Tall and large workshop self-made grid platform used as electromechanical pipeline and construction method of platform

A pipeline and grid technology, which is applied in the self-made grid platform and its construction field in tall workshops, can solve the problems of low construction cost and achieve the effects of good strength and rigidity, steel saving and good base structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

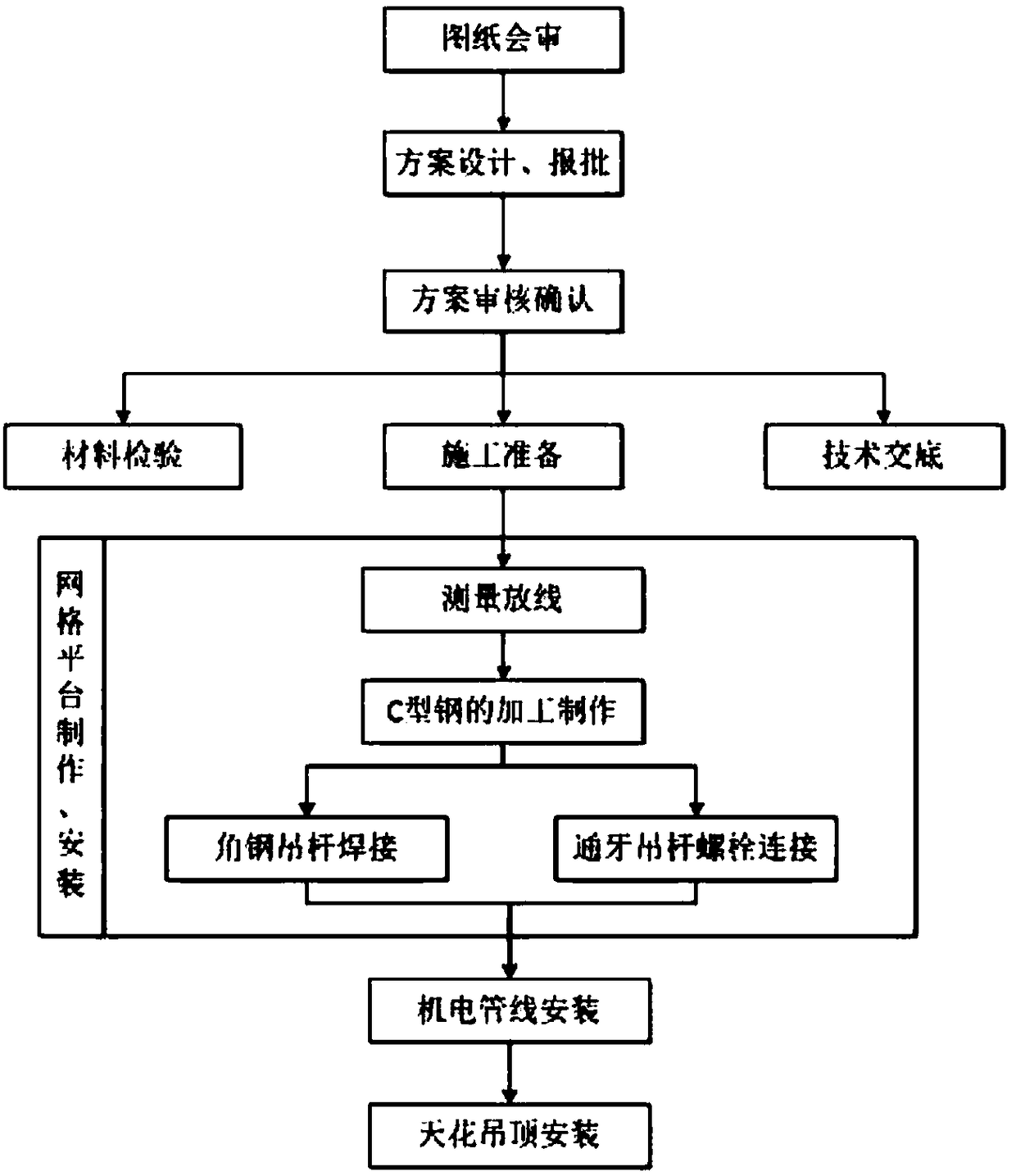

Method used

Image

Examples

Embodiment

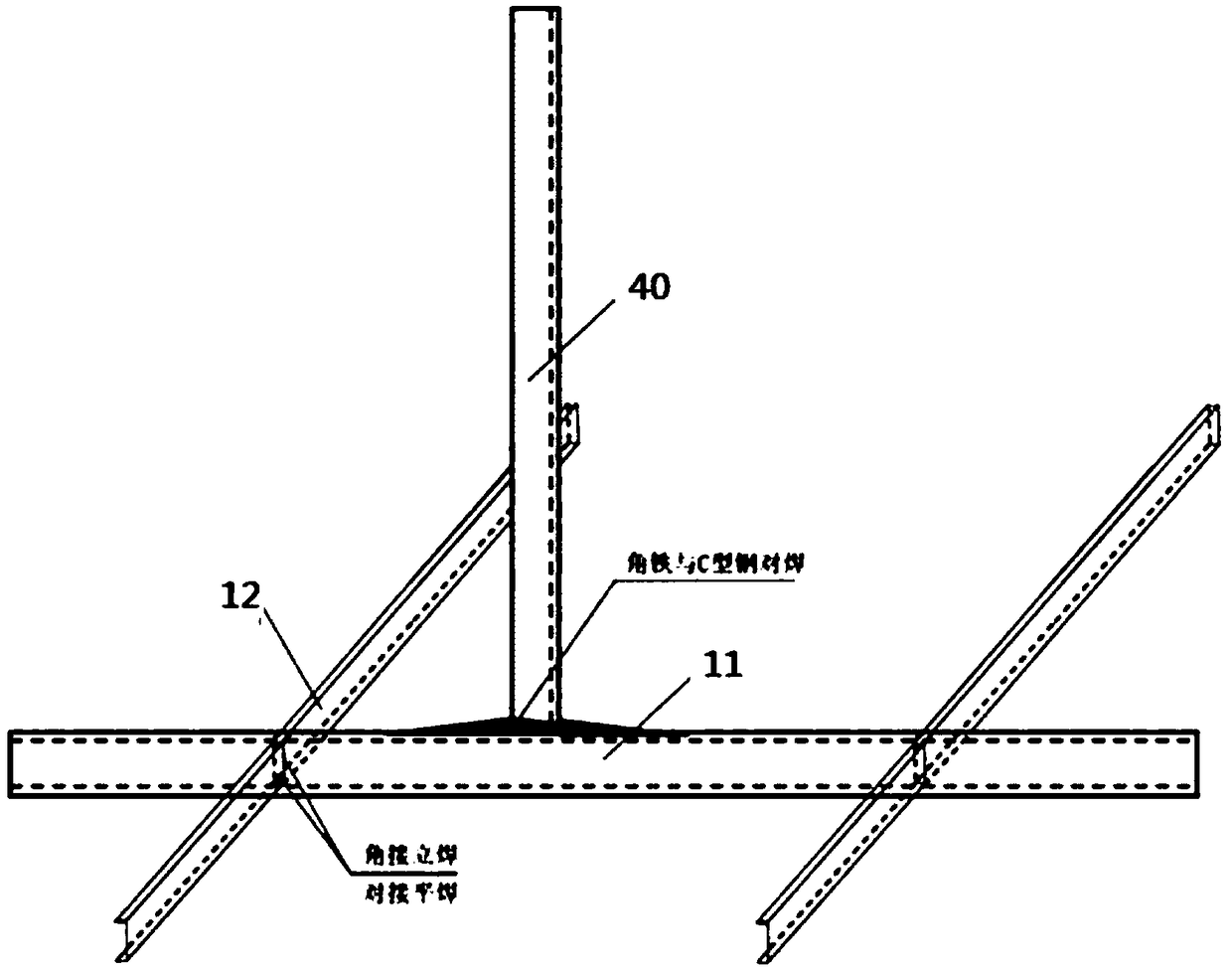

[0050] The specific embodiment of the present invention is Haolai Chemical (Zhongshan) Co., Ltd.'s fifth phase expansion project (oral cleaning products manufacturing) project, wherein the toothbrush workshop is built with steel structure, with a building area of 4266m22 , The construction scope of the toothbrush workshop includes: compressed air pipes, fans, galvanized steel air pipes, stainless steel air pipes, chilled water pipes, cooling water pipes, fire pipes, bridges, etc. The finished surface of the toothbrush workshop is 6.5m high due to the suspended ceiling, while the headroom of the workshop is 12m, and the difference between the two is 5.5m. It has the characteristics of large space and high height. If the ceiling uses traditional hanging ribs as brackets, when the length of the hanging ribs is greater than 1.5 meters, reverse support is required. 1.2m, plus air duct brackets, pipe brackets, trunking brackets, equipment hoisting brackets, etc., resulting in too ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com