Improved type axial-flow compressor

An axial-flow compressor and an improved technology, applied in the field of compressors, can solve the problems that the axial-flow compressor cannot be miniaturized, increase the manufacturing cost of the axial-flow compressor, the difficulty of repair, and the space occupied, so as to reduce the difficulty of operation and maintenance and cost, improve cooling effect, reduce the effect of space occupied

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

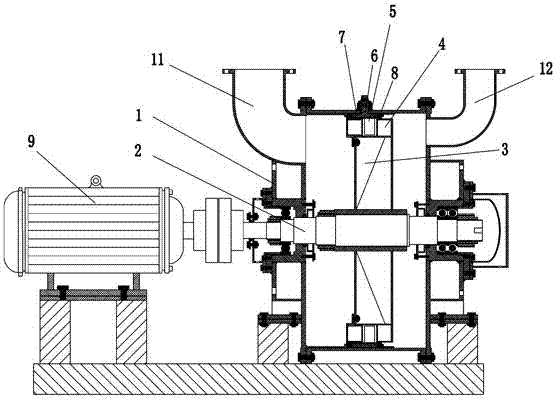

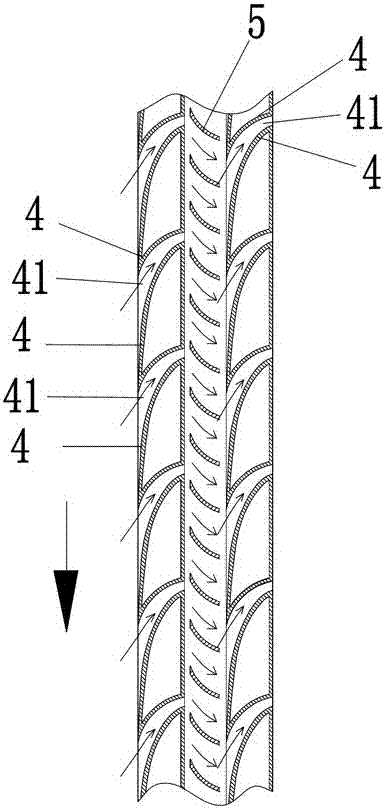

[0023] Such as Figure 1 to Figure 4 As shown, an improved axial flow compressor includes a body 1. The interior of the body 1 is hollow, and air inlets 11 and air outlets 12 are arranged on both ends. A rotating shaft 2 is arranged in the center of the body 1, and the rotating shaft 2 is connected to an external motor 9 to rotate. A runner 3 is fixed on the rotating shaft 2, and two sets of blades 4 that form an axial air flow when the runner 3 rotates are fixed on the circumferential surface of the runner 3. The two sets of blades 4 are arranged along the circumference of the runner 3 to form a 3 The front and rear groups on the circumferential surface form an air flow channel 41 between adjacent blades 4 on the same circle, and the inner wall of the body 1 between the two front and rear blades 4 is provided with a deflector 5 opposite to the direction of the blades 4 . Since the air flow passes through the two sets of blades 4 and the auxiliary blades 5 to form compressed ...

Embodiment 2

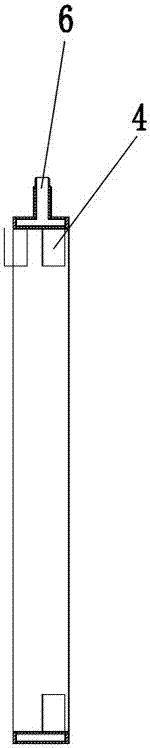

[0028] Another example Figure 5 Shown is another implementation of the invention. This realization scheme is an extension on the basis of the first embodiment, specifically adding three runners 3 parallel to the rotating shaft 2 , and a water cooling chamber 6 is provided between every adjacent blade 4 . The distribution and structure of blades 4 on each runner 3 and the distribution and structure of deflectors 5 are consistent with the structure and principle of Embodiment 1, and will not be repeated here.

[0029] After the air in this embodiment is compressed by the first stage, it is further compressed by the second stage and the third stage, so that the pressure of the gas is further increased and then increased, so that the compressed gas with higher pressure is output to meet the requirements of higher gas pressure. stressful occasions.

[0030] In addition to the above two schemes, four or more runners 3 can form more stages of compression units to provide higher-de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com