Thrust chamber body outer wall structure of liquid propellant rocket engine

A technology of liquid rockets and thrust chambers, applied in rocket engine devices, machines/engines, mechanical equipment, etc., can solve the problems of small pressure loss, good flow uniformity, unsuitable welding process, etc., and achieve small flow resistance loss and flow uniformity Strong ability, good strength and rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

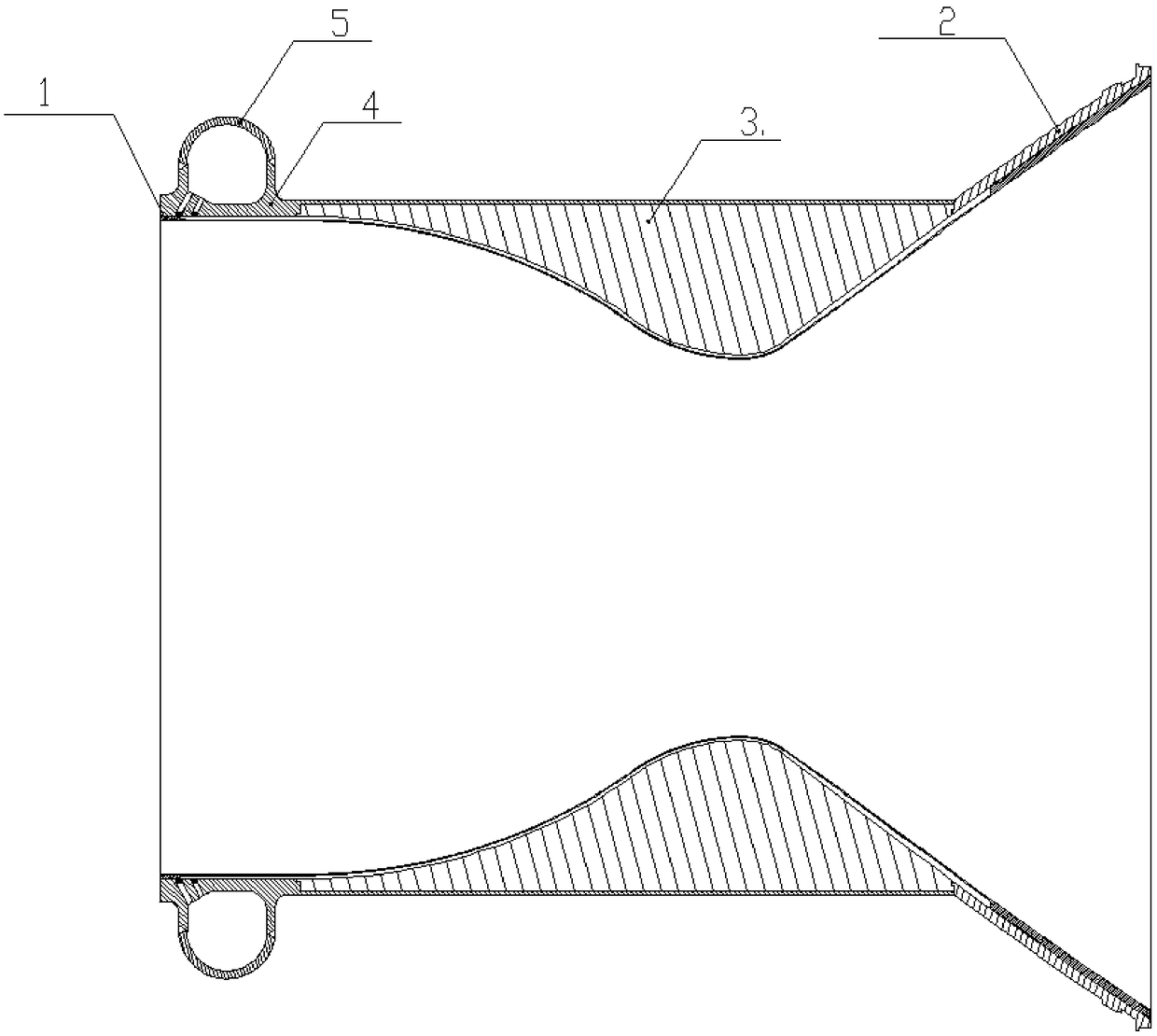

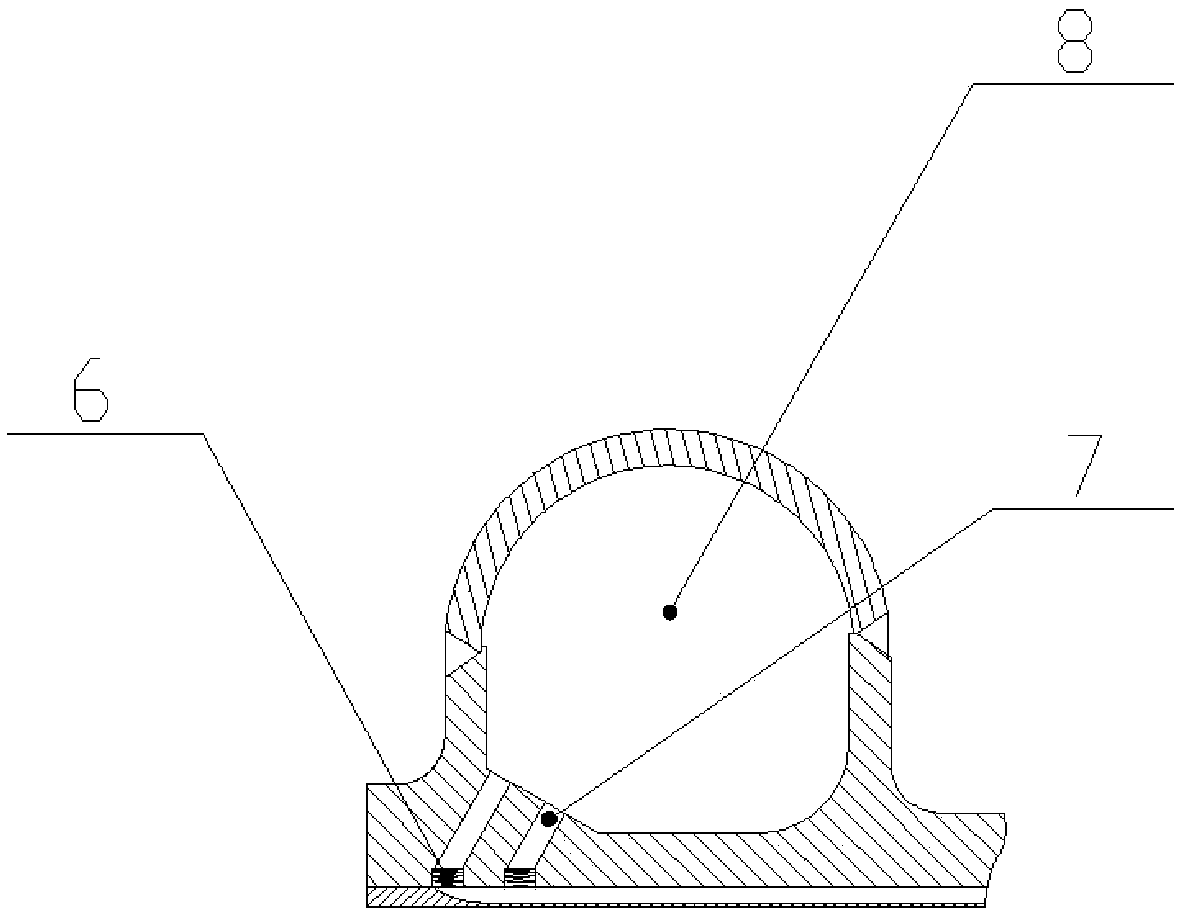

[0034] An outer wall structure of a thrust chamber of a liquid rocket engine, comprising an outer wall 2 of an expansion section, an outer wall 3 of a throat section, an outer wall 4 of a cylinder section, and an upper cover 5 of a liquid collecting ring. Wherein the outer wall 4 of the cylindrical section has the function of the lower cover of the liquid collecting ring.

[0035] One end of the outer wall 3 of the throat section is connected to the outer wall 2 of the expansion section; the other end of the outer wall 3 of the throat section is connected to the outer wall 4 of the cylindrical section, that is, the outer wall 2 of the expansion section, the outer wall 3 of the throat section, and the outer wall 4 of the cylindrical section are sequentially connected to the outer inner wall 1 After assembly, the outer wall 2 of the expansion section, the outer wall 3 of the throat section, and the outer wall 4 of the cylindrical section are connected by diffusion welding; the ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com