Joined body of carbon fiber reinforced composite material

A technology of carbon fiber and joint body, applied in the direction of connection, chemical instruments and methods, synthetic resin layered products, etc., can solve the problems of unfavorable mass production and insufficient technology establishment, and achieve light weight, excellent rigidity and strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

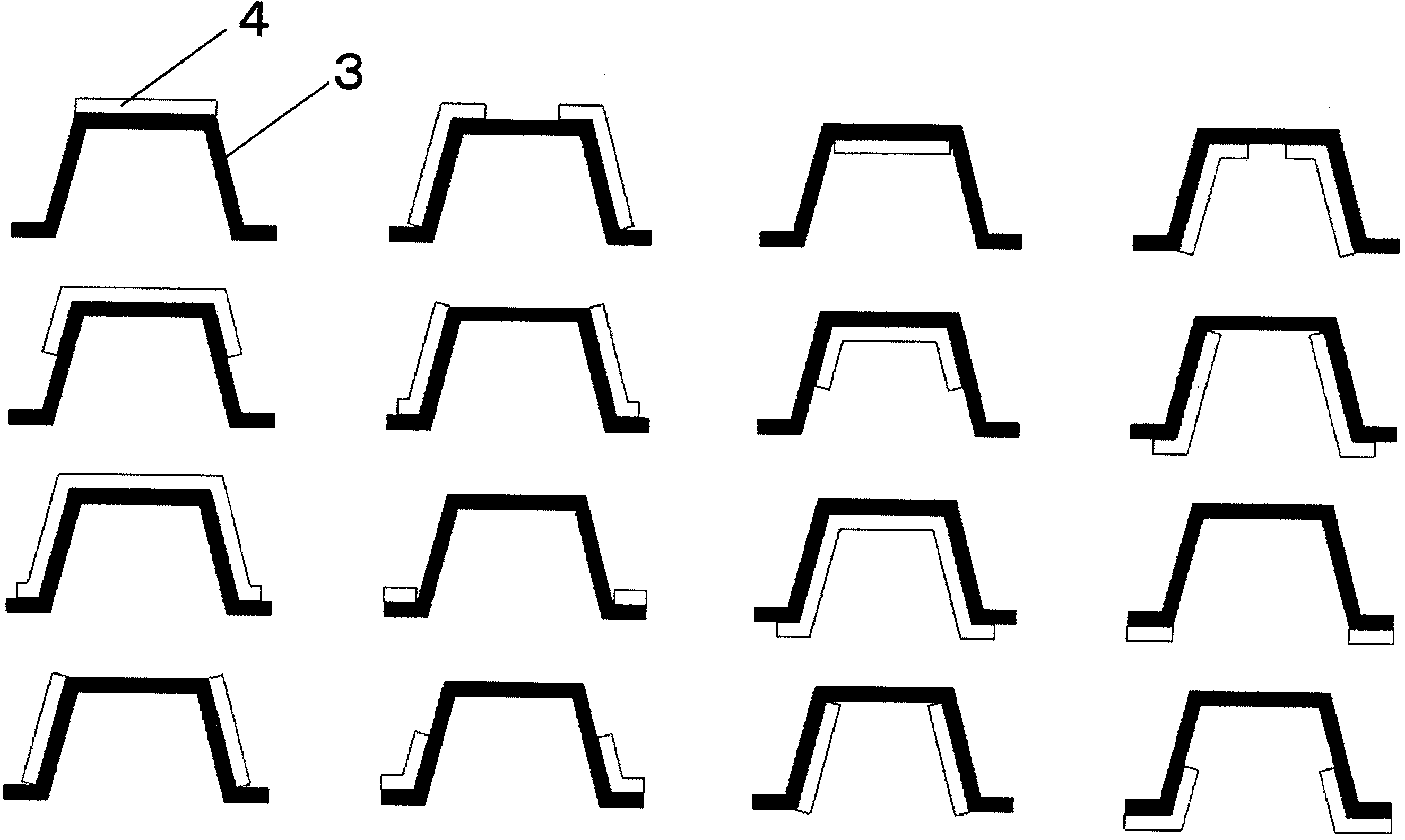

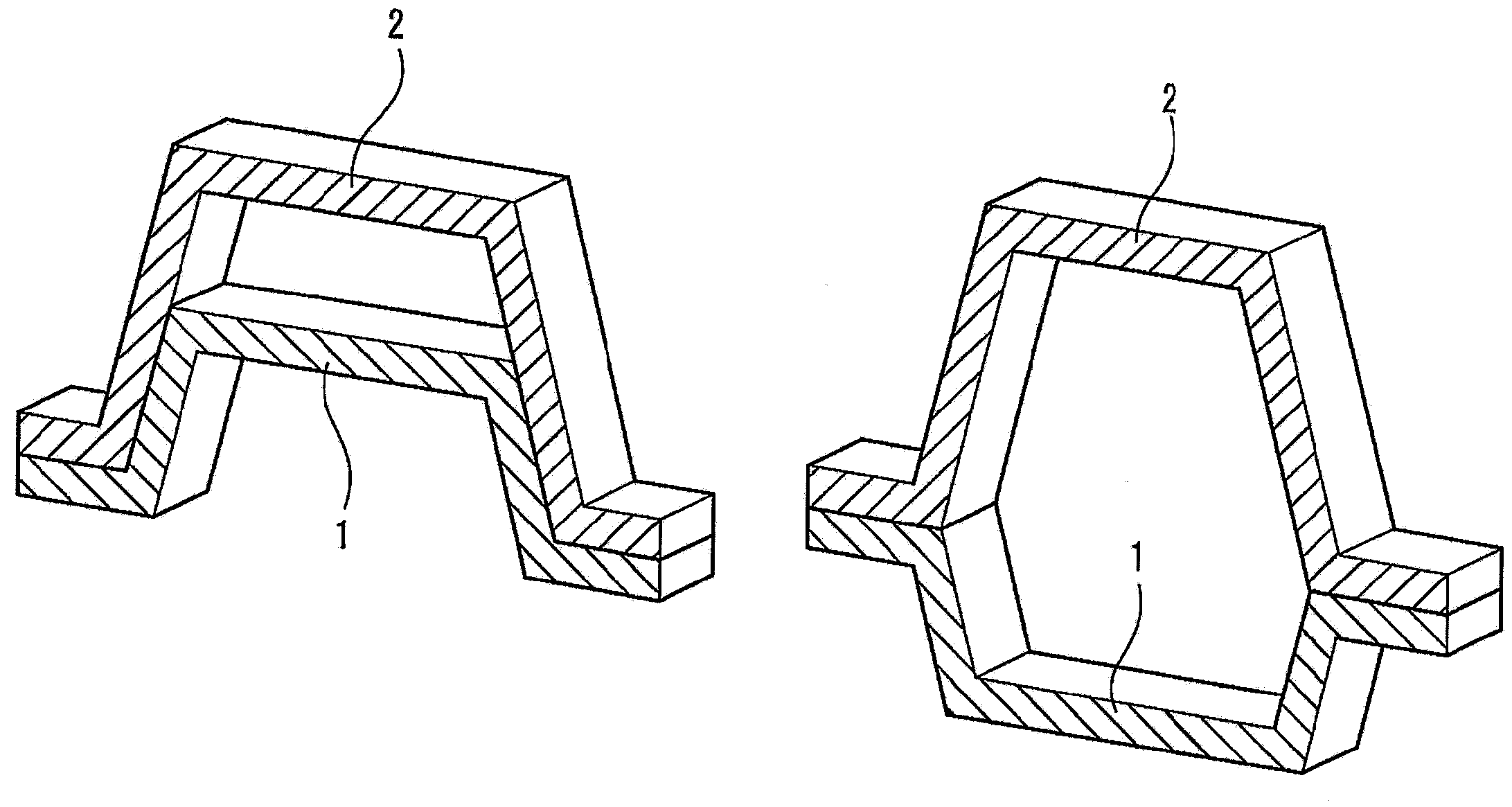

[0041] The present invention is a joined body produced by vibration welding as follows:

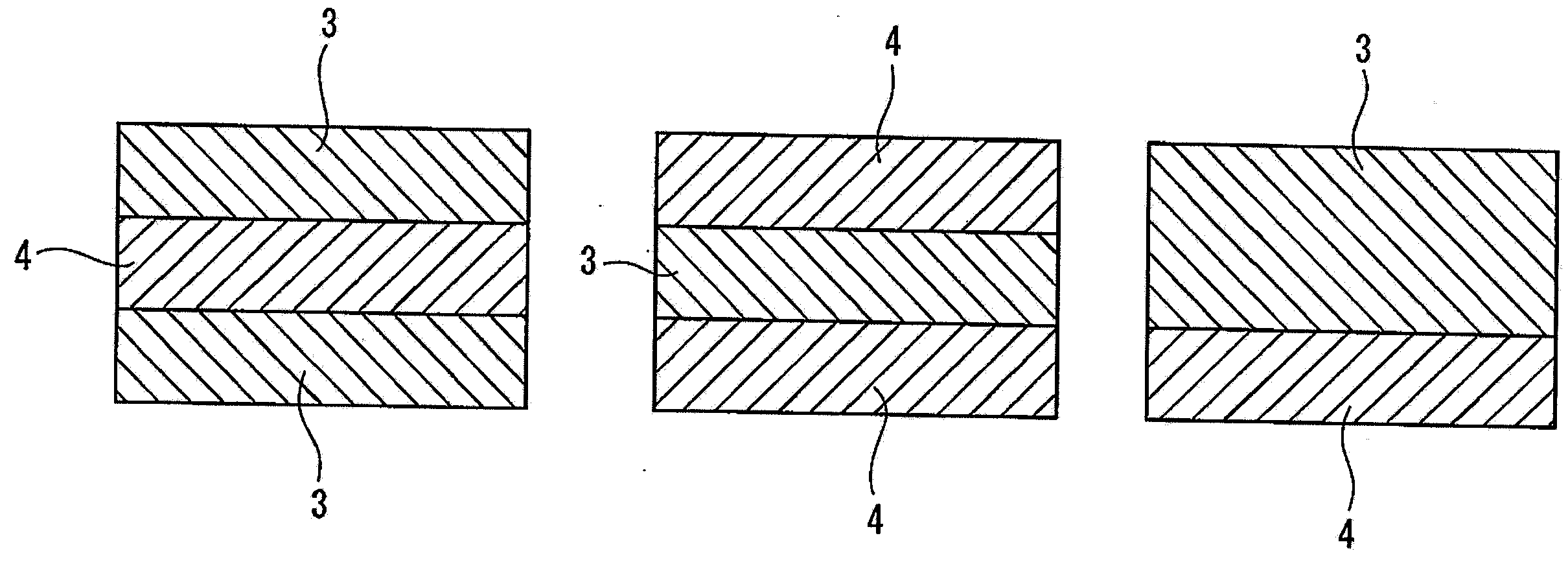

[0042] A reinforcement having at least one irregular layer in which chopped carbon fibers are irregularly oriented in a thermoplastic resin and at least one layer of unidirectional material in which continuous carbon fibers are unidirectionally aligned in a thermoplastic resin (the same as or different from said thermoplastic resin contained in said irregular layer); and

[0043] A reinforced member having an open cross-sectional shape, the reinforced member having irregular layers (chopped carbon fiber and thermoplastic resin may be the same as those contained in said irregular layers of said reinforcing member or different) and at least one selected from the group consisting of unidirectional material layers (continuous carbon fibers and thermoplastic resins may be the same or different from those contained in said unidirectional material layers of said reinforcement), wherein

[0044]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fiber length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com