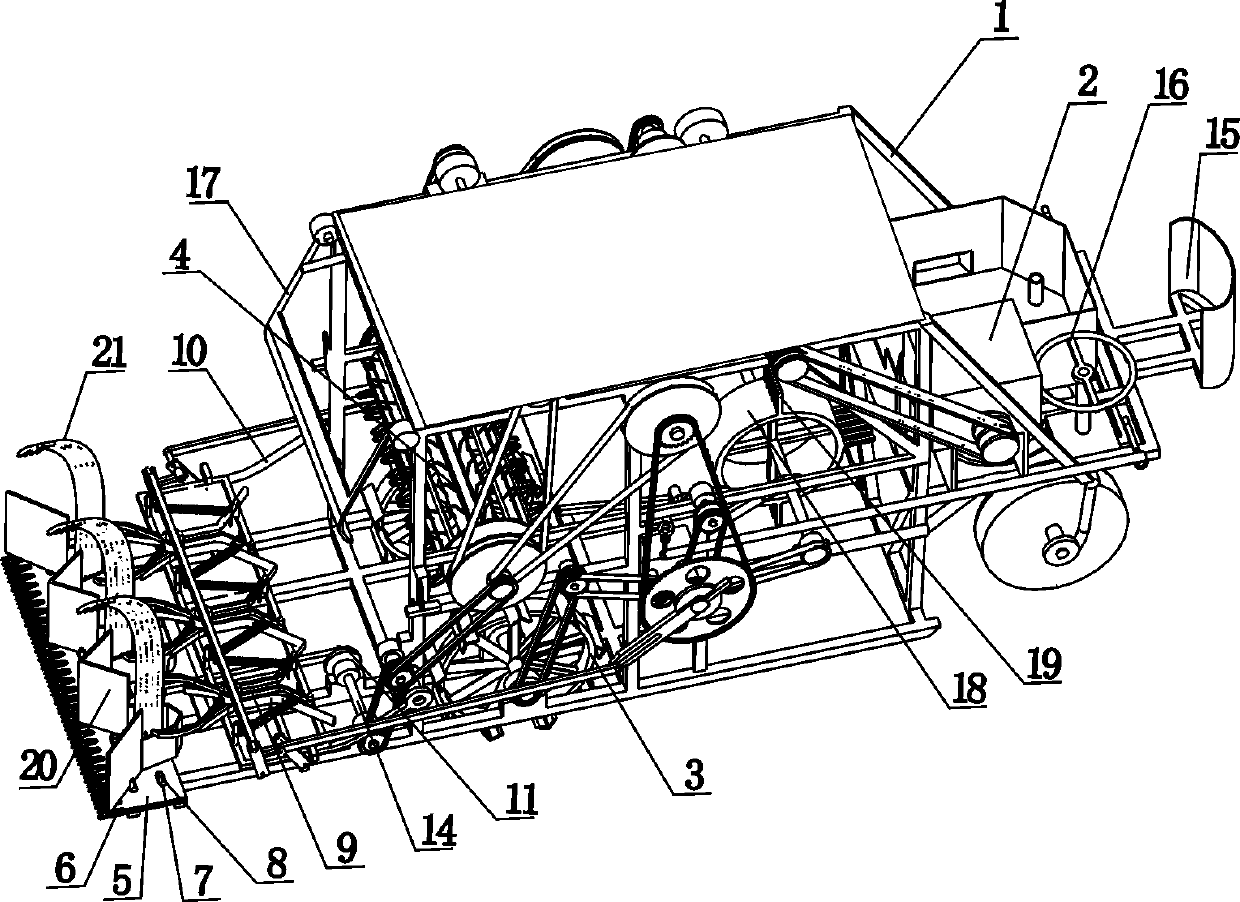

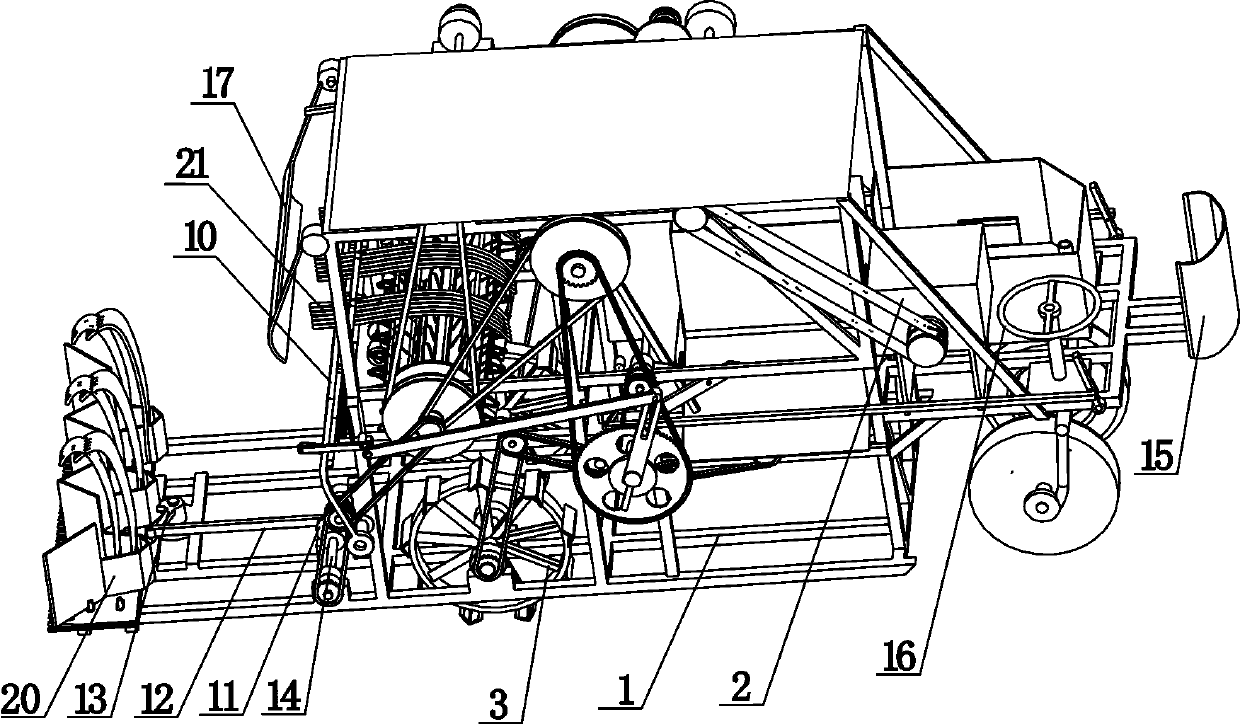

Crank-transmission-type sesame stalk threshing system

A technology of crank drive and sesame rod, which is applied to cutters, agricultural machinery and implements, and other applications. It can solve the problems of production reduction, sesame shedding, and low harvest rate, and achieve compact body structure, reduce vibration, and reduce the risk of falling into the field. loss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Such as figure 1 , 2 As shown, the crank-driven sesame rod threshing system includes a support body 1, an engine 2, a transmission mechanism, a wheel 3 and a threshing roller 4 in the sesame threshing bin, and the engine 2 drives the wheel 3 and the threshing roller 4 to rotate through the transmission mechanism. The front end of the support body 1 is provided with a sesame bar cutting mechanism, and the sesame bar cutting mechanism is composed of a cutting blade A5, a cutting blade B6 and a transmission assembly, and the front ends of the cutting blade A5 and the cutting blade B6 are provided with a row of cutting teeth, The cutting blade A5 is provided with a guide hole 7, and the cutting blade B6 is provided with a guide post 8. The cutting blade B6 is fixed on the support body 1, and the cutting blade A5 is arranged on the upper surface of the cutting blade B6 and the guide post 8 is inserted into the In the guide hole 7; the transmission assembly is composed of a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com