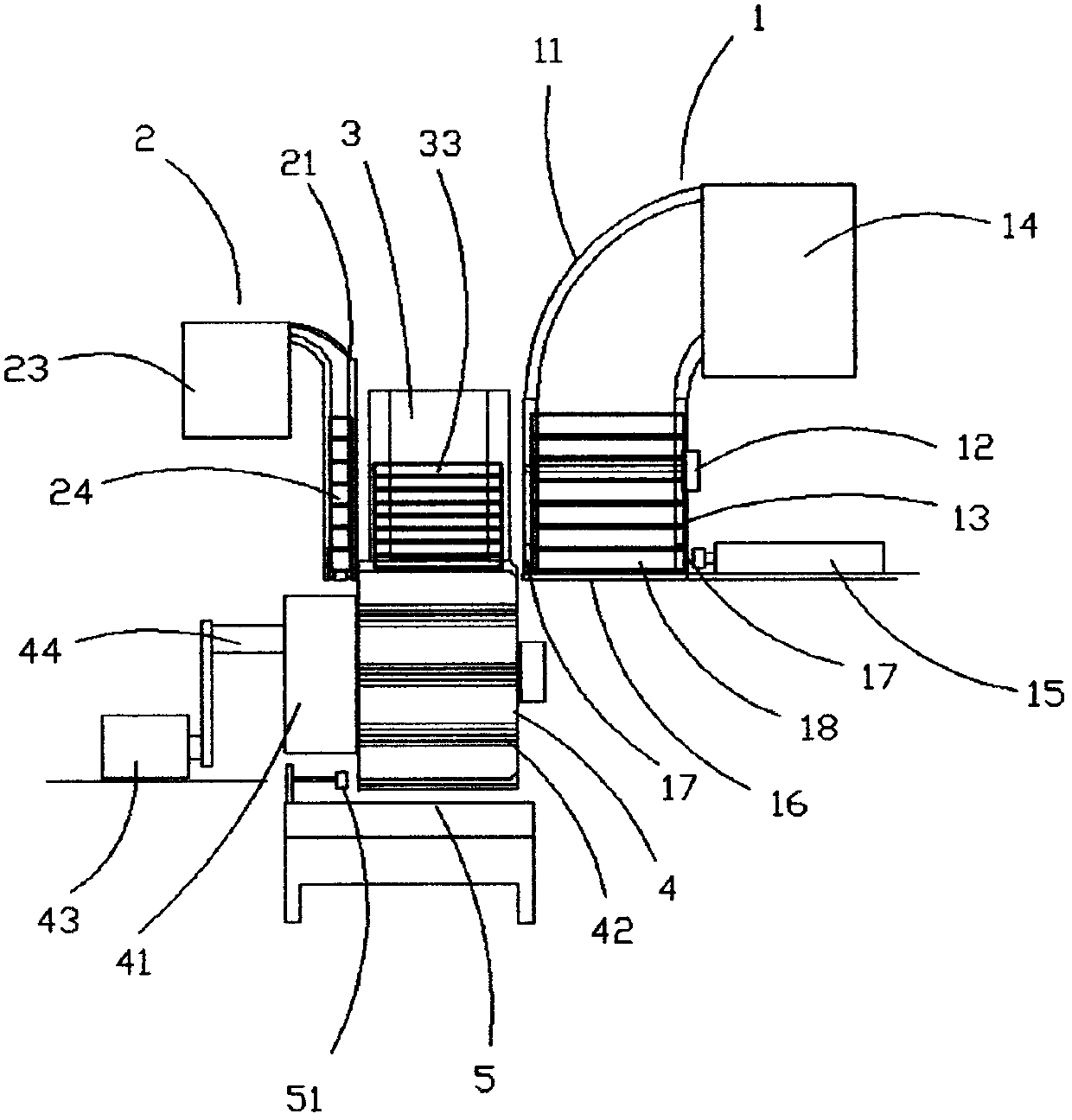

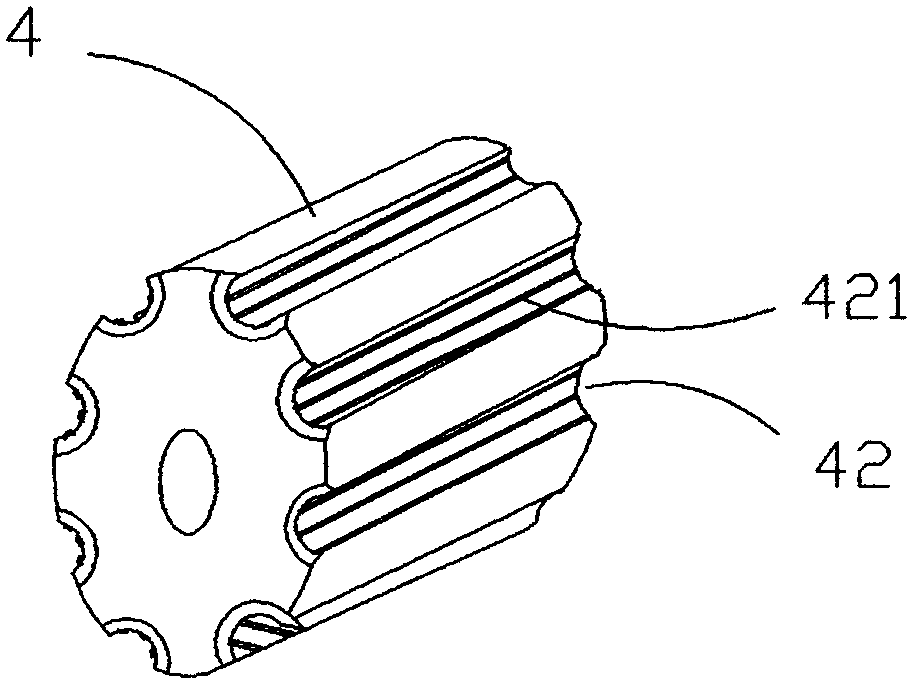

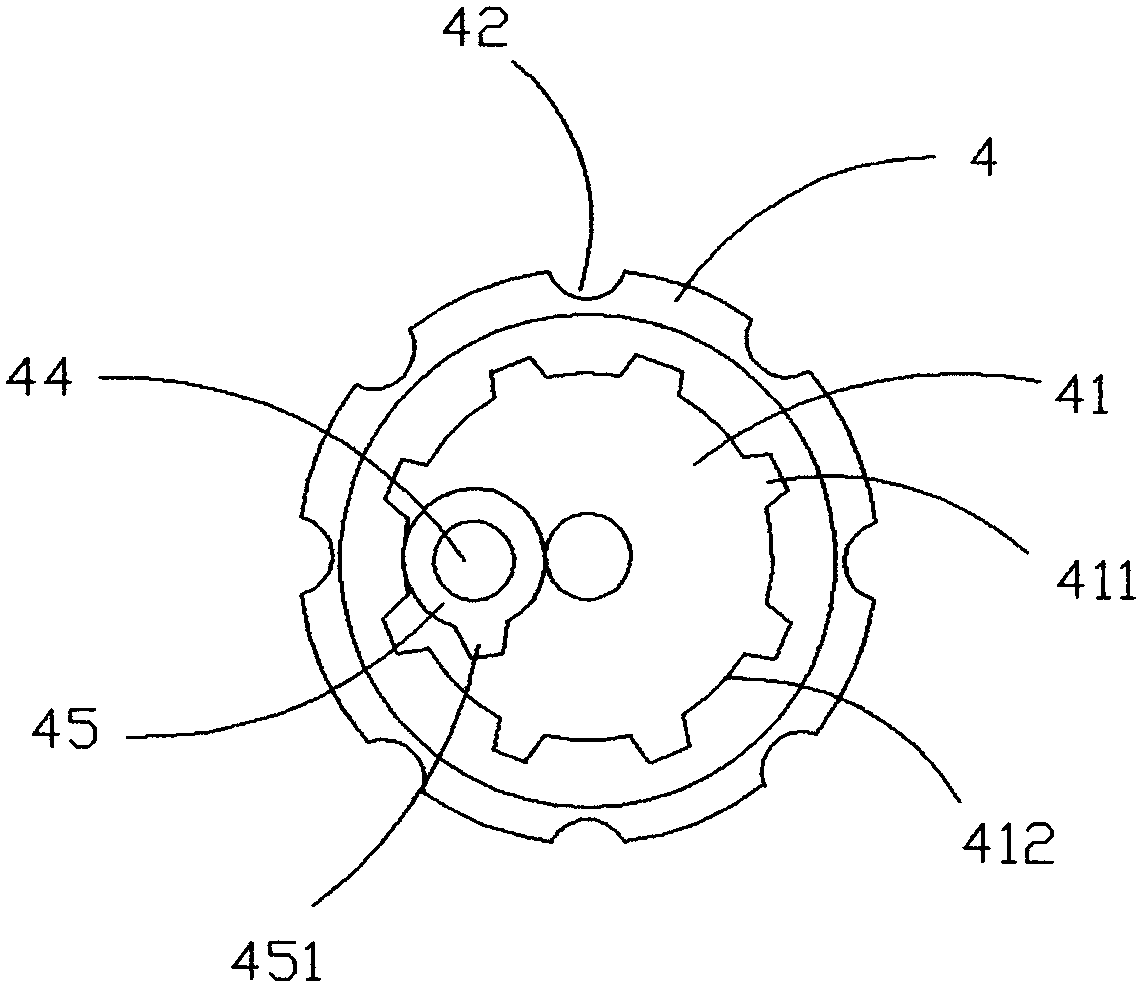

[0016] Such as figure 1 , 2 As shown in , 3 and 4, an automatic workpiece packaging system includes a cylinder conveying device 1, a cover conveying device 2, a runner 4, a workpiece output rack 3, and a conveying bracket 11 of the cylinder conveying device 1 is connected to a direction guide mechanism 14. One side of the conveying bracket 11 is provided with a width adjusting member 12, and the connection between the bottom of the bracket conveying channel 13 and the bottom plate 16 is provided with two correspondingly connected output holes 17, and the power mechanism 15 is located outside the output hole 17. The power mechanism 15 is a cylinder. The support slideway 21 of the cover conveying device 2 is connected to the vibration plate 23, the lower port of the support slideway 21 is provided with a reed tongue 22, the runner 4 is located between the cylinder conveying device 1 and the cover conveying device 2, and the workpiece output rack 3 is located above the runner 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com