Rapid Parts Process of Carbon Fiber Reinforced Paste Resin

A technology of paste resin and carbon fiber, which is applied in the field of rapid part technology of carbon fiber reinforced paste resin, can solve the problems of high cost, long development cycle, slow workpiece manufacturing speed, etc., and achieve light weight, short processing time and long processing cycle short effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

[0028] A rapid manufacturing process of carbon fiber reinforced paste resin, comprising the following steps:

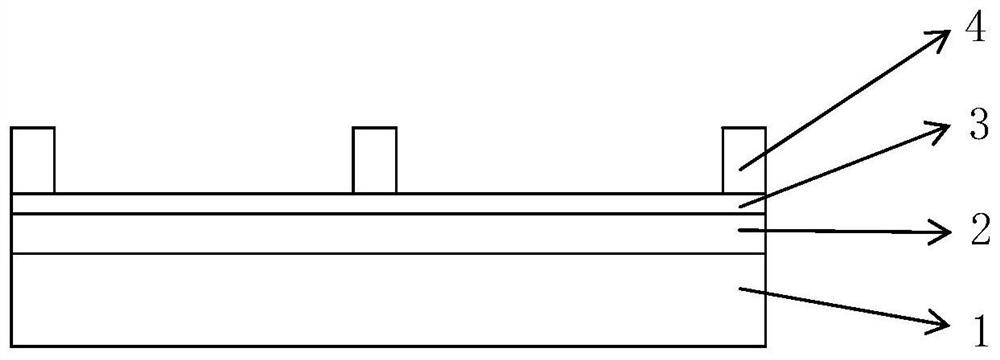

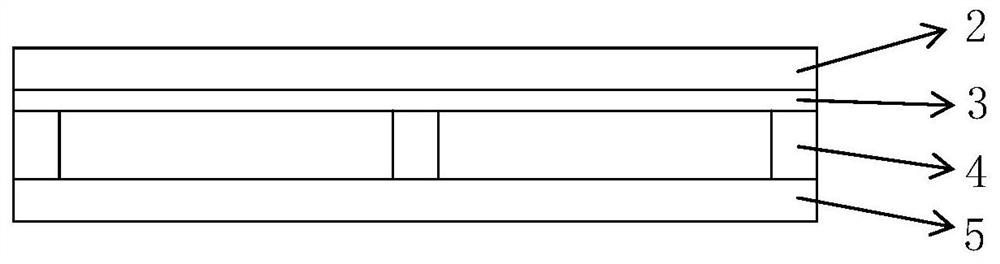

[0029] 1) Preparation of PS foam model: choose a density of 80kg / m 3 According to the required size, glue the PS foam board 1, clamp the bonded PS foam model on the CNC machine tool, and use the foam processing machine to machine the PS foam board according to the surface size of the workpiece model. The size requirements It is the processing amount of +20mm on the basis of the molding size, and use a vacuum cleaner to clean the processed foam, low cost investment, light processing, and less processing hours;

[0030] 2) Put SC167 / SC175 type epoxy paste resin and curing agent into the two-component extruder according to the mass rat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com