Thin-wall rectangular-cross-section pipe bending method

A rectangular cross-section, pipe technology, applied in the field of machining, can solve the problems of affecting the forming accuracy, wrinkling, affecting the beauty of the formed parts, etc., and achieve the effect of ensuring dimensional accuracy and precise forming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

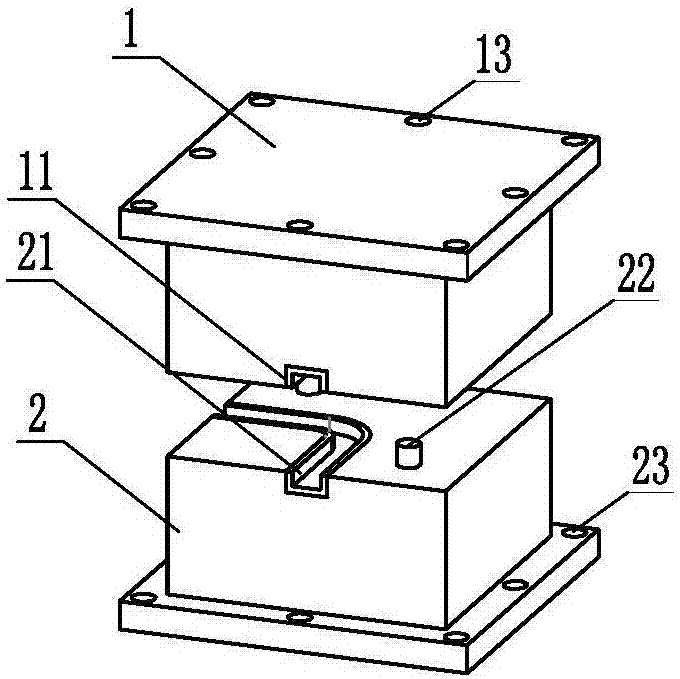

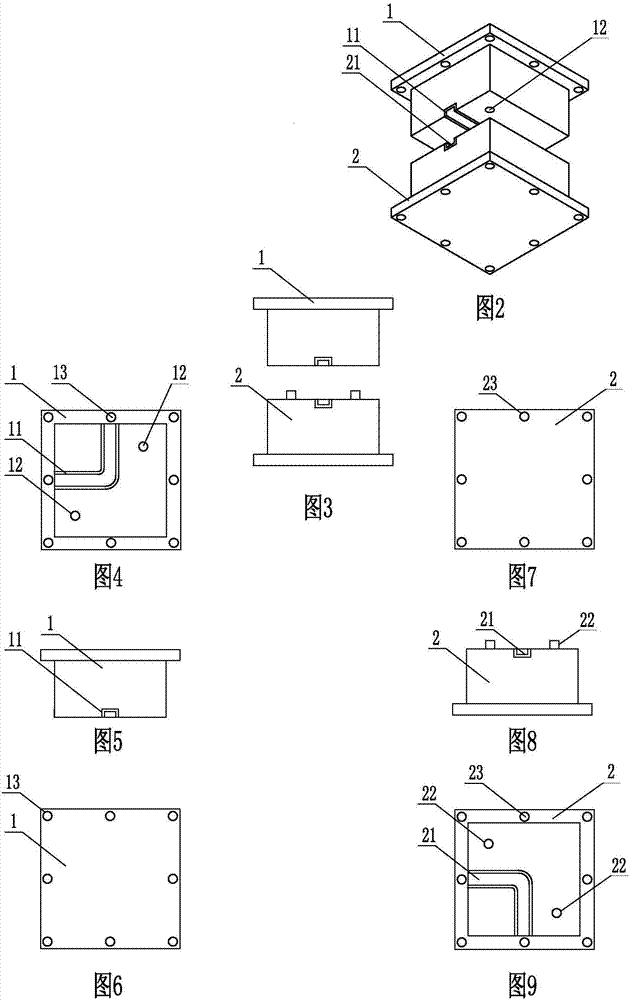

[0032] A method of bending a thin-walled rectangular section pipe, comprising the steps of:

[0033] S1. Pre-bending: The thin-walled rectangular cross-section pipe blank is pre-bent using the conventional methods of stretch bending, press bending or winding forming to obtain the same arc and length as the required thin-walled rectangular cross-section pipe bend, with wrinkles Thin-walled rectangular cross-section pipe pre-bending;

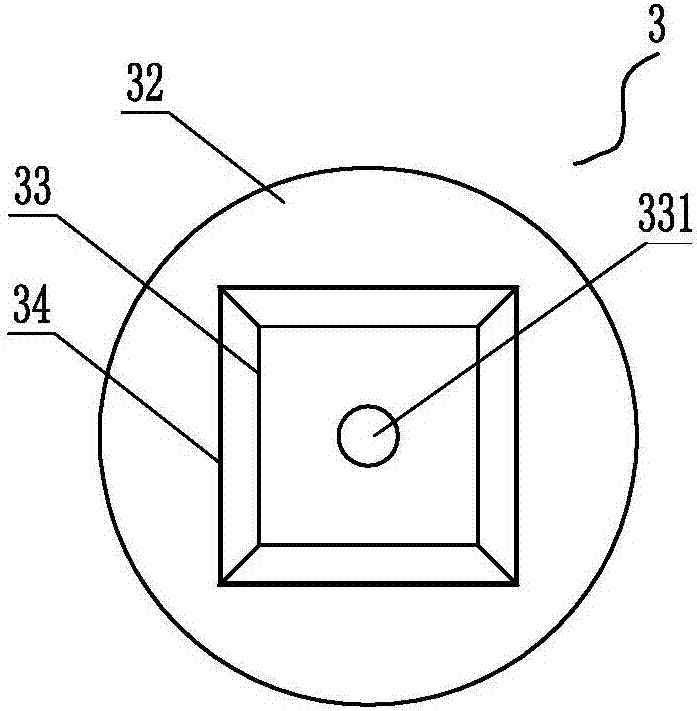

[0034] S2. Install the plastic mold: select the plastic mold corresponding to the radian and length of the thin-walled rectangular cross-section pipe bend required (length correspondence means that the length of the straight groove section of the plastic mold is consistent with the length of the straight pipe section of the pipe bend, so that During processing, the pipe bends all fall into the mold cavity of the shaping mold), the lower mold of the shaping mold is installed on the workbench of the hydraulic bulging press, and the upper mold is ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com