Construction method for after-pouring band beam-slab template

A construction method and technology of post-casting strips, which are applied in the fields of formwork/formwork/working frame, processing of building materials, preparation of building components on site, etc. Pulp misalignment and other problems, to achieve considerable economic benefits and production efficiency, reduce labor and machinery consumption, and ensure verticality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

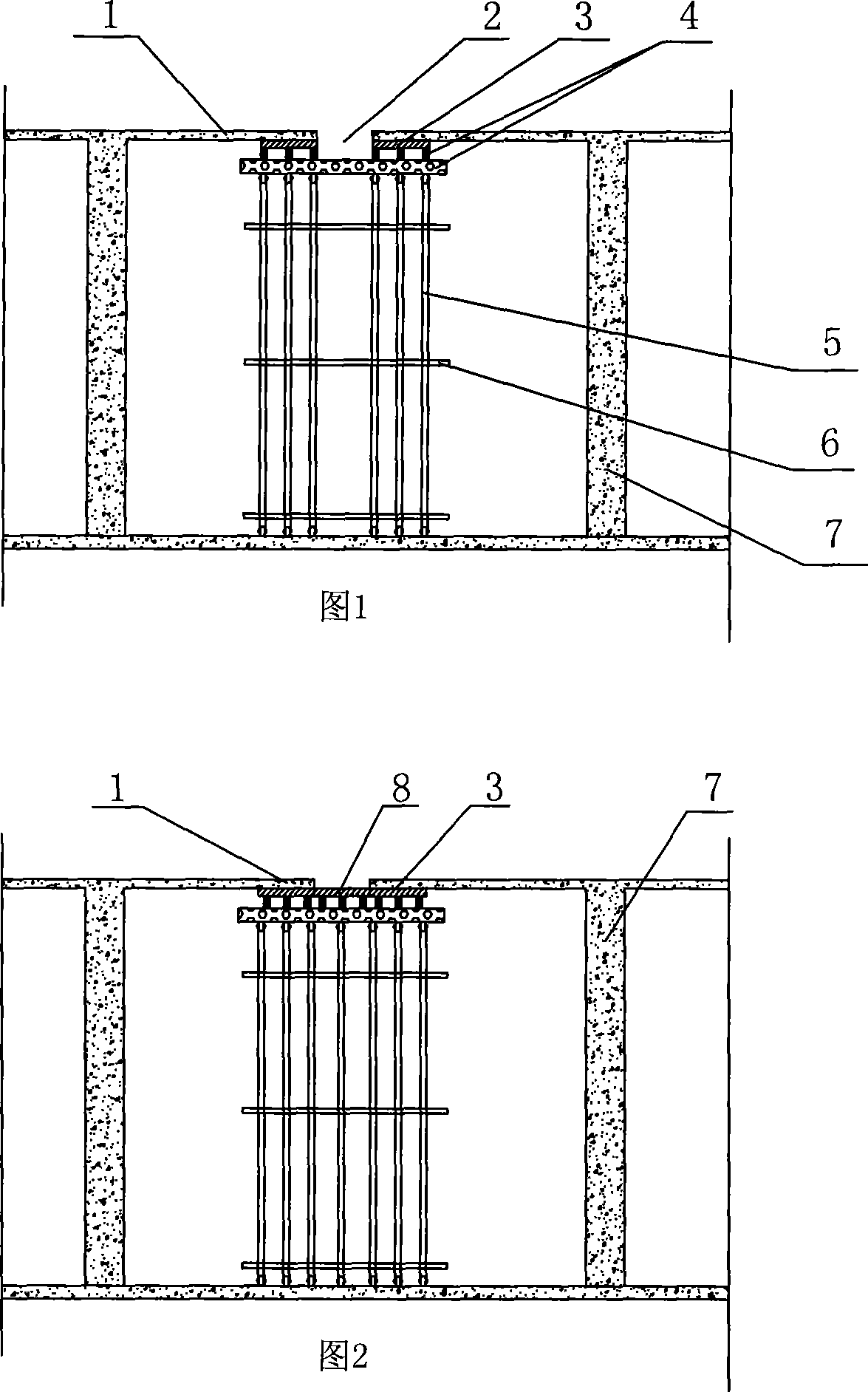

[0012] The technological process of the construction method of the post-casting belt beam slab formwork of the present invention is: axis review → set up the beam slab 1 formwork support (same as the known technology) → install the post-pouring belt 2 both sides formwork 3 and steel bars → pour concrete beam slab 1 and combine Maintenance → first pour concrete strength to meet the requirements of form removal and then remove the formwork (except the 800mm ~ 1000mm wide formwork and support on both sides of the post-pouring belt) → gouging the construction joints, cleaning and moisturizing, and then pouring formwork 8 after installation → check the epithelial elevation and flatness of formwork 8 →Connect with the adjacent formwork 3, see Figure 1 and Figure 2 for the support system.

[0013] The templates 3 on both sides of the post-casting belt are installed on both sides of the post-casting belt 2 with templates 3 having a width of 800 mm to 1000 mm. The formwork and supports...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com