Modular formwork elements for pouring concrete to form vertical structure and assembling method

A vertical structure, modular technology, applied in the direction of building components, infrastructure engineering, sheet pile walls, etc., can solve the problems of lack of structural rigidity of the formwork, difficulty in fixing the wall surface or covering layer, etc., to facilitate transportation and assembly, Good strength and rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

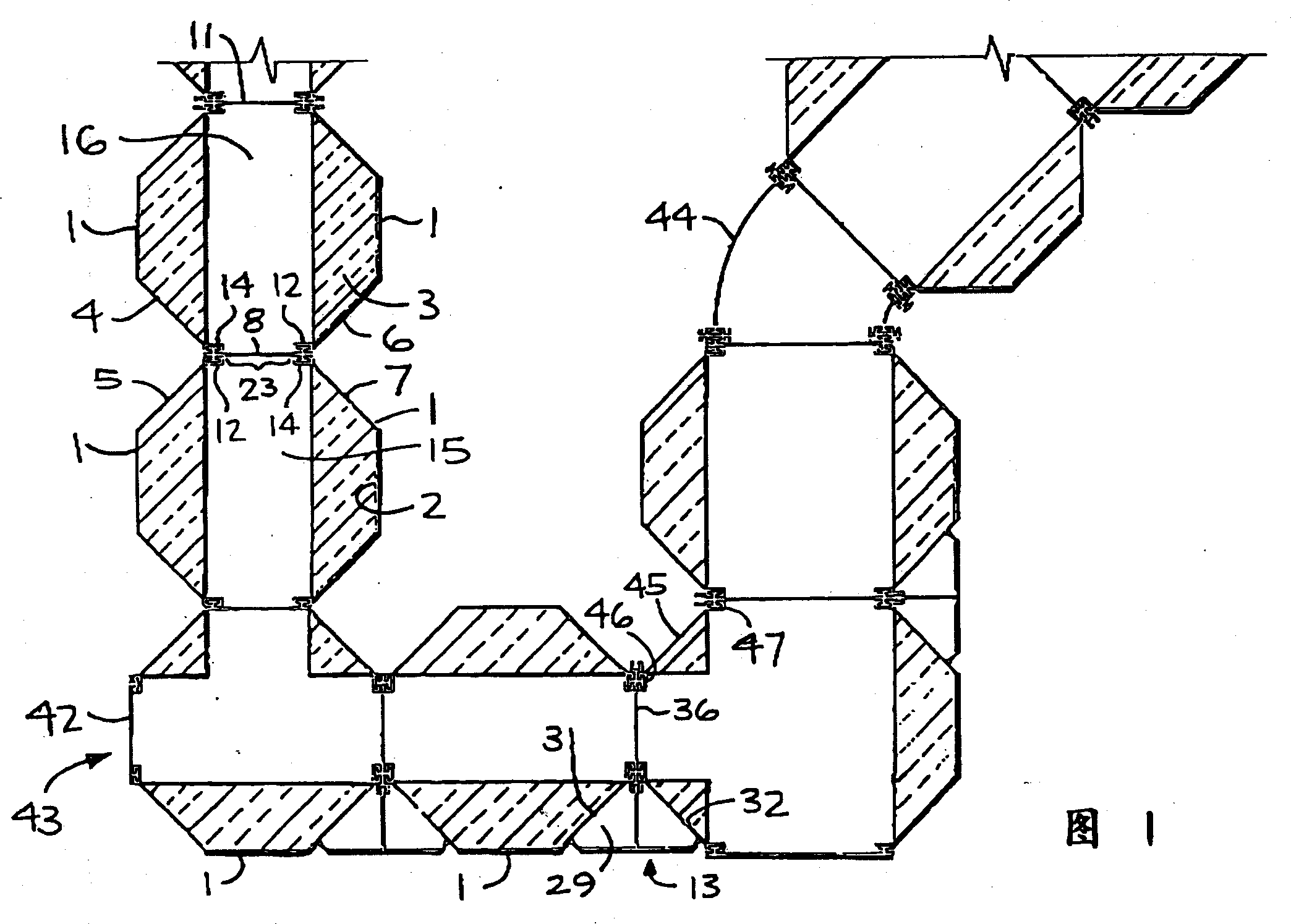

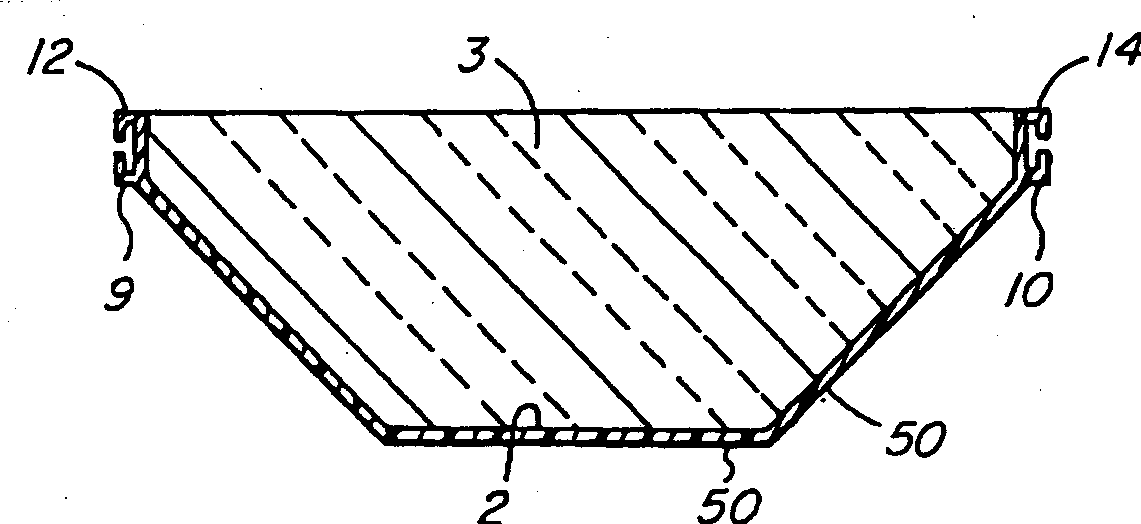

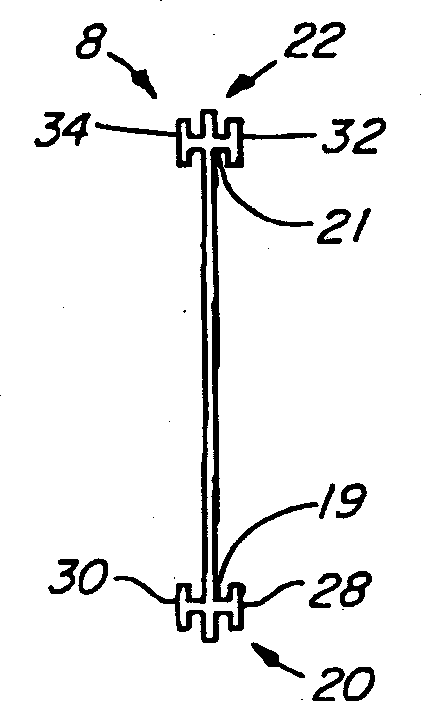

[0024] Referring to Figure 1, a set of generally concave elongate formwork elements 1 is provided. The elements are preferably made of a material such as polyvinyl chloride like the other components described herein. The elements have a surface 50 which may be three-sided or they may have more sides, be round or any other suitable shape, as long as the elements are substantially open so that the edges are not closed to each other. In this specification and in the claims, such a shape is referred to as "concave" for simplicity. The adoption of this shape gives the formwork a cylindrical appearance. The concavity also allows easy access to the inner surface 2 of the element 1 for placing or adhering various types of insulation (insulation) or linings inside the element before erecting the formwork or while making the elements 1 within the surface. Foam insulation as indicated at 3 may be used, or composite insulation or a thinner lining may be bonded to the inner surface of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com