Adjustable support pad stone template

An adjustable, formwork technology, applied in the direction of bridge parts, bridges, buildings, etc., can solve the problems of inability to adjust the height of the padding, the partial edge of the support is empty, the height difference of the four corners is difficult to control, etc. , to eliminate the unevenness of the four corners and ensure the effect of qualified quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

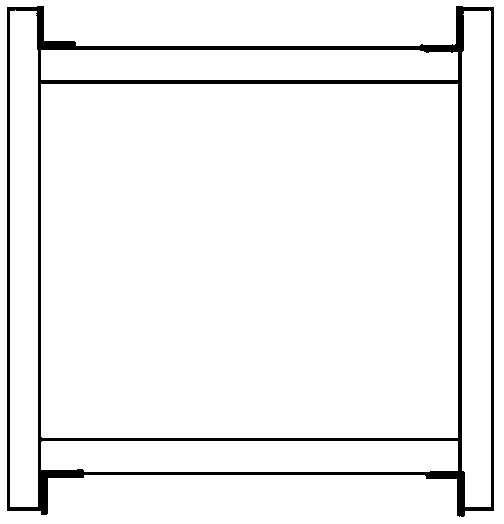

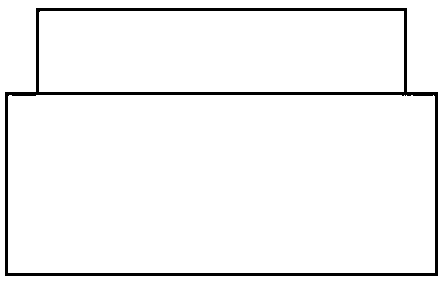

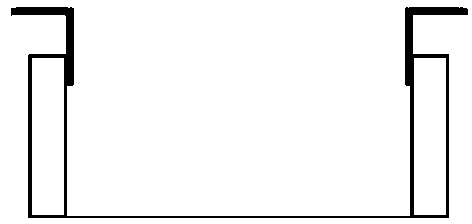

[0026] An adjustable bearing pad stone formwork, including a rectangular formwork made of square steel and a formwork adjustment device, the rectangular formwork is made of two horizontal square steels and two vertical square steels connected to each other, and the adjacent horizontal A detachable connection is formed between the square steel and the vertical square steel through a connecting device.

[0027] In one embodiment of the present invention, the connecting means are bolts.

[0028] In another embodiment of the present invention, the connecting means are pins.

[0029] In another embodiment of the present invention, tie rods or stiffening members are arranged between adjacent horizontal square steels and vertical square steels to provide assistance for fixing the formwork.

[0030] An obvious difference that the present invention is superior to the prior art is that the rectangular formwork is made of square steel, while the prior art generally adopts wooden formwor...

no. 2 example

[0033] Use epoxy resin mortar to fill the gap, and the mix ratio (weight ratio) of epoxy resin mortar is as follows:

[0034] Epoxy wax (6101): 95-99,

[0035] Ethylenediamine: 11-14,

[0036] Triethylenetetramine: 13-15,

[0037] Dibutyl phthalate: 8-11,

[0038] Cement or quartz powder or fine sand: 255-305.

[0039] As a further improvement of the present invention, right-angled connectors are provided at the joints between adjacent horizontal square steels and vertical square steels of the rectangular formwork to ensure that the four corners of the support pad stone formwork are all right angles.

[0040] The invention uses the square steel as the frame of the rectangular formwork to control the height of the supporting stone, and adjusts the height of the supporting stone through the movable angle steel, so as to ensure that the supporting supporting stone can be adjusted between the minimum height and the highest height.

[0041] On the four square steels of the adju...

no. 3 example

[0044] When the angle helix is screwed to the minimum, the support pad stone poured by using the support pad stone formwork of the present invention has the lowest height, which is the sum of the height of the square steel and the side thickness of the angle steel.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com