Combined sectional steel concrete beam

A technology of combined steel and concrete beams, which is applied in the design of steel concrete beams and building structures, can solve problems such as the unproposed structure optimization of combined steel concrete beams, the difficulty of connecting nodes and construction techniques, and the inability to meet the building space, etc., to achieve strength Good rigidity, uniform force, and good beam height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

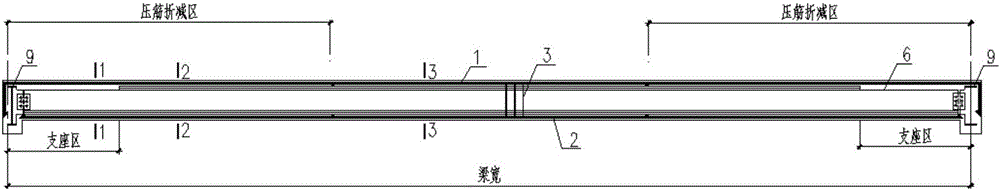

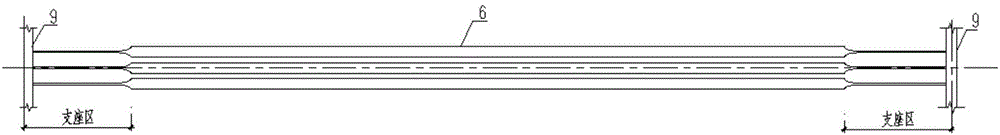

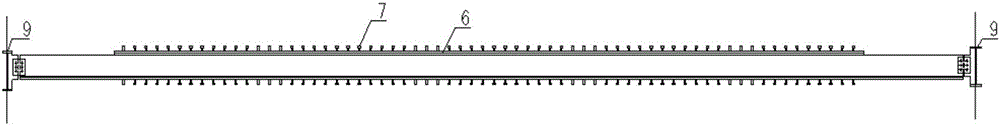

[0028] figure 1 Described, the composite steel-concrete beam comprises: composite steel 6, concrete, connecting node. Due to the section height limitation, in order to better meet the deflection crack limit requirements of the code members, several small steel plates can be selected according to the required height and stiffness of the structural beam, and thick steel plate connecting webs can be arranged at reasonable intervals to ensure the overall performance of the section steel. For the steel composite beam, in the case of larger reinforcements, the longitudinal reinforcements are arranged in parallel to avoid the arrangement of multiple rows of reinforcements. The upper flanges of various steel sections in the beam graduall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com