A kind of hard rock cutterhead and cantilever tunneling machine including the cutterhead

A cutter head and hard rock technology, applied in mining equipment, tunnels, earthwork drilling and mining, etc., can solve the problems of slow driving efficiency in hard rock formations, and achieve improved rock breaking efficiency, uniform force, and the ability to resist deformation and damage strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

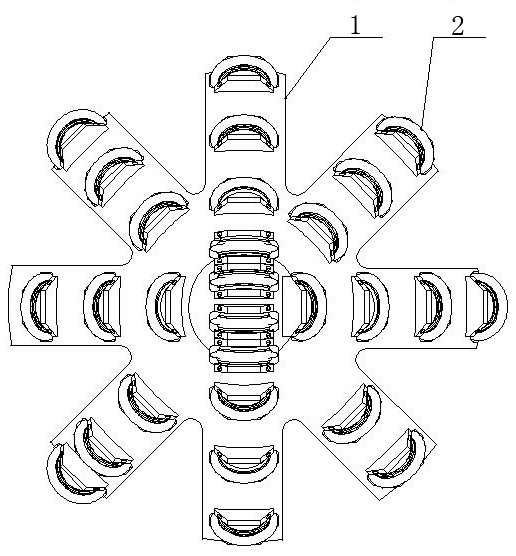

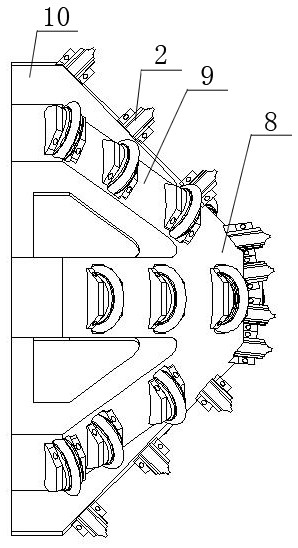

[0032] Such as figure 1 and 2 As shown, a hard rock cutter head includes a main structure 1 of the cutter head. The main structure 1 of the cutter head includes a head 8, a spoke 9 and a flange 10. The head 8 is connected to the spoke 9, and the two are processed by the whole plate. The spokes 9 are welded to the flange 10, and the flange is used to connect with the rotating shaft of the roadheader. The spokes 9 are arranged in the shape of a rice. Similarly, the spokes 9 can be arranged in a cross or * shape. The head 8, the spokes 9 and the flange 10 forms a conical cutter head main structure 1 . There are detachable cutters on the head 8 and spokes 9, the cutter is the hob 2, the hobs on the conical surface of the cutter head are arranged with 12-inch or 14-inch hobs, 2 on the same track, and 3 edge hobs are arranged on the same track , the same cutter can be a gear cutter, which improves the adaptability of the cutter head to the formation.

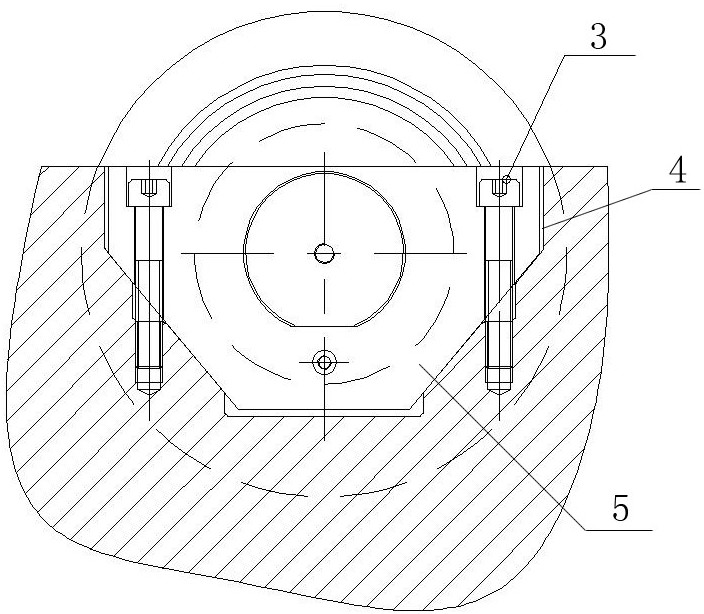

[0033] Such as image 3 As...

Embodiment 2

[0037] A cantilever tunneling machine including a hard rock cutter head, the structure of the hard rock cutter head is the same as that in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com